Átfogó útmutató az SMT szállítószalagokhoz a Fancorttól

Tartalomjegyzék

- Bevezetés az SMT szállítószalagokba

- SMT szállítószalagok műszaki specifikációi

- Különböző szállítószalag-modellek összehasonlító elemzése

- Integráció SMEMA és egyéb berendezésekkel

- Valós alkalmazások és előnyök

- Karbantartás és hibaelhárítás

- GYIK szakasz

- Következtetés és cselekvésre való felhívás

Bevezetés

A Fancort fejlett SMT anyagmozgató szállítószalag-termékcsaládjának bemutatásával ez az útmutató a gyártási mérnökök, a gyártósor-felügyelők és a beszerzési szakemberek számára nyújt információkat a gyártósor hatékonyságának növelésére tervezett optimális anyagmozgatási megoldásokról.

A felületi szerelésű technológia (SMT) szállítószalagjai elengedhetetlen alkatrészek a modern elektronikai gyártás területén. Ezek a szállítószalagok kritikus funkciót látnak el: elősegítik a nyomtatott áramköri lapok (PCB-k) hatékony és pontos szállítását a gyártósor különböző szakaszaiban. Azáltal, hogy biztosítják a PCB-k zökkenőmentes mozgatását az egyik feldolgozási ponttól a következőig, az SMT szállítószalagok segítik fenntartani a nagy volumenű gyártási környezetekben szükséges konzisztenciát és sebességet.

Az SMT szállítószalagok bonyolult működésének megértése elengedhetetlen azoknak a gyártóknak, akik optimalizálni szeretnék gyártósoruk működését. Ezek a szállítószalagok kifejezetten úgy lettek kialakítva, hogy óvatosan kezeljék a kényes és összetett alkatrészeket, miközben magas áteresztőképességet biztosítanak. Gyakran állítható sebességgel és sima működéssel rendelkeznek, hogy alkalmazkodjanak a PCB-összeszerelés különböző szakaszaihoz, mint például a forrasztópaszta felvitele, az alkatrészek elhelyezése és a végső ellenőrzés. Az SMT-folyamatokban a szállítószalagok fontosságáról további információkat a Végső útmutató: SMT gépek és szállítószalagok.

A Fancort, az elektronikai gyártóipar elismert szereplője, széles körű SMT anyagmozgatási megoldások nyújtására specializálódott. Szállítószalagjaik úgy lettek kialakítva, hogy megfeleljenek a gyártók változatos igényeinek, biztosítva a gyártósorok megbízhatóságát és rugalmasságát. A Fancort kínálatában számos szállítószalag-modell található, amelyek zökkenőmentesen integrálhatók a meglévő rendszerekbe, növelve a hatékonyságot és a termelékenységet.

Az SMT szállítószalagok egyik kiemelkedő tulajdonsága, hogy integrálhatók a Surface Mount Equipment Manufacturers Association (SMEMA) szabványokkal. Ez a kompatibilitás lehetővé teszi a gyártósoron belüli különböző berendezések közötti egyszerű kommunikációt és koordinációt, tovább növelve a működési hatékonyságot.

Ezenkívül a Fancort szállítószalagjai felhasználóbarát felülettel és testreszabási lehetőségekkel rendelkeznek. Ez az alkalmazkodóképesség biztosítja, hogy a berendezés az adott gyártási követelményekhez igazodjon, függetlenül attól, hogy nagy mennyiségű kis alkatrész vagy speciális méretű NYÁK-lapok kezeléséről van szó.

A versenyképesség megőrzésére törekvő gyártók számára alapvető fontosságú a Fancorthoz hasonló megbízható beszállítók fejlett SMT szállítószalagjainak alkalmazása. Ezek a szállítószalagok nemcsak a gyártási sebességet és pontosságot növelik, hanem kulcsszerepet játszanak a leállások csökkentésében és a működési eltérések minimalizálásában is.

