Table of Content

- Introduction to Reflow Soldering

- Key Concepts and Terminology (Glossary)

- Step-by-Step Reflow Soldering Process

- Types of Reflow Ovens and Equipment

- Common Defects and Troubleshooting (Tombstoning, Voids, etc.)

- Comparative Analysis: Reflow vs. Other Soldering Techniques

- Advancements and Latest Technologies (AI, Automation)

- Environmental and Regulatory Considerations

- Real-World Case Studies and Applications

- Interactive Visuals: Diagrams and Videos

- Summary and Key Takeaways

- References and Additional Resources

Bevezetés

Reflow soldering is the backbone of modern electronics manufacturing, allowing for the efficient and robust assembly of PCBs with intricate components. This comprehensive guide serves as a resource for professionals seeking to master the nuances of reflow soldering, gain insight into troubleshooting and advancements, and explore the environmental and regulatory landscape of the industry.

Reflow soldering is an essential technique in the assembly of printed circuit boards (PCBs), crucial for ensuring effective electrical connections in a wide range of electronic devices. At its core, this process involves applying solder paste—a mixture of powdered metal solder spheres and a specialized flux—onto the PCB’s pads where electronic components are to be mounted. Once the components are placed on the PCB, the assembly undergoes thermal treatment in a reflow oven. For a deeper understanding of the SMT process and technology, including the critical role of chillers in temperature control, you can explore the SMT Reflow Oven Process guide or learn about the critical role of chillers in reflow oven temperature control.

During this heating phase, the reflow oven gradually raises the temperature, melting the solder paste. This transition from a solid to a liquid phase allows the solder to flow and wet the surfaces of the component leads and PCB pads, forming strong, reliable bonds once cooled. These conductive connections are instrumental in the operational integrity of electronic devices, ensuring that signals and power can be both conducted and controlled efficiently across the circuit board.

Reflow soldering offers several benefits over other techniques, particularly in terms of consistency and scalability. It is well-suited for the mass production of PCBs, providing uniform solder joints that are less susceptible to human error compared to manual soldering methods.

The process begins with the design and preparation of the PCB, ensuring alignment with the components and suitability for the reflow method. Once the solder paste is applied using a stencil, components are positioned. The assembly is then exposed to a carefully controlled heat profile within the reflow oven. This profile includes preheating, soaking, reflow, and cooling phases, each critical for minimizing thermal shock and ensuring optimum solder flow.

Despite its advantages, reflow soldering is not without challenges. Issues like tombstoning, where components lift on one end, or voids, which are gaps in the solder joint, can occur if parameters are not finely tuned. However, advancements in reflow technology have led to the integration of AI and automation, enhancing process precision and defect detection.

This article will delve deeper into these aspects, exploring troubleshooting techniques and highlighting innovations that are shaping the future of reflow soldering in electronics manufacturing. Readers will gain a comprehensive understanding of this pivotal process, bolstered by diagrams, case studies, and comparisons with other soldering methods.

Key Concepts and Terminology (Glossary)

Understanding the nuances of reflow soldering is essential for anyone working in electronics manufacturing. This glossary provides a comprehensive look at some of the key terms and concepts integral to mastering reflow soldering processes, making it easier to troubleshoot and optimize workflows.

- Reflow forrasztás: A process used to attach electrical components to their respective contact points on a printed circuit board (PCB) by heating the board to a temperature that melts the solder, creating a strong bond once cooled. For more on the reflow oven process, see our guide.

- Tombstoning: A defect occurring when components partially lift off the PCB during the soldering process, resembling a tombstone. This is usually due to uneven heating or incorrect solder paste application. Explore common defects and troubleshooting strategies.

- Ürességek: Air pockets trapped in the solder joints, which can weaken the bond and affect the thermal and electrical conductivity. Voids are often caused by improper solder paste composition or insufficient pre-soldering cleaning. Wave soldering techniques can also affect solder void formation.

- Solder Paste: A mixture of solder alloy and flux applied to the PCB to join components during reflow soldering. The paste must be carefully applied and controlled in consistency to ensure reliability.

- Reflow kemence: Equipment used to heat the solder paste to the necessary reflow temperature. Reflow ovens come in various types such as convection, vapor phase, and infrared, each with unique benefits.

- Flux: A chemical cleaning agent crucial to improving the wetting ability of the solder by removing oxides from the surfaces to be soldered.

- Profile: This refers to the temperature timeline the PCB follows through the reflow oven. A well-designed thermal profile ensures optimal heating and cooling stages to prevent defects like tombstoning and solder balling.

- Thermal Management: The practice of controlling the heat distribution on the PCB to achieve uniform soldering and to avoid damages to sensitive components.

- Pad Lift: A defect where the pad (the copper attachment point on the PCB) delaminates from the board due to excessive heat or poor-quality board fabrication.

