SMT curing ovens, like S&M‘s curving oven, help you make lots of electronics fast and well. These ovens give steady heat and keep the temperature just right.

Sie erhalten stronger and better electronic parts because the ovens cure glue and solder carefully.

The ovens help with important jobs like baking and bonding, so your devices turn out the same and work well.

S&M works on new ideas to give you machines that make your products better and help you work faster every day.

Wichtigste Erkenntnisse

SMT curing ovens keep the temperature steady. This makes electronic parts stronger and more reliable. Using S&M’s curing ovens can make production faster by up to 40%. This helps companies make more boards in less time. The ovens help control flux well. This lowers mistakes and makes solder joints better. S&M’s modular design is easy to add to other machines. It is simple to make production bigger when needed. Taking care of the curing oven often can make it work better and last longer. This saves money over time.

SMT Curing Oven Functions in Mass Production

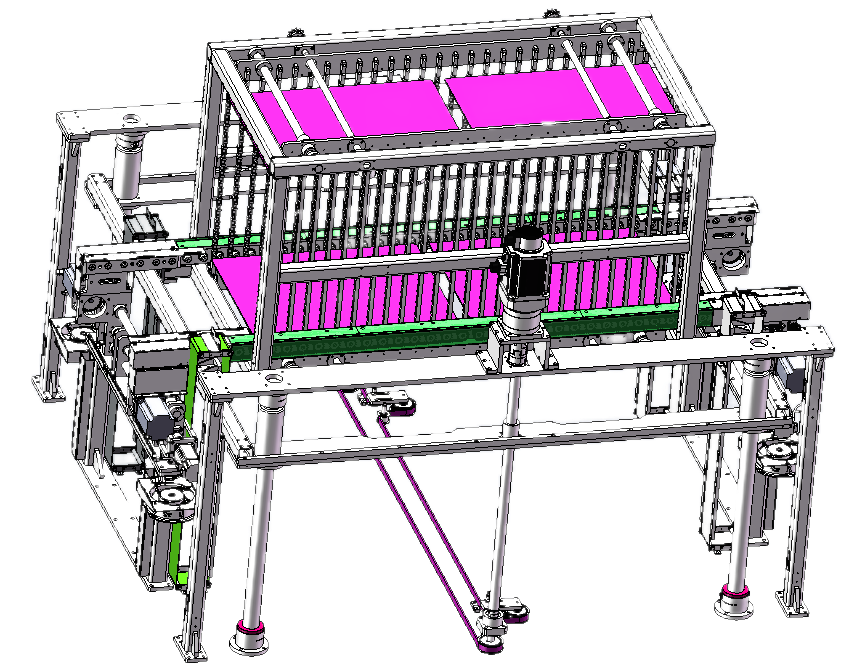

Role in SMT Assembly Lines

A Aushärteofen helps your smt assembly line work well. It melts adhesive to stick surface mount parts to the PCB. The oven works fast, so you can make more boards. This keeps your work steady and smooth. S&M’s Magazine Vertical Curing Oven fits your needs. It goes right into your automated line. You do not have to move boards by hand.

Here is how a curing oven helps your assembly line:

Funktion | Beschreibung |

|---|---|

Curing | Melts the adhesive to bond surface mount components to the PCB. |

Flux extraction and removal | Removes flux residues to keep your boards clean and reliable. |

Automation Benefits | Streamlines temperature control, conveyor handling, and inspections. |

Robotic Handling | Improves throughput and keeps tight tolerances with AOI integration. |

Energie-Effizienz | Reduces energy consumption for reflow ovens and lowers costs. |

IIoT Connectivity | Lets you monitor and optimize your line remotely for better solutions. |

These solutions help you make more boards at once. The oven uses AI and smart monitoring. You can change curing profiles to stop problems like tombstoning or solder bridges. The oven also finds when it needs fixing, so your line does not stop.

Temperature Control and Uniformity

You want every board to be the same and work right. The smt curing oven lets you set the time and heat. It keeps the temperature very steady, within less than ± 1°C. This gives you even curing and better quality.

