How to Compare Top Reflow Oven Manufacturers: A Comprehensive Guide

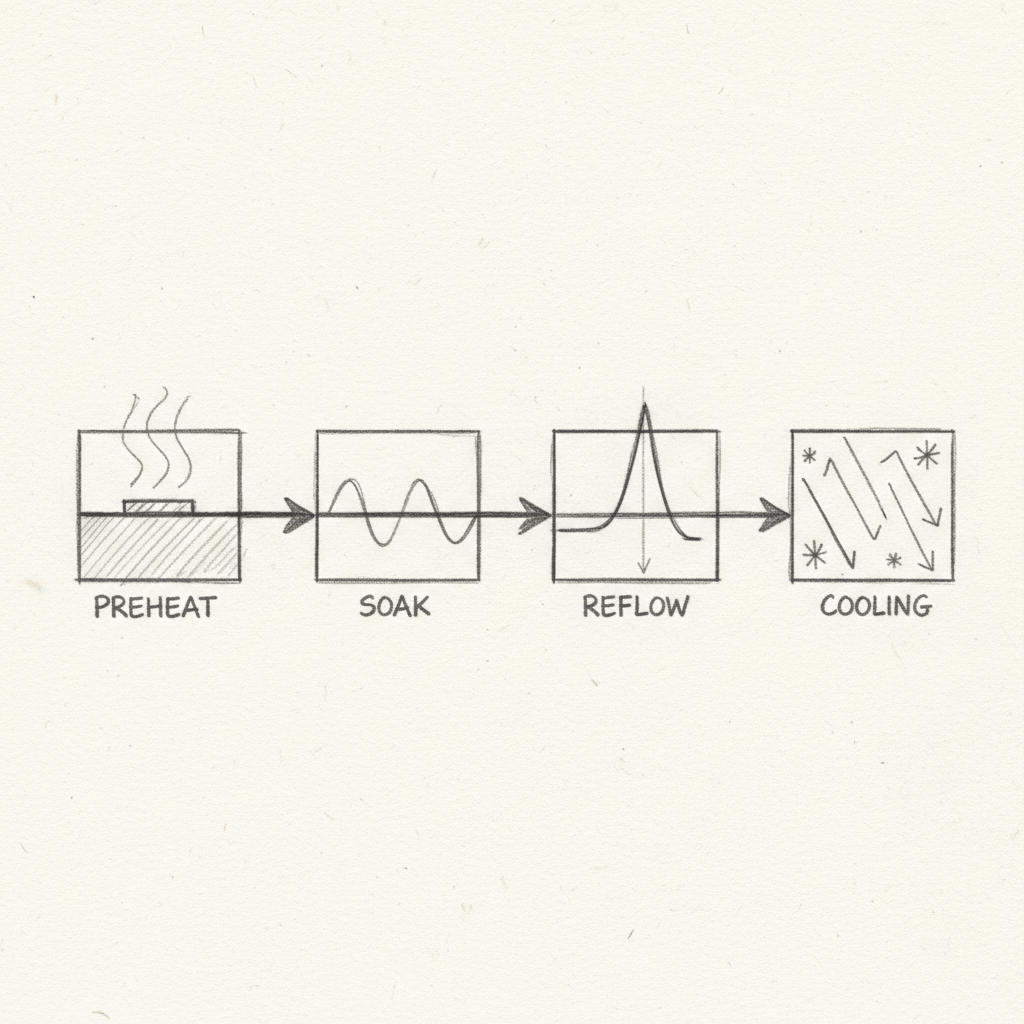

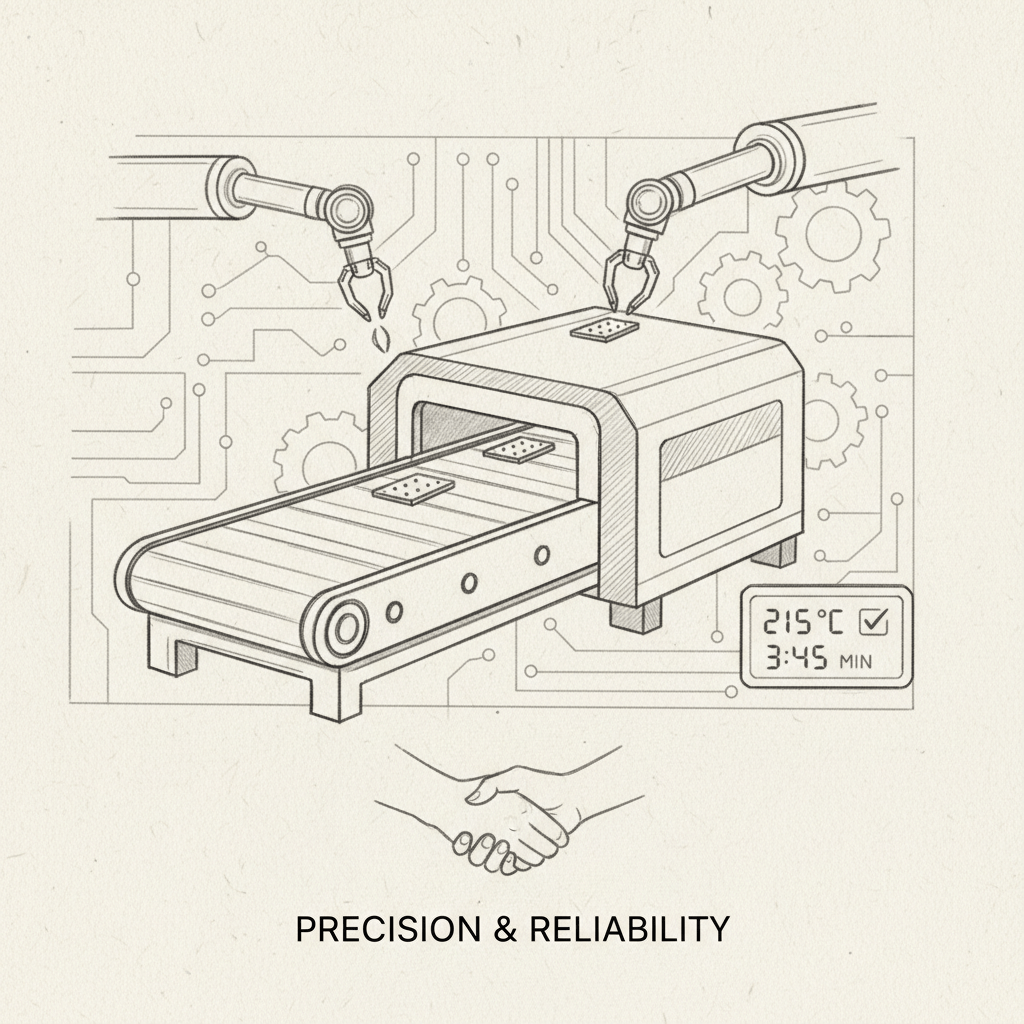

Reflow ovens play a crucial role in SMT processes by ensuring precise soldering of components onto PCBs, and selecting the right manufacturer is key to maintaining production quality. The guide recommends evaluating manufacturers based on precision, energy efficiency, scalability, and strong support systems. Emphasizing energy-saving technologies, modular designs, and customer support are essential for aligning with sustainability goals and ensuring flexibility in production. Manufacturers should also focus on regular maintenance and testing to optimize reflow oven performance, which includes cycle time efficiency and heat distribution, to enhance product quality and operational efficiency. Prioritizing these criteria helps manufacturers achieve competitive agility in dynamic markets.