The most important step when you choose the right PCB conveyor length is to match it to your PCB size, transport distance, and SMT line layout. Conveyor speed, flexibility, and automation level also play key roles in this decision. > Take a systematic approach so you avoid bottlenecks and keep your workflow smooth. Focus on both your current and future production needs for the best results.

Klíčové poznatky

- Measure your largest PCB to determine the right conveyor length. This prevents jams and ensures smooth operation.

- Consider the transport distance between machines. Choose a conveyor that fits your layout to avoid bottlenecks.

- Adjust conveyor speed to balance throughput and quality. Test different speeds to find the optimal setting for your PCBs.

- Select flexible and modular conveyors. These systems adapt to changing production needs and save costs.

- Always integrate conveyors with other SMT equipment. This enhances workflow efficiency and reduces downtime.

Choose the Right PCB Conveyor Length

PCB Size

When you choose the right PCB conveyor length, you must first consider the size of your printed circuit boards. PCB size directly affects how much space each board needs on the conveyor. Standard panel sizes help you match your conveyor to your production needs. Here is a table showing common PCB sizes and their conveyor length requirements:

| PCB Size | Conveyor Length Requirement |

| ——– | ———————————————- |

| 500mm | Must not exceed 500mm |

| 1000mm | Suitable for 50-1000mm |

| 1200mm | Requires a larger motor due to weight and size |

You will often work with three main categories of PCB panels:

- Small Panels: Around 100mm x 100mm, ideal for prototyping.

- Medium Panels: Typically 200mm x 300mm, suitable for mid-volume runs.

- Large Panels: Up to 500mm x 400mm or more, used for high-volume production.

Panel sizes in SMT manufacturing can vary, but standard dimensions help ensure compatibility with automated equipment. Small panels are best for testing and development. Medium and large panels support higher production volumes. Adjustable conveyor settings let you handle different PCB sizes, so you can keep your line efficient and flexible. If you plan to run multiple board sizes, modular conveyors make it easier to adapt.

Tip: Always measure your largest PCB and select a conveyor that can handle it. This prevents jams and keeps your SMT line running smoothly.

Transport Distance

Transport distance is the length your PCB must travel between machines on the SMT line. You need to choose the right PCB conveyor length to bridge these gaps without wasting space or causing bottlenecks. If your machines sit close together, a short conveyor works best. For longer distances, you need a longer conveyor or several modular sections.

Adjustable conveyors help you manage different layouts. You can change their length or add sections as your production line grows. This flexibility supports both current and future needs. Manufacturers often plan for future growth by choosing modular systems and ensuring compatibility with existing machines. Here is a quick overview of strategies:

| Strategy | Description |

| ————— | —————————————————————– |

| Future Planning | Plan for future growth when selecting PCB conveyors. |

| Modular Systems | Modular systems adapt to changing needs. |

| Compatibility | Ensure compatibility with existing machines to minimize downtime. |

| Maintenance | Choose equipment with easy maintenance and good supplier support. |

Poznámka: Measure the space between each piece of equipment before you choose the right PCB conveyor length. This helps you avoid costly mistakes and downtime.

Rychlost dopravníku

Conveyor speed plays a key role in SMT production. It affects how quickly your PCBs move through the line and how much time they spend at each process step. The right speed balances throughput and quality. If you set the conveyor too fast, you risk poor solder joints. If you set it too slow, you may damage components or create solder bridges.

