You get help from SMT automation systems. They help you control heat and improve solder quality. When you use exact temperature checks, you lower mistakes in your electronics. Automation helps you follow good rules. This makes solder joints stronger and cuts down on errors.

- Thermal profiling enhances the reflow soldering process for better solder quality.

- You get more reliable solder joints.

- You see fewer mistakes in production.

| Evidence Type | Details |

| ————————- | ———————————————————————————————————————————————————- |

| Defect Rate Improvement | Advanced thermal profiling causes an 85% drop in defect rates. |

| First-pass Yield Increase | First-pass yield can go up to 98% with good thermal profiling. |

| Solder Joint Quality | Stronger solder joints occur with exact temperature control, ensuring superior solder quality. |

S&M provides you with new SMT solutions. These help you achieve high goals in production.

Principales conclusiones

- SMT automation systems help make solder joints stronger by controlling heat well.

- Utilizando exact temperature checks lowers mistakes in making things. This makes customers happier and causes fewer errors.

- Keeping SMT machines clean and checking them often helps them work the same way every time. This stops problems with soldering.

- Automation lets people watch and change heat levels as things are made. This makes solder joints more reliable.

- S&M’s smart tools and help make your SMT process better. They help you reach big production goals.

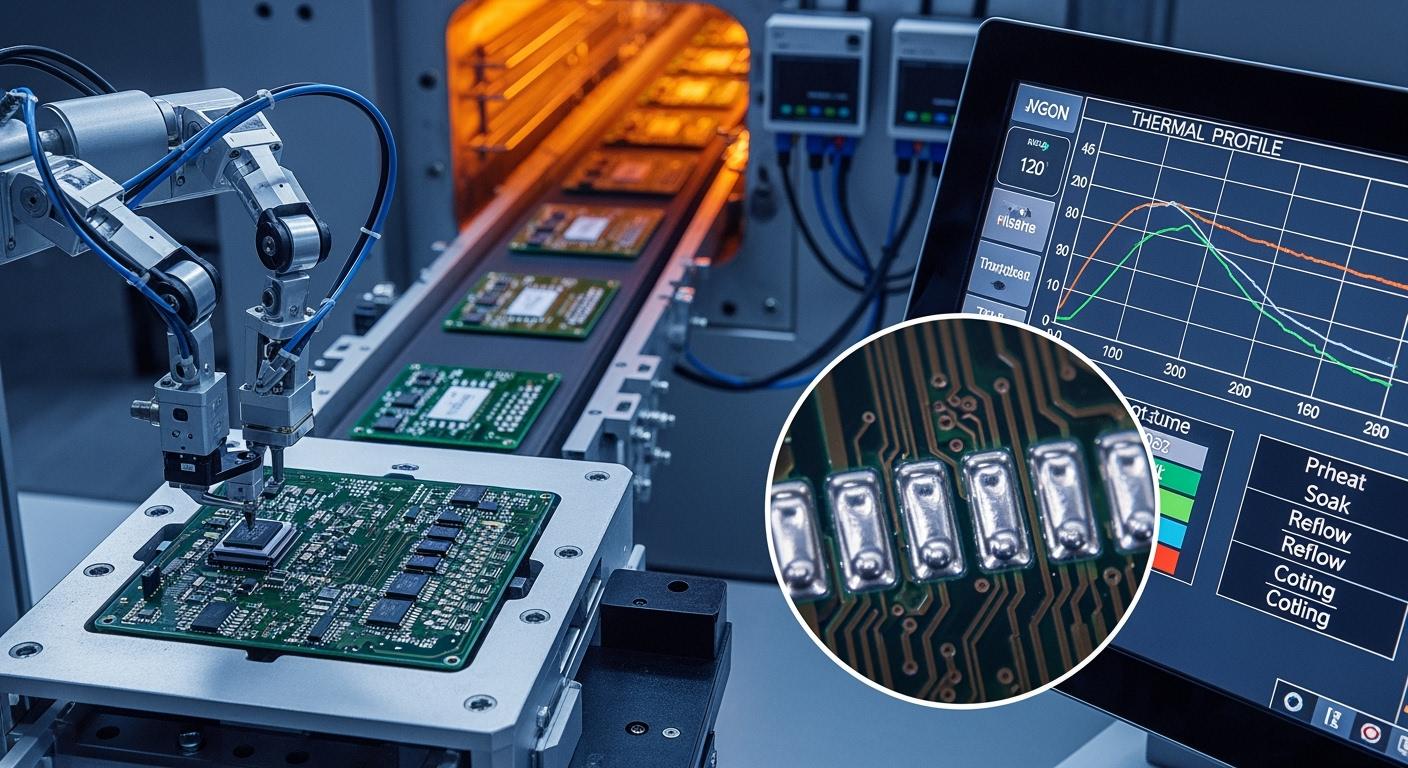

Thermal Profile Control in SMT Automation

Fuente de la imagen: unsplash

Understanding Temperature Profiling

It is important to know about perfil de temperatura in SMT soldering. Temperature profiling means you check and control the heat on circuit boards during soldering. This helps stop problems like weak solder joints or broken parts.

There are four main steps in temperature profiling for reflow soldering:

- Preheat (ramp): You slowly make the board warmer, about 0.5–2.0°C each second. This keeps your parts safe from sudden heat.

- Soak: You hold the board at one temperature. This lets the flux work and spreads heat everywhere.

