جدول المحتويات

- Introduction to SMT Machines

- History and Evolution of SMT Technology

- Key Technical Specifications

- Operational Principles of SMT Machines

- Case Studies of SMT in Industry Applications

- AI and Machine Learning in SMT Machines

- Comparative Analysis of SMT Machine Features

- Maintenance and Troubleshooting Guide

- Choosing the Right SMT Machine: Factors to Consider

- Future Trends in SMT Technology

- Economic Considerations: ROI and Cost Analysis

- Glossary of Terms

Introduction to SMT Machines

This comprehensive guide is designed to assist potential buyers in making well-informed choices regarding SMT (Surface Mount Technology) machines. By exploring technical specifications, industry applications, and anticipated future trends, the guide provides essential insights into modern electronics manufacturing. Additionally, it integrates case studies, diagrams, and maintenance tips, catering to engineers, production managers, and procurement specialists.

Surface Mount Technology (SMT) is a transformative approach to electronic manufacturing where components are placed directly onto the surface of printed circuit boards (PCBs). SMT machines play a crucial role in this process by ensuring precision, speed, and efficiency in component placement, soldering, and inspection.

Understanding SMT Machines

SMT machines automate the assembly of electronic circuits without the need for wires or leads, making them indispensable tools in the manufacturing industry…

The Role of SMT Machines in Modern Electronics

The advent of SMT technology revolutionized the electronics industry by enabling the production of compact and high-performing devices…

For more on how conveyors work within the SMT process, check this guide on SMT Conveyor Belt Replacement.

Enhancing Understanding through Visuals

…In summary, SMT machines are integral to today’s electronics production, driving both efficiency and innovation…