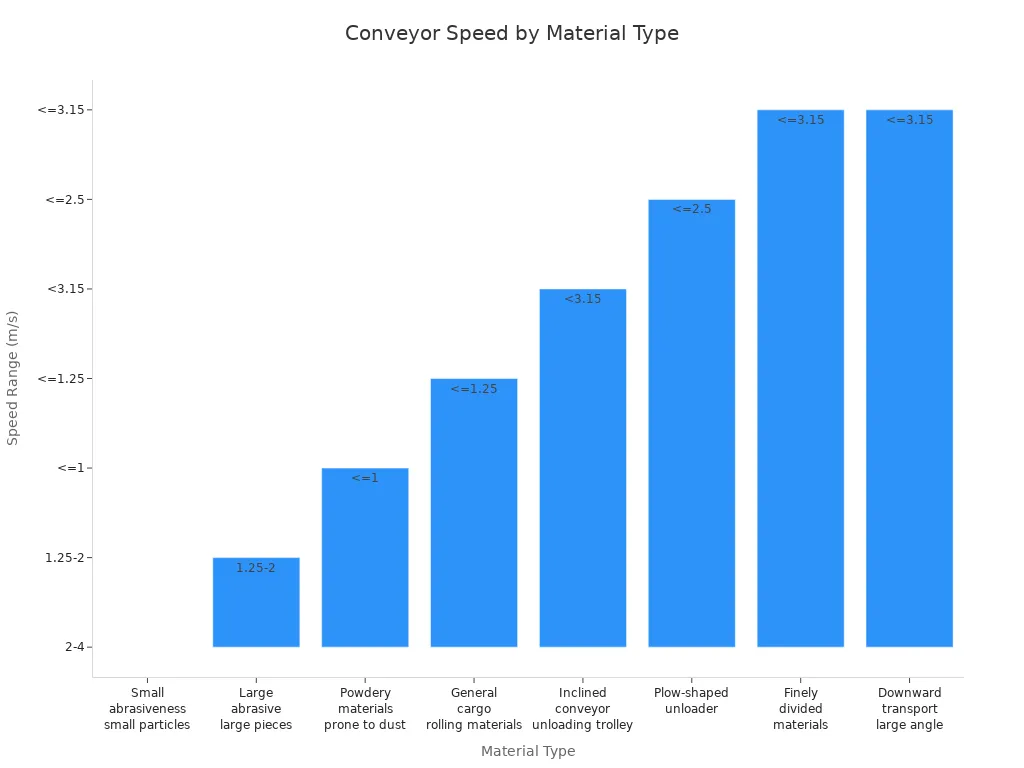

Zde je table showing recommended conveyor speeds for different material types:

| Material Type | Recommended Speed Range |

| —————————————— | ———————– |

| Small abrasiveness and small particles | 2 to 4 m/s |

| Large abrasive and large pieces | 1.25 to 2 m/s |

| Powdery materials are prone to dust | ≤ 1 m/s |

| General cargo and rolling materials | ≤ 1.25 m/s |

| Inclined conveyor with unloading trolley | < 3.15 m/s |

| Plow-shaped unloader | ≤ 2.5 m/s |

| Finely divided materials | ≤ 3.15 m/s |

| Downward transportation with a large angle | ≤ 3.15 m/s |

Měli byste aim for a conveyor speed between 1.0 and 1.5 meters per minute for most PCB designs. This range supports both high throughput and good solder quality. Adjustable speed settings let you fine-tune the process for different board types and densities.

- Conveyor speed affects the exposure time of PCBs to solder waves.

- Fast speeds can cause incomplete solder joints.

- Slow speeds may lead to overheating and defects.

- The optimal speed depends on your PCB design and component density.

Tip: Test different conveyor speeds with your actual PCBs. Monitor solder quality and adjust as needed to find the best balance.

When you choose the right PCB conveyor length, always consider how speed, PCB size, and transport distance work together. This approach helps you build a flexible, efficient SMT line that meets both current and future needs.

Key Factors to Consider

Flexibility and Adjustability

You need flexible and adjustable conveyors to keep your SMT line efficient. These systems let you change conveyor width and height, so you can handle different PCB sizes and production volumes. Adjustable conveyors use modular designs and smooth screws for easy width changes. You can customize lengths and control speed to match your workflow.

Here is a table showing the main benefits of conveyor flexibility and adjustability:

| Benefit | Description |

| ———————— | ———————————————————————– |

| Increased Productivity | Modify conveyors for new product lines to boost productivity. |

| Reduced Costs | Adapt conveyors without buying new equipment, lowering costs. |

| Improved Quality Control | Adjust conveyors for better quality management during production. |

| Enhanced Flexibility | Handle various goods and adapt to changing needs for better efficiency. |

- Flexible conveyors maximize space by expanding or contracting as needed.

- You save time and labor with quick reconfiguration.

- Adaptable systems integrate easily with other material handling equipment.

When you choose the right PCB conveyor, flexibility helps you respond to changes in production quickly. You can keep your line running smoothly even when you switch PCB sizes or increase output.