Összefoglalva: a videók és interaktív diagramokhoz hasonló multimédiás elemek integrálásával a gyártók mélyebb betekintést nyerhetnek az SMT szállítószalagok működésébe és azok előnyeibe. Ez a holisztikus megközelítés nemcsak gazdagabbá teszi a tanulási élményt, hanem segít a gyártási munkafolyamatok javítását célzó, megalapozott döntések meghozatalában is.

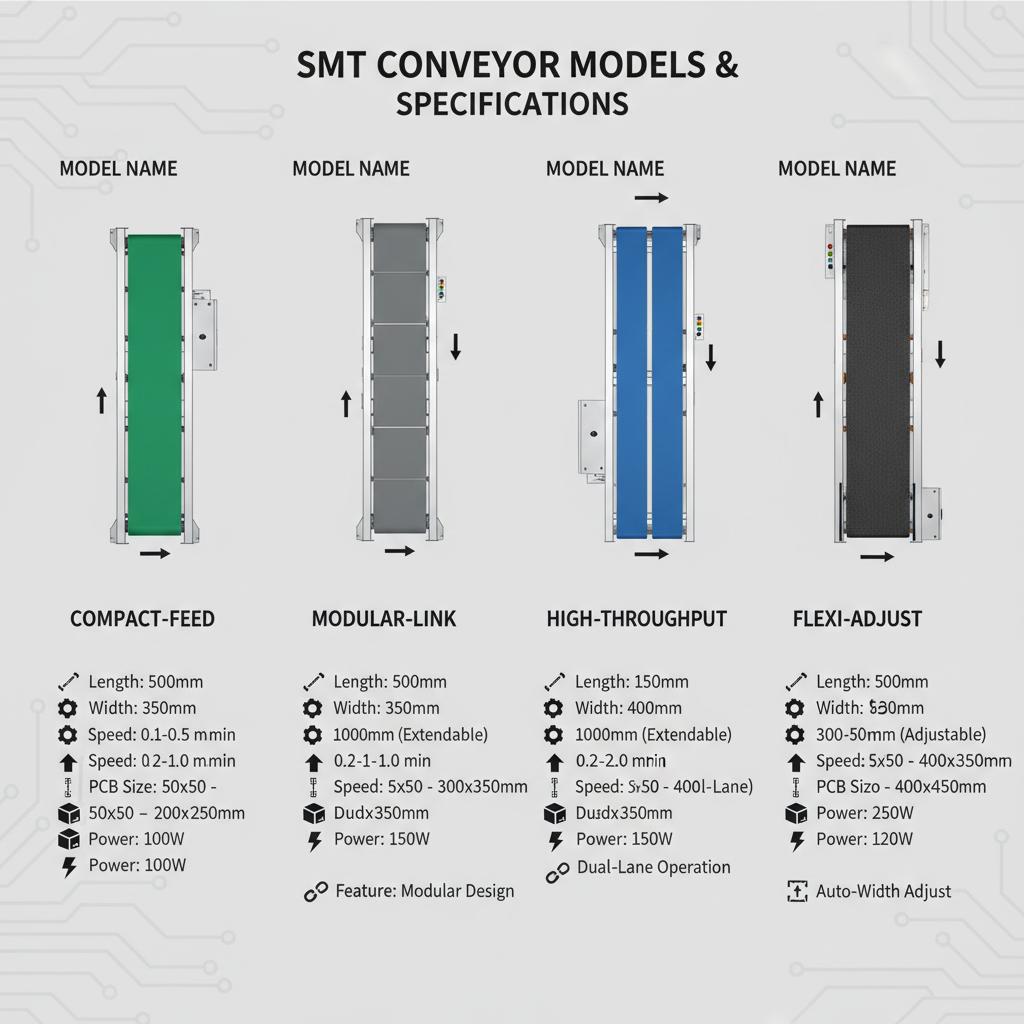

SMT szállítószalagok műszaki specifikációi

A Fancort sokoldalú SMT szállítószalag-választékot kínál, amelyeket különböző működési követelményeknek megfelelően terveztek. Minden modell egyedi műszaki jellemzőkkel rendelkezik, mint például méretek, teherbírás és energiaigény, így a gyártók kiválaszthatják a saját gyártósorukhoz leginkább megfelelő opciót.