- Reflow (peak): You heat the board to the highest point, 15–25°C above the solder’s melting point. You keep it there for 30–90 seconds to make strong solder joints.

- Cooling: You cool the board down at about 4°C each second. This step makes the solder joints strong.

You need to use careful temperature profiling so each step happens at the right time and heat. If you skip this, you might get solder bridging, tombstoning, or weak joints. You can also have trouble if you place parts wrong or read thermal profiling data incorrectly. Even small changes in room temperature or airflow can change your results.

Role of Automation in Thermal Management

Automation helps you control thermal profiles very well. Automated SMT systems use special machines to watch and change temperature profiles as you work. This keeps your soldering good and lowers mistakes.

Here is a table showing common temperature profiling tools in SMT automation:

| Equipment Type | Features |

| ———————————————————————————– | ——————————————————————————– |

| SMT Horno de reflujo | 10 zone profiling, even heat, software checks forced air/nitrogen convection. |

| External Thermocouple Control (ETC) | Gives exact temperature readings, stops overheating, keeps heating steady. |

| Small and Benchtop Reflow Ovens | Good for fixing circuits, making delicate parts, and research. |

| Datapaq Reflow Tracker System | Watches and records temperature profiles, keeps soldering conditions just right. |

Automated SMT systems use real-time monitoring and automatic testing. These tools help you find and fix problems early. You can use Lean Six Sigma ideas to cut waste and make quality better. S&M’s selective wave soldering machines use smart monitoring to check temperature and solder flow. You get updates and alerts if temperatures go outside safe ranges. The system saves temperature data at every step. This helps you keep your process steady and repeatable.

Tip: Use careful temperature profiling with automated systems to stop soldering problems and keep your production line working well.

S&M’s Solutions for Precise Thermal Profiles

S&M gives you smart solutions for controlling heat in SMT production. You can use their reflow ovens, nitrogen or air wave soldering machines, and vertical curing ovens to control temperature profiles exactly. These products fit into your SMT lines easily.