Úroveň automatizace

Automation plays a big role in SMT production. Automated conveyor systems reduce manual work and improve efficiency. You can use magazine-style buffers for temporary storage, which helps manage PCB flow. These systems have user-friendly interfaces and sturdy designs, making them easy to add to automated lines.

- Automated conveyors load and unload PCBs, streamlining production.

- They reduce downtime and keep your workflow continuous.

- Automatic magazine-type buffers minimize handling errors and work with different PCB sizes.

You should look for conveyors that support automation if you want to boost productivity and reduce mistakes. Automation lets you focus on quality and speed.

Line Layout

Your SMT line layout affects conveyor length and workflow. A well-organized layout reduces bottlenecks and uses space wisely. You can optimize workflow and efficiency by integrating conveyor systems with other SMT equipment. Fast line reconfiguration and reduced setup times help you meet production goals.

When you plan your layout, measure the space between machines and think about future changes. Integrated conveyor systems make it easier to adjust your line as your needs grow. You can choose the right PCB conveyor length by considering layout, flexibility, and automation together.

Tip: Always integrate conveyors with other SMT equipment for a smooth and efficient workflow.

Steps to Make the Right Choice

Measure and Plan

Start by measuring the largest PCB you plan to use. Record the length and width. Check the distance between each machine in your SMT line. You need these numbers to choose the right PCB conveyor length. Draw a simple layout of your production area. Mark where each piece of equipment sits. This helps you see how much space you have for conveyors. Make a list of your current needs and think about future changes. If you plan to add new machines or run larger boards, leave extra room in your plan.

Tip: Use a tape measure and a notepad to keep track of all measurements. Accurate planning saves time and money.

Evaluate Compatibility

You must check if the conveyor fits with your existing SMT machines. Look for these key compatibility factors:

- The conveyor should work with your pick-and-place systems. Smooth integration boosts productivity and reduces downtime.

- Make sure the conveyor matches the space and layout of your line. This helps you use your area efficiently.

- The conveyor must connect easily with other equipment. This keeps your workflow steady.

If you want to upgrade or expand, modular conveyors offer more flexibility. You can add or remove sections as your needs change. Always ask your supplier about integration options before you buy.

Avoid Common Mistakes

Many people make mistakes when choosing the right PCB conveyor length. You can avoid these problems by following a few simple steps:

| Mistake | How to Avoid It |

| ———————– | ————————————— |

| Overestimating length | Measure carefully and plan for growth |

| Underestimating length | Check all PCB sizes and transport needs |

| Ignoring integration | Confirm compatibility with all machines |

| Forgetting future needs | Choose modular systems for flexibility |

Do not guess the conveyor length. Always measure and double-check. If you ignore integration, you may face costly delays. Plan for future changes so your SMT line stays efficient.

You need to focus on these key factors when you choose a PCB conveyor length:

- Velikost PCB

- Transport distance

- Rychlost dopravníku

- Flexibilita

- Automation level

- Line layout

Follow the steps in this guide to make confident decisions for your SMT line. Review your conveyor setup regularly. Production needs can change over time. Staying proactive helps you keep your workflow efficient and ready for future growth.

ČASTO KLADENÉ DOTAZY

What is the best way to measure PCB conveyor length for my SMT line?

You should measure the largest PCB you plan to use. Record the distance between each machine. Add extra space for future upgrades. Use a tape measure for accuracy.

Can I use one conveyor for different PCB sizes?

Yes, you can use adjustable or modular conveyors. These systems let you change the width and length. You can handle small and large PCBs without buying new equipment.

How does conveyor speed affect my production quality?

Conveyor speed controls how fast PCBs move through your line. Fast speeds may cause poor solder joints. Slow speeds can overheat components. Test different speeds to find the best setting.

Do I need to integrate conveyors with other SMT equipment?

You should always integrate conveyors with pick-and-place machines and reflow ovens. This keeps your workflow smooth. Integration reduces downtime and improves efficiency.

What mistakes should I avoid when choosing conveyor length?

Avoid guessing measurements.

Always check compatibility with your machines.

Plan for future changes.

Choose modular systems for flexibility.

Measure carefully to prevent costly errors.