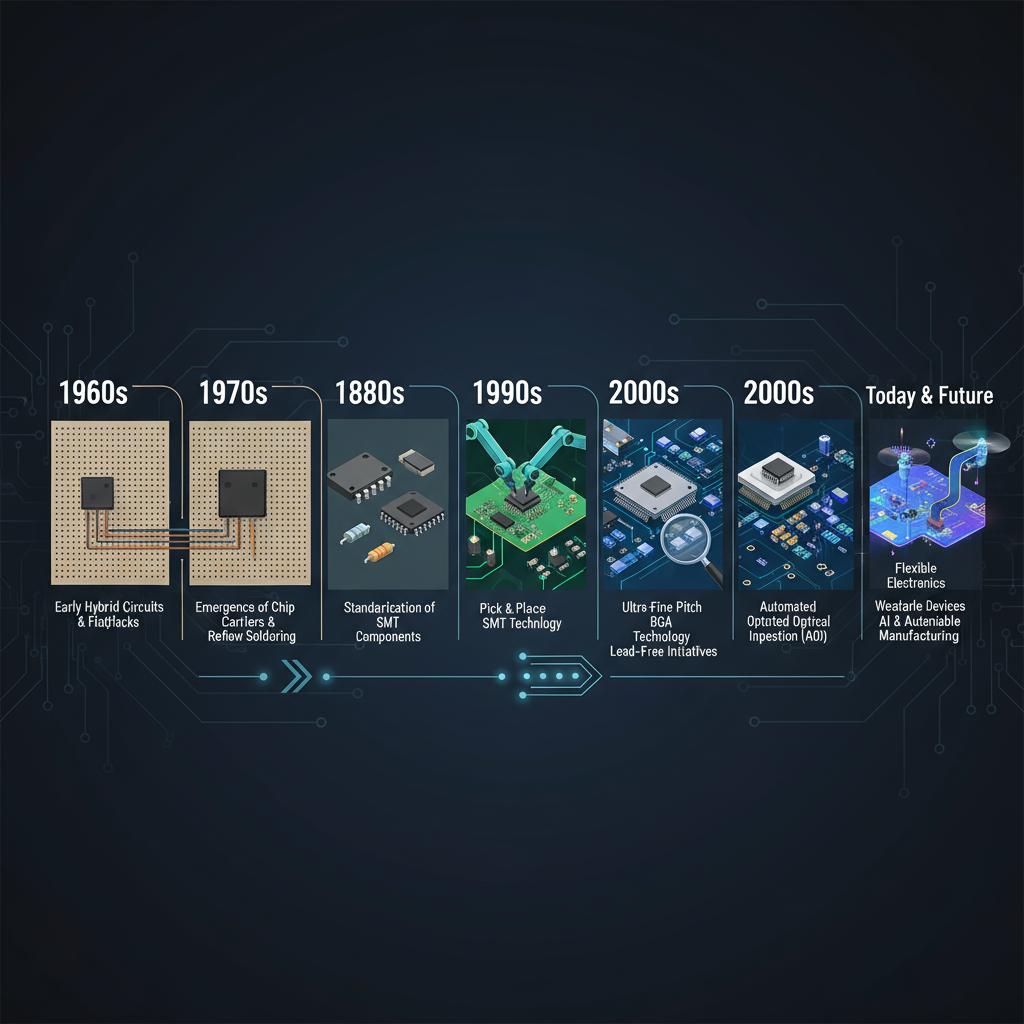

History and Evolution of SMT Technology

The Surface Mount Technology (SMT) has come a long way since its inception in the 1960s, revolutionizing the landscape of electronics manufacturing. SMT has significantly evolved, both in terms of technical capabilities…

Beginnings in the 1960s

The origins of SMT technology date back to the 1960s…

Rapid Growth in the 1980s

The 1980s witnessed remarkable growth and acceptance of SMT in the industry…

Innovation in the 1990s and 2000s

The 1990s brought about more sophisticated machine capabilities…

Present-Day Advances

Today, SMT technology is a cornerstone of modern electronics manufacturing, equipped with advanced robotics, computer vision, and AI integrations…

Key Technical Specifications of SMT Machines

Surface-Mount Technology (SMT) machines are essential in the electronics manufacturing industry…

Feeder Types

The feeder system is a vital component of an SMT machine…

Placement Accuracy

Placement accuracy is a decisive factor in selecting an SMT machine…

السرعة

Speed, or the throughput, of an SMT machine, is measured in components per hour (CPH)…

