You see new trends changing how factories use technology. Automation, artificial intelligence, and miniaturization are important. Green manufacturing and advanced PCB assembly also help. These trends make factories work faster. They help factories make better products. They also let factories change plans easily. S&M is a leader in making smart solutions for many industries. The global market for smt automation system factory technology was $215 billion in 2023. Asia-Pacific had the most installations.

Klíčové poznatky

Automation makes production faster. It cuts assembly time by 30-50%. It also lowers the number of mistakes a lot.

AI and machine learning help check quality better. Factories can find and fix problems fast. This makes products better.

Green manufacturing helps use less waste and energy. Factories become more eco-friendly but still keep good quality.

Smart robotics make work more efficient and steady. They help get high-quality results with fewer human mistakes.

Automation is flexible. Factories can change fast for new products or market needs. This saves both time and money.

SMT Automation System Factory Overview

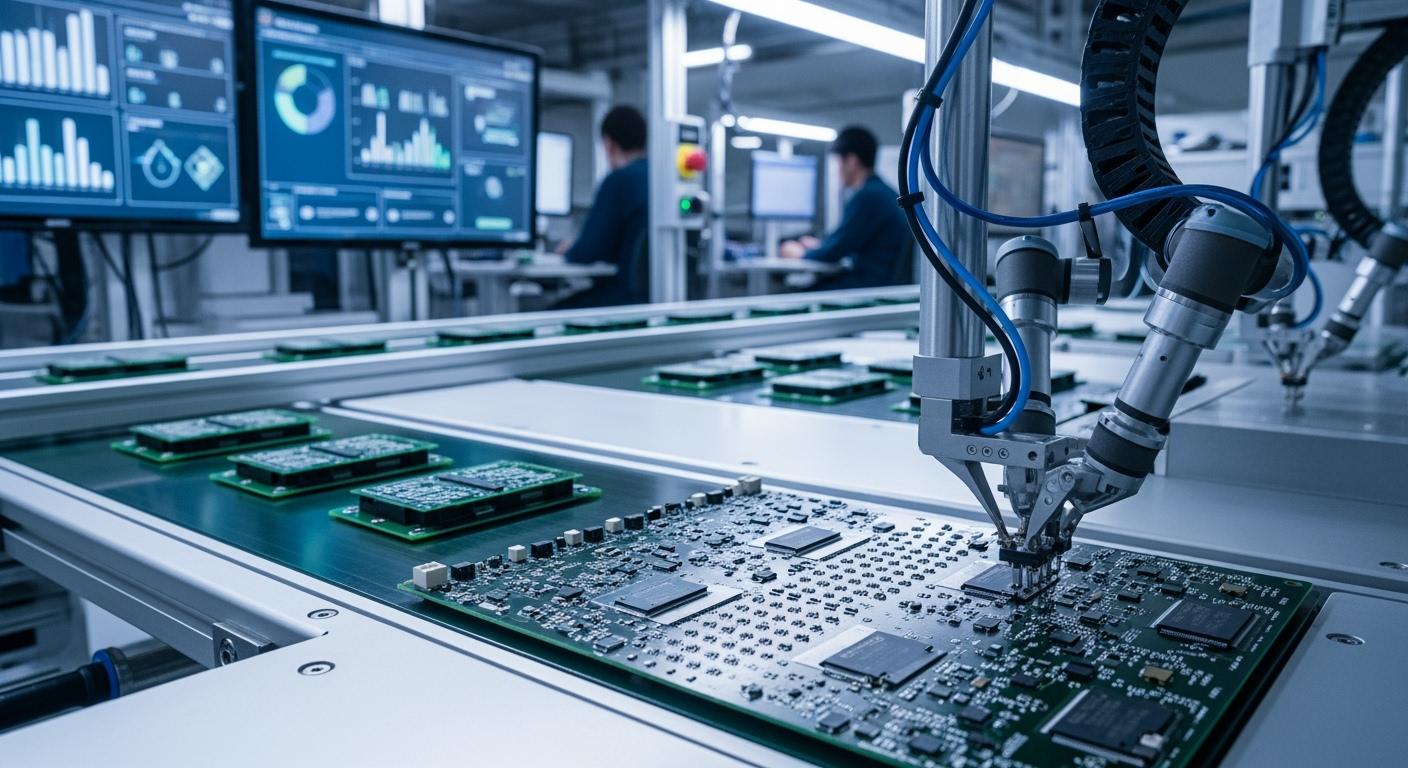

Role in Electronics Manufacturing

SMT automation system factory technology is changing electronics. S&M is leading this change with new ideas and care for the environment. The company makes solutions for many fields, like cars, health, and metal work. S&M makes machines better and builds new tools to help factories work well.