- Surface Mount Technology (SMT): A method for producing electronic circuits where the components are mounted directly onto the surface of PCBs, often used in automation and efficient manufacturing processes.

This glossary serves as a foundation for understanding the complex elements involved in reflow soldering, supporting the step-by-step exploration of the process and troubleshooting potential issues efficiently.

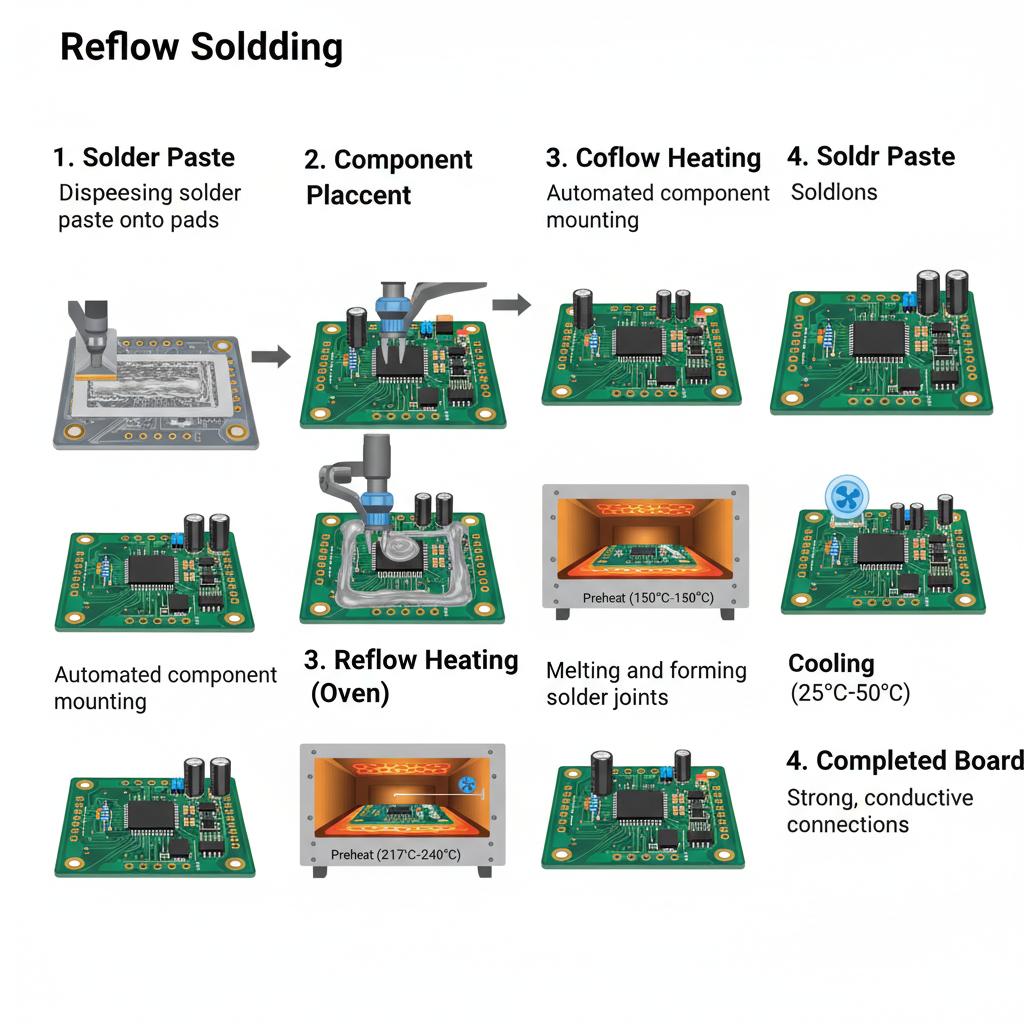

Step-by-Step Reflow Soldering Process

Reflow soldering is a vital process in the assembly of printed circuit boards (PCBs), which ensures the reliable joining of components. Understanding each phase of this multi-step process is crucial for engineers and technicians striving for optimal quality in electronics manufacturing. Below, we dive into the step-by-step breakdown of the reflow soldering process, detailing each critical phase.

1. Preheating Phase

The preheating phase is the initial stage in reflow soldering, where PCBs are gradually heated to a specific temperature. This controlled heating begins at room temperature, aiming to eliminate thermal shocks and to evenly distribute heat across the board. This phase primarily serves to activate the flux, which cleans oxidized surfaces on components and pads, ensuring a proper solder joint. Engineers must monitor heating rates and thermal profiles to prevent component damage and ensure uniform heat distribution.

- Gradual temperature ramp-up to prevent thermal stress.

- Uniform temperature distribution across the PCB.

- Monitoring flux activation for optimal cleaning.

2. Soaking Phase

Following preheating, the soaking phase involves maintaining a steady, elevated temperature to further stabilize the components and the PCB. This phase facilitates extended flux activity and helps equalize the temperature throughout the board, reducing issues like tombstoning. For more on preventing solder bridging, you can refer to our Comprehensive Guide To Preventing Solder Bridging In Wave Soldering.