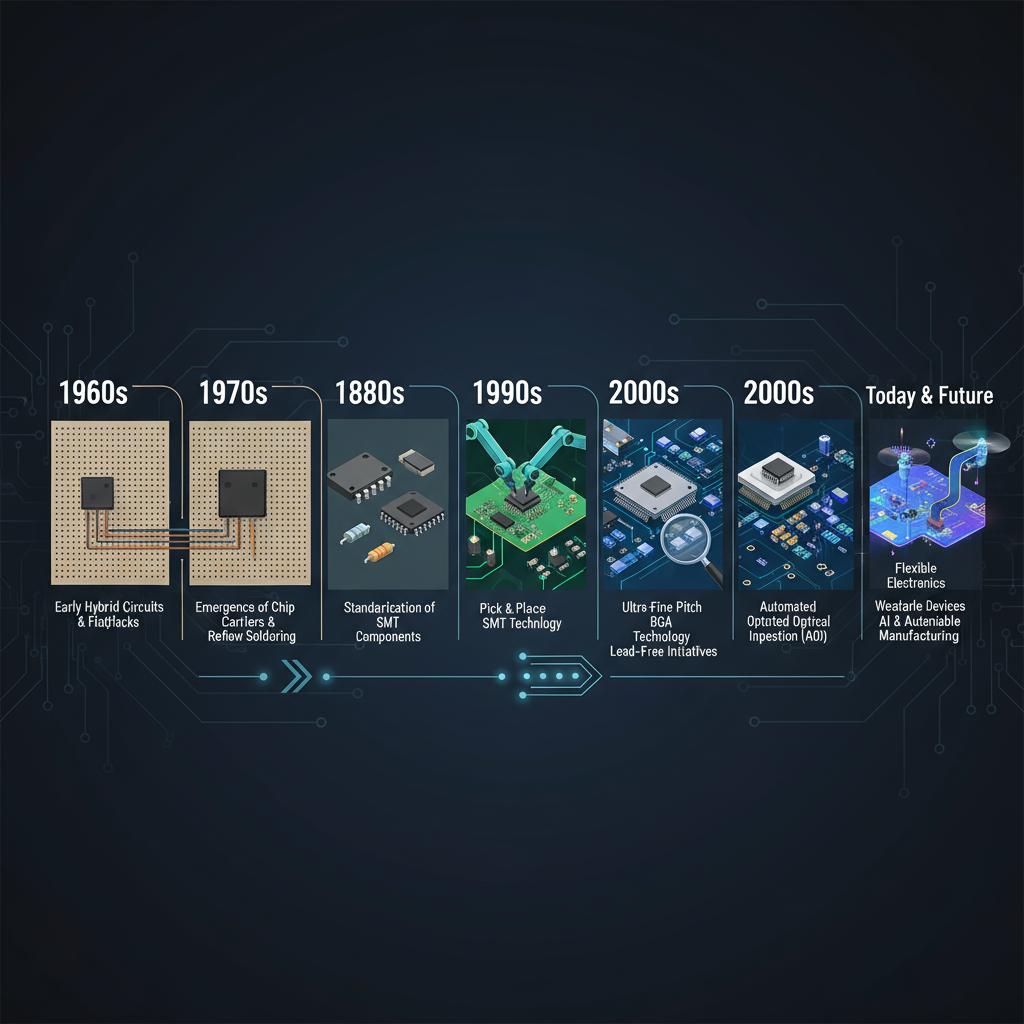

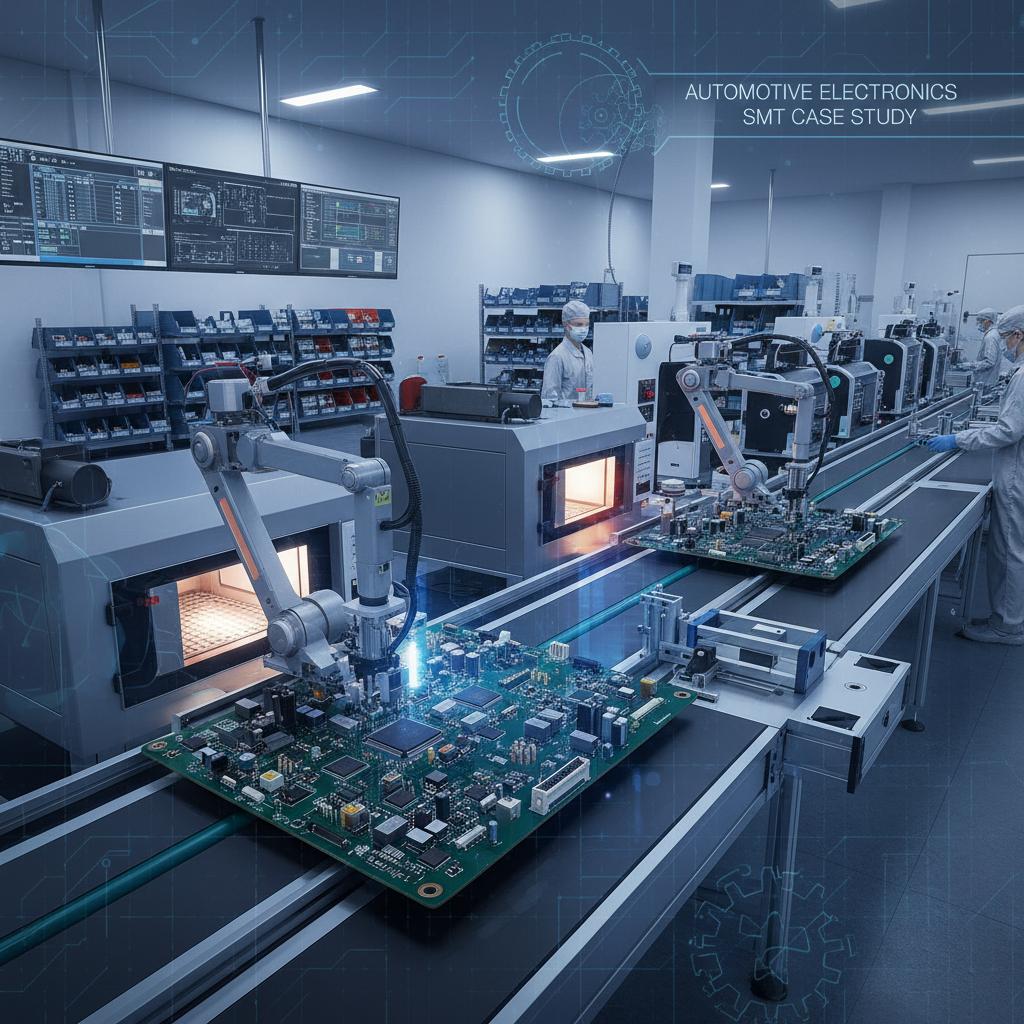

Operational Principles of SMT Machines

Surface Mount Technology (SMT) machines are pivotal in electronic manufacturing…

Step 1: Surface Preparation

Before components can be placed, the PCB surface must be meticulously prepared…

Step 2: Paste Application

The next stage is applying solder paste to the PCB…

Step 3: Component Placement