The world market for SMT placement equipment was $2.85 billion in 2024. Experts think it will almost reach $4.9 billion by 2032. This is because people want smaller and smarter electronics. SMT automation system factory solutions are in things you use every day, like phones and medical tools.

Automation lets factories work faster and make fewer mistakes. There are big changes in how things are made:

Assembly time can be 30-50% less.

Defect rates can drop below 100 parts per million.

Companies often get their money back in 1-2 years.

Quality control gets better too. Factories use Automated Optical Inspection and X-Ray systems to find problems early. This means you get better products with fewer mistakes.

Key Benefits and Challenges

SMT automation has many good points for electronics making. You get circuit boards that are smaller and lighter. Things are made faster and cost less. Electrical performance is better, and more parts fit in small spaces.

Výhody | Výzvy |

|---|---|

Hard to fix by hand | |

Faster manufacturing | Not good for high-power uses |

Better electrical performance | Can break from stress |

Lower costs | |

More parts in less space |

There are some problems, like fixing things by hand or dealing with stress. But the good things about smt automation system factory solutions are much greater than the bad. S&M keeps leading and helps you keep up with new electronics.

Key Trends in SMT Automation

S&M is a leader in new ideas and caring for the planet. These values show in every part of their smt automation system factory solutions. The newest trends change how you make electronics today. Let’s look at each trend and see how S&M helps you reach your goals.

AI and Machine Learning

AI and machine learning make your factory smarter. These tools help you find problems fast. You can fix issues before they get worse. Here is what AI does in your smt automation system factory:

Machine learning finds defects quickly and correctly.

AI spots misalignments, soldering errors, and missing parts in seconds.

Real-time data helps you know when machines need care, so you stop breakdowns.

AOI systems get faster and smarter with deep learning.

Cobots help you work faster and more accurately.

AI helps you place parts better and catch faults right away. You keep your line running well and make better products.

