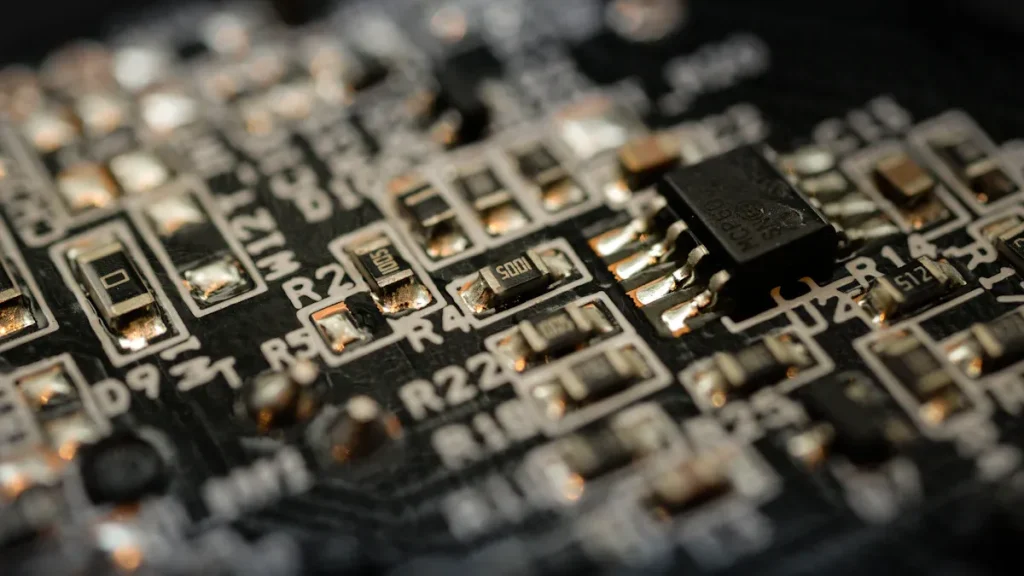

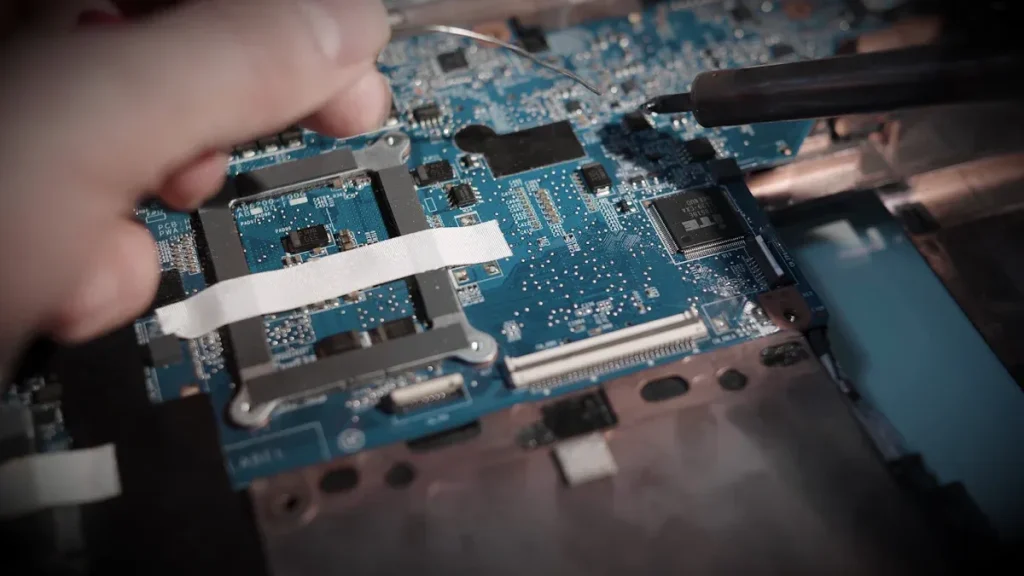

Anwendung des NG/OK-Förderers in der Qualitätskontrolle von SMT-Linien

NG/OK Screening Machines automatisieren die Leiterplattensortierung in SMT-Linien, verbessern die Qualitätskontrolle, reduzieren Fehler und steigern die Effizienz durch Inspektionsdaten in Echtzeit.