Following solder paste application, components are placed on the PCB…

Step 4: Reflow Soldering

Once components are positioned, the PCB undergoes reflow soldering…

Step 5: Inspection and Quality Assurance

The final step integrates sophisticated inspection systems…

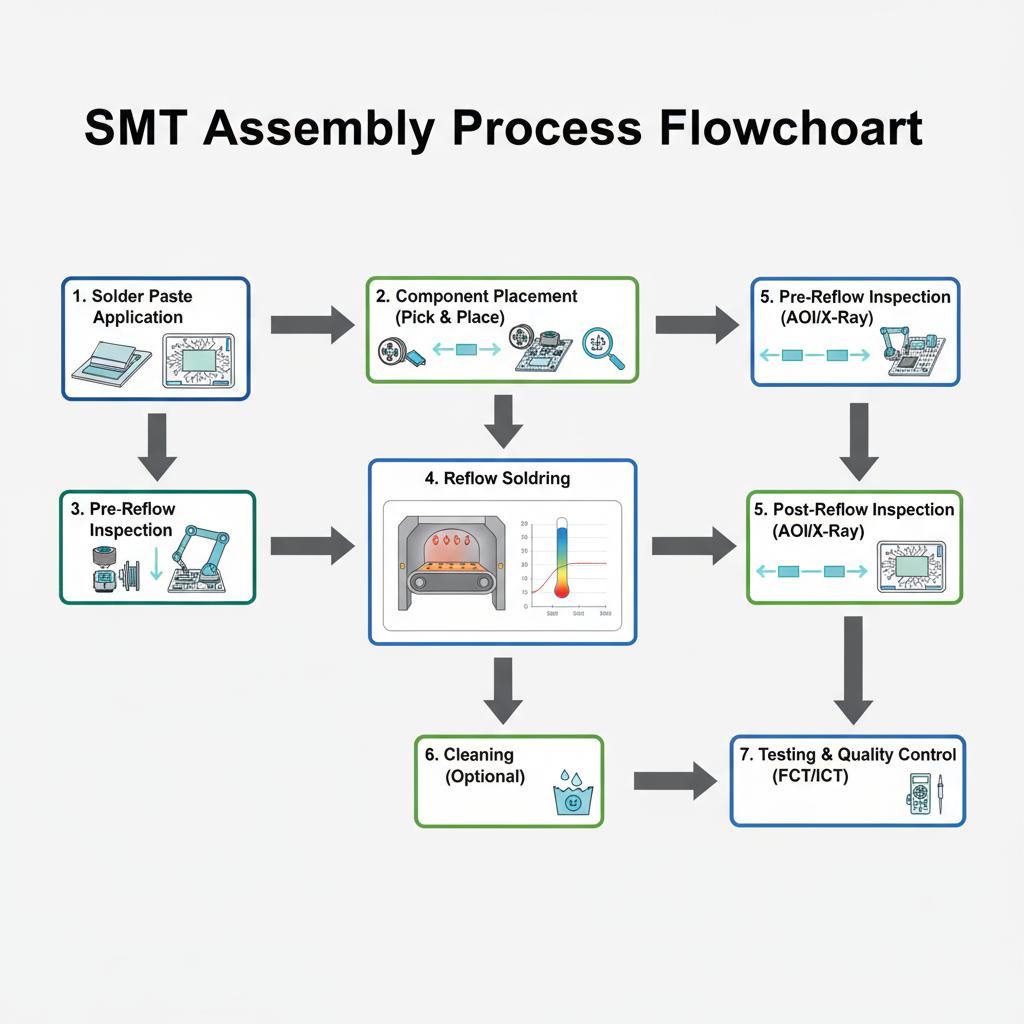

Case Studies of SMT in Industry Applications

Surface Mount Technology (SMT) has revolutionized manufacturing processes across various sectors…

