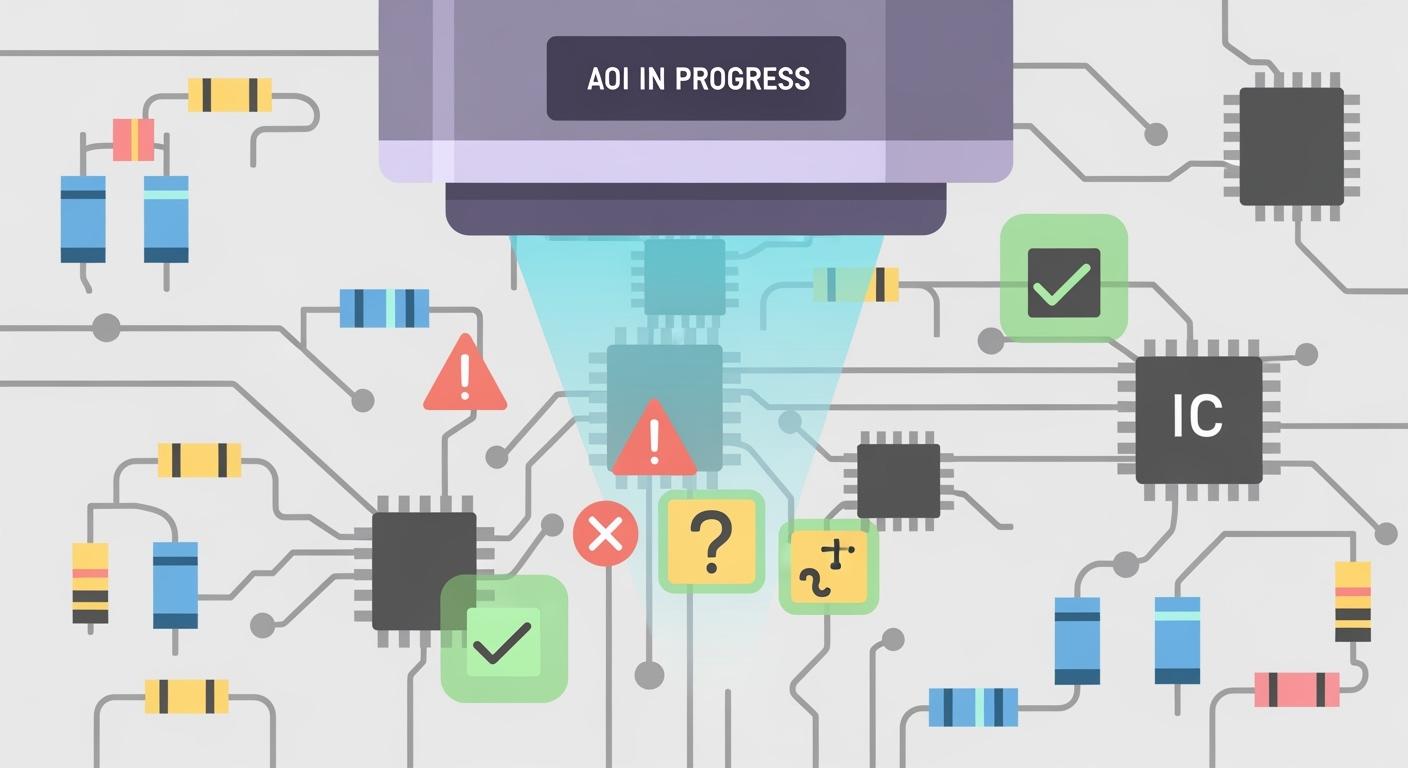

You can encounter AOI inspection issues that lower detection accuracy, which can negatively impact your product quality. The most significant AOI inspection issues include high false positive rates, high false negative rates, and the necessity for high-quality imaging. Refer to the table below for a quick summary:

Issue Type | Impact on Detection Accuracy |

|---|---|

High false positive rates | This can lead to extra rework and more checks, ultimately slowing down your workflow. |

High false negative rates | Defective products may reach customers, potentially damaging your company’s reputation and incurring additional costs. |

Dependence on high-quality imaging | Poor lighting or variations can obscure issues, resulting in false negatives or positives. |

AOI systems assist in identifying missing components and soldering errors, making the inspection of electronics more efficient and effective. SADOMASOQUISMO’s advanced tools, such as the Nitrogen reflow oven, enhance your ability to detect defects and maintain high product quality.

Principales conclusiones

High false positive and negative rates can hurt product quality. Calibrating your AOI system often keeps it accurate and stops expensive mistakes.

Good lighting is very important for AOI inspection. Use soft LED lights and special filters to cut down glare and find more defects.

Training operators is very important. Give hands-on lessons and certificates to lower mistakes and help them spot more defects.

Take care of your AOI equipment often. Follow a schedule to keep it working well and stop errors in finding defects.

Watch things like temperature and humidity. Keeping the factory steady helps AOI work better and lowers false alarms.