If the heat is not steady, you can get problems. Flux residue, solder balls, or parts moving can happen. S&M’s solutions help you stop these issues. You get fewer cold solder joints and less flux slumping. The oven blows hot air and uses PID closed-loop control. This keeps the heat even on all boards.

You stop tombstoning and solder bridging.

You prevent voids in solder joints and non-wetting.

You avoid uneven heating and blowholes.

You cut down on flux problems and make reflow ovens work better.

With advanced smt equipment, you make more boards and use less energy. Your products stay strong, and your line works well.

Benefits of S&M Curving Oven in High-Volume SMT

Throughput and Efficiency

You want your smt assembly line to work fast. S&M’s curving oven helps you make more boards. The oven has special insulation and heat recovery systems. These features help you use less energy, up to 30% less. You save money and help the planet too. The oven has a computer system for easy control. You can watch the temperature and change settings right away.

Manufacturers say they make boards 40% faster with direct-impingement ovens. The oven heats up quickly, so you need less space. You can fit more smt machines in your factory. The oven is built in parts, so fixing it is easy. You can swap parts fast and keep working. Less downtime means you make more boards each day.

Tip: S&M solutions help you do more work with less effort. You can make more products and keep your line moving.

Here is a table that shows the main benefits:

Nutzen Sie | Beschreibung |

|---|---|

Uses 25-30% less power with new insulation and heat recovery. | |

Automatisierung | Computer system lets you manage profiles and watch temperature in real time. |

Wartung | Modular design lets you swap parts fast and recover rosin online. |

Sicherheitsmerkmale | Has alarms, circuit breakers, and safe heating zones. |

Temperaturkontrolle | Uses many thermocouples for testing and steady heating. |

Consistency and Quality

You want every board to look and work the same. S&M’s curving oven keeps the temperature steady. The oven uses many thermocouples and PID closed-loop control. This makes sure all boards get even heat. You avoid problems like flux residue and solder balls. The oven blows hot air to help remove flux. You get clean boards and strong solder joints.

The oven’s technology helps you have fewer mistakes. You see less damage and fewer bad solder joints. Your yield rates go up. You spend less time fixing errors and more time making boards. The oven keeps the temperature from changing too much. This helps you make more boards right the first time.

Impact Category | Beschreibung |

|---|---|

Makes sure solder melts and sticks right, stopping bad joints. | |

Component Damage | Keeps parts at safe temperatures, so they do not get hurt. |

Yield Rates | Keeps temperature steady, so you make more good boards and save money. |

You also pay less for energy and repairs. The oven’s design helps you save money over time. You use less power and make less waste. This helps your company be more green.