Consumer Electronics: A Testament to Efficiency and Precision

Samsung Electronics: As a giant in consumer electronics…

Automotive Industry: The Road to Innovation

Toyota Motors: Renowned for their reliability and innovation…

Telecommunications: Enhancing Connectivity

Nokia Networks: In telecommunications, Nokia has employed SMT…

AI and Machine Learning in SMT Machines

Surface Mount Technology (SMT) machines have profoundly transformed modern manufacturing processes…

Enhancements in Precision and Error Reduction

AI and ML empower SMT machines to achieve higher precision levels…

Predictive Maintenance and Operational Efficiency

One of the salient features of AI-driven SMT machines is their ability to predict maintenance needs…

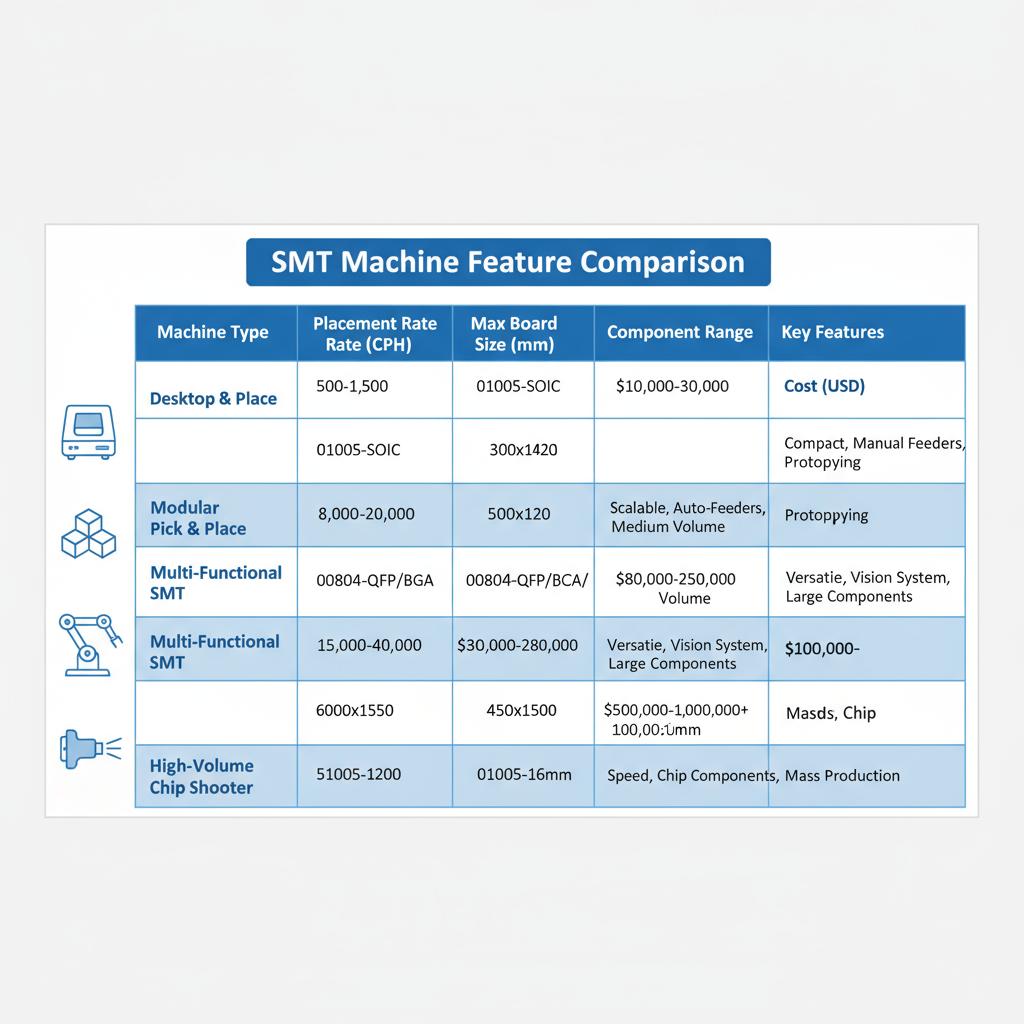

Comparative Analysis of SMT Machine Features

Surface Mount Technology (SMT) machines are pivotal to modern electronics manufacturing…

Types of SMT Machines

Pick-and-Place Machines: Predominantly used to mount components onto PCBs with precision…

