Key Benefits of Selective Wave Soldering for Electronics Manufacturers

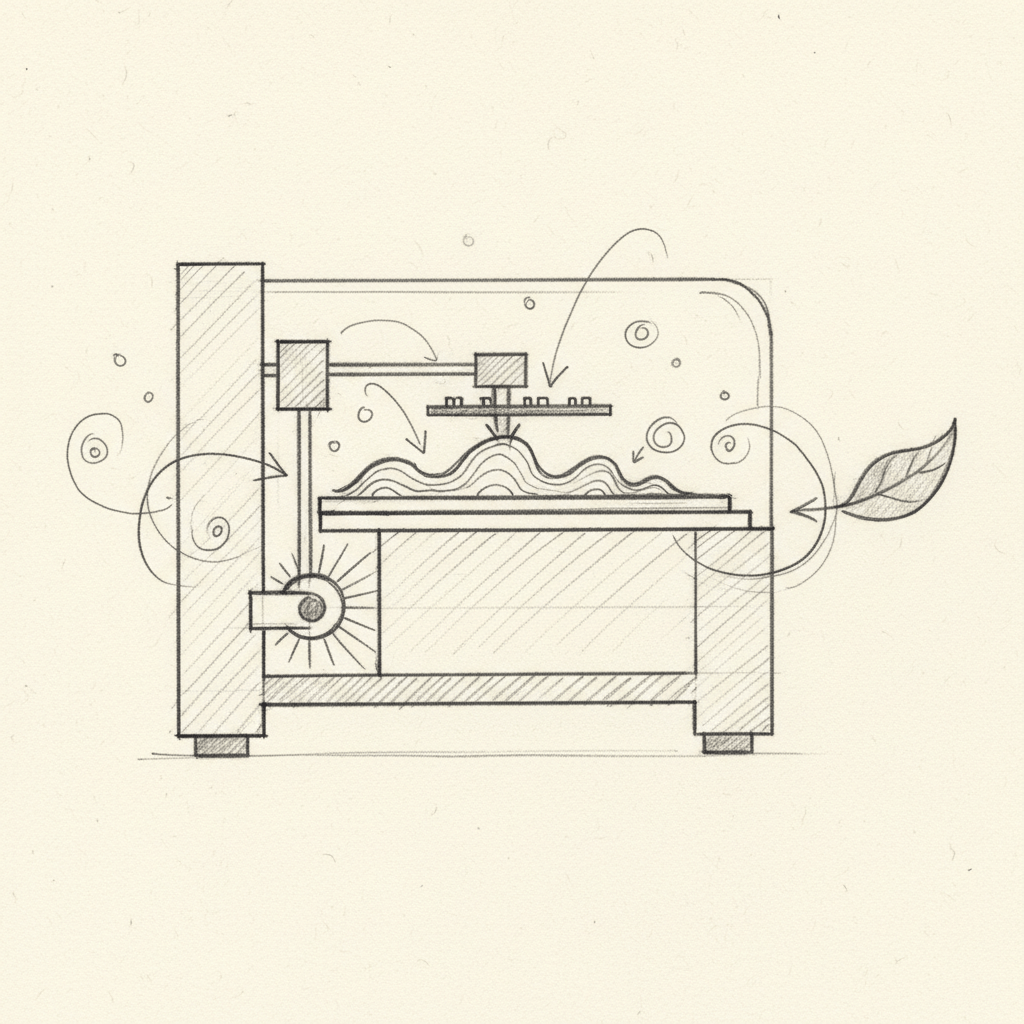

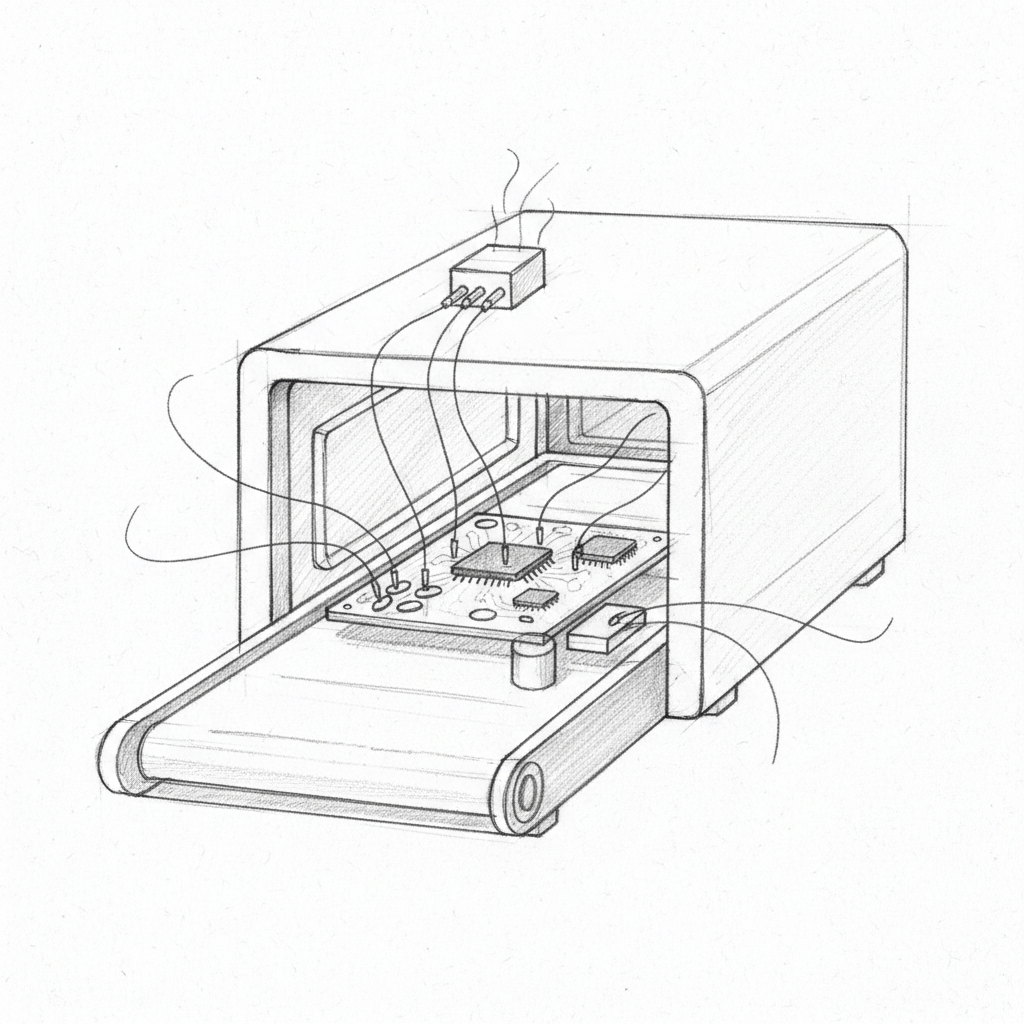

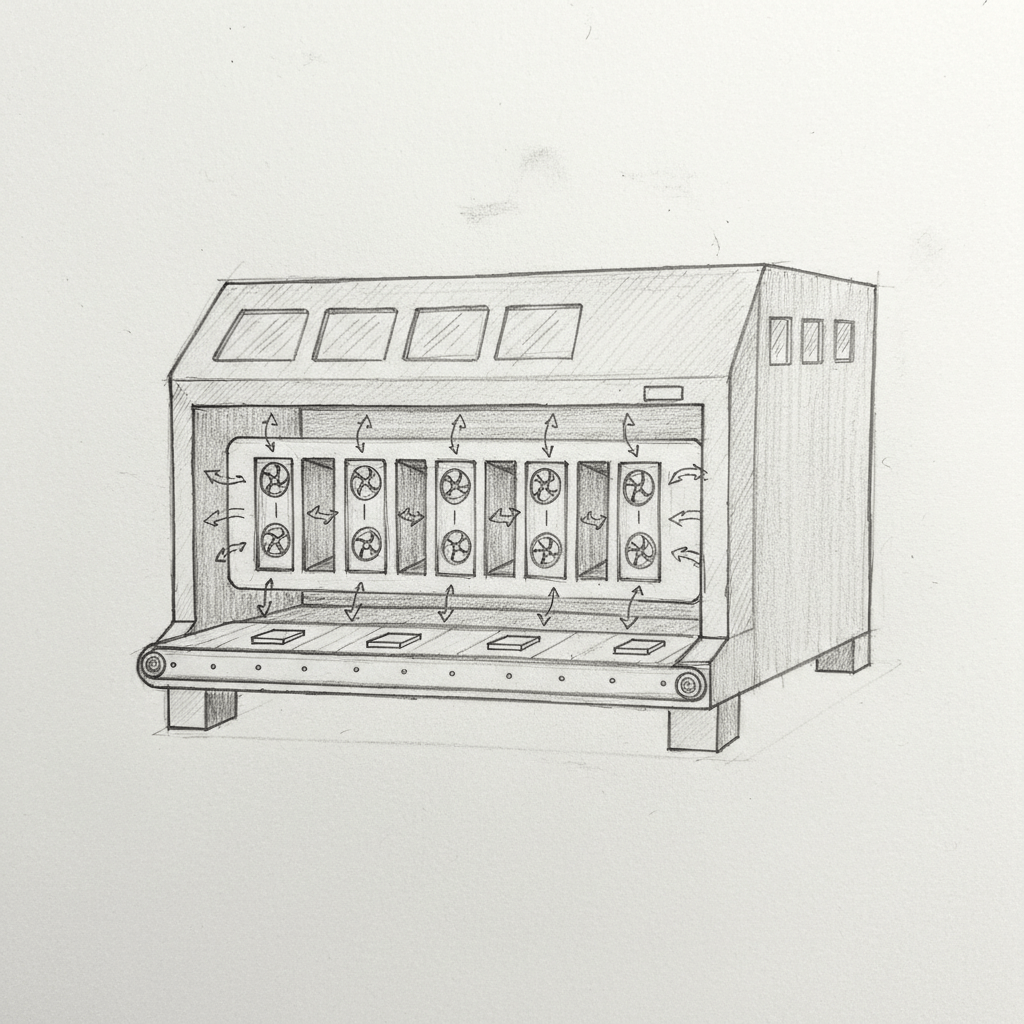

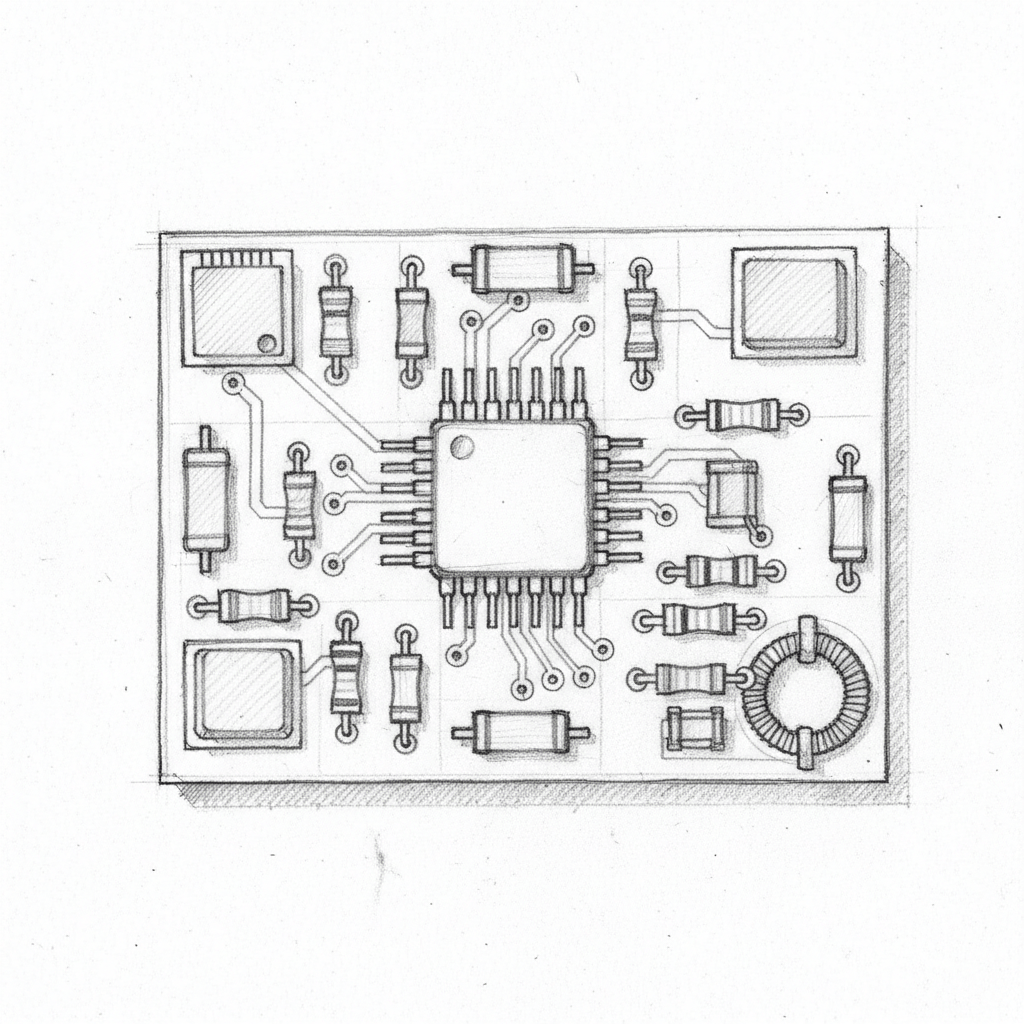

Selective wave soldering is a pivotal process within the domain of electronics manufacturing, providing a strategic alternative to traditional wave soldering methods. Unlike conventional wave soldering that immerses the entire underside of a printed circuit board (PCB) into a molten solder wave, selective wave soldering applies solder selectively to precise through-hole components using programmed nozzles. This precision minimizes heat exposure to surrounding areas, thus addressing various electronics manufacturing challenges.