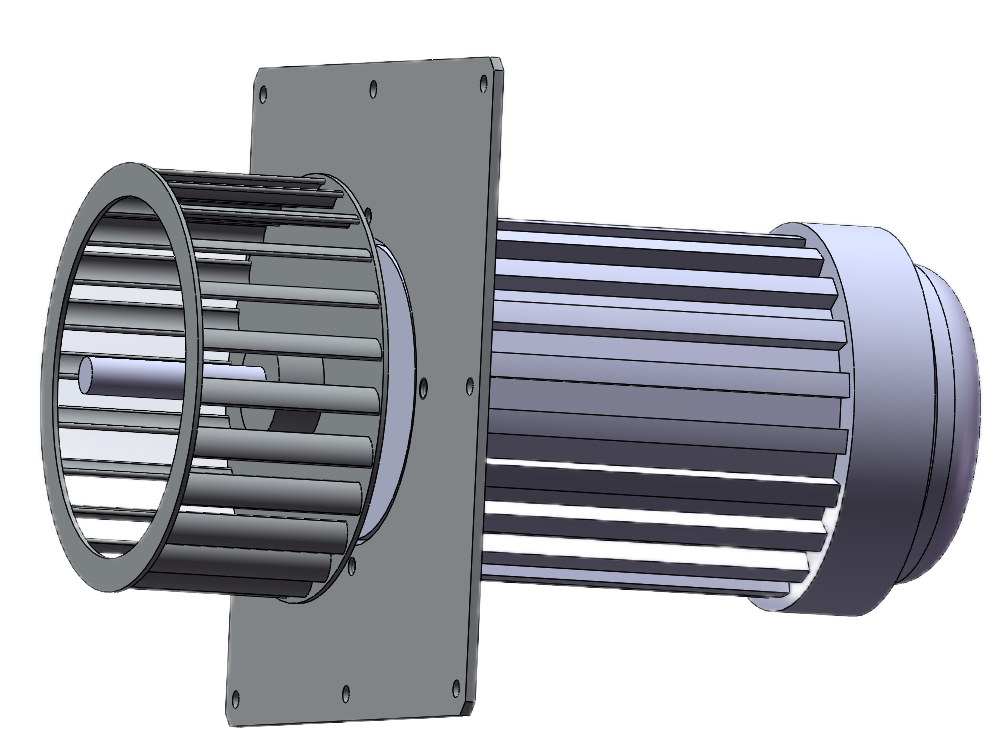

Advanced Transmission Design

S&M’s Magazine Vertical Curing Oven uses a needle roller system. This helps your smt equipment run smoother. The rollers are long and strong, so they last longer. Boards move smoothly and do not get stuck. If a board gets stuck, the system stops by itself. This keeps your boards safe and your line running.

You keep the oven clean inside. The system stops glue from spilling or moving. Your boards stay in place, and curing stays the same. You get better results every time. The oven lets you change the width with a button. You can use different board sizes without slowing down.

Needle roller bearings help control movement and lower friction.

The design makes the oven last longer and work better.

You get a strong solution for making lots of boards.

S&M solutions help you make more boards, better boards, and safer boards. Your smt assembly line works well, and your customers trust your products.

Operational Advantages of SMT Curing Ovens

Reliability and Uptime

You want your smt assembly line to keep running without stops. A curing oven from S&M gives you strong reliability. The oven uses a UPS power supply. If the power goes out, the oven keeps working long enough to move all boards out safely. This protects your products and keeps your line moving. The intelligent fault layer shielding lets you skip only the problem layer, so the rest of your boards keep curing. You do not lose throughput because of one small issue.

A good Abkühlungsgeschwindigkeit helps you get strong solder joints and fewer defects. Look at this table to see how cooling rate affects your boards:

Abkühlungsgeschwindigkeit (°C/s) | Auswirkungen auf die Qualität der Lötverbindungen | Auswirkungen auf die PCB-Zuverlässigkeit |

|---|---|---|

1.5 – 10 | Starke, zuverlässige Lötverbindungen | Weniger Mängel |

Zu langsam | Schwache, raue Gefüge | Höhere Ausfallwahrscheinlichkeit |

You get higher throughput and better quality when your oven keeps the right cooling speed. S&M solutions help you avoid downtime and keep your smt equipment running.

Scalability for Production Growth

Your business may grow, and you need more capacity. S&M’s curing oven supports modular configurations. You can add more ovens or connect them to new smt assembly machines. This helps you scale up your throughput without changing your whole line. The oven’s advanced temperature control keeps every board the same, even as you make more products.

Here is a table that shows how ovens help you grow:

Evidenzpunkt | Beschreibung |

|---|---|

Modular Configurations | You can add ovens to increase capacity and flexibility. |

Advanced Temperature Control | You get even curing and fewer defects. |

Smart Ovens | Real-time monitoring and predictive maintenance help you plan. |

Industry 4.0 Practices | Automation and data help you make better decisions. |

You can trust S&M solutions to grow with your needs. The oven’s MES compatibility lets you connect to your factory’s data system. You can track throughput, energy consumption for reflow ovens, and flux extraction and removal.

Intelligent Fault Management

You want your smt equipment to fix problems fast. S&M’s solutions use intelligent fault layer shielding. If a board gets stuck, the oven stops only that layer. The rest of your boards keep moving. This keeps your throughput high. The oven’s touch screen shows you where the problem is. You can fix it quickly and keep working.

The oven’s MES compatibility helps you watch your line in real time. You can see how much flux is left, check the status of your smt assembly line, and plan for maintenance. The UPS power supply protects your boards if the power fails. You do not lose products or waste time.