الميزات الرئيسية التي يجب مراعاتها

Speed and Throughput: Essential for high-volume production environments…

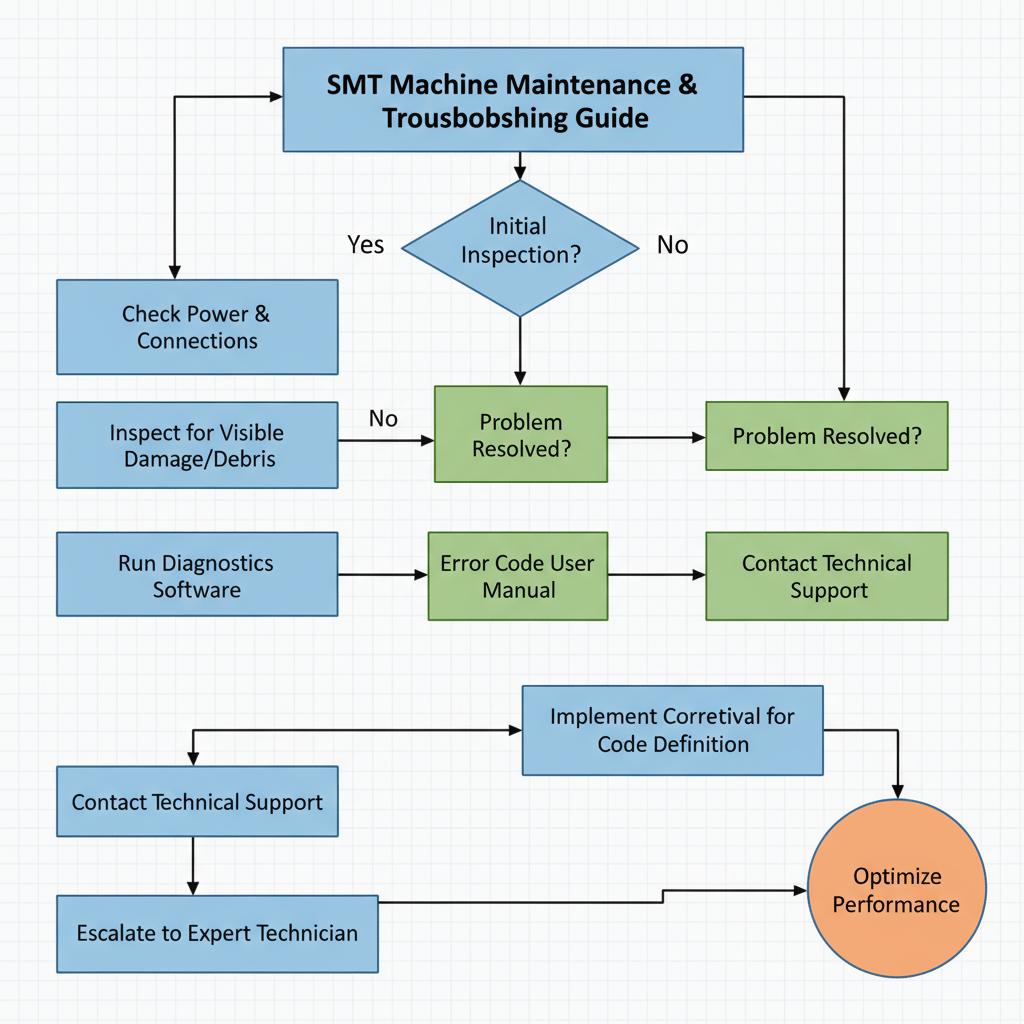

Maintenance and Troubleshooting Guide for SMT Machines

Maintaining Surface Mount Technology (SMT) machines is paramount to ensuring their longevity…

Regular Maintenance Practices

Scheduled Cleaning and Inspection: Weekly Cleaning: Wipe down machines…

استكشاف المشاكل الشائعة وإصلاحها

Component Misalignment: Often caused by misaligned feeders…

Choosing the Right SMT Machine: Factors to Consider

Selecting the right Surface Mount Technology (SMT) machine is a crucial decision…

Understanding Your Specific Needs

Before making a selection, it’s vital to thoroughly understand your specific manufacturing requirements…

Analyzing Cost Versus Benefits

Cost is a major factor, but it should be balanced with the long-term benefits…

Future Trends in SMT Technology

The landscape of Surface Mount Technology (SMT) is evolving at a rapid pace…

Advanced Equipment Design

One prominent trend in SMT involves the development of more compact and highly efficient machines…