- Steady temperature maintenance.

- Optimal duration to ensure complete flux activity.

- Prevention of component leap or tombstoning.

3. Reflow Phase

The reflow phase, also known as the peak phase, is the most critical in the soldering process. During this stage, the PCB reaches its highest temperature, causing the solder paste to melt and form reliable joints between the component leads and PCB pads. Effective reflow ensures strong and electrically sound connections. Insights into how temperature control aids this can be found in our article on The Critical Role of Chillers in Reflow Oven Temperature Control.

- Achieving and maintaining peak temperature without overheating components.

- Uniform melting of solder paste.

- Preventing solder bridging and other defects.

4. Cooling Phase

The cooling phase concludes the reflow process, where the temperature is gradually reduced to solidify the solder joints. Rapid or uneven cooling can lead to defects such as cracking or voids. Controlled cooling preserves the metallurgical integrity of the solder joint, ensuring durability.

- Controlled cooling rate to avoid thermal shock.

- Ensuring solidification without stressing the solder joints.

- Prevention of defects like cracks and voids.

Következtetés

A meticulous approach to each phase in reflow soldering is essential for achieving quality results. From carefully ramping up temperatures in preheating to ensuring gentle cooling, each step is designed to mitigate potential defects and enhance the reliability of the finished product. Engineers must continuously monitor and control variables across these phases to maintain a high standard of manufacturing quality.

This guide complements real-world case studies and the comparative analysis of other soldering techniques, providing a comprehensive understanding of reflow soldering—an invaluable asset in modern electronics manufacturing.

Types of Reflow Ovens and Equipment

Reflow soldering is a critical process in the assembly of electronic components onto printed circuit boards (PCBs). The choice of reflow ovens and equipment plays a crucial role in the efficiency and effectiveness of this process. There are several types of reflow ovens used in the industry, each with specific benefits and limitations. This section explores these oven types, providing insight into selecting the appropriate equipment for varying applications.

Konvekciós sütők

Convection ovens are the most commonly used type of reflow oven in the industry. They work by circulating hot air to heat PCBs evenly, which ensures consistent soldering results across the board. For more on how convection ovens integrate with other SMT machines, you can refer to our Végső útmutató: SMT gépek és szállítószalagok.

- Uniform Heating: Convection ovens provide uniform heat distribution, which is essential for achieving consistent solder melts.

- Versatility: They are capable of processing a wide range of PCB sizes and types, making them suitable for various industries.

- Energy Efficiency: Modern convection ovens are designed to be energy-efficient, reducing operational costs.

Limitations:

- Slow Heating Rates: While effective, they typically have slower heating rates compared to other types, which could impact throughput.

- Large Footprint: These ovens can take up significant space, which might be a constraint for limited-space facilities.

Infrared Ovens

Infrared ovens utilize infrared radiation to heat the solder paste directly on the PCB. This method is faster than convection heating and can be more energy-efficient.

- Rapid Heating: Infrared ovens provide faster heating rates, which can lead to increased throughput.

- Energy Efficiency: Direct heating of solder reduces energy waste, potentially lowering costs.

- Space Efficiency: Typically smaller in footprint compared to convection ovens, ideal for facilities with space limitations.

Limitations:

- Non-Uniform Heating: Infrared heating might lead to uneven temperature distribution, potentially causing solder defects.

- Component Damage Risk: Higher frequencies of infrared radiation can damage sensitive components.

Gőzfázisú kemencék

Vapor phase ovens, also known as condensation soldering ovens, use a heated liquid vapor to transfer heat to the PCB. This method provides a very uniform heat distribution and precise temperature control. For a deeper understanding, explore our article on The Critical Role of Chillers in Reflow Oven Temperature Control.

- Uniform Heating: Offers excellent temperature uniformity across the board.

- Controlled Heating: High precision in heat application makes them suitable for complex and high-density assemblies.

- Minimal Oxidation: The vapor phase process reduces the risk of oxidation which can improve solder joint reliability.

Limitations:

- Cost: Vapor phase ovens are generally more expensive than other types, which could be a deterrent for smaller operations.

- Environmental Concerns: The use of specialized fluids raises environmental and safety concerns that must be monitored.

Choosing the Right Equipment

Selecting the appropriate reflow oven depends on the specific needs of the application, including PCB size, production volume, budget constraints, and environmental factors.

- Production Volume: High-volume operations might benefit from convection ovens due to their versatility, while smaller or prototype projects might opt for vapor phase ovens for precision.

- Budget: Infrared ovens might be more cost-effective for operations where rapid heating is prioritized without the need for high precision.

- Space and Environmental Considerations: Facilities with limited space may prefer infrared ovens and need to evaluate vapor phase ovens for environmental compliance.