AOI Inspection Issues Affecting Accuracy

Calibration Problems

You need your AOI inspection system to find surface defects. It should also be very accurate. If there are calibration problems, the system can miss defects. It might also say good boards are bad. When calibration is off, the system has trouble with tricky patterns. It also struggles with changing light. This can cause both false positives and false negatives. These mistakes cost more money. They also make products less reliable.

Consejo: Calibrating your inspection system often keeps it accurate. This helps you avoid expensive errors.

He aquí un cuadro que muestra good calibration steps to follow:

Calibration Procedure | Descripción |

|---|---|

Verify Positional Accuracy | Use a board with special points to check if the system is right. |

Check Software Algorithms | Test the system on boards with known problems to see if it works. |

Schedule Regular Maintenance | Check the system every 3 to 6 months or after 10,000 checks to keep it working well. |

S&M makes inspection systems that are easy to calibrate. Their systems also work well and are reliable.

Lighting Issues in Automated Optical Inspection

Lighting is very important in automated optical inspection. Bad lighting makes it hard for the system to find surface defects. It can also cause false alarms. Shiny metals can make glare. Changing light and reflections can make it harder to spot problems. Detection accuracy can drop by up to 70%. You might get more false positives and false negatives. This means more mistakes and less trust in the results.

Some common lighting problems are:

Glare from shiny plastics or metals confuses the system.

Shadows and reflections can hide surface defects.

Changing light makes more false alarms and missed problems.

To find more defects, use good lighting like diffused LED lights, polarization filters, and lights from different angles. Many AOI systems now use lights from many angles. This can help find up to 30% more defects. S&M’s inspection systems use these lighting tools. They help you find surface defects more easily.

Programming and Algorithm Errors

Programming and algorithm errors in AOI software can cause false positives. They can also make the system miss surface defects. If the system cannot tell normal changes from real problems, you get more false alarms and missed defects. Operator mistakes during setup or calibration can cause up to 30% of AOI errors. This happens a lot when you first use a new system.

You can lower these errors by:

Making clear inspection rules before starting.

Testing your plan with pilot projects.

Making sure lighting and imaging are set up right.

Training your operators and maintenance staff.

Writing down and following steps for handling defects.

Updating programming when your designs change.

Changing inspection settings like camera resolution and light strength.

If you follow these steps, you will find more defects. You will also have fewer false alarms. Your inspection system will work better. S&M works hard to give you quality and new ideas. Their automated optical inspection gives you good results, even when your production changes.

Soldering Defects and Component Placement

Solder Joint Variability

Soldering defects are a big problem in surface mount technology. Solder joints can look different, which lowers board quality. Glossy solder masks look nice, but they make glare and reflections. This makes it hard for AOI systems to find problems. You might get more false positives or miss real defects. This costs more money and slows down work. Matte finishes can help lower errors by up to 15%. Good lighting and the type of solder joint also matter. If you use steady lighting and pick the right finish, you can check solder joints better and make boards higher quality.

Cause of Variability | Impact on AOI Inspection Results |

|---|---|

Stability of illumination light | Changing light makes it hard to find problems |

Environmental light | Makes it harder to trust defect checks |

Surface characteristics of joints | Shiny or bumpy joints cause more mistakes or missed problems |

Different solder joint types | Need special ways to find problems |

Glossy finishes | More glare, more mistakes, checks take up to 20% longer |

Matte finishes | Fewer mistakes, up to 15% better quality |

Component Misalignment

Placing parts in the right spot is very important for good boards. If parts are not placed right, AOI systems can find small mistakes, even if a part is off by just 0.02 mm. Common smt problems are parts in the wrong spot, facing the wrong way, missing parts, tombstoning, and wrong parts. Bad placement can make circuits fail and lower quality. AOI checks for correct direction, pin spots, and missing parts after soldering. If you fix placement mistakes, you get better and more reliable boards.

Positional errors: Parts not in the center of pads

Orientation errors: Parts turned the wrong way

Missing components: Pads left empty after placing parts

Tombstoning: Small parts stand up because of uneven solder

Wrong components: Wrong parts put on the board

Reducing Soldering Defects with S&M Nitrogen Reflow Oven

You can have fewer soldering problems and better boards with advanced controls. S&M’s Nitrogen reflow oven lets you control temperature and heat very well. This oven helps surface mount technology by stopping oxidation and making even solder joints. The oven is easy to take care of, so your line keeps running. With better control, you see fewer problems and more even results. This means better boards and fewer issues when checking solder joints. S&M’s tools help you place parts right and lower placement mistakes, making your line work better.

Operator and Maintenance Factors in AOI

Operator Errors in Defect Detection

You are important for aoi success. Mistakes by operators can mean missed defects. They can also cause extra checks that are not needed. Training and certification help you avoid these problems. When you get hands-on training, you learn how to use aoi tools. Workshops with certified trainers teach real maintenance and operation skills. Online courses let you learn when you have time. AR and VR training give you practice without stopping work. Regular training keeps you up to date on inspection and safety. Getting certified in IPC standards helps you handle tough defect detection jobs and keep quality high.