- A modell műszaki adatai: Méretek: 1000 x 300 mm, Teherbírás: 50 kg, Teljesítmény: 0,5 kW

- B modell műszaki adatok: Méretek: 1200 x 400 mm, Teherbírás: 70 kg, Teljesítmény: 0,8 kW

Minden modell úgy lett kialakítva, hogy optimalizálja a gyártási környezetben rendelkezésre álló teret és hatékonyságot, miközben biztosítja a megbízhatóságot és a teljesítményt. A mélyebb megértés érdekében fedezze fel a multimédiás elemeket, például videókat és interaktív diagramokat, amelyek vizualizálják az áramelosztást, a működési folyamatot és egyéb műszaki részleteket. Ezek az elemek nemcsak fokozzák az érdeklődést, hanem gyakorlati betekintést nyújtanak abba is, hogy az egyes szállítószalagok hogyan integrálódnak a meglévő gyártási rendszerekbe. Az SMT-gépekről és szállítószalagokról szóló részletesebb útmutatásért tekintse meg Végső útmutató: SMT gépek és szállítószalagok.

SMT szállítószalagok műszaki specifikációi

Az SMT (Surface Mount Technology) szállítószalagok műszaki specifikációi elengedhetetlenek a legjobb megoldások kiválasztásához, amelyek az egyedi gyártási követelményeknek megfelelnek. Ezek az adatok tájékoztatják a potenciális vásárlókat az egyes modellek részletes jellemzőiről, lehetővé téve számukra a megalapozott döntéshozatalt.

Főbb műszaki adatok

- Szállítószalag hossza és szélessége: A szállítószalag hossza és szélessége döntő fontosságú a különböző méretű táblák befogadásához. A Fancort kis méretű NYÁK-okhoz alkalmas kompakt modellektől a nagyobb táblákhoz alkalmas hosszabb változatokig terjedő szállítószalagokat kínál.

- Példa: Az FC-500-L modell hossza 500 mm, szélessége pedig állítható, így különböző méretű táblák hatékony kezelésére alkalmas.

- Sebességszabályozás: A sebesség egy fontos paraméter, amely befolyásolja a teljes gyártási ciklus időtartamát. Minden modell állítható sebességbeállításokkal rendelkezik, amelyek általában 0,5 m/perc és 20 m/perc között mozognak.

- Példa: Az FC-700-S modell zökkenőmentes sebességbeállítást biztosít, amely megfelel a különböző gyártási követelményeknek. Fedezze fel átfogó útmutatónkat az SMT szállítószalag cseréjéről, hogy megértse, hogyan befolyásolja a sebességszabályozás a szalag élettartamát.

- Átviteli magasság: Az átviteli magasság állandósága biztosítja a könnyű integrálhatóságot más gyártósori berendezésekkel. A Fancort szállítószalagok támogatják a szabványos átviteli magasságokat, amelyek általában 950 mm körüliek, de a követelményeknek megfelelően állíthatóak.

- Példa: Az FC-300-H magassága állítható, így zökkenőmentesen illeszkedik más SMT-eszközökhöz. Az SMT-berendezések hatékony integrálásáról további információkat az SMT-gépekről és szállítószalagokról szóló átfogó útmutatónkban talál.

- Szállító típus: Az SMT szállítószalagok kétféle típusban kaphatók: élszalagos és lapos szalagos szállítószalagok, amelyek különböző alkalmazásokhoz alkalmasak.

- Példa: Az FC-250-EB egy olyan élszalag-modell, amelyet úgy terveztek, hogy a táblákkal való érintkezés minimális legyen, így biztosítva a pontos szállítást.

- Terhelhetőség: A teherbírás határozza meg a szállítószalag tartósságát és az általa szállítható termékek típusait. A Fancort modellek különböző súlyosztályokhoz lettek tervezve.

- Példa: Az FC-1000-LC modell akár 10 kg-os terhelést is elbír, így ideális nehezebb táblák vagy panelekhez.

- Tápegység: Gondoskodjon a létesítmény áramellátásával való kompatibilitásról. A standard opciók között szerepelnek a 110–240 V, 50/60 Hz konfigurációk.