In conclusion, understanding the benefits and limitations of each oven type is essential for optimizing the reflow soldering process. Integration of simplified diagrams and videos can aid in visualizing these complex processes effectively. Understanding glossary terms and considering case studies and advancements in technology will further enhance decision-making in selecting reflow equipment. The right choice can lead to improved product quality, efficiency, and compliance with environmental and regulatory standards.

Common Defects and Troubleshooting (Tombstoning, Voids, etc.)

Reflow soldering, a critical process in electronics manufacturing, frequently encounters defects that can affect the quality and functionality of the final product. Understanding these defects and employing effective troubleshooting methods is crucial for producing reliable solder joints.

1. Tombstoning

Meghatározás: Tombstoning, named for the way a component stands on its end resembling a tombstone, occurs when one end of a surface-mount component lifts off the solder pad during soldering.

Causes:

- Uneven heating of the solder pads.

- Imbalance in solder paste volume between the two ends of a component.

- Eltérés during placement.

Troubleshooting:

- Assess the thermal profile: Ensure uniform heating across the solder pads. Adjust the oven settings for consistent temperature ramp-up.

- Optimize solder paste deposition: Use precise stencil designs to ensure equal distribution of solder paste for each component terminal.

- Correct placement alignment: Through automated visual inspection, ensure precise alignment during component placement.

2. Voids

Meghatározás: Voids are air bubbles trapped within the solder joint, which can weaken the joint’s mechanical integrity and affect electrical performance.

Causes:

- Entrapped gases due to quick heating.

- Excessive flux residues causing cavities.

- Uneven solder paste syringes usage.

Troubleshooting:

- Control the reflow profile: Adapt heat-up and cooling segments to prevent gas entrapment.

- Improve flux management: Ensure the use of high-quality flux with appropriate activation temperatures.

- Utilize consistent paste application: Employ automated dispensing techniques for uniform paste application.

3. Bridging

Meghatározás: Bridging occurs when excess solder creates an unintended electrical connection between components or pads.

Causes:

- Excessive solder paste application.

- Solder mask misalignment.

Troubleshooting:

- Review stencil design: Adjust aperture sizes to control the amount of paste dispensed.

- Use precise component alignment: Automated machinery can help ensure accurate placement, reducing the likelihood of bridging.

For more insights on preventing solder bridging, explore our Comprehensive Guide To Preventing Solder Bridging In Wave Soldering.

4. Insufficient Solder Wetting

Meghatározás: Poor wetting results in the solder not spreading properly over the pad or component terminal.

Causes:

- Contaminated surfaces: Oxidation or impurities on pads/component leads.

- Suboptimal solder paste properties.

Troubleshooting:

- Implement thorough cleaning: Ensure pads and terminals are free from contaminants prior to soldering.

- Select suitable solder paste: Choose paste with appropriate properties for the specific components used.

Practical Advice and Solutions

- Use visual aids: Employ diagrams and videos for team training to visually depict common defects and their solutions.

- Real-world case analysis: Study past production logs to identify recurring issues and successful mitigation practices.

Enhancing Solder Joint Quality

To enhance solder joint quality, it is critical to integrate advancements in process control technologies such as AI-enhanced ovens that predict and adjust for potential defects before they occur. The use of IoT-connected sensors can also provide real-time feedback for adjustments during the soldering process.

Következtetés

Understanding and addressing common defects in reflow soldering is vital for optimizing the soldering process and ensuring the reliability of electronic products. By applying comprehensive troubleshooting techniques, manufacturers can significantly improve the quality of their solder joints, guarding against mechanical and electrical failures that compromise product integrity.

With the integration of simplified diagrams and interactive tools, these concepts can be effectively taught within manufacturing environments to ensure a practical approach to skill development and enhancement.

Glossary

- Thermal Profile: Refers to the controlled temperature progression in a reflow oven.

- Flux: A chemical used to remove oxidation and improve the flow of solder.

The solutions outlined, while focusing on tombstoning, voids, bridging, and wetting, also provide a strategic framework applicable to other soldering defects, ensuring this section remains comprehensive and practically useful.

Comparative Analysis: Reflow vs. Other Soldering Techniques

Reflow soldering is one of several techniques employed in PCB assembly, alongside wave soldering and hand soldering. Each of these methods has distinct characteristics that affect quality, efficiency, and cost-effectiveness.

Reflow forrasztás

Reflow soldering is primarily used for Surface Mount Technology (SMT) and involves the application of solder paste to a PCB before heating the entire board in a reflow oven. This controlled process ensures that solder melts and flows to create a reliable connection between components and the circuit board (Comprehensive Guide To The SMT Reflow Oven Process).

Előnyök:

- Consistency: Provides high-quality, consistent results due to the precise control of temperature profiles.

- Automation: High degree of automation, reducing the need for manual labor and human error.

- Scalability: Ideal for high-volume production, as reflow ovens can handle multiple boards simultaneously.