Hands-on training at your workplace

Workshops led by certified trainers

Online courses for flexible learning

AR and VR lessons for practice

Regular updates on inspection methods

Certification in IPC and EPTAC standards

Maintenance Lapses Impacting Accuracy

You need to keep aoi equipment working well for good defect detection. If you skip maintenance, you can get more mistakes and lower quality. A good maintenance plan helps you stop these problems. The table below shows how often you should do aoi maintenance:

Frecuencia | Maintenance Task |

|---|---|

Diario | Look for dust, dirt, or damage; check camera lenses and lights. |

Semanal | Clean conveyor belts and sensors; check for software updates; write down small issues. |

Mensualmente | Clean parts deeply; test defect detection with a known bad PCB. |

Quarterly | Check mechanical parts closely; calibrate cameras and sensors. |

S&M’s modular design makes it easy to fix or upgrade parts. This helps your line keep running and keeps quality high.

Best Practices for AOI System Reliability

You can make aoi more reliable and have less downtime by following best practices. Updating software helps you use new algorithms for better checks. Training more team members stops problems if someone is gone. Use aoi data to make your quality control better, like changing soldering temperatures to lower defects. Plan for more aoi units as you grow to keep things running well.

Buenas prácticas | Descripción |

|---|---|

Update aoi software for better detection and quality. | |

Cross-Training | Train more team members to use aoi equipment. |

Continuous Improvement | Use aoi data to make your process better and lower defects. |

Scalability Planning | Add or upgrade aoi units as you make more products. |

S&M’s modular aoi equipment helps you follow these best practices. The design lets you upgrade and maintain easily, so you keep high quality and efficiency in your checks.

Environmental and Board Variability Challenges

Environmental Effects on Automated Optical Inspection

Your factory can have problems that hurt aoi accuracy. Things like temperature changes, humidity, dust, and electromagnetic interference cause trouble. Even small changes can make the system miss defects or give false alarms. Keeping the area steady helps aoi work well.

AOI equipment must work well in your factory. If the room gets hot or cold, or if there is dust or interference, the AOI must still check boards correctly.

Humidity, dust, and temperature can change how good PCB assemblies are. You need to control these things to stop corrosion, contamination, and heat damage.

PCB and Component Variability

Boards and parts can also make things hard for aoi. If the PCB layout or part placement changes, the system can get confused. This can make it miss problems or say good boards are bad. You need to handle these changes to keep things running well.

Putting parts in the right spot helps signals and saves money.

Making sure all ICs face the same way helps with layout and stops mistakes.

Splitting the PCB into areas for different parts stops signal problems.

Keep parts that do not use power away from hot spots like IGBTs and MOSFETs.

Give enough space for copper traces, especially in small designs, so routing is easier.

Managing Variability for Consistent Accuracy

You can fix these problems with good steps. Keep your factory steady. Use climate control for temperature and humidity. Add anti-static tools to protect electronics. Collect data to find problems early. Automate important jobs to stop mistakes. Use control charts to watch for changes and catch problems before they hurt aoi results.

Method | Descripción |

|---|---|

Data Collection | Use systems to get real-time data from machines and spot problems early. |

Control Charts | Watch key numbers and mark anything that looks wrong. |

Automating Key Processes | Automation helps stop mistakes and keeps output steady. |

Environmental Control | Keep the room steady to stop problems from temperature and humidity changes. |

You can look at examples from other companies. The Q-upAuto system checks mounting and maintenance in real time to find defects. In one case, changing a nozzle after finding problems made the defect rate go from 1.00% to 0.00%. This shows that controlling changes in your factory can fix tough aoi problems and make inspection better.

You deal with lots of problems in aoi. Calibration problems can make aoi less accurate. Bad lighting also causes mistakes. Programming errors are another issue. Solder joints can look different and confuse aoi. Parts might not be placed right. Operator mistakes can hurt aoi results. Not taking care of machines makes things worse. Changes in the environment make aoi harder. Boards can be different and cause trouble. You need to fix these problems early to help aoi work better.

Experts say you should do these things for better aoi:

Use AI-powered aoi to find more defects, up to 30% better.

Try machine learning in aoi so it learns new defect types.

Use digital supply chain tools to get aoi data fast and lower defects by 15-20%.

S&M’s Nitrogen reflow oven helps you get good aoi results. Check your aoi process often to keep it working well. Follow smart steps to make aoi more reliable and get better checks.

PREGUNTAS FRECUENTES

What is the most common cause of AOI false positives?

False positives happen a lot because of bad lighting or wrong calibration. These problems make the system say good boards are bad. If you check calibration often and set up lighting well, you can lower these mistakes.

How does S&M’s Nitrogen reflow oven improve AOI inspection results?

S&M’s Nitrogen reflow oven helps make solder joints more even. The oven keeps the temperature steady and stops oxidation. This means you get fewer soldering problems and AOI finds defects better.

How often should you calibrate your AOI system?

You need to calibrate your AOI system every 3 to 6 months. You should also do it after 10,000 checks. Doing this often keeps your system working well and makes it more reliable.

What steps help you minimize operator errors in AOI inspection?

Train your team many times. Use hands-on classes, online lessons, and certification programs. When operators learn well, they find defects better and keep inspections running smoothly.