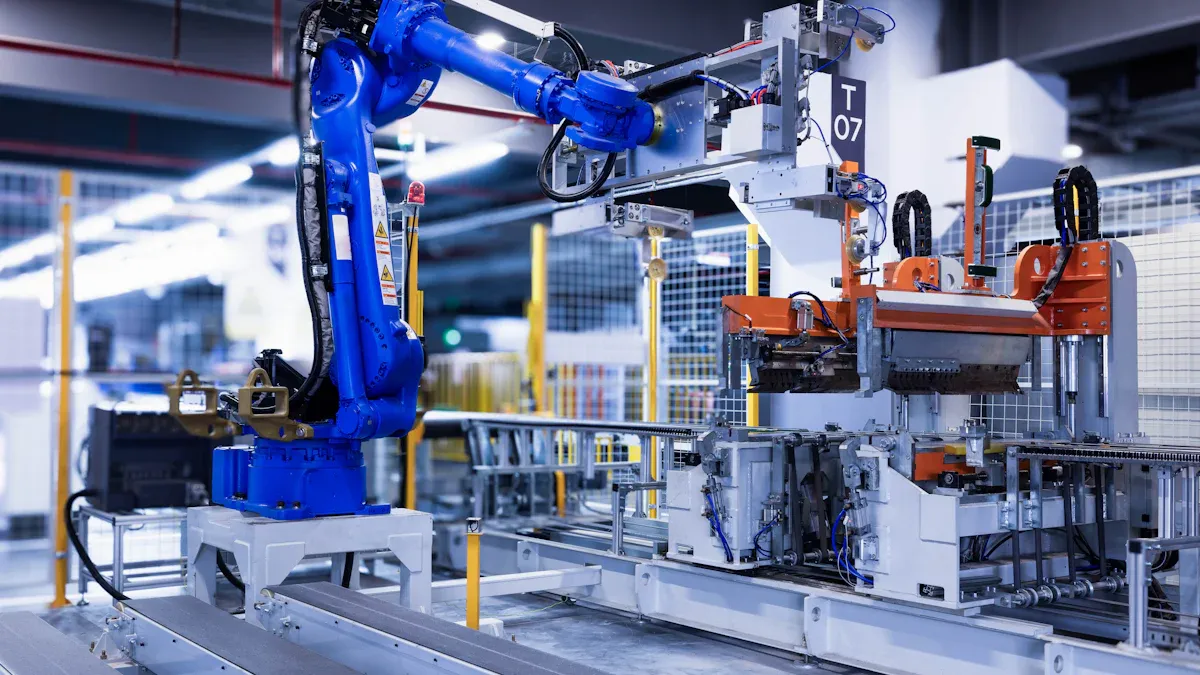

Smart Robotics

Smart robots change how you build things. They work with you to make each step faster and more exact. Here is a table that shows how smart robotics help your factory:

Benefit | Popis |

|---|---|

Sensors watch machines and tell you when to fix them before they break. | |

Kontrola kvality | Robots check for defects right away, so you waste less and get better parts. |

Higher Efficiency | Automation speeds up each cycle and cuts down on mistakes. |

Improved Product Quality | Robots do the same job every time, so your products stay top quality. |

S&M’s smart conveyors and soldering systems use these robots. You get steady, high-quality results every time.

IoT and Data Integration

You can connect your machines and collect data right away. This is what IoT and data integration bring to your smt automation system factory:

You cut breakdowns by up to half.

You lower maintenance costs by 20–30%.

S&M’s control software lets you manage your process and recipes easily. You see everything as it happens and make changes fast.

Green Manufacturing

You help the planet when you use green manufacturing. S&M makes energy-saving machines and supports eco-friendly ways. Here are some ways you can make your factory greener:

Use water-based cleaners to cut VOC emissions by half.

Use energy-saving machines to lower power use by 10-15% and reduce greenhouse gases.

Find ways to cut carbon emissions from start to finish.

Fix and reuse products to make less electronic waste.

S&M’s lead-free ovens and low-nitrogen soldering machines help you meet green goals without losing quality.

Miniaturization and Advanced Materials

You can make smaller, lighter, and smarter products with new materials and miniaturization. Here is a table that shows the impact:

Dopad | Reduction (%) |

|---|---|

60% – 90% | |

Weight of components | 60% – 80% |

You fit more circuits in less space and make connections shorter. This means better performance and less signal loss. S&M’s advanced placement machines reach sub-30-micron accuracy, so you can build the next generation of electronics.

Tip: When you choose S&M, you get flexible solutions that match the latest trends. You stay ahead in speed, quality, and sustainability.

Dopad na výrobu

Rychlost a propustnost

Automation makes factories work much faster. Machines do not stop, so you make more things in less time. Many companies save money and make more products with smart systems. For example:

Real-time monitoring helps you find problems early. You waste less material and can save up to $600,000 each year.

Automated tracking and KPI generation show how your line is working. You find ways to work faster.

Advanced machines help you switch jobs quickly. Your line keeps moving and stays reliable.

S&M’s solutions for LED and MiniLED lines show these good changes. You get fast speed and steady output, even when you need to make more.

Quality and Yield

Automation helps you make better products and more of them. Machines place parts very accurately, so you have fewer mistakes. Here is a table that shows how automation helps:

Benefit | Popis |

|---|---|

Enhanced Efficiency | Machines work fast and keep up with demand. |

Konzistentní kvalita | Automated systems reduce human error and keep quality high. |

Úspora nákladů | You save money by making fewer mistakes and using less material. |

Flexibilita | You can change your line for new products easily. |

S&M’s medical device solutions need perfect quality. Automation helps you meet strict rules every time.

Flexibility and Customization

Automation lets you change your line quickly. You can make different products without slowing down. Automation helps you:

Work faster and make fewer mistakes.

Spend less on workers and make your line more flexible.

Change for new products or market needs quickly.

S&M’s systems for New Energy and MiniLED help you switch between products and set up your line for special jobs.

Efektivita nákladů

Automation helps you save money. Machines work faster and more accurately, so you make more things for less money. Here is a table that shows how automation helps you save:

Evidence Point | Popis |

|---|---|

Increased Automation | You do more with less work and lower costs. |

Precision and Speed | Machines place parts fast and correctly. |

Cost Reduction | You make more things for less money. |

AI Enhancements | AI finds problems and helps you fix them quickly. |

Predictive Maintenance | Machines tell you when they need care, so you avoid breakdowns. |

S&M’s smt automation system factory solutions help you make lots of products and keep costs low. Automation cuts human mistakes, so you get better products and save money.