Hátrányok:

- Initial Cost: The equipment required for reflow soldering is expensive, which can be prohibitive for small-scale operations.

- Complexity: Requires precise setup and maintenance, increasing operational complexity.

Hullámforrasztás

Wave soldering is a method traditionally used for through-hole components, where boards pass over a wave of molten solder. This technique is recognized for its effectiveness in handling double-sided PCBs with through-hole components (Wave Soldering Comprehensive Guide: Principles, Process, & Optimization).

Előnyök:

- Efficiency in Through-Hole Production: Efficient for mass production of through-hole PCBs, saving time on manual soldering tasks.

- Speed: Faster as compared to hand soldering for through-hole components when set up properly.

Hátrányok:

- Limited SMT Application: Not ideal for SMT components, limiting its use in modern PCB designs.

- Defect Rates: Higher risk of defects such as shorts or bridges if not controlled properly.

Kézi forrasztás

Hand soldering involves the manual application of heat and solder using a soldering iron to join components on a PCB. While considered a traditional technique, it remains relevant for prototypes and small batch productions.

Előnyök:

- Flexibility: Allows for the soldering of individual and small batch components, suitable for repairs and small-scale productions.

- Accessibility: Requires minimal setup and is cost-effective for low-volume production.

Hátrányok:

- Time-Consuming: Labor-intensive and slower than automated techniques, making it impractical for high-volume manufacturing.

- Inconsistency: Quality highly depends on the skill of the operator, leading to potential inconsistency.

Következtetés

Each soldering technique carries its unique advantages and disadvantages. Reflow soldering stands out in automated, high-volume SMT applications but comes with high initial costs and complexity. Wave soldering is excellent for mass-producing through-hole designs but isn’t well-suited for SMT components. Hand soldering provides flexibility and cost benefits for low-volume and prototype applications, albeit with slower production speeds and potential quality variability. Selecting the appropriate soldering method hinges on the specific needs of your production process, available resources, and design requirements.

Megjegyzés: Simplified diagrams and tutorial videos can greatly enhance understanding, while a glossary of terms will assist readers in grasping key concepts effectively. The inclusion of case studies can further elucidate the practical applications of each soldering technique.

Advancements and Latest Technologies (AI, Automation)

The field of reflow soldering has seen significant advancements in recent years, with the integration of artificial intelligence (AI) and automation leading the charge toward enhanced precision and efficiency. These technologies have revolutionized traditional practices by streamlining operations, reducing human error, and allowing for real-time monitoring of the soldering process.

AI-driven systems in reflow soldering ovens are equipped with algorithms capable of analyzing historical data to optimize temperature profiles and reflow times for different types of solder pastes and electronic components. This capability ensures that even the slightest variations in products or materials are accounted for, minimizing defects such as voids and tombstoning. AI assists in maintaining consistent quality, detecting anomalies during the reflow process, and making real-time adjustments to parameters such as conveyor speed and peak temperature, ultimately improving yield rates.

Automation enhances the reflow soldering process by reducing the dependency on manual interventions and increasing throughput. Automated reflow ovens can handle large volumes with precision, ensuring every board receives the same level of attention to detail. For more details on how SMT conveyors contribute to this automation, check out our Átfogó útmutató az SMT szállítószalagokhoz a Fancorttól. Machine learning algorithms continuously refine processes, leading to constant improvements in efficiency.

Moreover, the integration of AI and automation into reflow soldering is now a common practice in the electronics manufacturing industry. These technologies are being adopted by leading companies seeking to maintain competitiveness through quality and speed. AI-powered visual inspection systems, for example, use high-resolution cameras and machine learning to inspect solder joints instantly, identifying defects more accurately than manual inspections.

The shift towards smart manufacturing is also evident as factories adopt Industry 4.0 technologies, connecting reflow soldering ovens with other equipment in a seamless digital ecosystem. This connectivity supports predictive maintenance, reducing downtime and extending equipment lifespan by predicting failures before they occur. For companies interested in automation solutions, check out n8n’s capabilities.

While these technologies make the reflow soldering process more efficient and reliable, they also align with environmental and regulatory considerations by reducing material wastage and optimizing energy consumption. This not only contributes to sustainability but also ensures compliance with stringent regulations governing the electronics manufacturing industry.

Következtetés

In conclusion, the adoption of AI and automation in reflow soldering represents a significant step forward in meeting the demands of modern electronics manufacturing. As the technology continues to evolve, we can expect even more innovative developments that will further refine and enhance the reflow soldering process. These advancements promise to deliver higher precision, faster production times, and a greater ability to meet evolving industry standards.

Environmental and Regulatory Considerations

Reflow soldering is a critical process in the manufacturing of electronic circuit boards, and its environmental and regulatory considerations have become increasingly prominent. The shift towards lead-free soldering is one of the most significant environmental impacts in this field, primarily driven by the Restriction of Hazardous Substances (RoHS) directive and other global standards aimed at minimizing environmental harm.