- Példa: Az FC-450-PS kettős feszültségbemenetet támogat, hogy megfeleljen a nemzetközi szabványoknak.

- ESD biztonsági funkciók: Az elektrosztatikus kisülés megelőzése érdekében számos Fancort szállítószalag ESD-szalagokkal és földelőpontokkal van felszerelve.

- Példa: Az FC-350-ES tanúsított ESD védelmet biztosít az érzékeny elektronikus alkatrészek védelme érdekében.

Multimédia és interaktív elemek

A közönség teljes figyelmének lekötése érdekében ajánlott multimédiás elemeket beépíteni, például videókat, amelyek bemutatják az egyes modelleket működési környezetben, valamint interaktív diagramokat, amelyek kiemelik az egyes egységek műszaki adatait.

- Videók: Fontolja meg olyan bemutató videók beágyazását, amelyek bemutatják, hogy az egyes specifikációk, például a sebességszabályozás és az ESD biztonsági funkciók, hogyan működnek valós gyártási helyzetekben. Ez nemcsak a termék képességeit mutatja be, hanem a potenciális vásárlókat is megtanítja arra, hogyan optimalizálhatják azok használatát.

- Interaktív diagramok: Használjon interaktív diagramokat, amelyek lehetővé teszik a felhasználók számára, hogy az egérmutatóval a szállítószalag-modellek különböző részeire mutatva többet tudjanak meg az egyes specifikációkról. Például a diagramon a sebességszabályozó panelen kattintva további részleteket kaphat annak működéséről és előnyeiről.

Következtetés

Ezek a műszaki specifikációk alapvető útmutatásként szolgálnak a Fancort SMT szállítószalagok képességeinek és előnyeinek megértéséhez. A Fancort részletes információkat nyújt az egyes modellek méreteiről, képességeiről és biztonsági jellemzőiről, így biztosítva, hogy minden vásárló megtalálja az ideális szállítószalagot a gyártósor hatékonyságának növeléséhez. A multimédia használatának ösztönzése javítja a potenciális vásárlók tanulási élményét és elkötelezettségét.

Ezen specifikációk megértésével a potenciális vásárlók kiválaszthatják a saját igényeiknek megfelelő szállítószalag-rendszert, amely magas teljesítményt és könnyű integrálhatóságot biztosít a meglévő gyártósorokba.

Különböző szállítószalag-modellek összehasonlító elemzése

A megfelelő SMT szállítószalag modell kiválasztása elengedhetetlen a gyártási hatékonyság optimalizálásához és az egyedi működési igények kielégítéséhez. A Fancort számos modellt kínál, amelyek mindegyike az adott iparág speciális igényeinek kielégítésére lett tervezve. Ebben a részben összehasonlító táblázatot mutatunk be, amely segít megérteni a modellek közötti legfontosabb különbségeket, különös tekintettel olyan szempontokra, mint a kompatibilitás, a sebesség és a teherbírás.

A modellek közötti főbb különbségek

| Modell neve | Kompatibilitás | Sebesség (m/min) | Teherbírás (kg) | Különleges jellemzők |

|---|---|---|---|---|

| A1 modell | Univerzális SMT sorok | 50 | 30 | Fokozott pontosság |

| B2 modell | Testreszabható beállítások | 45 | 25 | Kompakt kialakítás |

| C3 modell | Integrált rendszerek | 55 | 35 | Nagy tartósság |

| D4 modell | Nagy sebességű gyártás | 70 | 40 | Valós idejű figyelés |

Multimédiás elemek

Az elkötelezettség növelése és az interaktívabb élmény biztosítása érdekében fontolja meg multimédiás elemek, például a szállítószalagok működését bemutató videók és az áramlási folyamatokat szemléltető interaktív diagramok integrálását. Ezek az eszközök mélyebb betekintést nyújtanak az egyes modellek különböző körülmények közötti működésébe, tovább segítve a döntéshozatali folyamatot. Az SMT-gépek és szállítószalagok átfogó megértéséhez hasznos lehet a Végső útmutató: SMT gépek és szállítószalagok hasznos.

