Optimizing Reflow Oven Performance in SMT Manufacturing

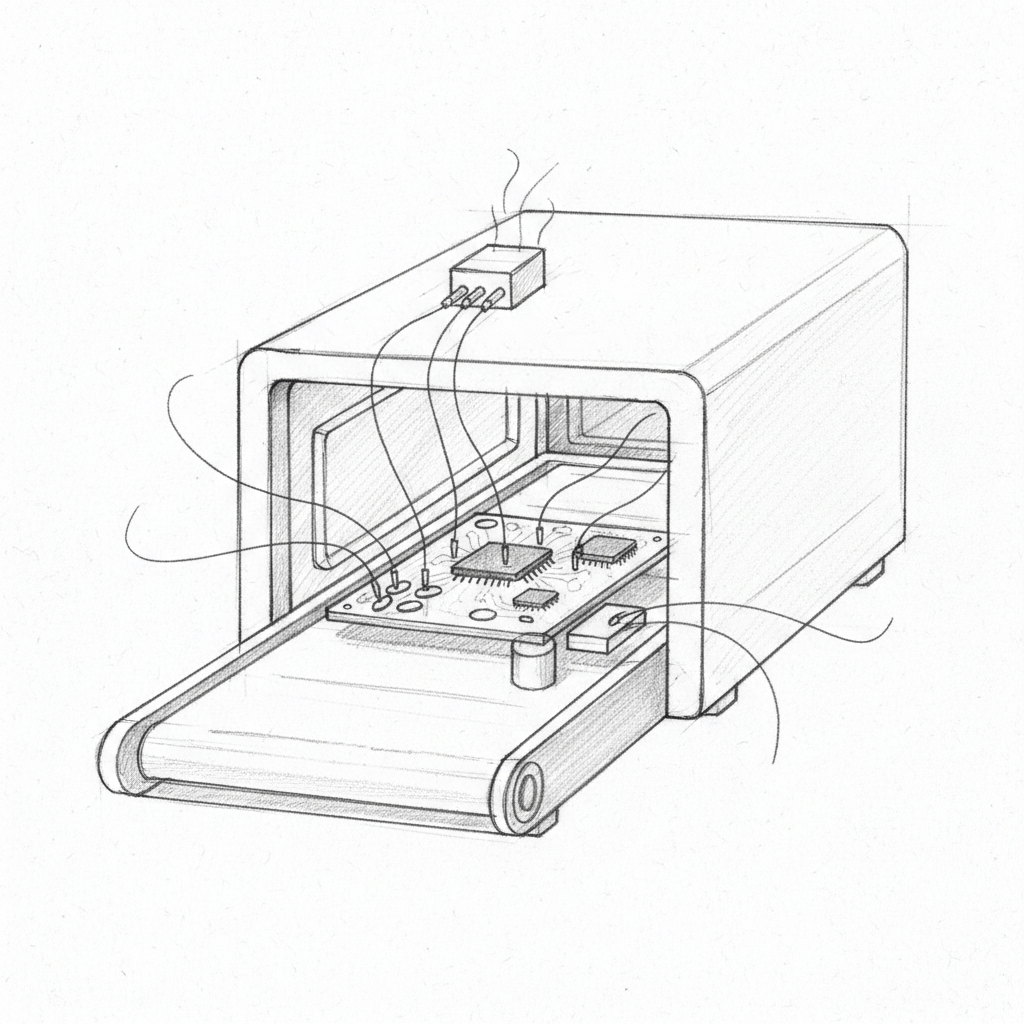

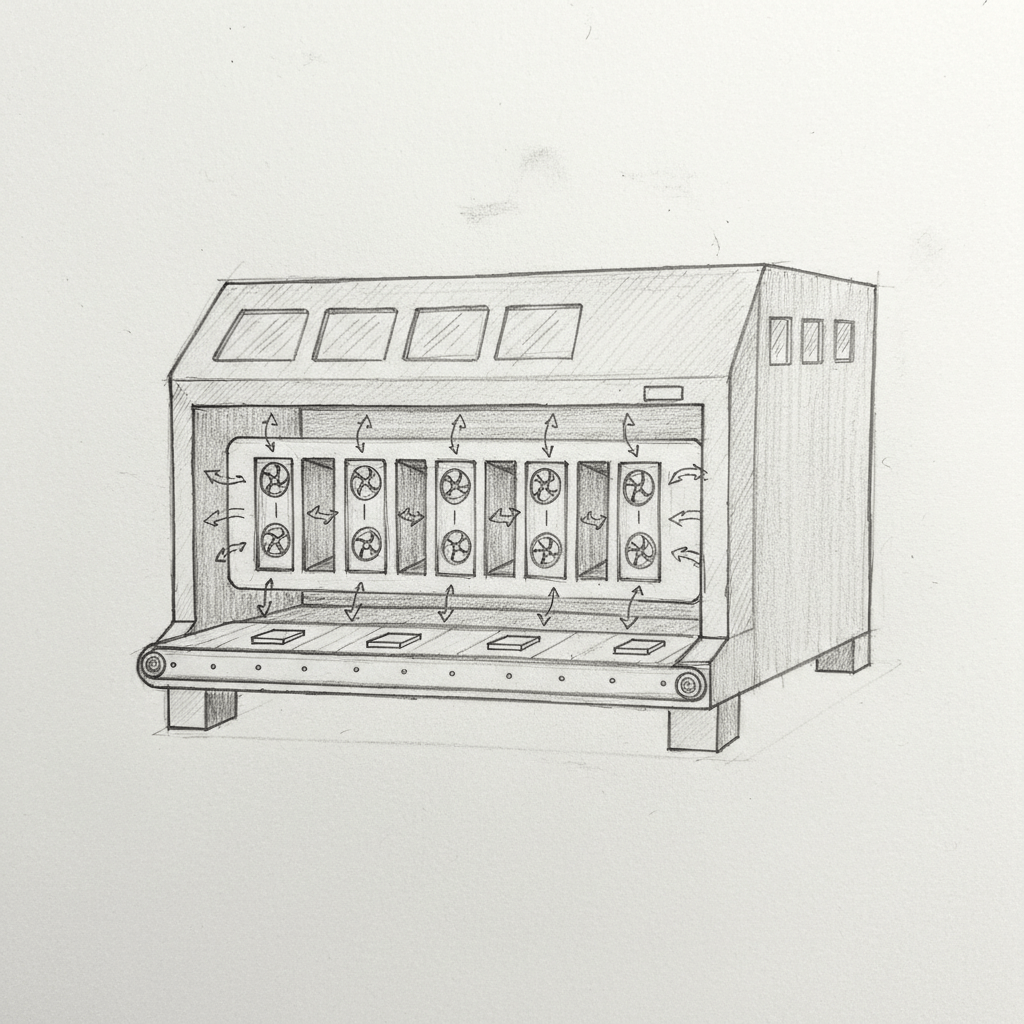

In the realm of Surface Mount Technology (SMT) manufacturing, reflow ovens play a pivotal role by facilitating the soldering process for electronic components. These ovens are integral to the assembly line, providing the necessary heat to melt solder paste and establish reliable electrical connections between components and printed circuit boards [(PCBs)](https://www.pcbonline.com/blog/smt-surface-mount-technology.html). The meticulous control of thermal profiles offered by these ovens is crucial, ensuring the prevention of defects and compliance with stringent lead-free soldering standards.