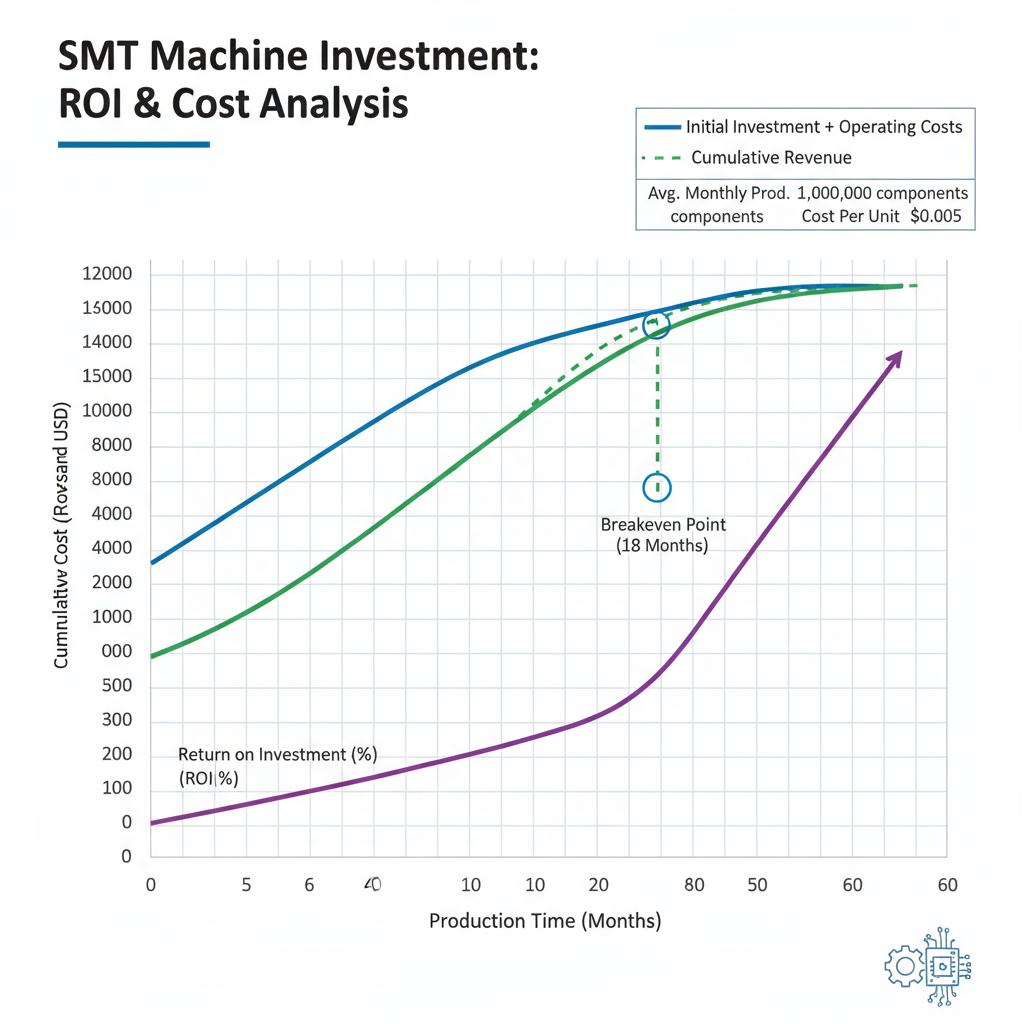

Economic Considerations: ROI and Cost Analysis

Investing in Surface Mount Technology (SMT) machines requires a thorough understanding of the economic implications…

Understanding ROI in SMT Investments

Return on Investment (ROI) is a crucial metric for any business considering the purchase of SMT machines…

Glossary of Terms

SMT (Surface Mount Technology): A method for producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs)…

PCB (Printed Circuit Board): An essential component that connects electronic components using conductive pathways etched from copper sheets laminated onto a non-conductive substrate…

This guide serves as an invaluable resource for anyone involved in the selection or management of SMT machines, offering a wide spectrum of information from basic introductions to detailed technical comparisons. The inclusion of AI and future trends ensures readers are prepared for emerging challenges. Practical decision-making tools and guides on maintenance cement this text as essential reading.