Amikor kiválasztja az Ön igényeinek leginkább megfelelő modellt, ne csak a műszaki specifikációkat vegye figyelembe, hanem a termelési célokat és a környezeti tényezőket is. A Fancort csapata részletes értékelésekkel segíti Önt abban, hogy választása maximális hatékonyságot és termelékenységet biztosítson.

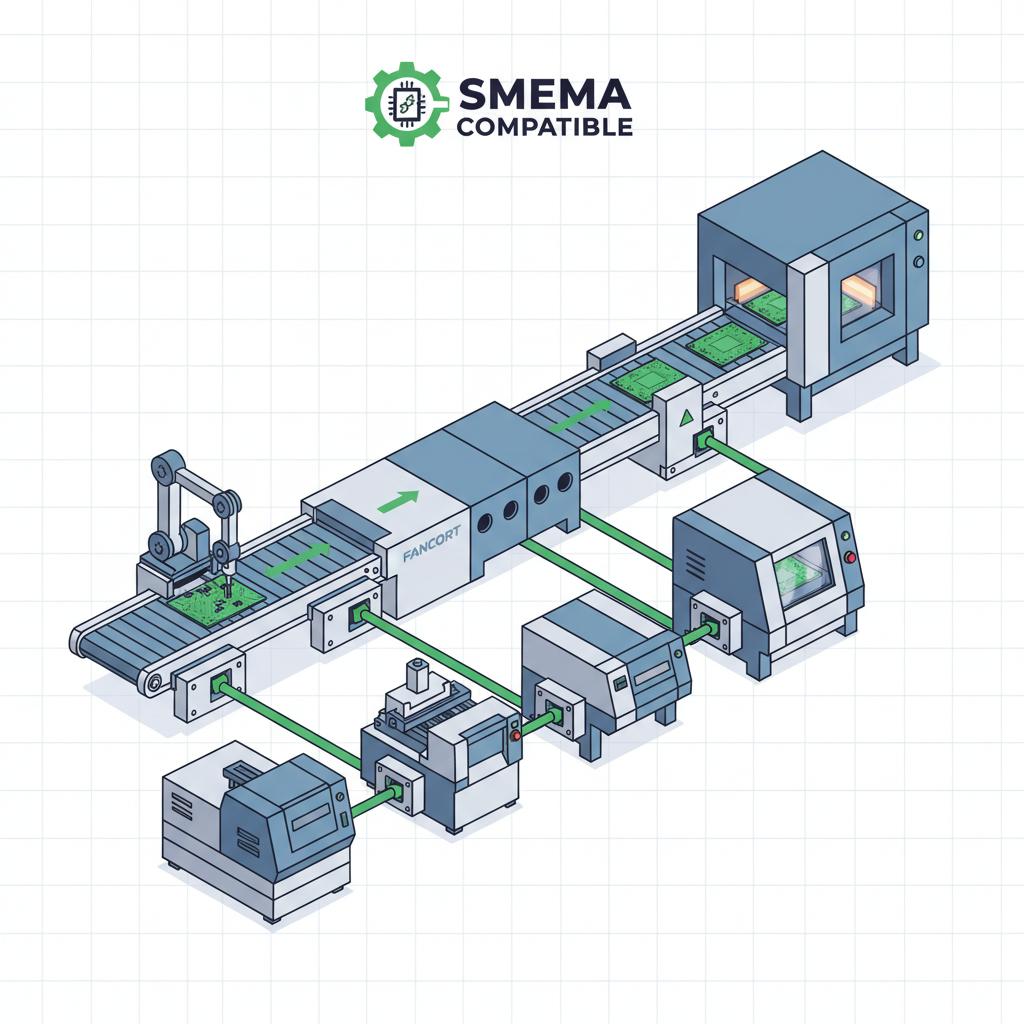

Integráció SMEMA és egyéb berendezésekkel

Az elektronikai gyártás gyorsan változó világában a technológiák kompatibilitása és zökkenőmentes integrációja meghatározhatja a gyártósorok hatékonyságát és eredményességét. A Fancort SMT szállítószalagjainak egyik alapvető jellemzője, hogy kiválóan kompatibilisek az SMEMA (Surface Mount Equipment Manufacturers Association) szabványokkal, ami megkönnyíti a meglévő és jövőbeli rendszerekkel való harmonikus integrációt.