Tip: Use S&M solutions to keep your line running, save energy, and get the most from your smt assembly machines.

You get less downtime, better throughput, and safer boards. The oven’s design helps you handle flux, keep your line clean, and support higher throughput every day.

Practical Considerations for Choosing a Curing Oven

Key Features for Mass Production

When picking a curing oven for your smt equipment, you should look for features that help you make more boards faster. The best oven gives you steady results and helps you grow your business. Here is a table to show what is important:

Merkmal | Beschreibung |

|---|---|

Precise Temperature Control | Stops damage to sensitive electronic parts. |

Fast Curing | Makes processing quicker and lets you make more boards. |

Uses less energy and saves you money. | |

Gleichmäßige Wärmeverteilung | Gives even results and stops problems with materials. |

Continuous Conveyor Process | Keeps your line moving so you can make more boards. |

Reliable Performance on Dense PCBAs | Cures coatings in hard-to-reach spots. |

Larger Processing Area | Lets you cure more boards at the same time. |

Gentle Temperature Profile | Protects delicate parts and materials from harm. |

Superior for Thick Coatings | Handles thick layers and cures them evenly. |

Innovative Technology | Uses new systems for very accurate results. |

S&M’s Magazine Vertical Curing Oven has these features. You get steady temperature, fast curing, and space for many boards. This helps you meet demand and make strong products.

Maintenance and Cost Efficiency

You want your curing oven to last and work well. Taking care of it helps it run better. Here are some easy steps:

Look inside the oven to keep electrical parts clean.

Check the exhaust for dirt that could block air.

Take care of heating parts so they work well.

Doing these things helps you avoid trouble and save money. S&M ovens use good parts, so you do not fix them as much. Energy-saving designs lower your bills and help the environment. You get more for your money.

Integration with SMT Lines

Your curing oven should fit easily with your smt equipment. S&M ovens have features that make this simple. You get 6 to 12 heating zones for good control and 1 to 2 cooling zones for the right cooling speed. MES compatibility lets you connect your oven to your factory’s computer system. You can track flux, watch how many boards you make, and change recipes with a barcode scanner.

Merkmal | Beschreibung |

|---|---|

MES Compatibility | Connects to computers for better tracking. |

Automation & Traceability | Changes recipes and tracks boards by itself. |

Stable Temperature Profiles | Keeps heat steady for great results. |

Effective Nozzle Design | Spreads heat evenly for strong solder joints. |

These features help you handle more flux, keep your line clean, and make more boards every day.

You need a good curing oven to make more products. S&M’s solutions help you make more and get better results. You can control the temperature very well, so you get fewer mistakes and stronger boards. These ovens keep your line working and take care of flux. You can trust the curing oven to handle flux, help your smt equipment, and keep things clean. With these ovens, you control flux, make better boards, and your factory works better.

Good temperature control means fewer mistakes and stronger boards.

The oven works all the time in automated lines, so you save work and get more done.

Even heat and air help you do the same job every time and handle flux, so your business does better.

FAQ

What is the main benefit of using S&M solutions in mass-production SMT environments?

You get reliable results with S&M solutions. These solutions help you control temperature, manage flux, and keep your smt equipment running. You can make more boards with less waste. Your production line stays efficient and strong.

How does the oven handle flux during the curing process?

The oven uses a smart system to manage flux. Hot air circulation and precise controls help remove flux from your boards. You get clean results. This process also helps improve flux collection system performance in your factory.

What is the cooling capacity needed for high-volume SMT lines?

You need enough cooling capacity to keep your boards safe. S&M solutions give you the right cooling for your smt equipment. This keeps solder joints strong and helps you avoid defects from leftover flux.

Can S&M solutions help increase my factory’s capacity?

Yes, S&M solutions let you scale up your capacity. You can add more ovens or connect them with other machines. These solutions help you meet higher demand and keep your line moving.

How do S&M solutions support flux management and collection?

S&M solutions focus on flux control. You get systems that collect and remove flux during curing. This keeps your workspace clean and your boards high quality. Good flux management also protects your smt equipment from damage.