Environmental Impacts

Historically, lead has been a primary component in soldering due to its advantageous properties such as low melting points and cost-effectiveness. However, the use of lead poses severe environmental threats due to its toxicity, which can lead to soil and water contamination. Thus, the transition to lead-free solder alloys, which typically consist of tin, silver, and copper (SAC), has been crucial in reducing these ecological risks.

Lead-free soldering not only helps mitigate the environmentally hazardous impacts but also supports the recycling and disposal process of electronic waste, as components are easier to recycle when lead content is reduced. references to articles such as “Reflow Oven and Chiller: The Perfect Partnership for Soldering Stability” can provide insight into how reflow ovens adapt to lead-free soldering requirements. Nevertheless, a downside of lead-free soldering is its requirement for higher reflow temperatures, which increases energy consumption and, consequently, the carbon footprint

Regulatory Considerations

Globally, the RoHS directive has been pivotal in enforcing the adoption of lead-free soldering in electronics manufacturing. RoHS compliance ensures that harmful materials like lead, mercury, cadmium, and certain flame retardants are restricted. Non-compliance can result in significant penalties and loss of market access, particularly in the European Union.

Additionally, the Waste Electrical and Electronic Equipment (WEEE) directive overlaps with RoHS, focusing on the recycling and proper disposal of electronic waste. For more on recycling challenges, see “Wave Soldering Comprehensive Guide: Principles, Process, Optimization – S&M”. Other standards, such as California’s Electronic Waste Recycling Act, mirror these international efforts, promoting eco-friendly practices in manufacturing and disposal.

The transition towards environmentally friendly soldering processes not only complies with regulatory demands but also promotes sustainable development goals, signifying a positive stride towards protecting the environment while maintaining industrial growth. These efforts underscore the global responsibility manufacturers have in minimizing environmental impact while adhering to evolving regulatory landscapes.

Real-World Case Studies and Applications

Reflow soldering has become a pivotal technique in the manufacturing of printed circuit boards (PCBs), offering precision and efficiency that is leveraged across various industries. This section presents case studies that demonstrate the successful application of reflow soldering techniques, focusing on challenges faced and solutions implemented, as well as showcasing innovation in industry applications.

Case Study 1: Aerospace Industry Innovation

In the aerospace industry, the demand for high-reliability electronics is paramount. A leading aerospace firm was faced with the challenge of producing lightweight yet robust PCBs that could withstand extreme temperatures and vibrations in flight. The solution was the implementation of advanced reflow ovens capable of precise temperature control to ensure consistent solder joints. By incorporating a nitrogen atmosphere within these ovens, the company minimized oxidation, resulting in improved joint quality and reliability. For further insights into how environmental control can enhance soldering stability, explore how chillers play a critical role in reflow oven temperature control here.

The firm also invested in automation, utilizing AI-driven software to monitor the reflow process and make real-time adjustments, thus significantly reducing human error and enhancing performance. This approach not only met the rigorous standards of the aerospace sector but also set new benchmarks in PCB manufacturing efficiency.

Case Study 2: Consumer Electronics’ Response to Miniaturization

The consumer electronics industry consistently pushes the boundaries of device miniaturization, which poses significant challenges in soldering processes. A major smartphone manufacturer faced obstacles in achieving soldering accuracy for increasingly compact components. To address these challenges, the company adopted reflow soldering with customized profiles tailored to each PCB layout and component specification.

Using cutting-edge reflow ovens equipped with multiple heating zones, the manufacturer was able to conduct detailed thermal profiling and adjust temperature curves specific to the assembly’s demands. This precision ensured optimal reflow without overheating, thus preventing defects such as tombstoning and excessive voids. To learn more about overcoming common defects, including solder bridging, check out this comprehensive guide here.

The integration of machine learning algorithms supported advanced diagnostics and predictive maintenance, significantly reducing downtime and elevating overall production efficiency. As a result, the company not only improved product quality but also enhanced its production timeline.

Case Study 3: Automotive Sector’s Embrace of Reflow Techniques

In the transition towards electric vehicles, the automotive sector is increasingly reliant on sophisticated electronic systems. An electric vehicle manufacturer faced the dual challenge of producing durable PCBs that could handle high electrical loads and expanding production capacity to meet growing demand.

Reflow soldering was pivotal, with the deployment of environmentally-friendly soldering materials meeting stringent regulatory standards. This manufacturer utilized reflow ovens with enhanced cooling and heating gradients, which facilitated precise soldering and minimized stress on components during assembly.

Moreover, the manufacturer’s employment of reflow soldering techniques contributed to the development of more reliable battery management systems and infotainment circuits, which were essential in distinguishing its vehicles in a competitive marketplace.