További információkért tekintse meg Végső útmutató: SMT gépek és szállítószalagok informatív, mivel részletesen bemutatja a különböző gépek és szállítószalag-rendszerek integrációját.

Az SMEMA szabványok alapvető fontosságúak az SMT szerelési környezetben, mivel biztosítják, hogy a különböző berendezések, a szállítószalagoktól és a pick-and-place gépektől a reflow kemencékig és az ellenőrző rendszerekig, kiterjedt testreszabás vagy módosítások nélkül is kommunikálhassanak és koordinálhassák egymás munkáját. Ez az interoperabilitás elengedhetetlen a gyártóüzem működési hatékonyságának maximalizálásához.

A SMEMA kompatibilitás fontossága

A SMEMA szabványok betartásával a Fancort szállítószalagjai garantálják, hogy könnyen integrálhatók bármely szabványos elektronikai gyártási környezetbe. Ez számos előnnyel jár:

- Csökkentett beállítási idő: Az SMEMA-kompatibilis rendszerek gyorsan integrálhatók a gyártósorokba, így nincs szükség további interfészekre vagy hosszadalmas konfigurálási időre.

- Rugalmasság: A gyártási igények változásával a SMEMA-kompatibilis kialakítás lehetővé teszi a gyártók számára, hogy minimális zavarral cseréljék ki vagy bővítsék berendezéseiket, így rugalmasak és reagálóképesek maradhatnak.

- Költséghatékonyság: Az egyedi integráció elkerülése csökkenti a gyártósor módosításával járó költségeket és a lehetséges leállási időt.

- Állandó teljesítmény: Az SMEMA kompatibilitás biztosítja a különböző berendezések közötti állandó minőséget és megbízhatóságot, ezáltal fenntartva a gyártás integritását és csökkentve a hibák számát.

Az SMEMA szabványokkal való integráció előnyei

- Egyszerűsített kommunikáció: A különböző eszközök közötti zökkenőmentes elektronikus kapcsolat lehetővé teszi a pontos vezérlést és időzítést, ami elengedhetetlen a gyors ütemű SMT-folyamatban.

- Fokozott vonalhatékonyság: A Fancort szállítószalagjaival a vonalon átívelő szinkron működés megakadályozza a szűk keresztmetszetek kialakulását és zökkenőmentesebb átmenetet biztosít a szakaszok között, ezáltal optimalizálva az áteresztőképességet.

- A gyártósorok jövőbiztosítása: Az SMEMA szabványok alkalmazásával a vállalkozások jobban felkészülhetnek a technológiai fejlődésre, biztosítva, hogy a legújabb berendezéseket zökkenőmentesen integrálhassák anélkül, hogy jelentős átalakításokra lenne szükség. Olvassa el cikkünket a SMT-folyamat és felületi szerelési technológia: A végleges útmutató további információkért a gyártási folyamatok jövőbiztosításáról.

- Javított minőségellenőrzés: Az SMEMA integráció által biztosított pontosság és megbízhatóságnak köszönhetően a minőség-ellenőrzési vizsgálatok hatékonyabban kezelhetők, így biztosítva, hogy a végtermékek megfeleljenek a kívánt specifikációknak.

Együttműködés más SMT berendezésekkel

A Fancort SMT szállítószalagjai nem csak az SMEMA-ról szólnak; úgy lettek kialakítva, hogy harmonizáljanak az SMT folyamatban használt sokféle más berendezéssel:

- Elhelyező gépek: A zökkenőmentes integráció biztosítja, hogy a szállítószalagon keresztül továbbított alkatrészek késedelem és igazítási problémák nélkül érkezzenek meg az elhelyező gépekhez.