Here is how S&M’s products help you control thermal profiles:

| Product Type | Role in Integration |

| ————————————– | ———————————————————————– |

| Reflow Oven | Needed for soldering in SMT production lines. |

| Nitrogen / Air Wave Solder | Makes soldering better and faster. |

| PCB Link Conveyor | Moves PCBs through the line, keeping work smooth. |

| Vertical Curing Oven | Dries materials used in SMT, works well with other machines. |

| Flip Chip Bonder | Helps with advanced assembly, important for modern SMT lines. |

| Cooling Type Temporary Storage Machine | Handles temperature-sensitive parts, keeps them safe during production. |

S&M’s solutions let you connect, automate, and improve your workflow. You get careful temperature profiling and strong solder joints. You can trust S&M to help you reach high standards in soldering and production.

Impact on Solder Quality and Reliability

Fuente de la imagen: pexels

Solder Joint Quality Improvement

You want your SMT products to have strong solder joints. Good solder joints depend on how well you control heat. When you set the reflow thermal profile just right, each joint gets enough heat. This helps the solder melt and stick parts together well.

Automated SMT systems make a big difference. These systems keep the temperature even across the board. You do not get cold spots or too much heat. Every solder joint gets the same amount of heat. This means better solder quality and fewer weak spots.

S&M’s SMT equipment checks the reflow thermal profile all the time. You get alerts if the temperature changes. This lets you fix problems before they hurt soldering quality. S&M’s customers say their solder joints are stronger and their products last longer.

Defect Reduction with Automated Systems

You can lower defects by using automated systems in your SMT line. These systems watch for problems and control the process. They catch issues early. You avoid mistakes like solder bridging and tombstoning. Automated optical inspection (AOI) checks every board for these problems:

- Solder bridging happens when solder joins two pads by mistake. AOI looks at the space between leads and pads to find this.

- Tombstoning happens when one end of a part lifts off the pad during reflow soldering. AOI checks the height and spot of each part to find this.

Automation makes a big change you can see in numbers. Here is a table that shows what happens before and after you use automated SMT soldering:

| Metric | Before Implementation | After Implementation |

| ——————— | ———————————————————————————————– | ———————- |

| Defect Rate | 8% | 2% |

| Customer Satisfaction | Declined | Significantly Improved |

| Year-on-Year Sales | N/A | Increased by 15% |

You get fewer defects and happier customers. S&M’s SMT solutions help you get these results. You can trust their machines to keep defects low and solder joints strong.

Note: Fewer defects mean less waste and more profit for your business.

Consistency and Repeatability in Soldering Quality

You need every batch to be the same. Automated SMT systems help by controlling the reflow thermal profile and keeping the temperature even. You get the same results every time, even with crowded boards.

Here are some ways automation helps you:

- Selective soldering lets you control how long, how hot, and how much solder you use. This makes your products more reliable and gives you more good boards.

- Automation cuts down on human mistakes. You get better work and the same soldering quality every time.

- Robotic arms and vision systems work very carefully. They give you the same results for every solder joint.

Over time, your products last longer. Automated soldering helps you work faster and keeps quality high. You get better accuracy and fewer soldering mistakes. Good quality control means fewer defects. Hand-made products often have more mistakes than automated ones. SMT soldering gives you better reliability because there are fewer mechanical solder joints. This lowers the chance of failure and makes your products stronger against bumps and drops.

S&M’s results show in what their customers say. Many companies see better solder quality, stronger joints, and more even temperatures after using S&M’s SMT solutions. You can count on S&M to help you reach high goals in soldering and making products.

Optimizing Soldering Quality with Automation

Key Parameters for Temperature Profiling

You must watch some important settings to keep your SMT process steady. These settings help you make good reflow profiles and better soldering quality. When you check these things, you make sure each board gets the right heat at the right time. Here are the most important settings:

- Zone power: This tells how much heat each oven part gives.

- Belt speed: This sets how fast boards move in the oven.

- Time offsets: These change how long heating or cooling lasts.

- Temperature offsets: These let you adjust heat at certain points.

