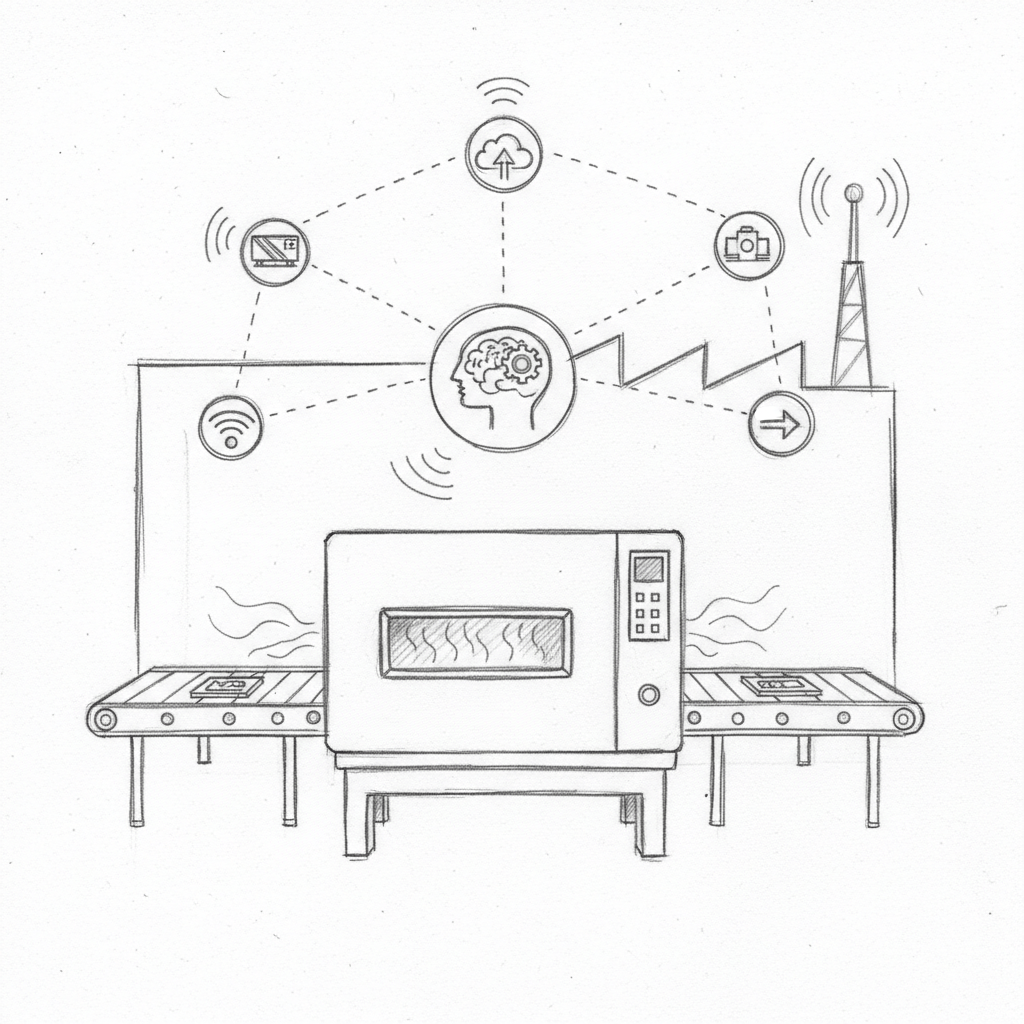

Reflow oven temperature profiles are critical frameworks detailing the various temperature levels and their corresponding durations utilized in the Surface Mount Technology (SMT) manufacturing process. These profiles are particularly instrumental in ensuring the precise heating and soldering of electronic components onto printed circuit boards (PCBs). A meticulously defined temperature profile is pivotal for achieving quality solder joints, therefore reducing the likelihood of defects.

The importance of accurate temperature profiling in SMT production cannot be overstated. It correlates directly with product quality, reliability, and manufacturing efficiency. By closely monitoring and adjusting the temperature profiles, manufacturers can mitigate several common issues such as solder bridging, voids, and tombstoning. Maintaining optimal temperature control is essential for maximizing throughput and minimizing cycle times, all while adhering to stringent quality standards that are crucial in electronics manufacturing.