Következtetés

These case studies illustrate the versatility and essential role of reflow soldering across diverse sectors. As industries continue to innovate and push technological limits, reflow soldering stands out for its adaptability and efficiency, making it indispensable in manufacturing high-quality electronic systems. The demonstrated success stories underscore the profound impact and potential of reflow soldering in shaping the future of electronic manufacturing.

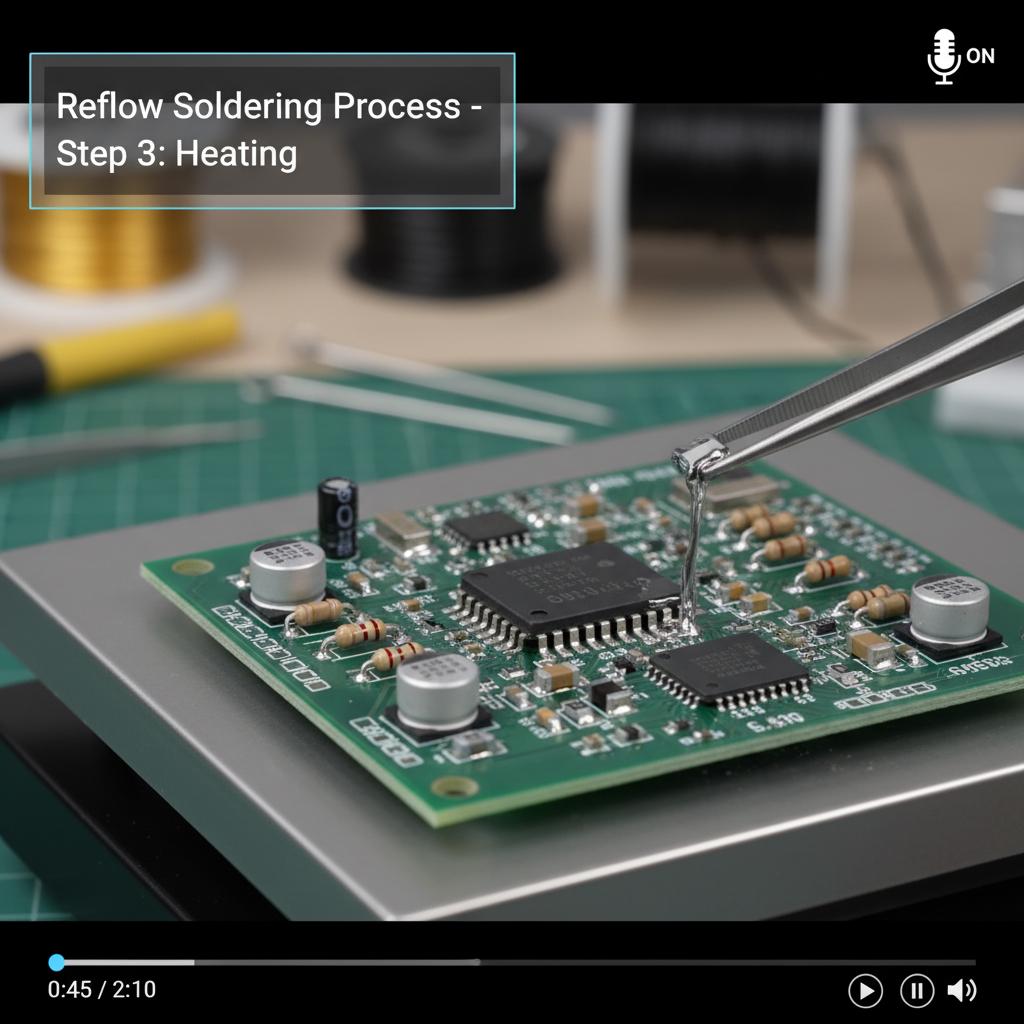

Interactive Visuals: Diagrams and Videos

Interactive visuals and videos play a pivotal role in enhancing the comprehensibility and engagement of technical topics, especially in fields like reflow soldering. These multimedia tools serve as dynamic aids, allowing readers to visualize complex processes and deepen their understanding through demonstration.

Incorporating simplified diagrams is crucial for breaking down intricate steps involved in reflow soldering. Diagrams can visually represent stages such as preheat, soak, and reflow phases, highlighting the critical temperature profiles needed for effective solder joint formation. By providing these visuals alongside a glossary of terms, readers can quickly grasp the terminology and concepts critical to mastering reflow soldering techniques.

Videos add another dimension to learning by offering real-time demonstrations of reflow soldering. They can showcase the procedure step-by-step, including preparation of the PCB, application of solder paste, selection of appropriate profiles for different components, and operation of reflow ovens. This not only allows viewers to see the technology in action but also addresses potential pitfalls, like tombstoning and voids, by showcasing troubleshooting techniques. Furthermore, including captions and descriptive alt text can ensure accessibility, making these resources valuable to all readers, including those with disabilities.