If you control these settings, you keep solder joints safe and make solder quality better. The table below shows how changing these things can affect your SMT process:

| Aspect | Impact |

| ———————————————————————————————————————– | ————————————————————————————– |

| Calidad de las soldaduras | Not enough heat makes poor wetting. Too much heat burns flux and hurts solder quality. |

| Component Damage | Too much heat can break parts. Not enough heat makes weak solder joints. |

| Process Windows | Steady heat makes your process work better. |

| Yield Rates | Good control means more working boards and fewer mistakes. |

Maintenance and Calibration Best Practices

You keep your SMT machines working well by doing good cleaning and checking. Clean machines help you stop problems with soldering and heat control. Here are some good habits:

- Use cleaning machines every 5-10 prints to keep stencils clean.

- Clean by hand with special cleaners or alcohol to stop damage.

- Check alignment and pressure every day to keep paste right.

- Make daily, weekly, and monthly cleaning plans to stop breakdowns.

- Control room heat and humidity for better machine work.

- Check the heat profile every week. Checking often helps you find small changes early.

- Calibrate your system often to keep heat steady and lower soldering mistakes.

Tip: Cleaning and checking often help you keep solder joints strong and your SMT process steady.

S&M’s Approach to Process Optimization

S&M gives you tools and help to make your SMT process better. Their systems help you track every board and control your process. For example, S&M’s Unique Identification (UID) system makes work-in-progress checks much faster. You get better tracking with UID numbers, so you can see reports on part numbers and user actions with times.

S&M also helps you with many services. The table below shows what you get:

| Service Type | Description |

| ————————— | —————————————————————— |

| Consulting | Advice to help you work better and compete. |

| Design and Engineering | Custom designs for what you need. |

| Development and Programming | Software for automation. |

| Startup Support | Help when you start new systems. |

| Continuous Support | Ongoing help to keep your systems working. |

| Migration and Retrofitting | Upgrades for older machines. |

| Mechanical Design | Engineering for machine parts. |

| Outsourcing Services | Extra help for your automation needs. |

You get more than just machines from S&M. You get a partner who helps you reach high soldering quality and strong solder joints. Their help and process control tools keep your SMT process steady and working well.

When you use SMT automation systems from S&M, you can control heat better. This helps you make stronger solder joints and better solder quality. These systems help you follow rules like J-STD-001 and IPC-A-610G. You will see fewer mistakes and your solder joints will be stronger. S&M’s solutions work well and help you make your process better.

| SMT Assembly Step | Description | Performance / Accuracy |

| ———————— | ———————————————- | ————————————— |

| Solder Paste Application | Puts paste on PCB pads very carefully | Very exact, less mistakes |

| Component Placement | Quickly and accurately puts all parts in place | Few errors, very accurate |

| Reflow Soldering | Uses ovens that control heat exactly | Strong solder joints, follows the rules |

- You get steady and reliable soldering every time.

- S&M’s advanced SMT solutions help you reach your production goals.

PREGUNTAS FRECUENTES

What is an SMT line solution?

An smt line solution uses machines to build electronics. These machines put parts on boards, solder them, and check for mistakes. You can make products faster and with better quality. Many factories use smt line solutions to help their work go smoother.

How does temperature monitoring help in SMT soldering?

Temperature monitoring checks the heat during soldering. This helps stop parts from getting too hot or too cold. You get stronger solder joints and fewer problems. Temperature monitoring helps your smt line solution work well.

Why is real-time closed-loop control important for SMT lines?

Real-time closed-loop control changes things right away. It watches your process and fixes heat fast. You get steady heat and strong solder joints. Your products meet high standards every time.

How do you keep solder joint integrity in SMT production?

You keep solder joints strong by using a good smt line solution. You set the right heat and check each joint. Machines place parts and solder them carefully. You get boards that work well and last longer.

What maintenance does an SMT line solution require?

You need to clean your smt line solution often. Check machines for damage and fix them. Change old parts and update the software. Follow a schedule to keep your smt line solution working well.

Consejo: You get better results when you follow a maintenance plan for your smt line solution.