Perfiles de temperatura de hornos de reflujo y soluciones para defectos de soldadura

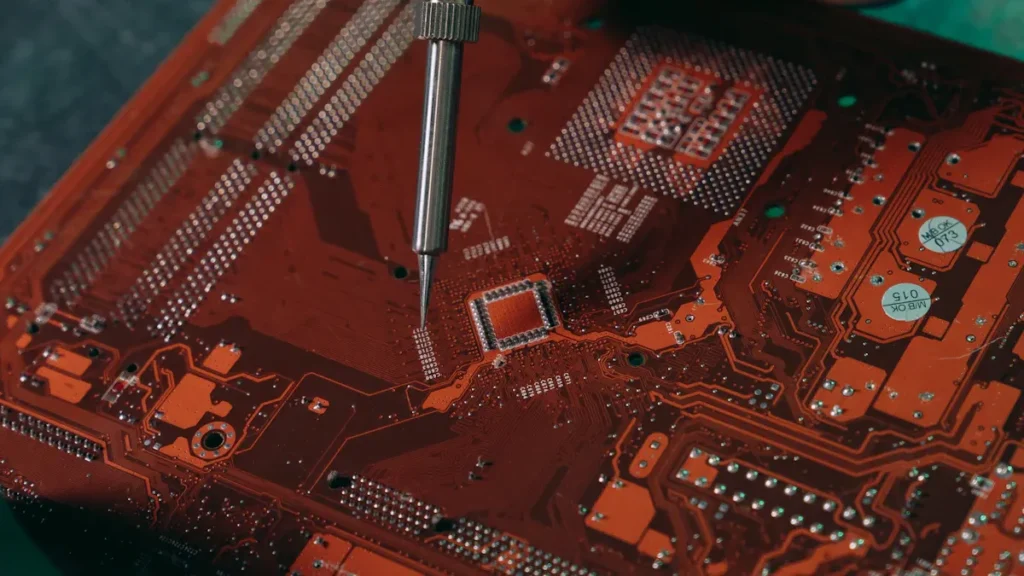

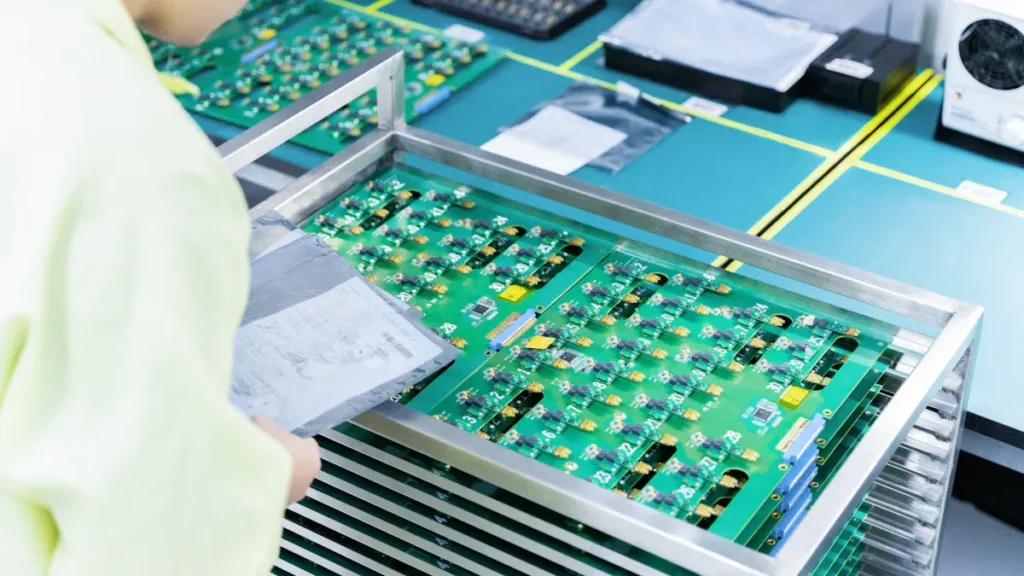

El perfilado de la temperatura del horno de reflujo evita los defectos de soldadura, mejora la fiabilidad de las placas de circuito impreso y garantiza una calidad óptima de las juntas de soldadura.