Real-world case studies enhanced by videos can highlight practical applications and demonstrate problem-solving in live scenarios. These cases can illustrate how different setups and adjustments in reflow ovens can overcome common defects, empowering readers with effective solutions.

Incorporation of interactive elements within these visuals can engage readers further, by enabling them to mimic scenarios or anticipate outcomes based on variable changes in the process. Tutorials embedded within the article can offer a hands-on approach to learning. For example, the relationship between reflow ovens and chillers, as discussed in “Reflow Oven and Chiller: The Perfect Partnership for Soldering Stability,” can be explored through interactive diagrams showing temperature control and stability.

Következtetés

In summary, the integration of interactive visuals and videos not only aids in demystifying the reflow soldering process but also enriches the article’s educational value. These elements ensure readers stay engaged and are equipped with practical knowledge and skills to apply in real-world settings, thus reinforcing the comprehensive nature of the guide.

Summary and Key Takeaways

Reflow soldering is a critical process in modern electronics manufacturing, providing a reliable method for creating stable and high-performing circuits. This guide has outlined the essentials of reflow soldering, offering insights into its practical applications across various industries.

Key points from the guide emphasize the versatility of reflow soldering, especially when compared to other techniques. Its ability to create precise connections without manual intervention reduces labor costs and increases production efficiency, as discussed in-depth in the Ultimate Guide: SMT Machines and Conveyors. The step-by-step overview of the reflow soldering process highlights key considerations, including temperature profiles and timing, which are crucial for achieving optimal results.

Understanding common defects like tombstoning and voids is vital, as highlighted in the SMT Process & Surface Mount Technology: The Definitive Guide. Quick-reference checklists provided in the guide help in troubleshooting these issues, ensuring that quality control is maintained throughout production. Additionally, learning about the different types of reflow ovens allows for informed decisions tailored to specific production needs, from small-scale workshops to large manufacturing plants.

The incorporation of advancements and the latest technologies such as AI and automation indicates significant improvements in process control and monitoring. These innovations not only enhance efficiency but also contribute to more sustainable practices by minimizing waste and energy consumption.

Environmental and regulatory considerations are another crucial aspect, ensuring that the reflow soldering process aligns with international standards and reduces the ecological footprint of electronic production.

With real-world case studies and interactive visuals like diagrams and videos, this guide provides a comprehensive yet accessible understanding of reflow soldering. Readers can leverage this knowledge to optimize their processes, anticipate challenges, and implement solutions effectively. The glossary of terms also facilitates a deeper understanding of industry terminology, making complex processes more approachable.

This guide serves as a valuable resource for anyone seeking to maximize the benefits of reflow soldering in their manufacturing processes, ensuring enhanced performance and innovation in electronic assembly.

References and Additional Resources

To expand your understanding of reflow soldering and the technology surrounding it, the following references and resources are invaluable. These resources encompass academic research, industry publications, and technical manuals that provide deep insights into both theoretical and practical aspects of reflow soldering.

References

- Wave Soldering Comprehensive Guide: Principles, Process, & Optimization – This guide covers principles and optimization strategies for soldering, offering context for both wave and reflow soldering.

- Soldering in Electronics Assembly by Makeit Labs – An online publication that covers the basics and advanced techniques of soldering processes in electronics.

- Reflow Soldering Processes by Ning-Cheng Lee – This book provides comprehensive coverage of soldering processes necessary for modern electronic manufacturing.

- Journal of Electronic Manufacturing – Access recent studies and papers on the latest advancements in soldering technologies and methodologies.

- SMT Surface Mount Technology Magazine – A leading publication offering articles on all facets of surface mount technology including reflow soldering.

- IPC Standards – essential for understanding the industry standards in soldering and electronics assembly.

Additional Resources

- A Comprehensive Guide To The SMT Reflow Oven Process – This guide delves into the specifics of the SMT reflow oven process, offering practical insight into real-world applications.

- IPC Training and Certification – Offers courses and certifications that can improve your knowledge and skills in reflow soldering.

- YouTube Channels like EEVblog – Channels that provide video demonstrations and tutorials on soldering techniques and other electronic manufacturing processes.

- Educational Platforms like Coursera or Udemy – Online courses specifically dedicated to electronics and soldering technologies.

- ResearchGate and Google Scholar – These platforms provide access to peer-reviewed papers and research articles in electronics manufacturing.

- Books and Guides from IEEE Xplore – An extensive library of books providing in-depth technical know-how about electronics and soldering.

These resources, combined with interactive diagrams and videos integrated into this guide, should serve as a comprehensive toolkit for mastering reflow soldering and exploring its intricacies in greater depth.

Következtetés

Reflow soldering is championed for its precision in creating high-quality solder joints essential for PCB assembly. This guide provides electronics manufacturing professionals with practical knowledge and insights into optimizing their reflow soldering processes, embracing advanced technologies, and adhering to regulatory standards.