S&M in SMT Automation System Factory

Innovative Solutions

S&M leads with smart ideas for your factory. The company brings new tools to every step. PassionIOT’s Smart Vertical Carousel and Smart Vertical Lift Module help you use space well. These systems let you get parts fast and keep things moving. You do not waste time looking for parts. Smart tracking and automatic picking make inventory simple. You make fewer errors and keep things running smoothly.

You also use Inovaxe’s lean material handling tools. These tools help you move and store parts better. You keep things neat and ready to use. Your factory works faster and needs less effort. S&M’s full SMT line solutions cover soldering and conveyors. You get machines that match your needs, like LEDs, MiniLEDs, new energy, or medical devices.

Tip: S&M’s advanced systems help you work faster and better. You stay ahead in a market that changes quickly.

Industry Recognition

You can trust S&M because it has won many awards. S&M is a national high-tech company. The company is honored as a “speciality and new small and medium-sized enterprise” and an “innovative small and medium-sized enterprise.” These awards show S&M is strong in the smt automation system factory field.

S&M sets high standards for quality and service. Many customers in China and worldwide pick S&M for their lines. You see S&M’s work in LED, smart display, new energy, and medical devices. The company helps you follow strict rules and reach your goals.

Future Outlook

Emerging Technologies

You will see new technologies change how SMT automatizace system factories work. These changes help you make better products. They also keep your factory running well. The market for SMT automation is growing quickly. Experts think it will grow by 5.5% each year from 2024 to 2032. Asia-Pacific will have the most growth. More factories there will use advanced systems.

Here are some technologies that shape the future:

Automatizace: New machines work faster and more accurately. You can make more products with less effort.

Integrace umělé inteligence: Artificial intelligence helps you find problems early. It predicts when machines need care. You get better results and fewer breakdowns.

Sustainability: Factories use less energy and make less waste. You help the planet and save money.

Smart Factories: IIoT connects your machines. You see data right away and make quick choices.

5G Impact: High-frequency devices need new ways to be made. You can meet these needs with better tools.

Note: You will see more miniaturization and smarter robots soon. These trends help you stay ahead in electronics manufacturing.

Preparing for Change

You need to get ready for new technology in your factory. Change works best when you focus on your people. When your team feels respected, they accept new ideas and tools.

You can get ready by doing these steps:

Put your team first. Make sure everyone feels important and ready for change.

Match your processes with new technology. This helps you build a strong base.

Buy high-resolution vision systems. These tools help you place parts very accurately.

You can also:

Check your processes often. Find and fix problems early.

Use traceability systems. Track every part and step for better quality.

Grow with automation. Meet demand and lower labor costs.

Cut waste. Use materials wisely and make your workflow better.

Stay competitive. Always look for new ideas and tools.

Tip: You can lead in SMT automation by using new ideas and helping your team. This way, you grow and do well in a changing market.

You see new things like IoT, robotics, and augmented reality changing factories. These new tools help factories work faster and make fewer mistakes. S&M is a leader and brings smart ideas to big companies. You can keep up with others by doing these things:

Look at how you work now and find jobs for automation.

Teach your team how to use the new systems.

Change how you work as you add new tools.

Always try to make your automation better.

Experts think factories will care more about quality and smarter machines soon. Machines will also be more reliable. You can get ready now and be a leader in the next big changes in SMT automation.

ČASTO KLADENÉ DOTAZY

What is SMT automation?

SMT automation means machines put and solder parts on circuit boards. This makes things faster and there are fewer errors. You can make good electronics with this technology.

How does AI improve SMT production?

AI helps find problems and tells you when machines need fixing. You spot issues early and fix them quickly. Your factory runs smoother and makes better products.

Why should you choose S&M for SMT solutions?

S&M gives you smart machines and systems. You get choices that work for many types of factories. S&M helps you do things faster, better, and in a greener way.

Can SMT automation help you save costs?

Yes. Automation means you need fewer workers and waste less material. You make more things with less work. Machines also tell you when to fix them, so you spend less on repairs.