- Reflow kemencék: A koordinált rendszerek biztosítják, hogy a táblák pontos időközönként kerüljenek kiszállításra, csökkentve ezzel a hőhatás okozta hőmérsékleti sokk vagy a hőhatás egyenetlen eloszlása miatt változó forrasztási minőség esélyét.

- Ellenőrző rendszerek: Az ellenőrzési pontokon történő gyors és következetes áthaladás megkönnyíti a valós idejű minőségértékelést, segítve a problémák azonnali azonosítását és kijavítását.

A hatékonyság növelése testreszabott megoldásokkal

Bár az SMEMA által biztosított szabványosítás hatalmas hatékonyságnövekedést eredményez, a Fancort tisztában van azzal is, hogy minden gyártási környezet egyedi. Szállítószalagjaik testreszabhatók, hogy jobban megfeleljenek az egyedi igényeknek, például a nem szabványos berendezések vagy speciális folyamatok követelményeinek.

Multimédiás elemek a jobb megértés érdekében

Az integrációs folyamat vizualizálásának elősegítése érdekében interaktív diagramok és lépésről lépésre bemutató videók segítik a SMEMA szabványokkal és más SMT folyamatokkal való harmonikus együttműködésük mélyebb megértését. Ezek az eszközök lehetővé teszik a gyártók számára az operátorok és a felügyelő személyzet jobb képzését, növelve ezzel a gyártósor általános hatékonyságát.

Következtetés

Az SMEMA integráció nem csupán technikai követelmény, hanem stratégiai előny is, amely szilárd alapot biztosít az agilis, költséghatékony és skálázható gyártási megoldásokhoz. A Fancort SMT szállítószalagjaival a vállalatok könnyedén elérhetik a világszínvonalú működési hatékonyságot és megőrizhetik versenyelőnyüket a folyamatosan fejlődő elektronikai piacon. Akár egy meglévő gyártósor korszerűsítéséről, akár egy új gyártósor felállításáról van szó, a SMEMA-kompatibilis Fancort szállítószalagok választása döntő lépés a gyártási folyamatok hosszú távú sikerének és megbízhatóságának biztosítása felé.

Legyen a Fancort a sikeres partnered, és növelje termelési kapacitását a legmodernebb SMT szállítószalagjainkkal. Ha részletes tanácsadást szeretne kapni, és meg szeretné tekinteni termékeinket működés közben, vegye fel velünk a kapcsolatot még ma.

Valós alkalmazások és előnyök

Az elektronikai gyártás gyorsan változó világában a hatékonyság és a megbízhatóság kiemelten fontos. A Fancort felületi szerelési technológiájú (SMT) szállítószalagjai számos valós alkalmazásban bizonyultak felbecsülhetetlen értékű eszközöknek. Ez a szakasz gyakorlati esettanulmányokat és ügyfélajánlásokat mutat be, amelyek bemutatják, hogy ezek a szállítószalagok milyen kézzelfogható előnyökkel járnak a gyártási folyamatokban.

Esettanulmányok

1. Növekedett teljesítmény egy technológiai gyártási óriásnál

Egy neves technológiai vállalat, amely csúcskategóriás fogyasztói elektronikai termékek gyártásáról ismert, szűk keresztmetszetekkel szembesült PCB-összeszerelő sorain. A Fancort SMT szállítószalagjainak integrálásával a telepítés utáni első három hónapban 20%-es teljesítménynövekedést jelentettek. A szállítószalagok elősegítették a PCB-k zökkenőmentesebb és gyorsabb átszállítását az összeszerelő állomások között, jelentősen csökkentve az állásidőt. Fedezze fel, hogyan javítják a szállítószalagok az SMT-folyamatok hatékonyságát.

2. Csökkentett leállási idő egy autóelektronikai vállalatnál

Egy autóelektronikai gyártó cégnek gyakori szállítószalag-meghibásodások miatt leállásokkal kellett megküzdenie. A robusztus kialakítású és kiváló tartósságú Fancort SMT szállítószalagokra való áttéréssel a cég jelentősen csökkentette a nem tervezett leállások számát. Karbantartási nyilvántartásaik szerint a karbantartással kapcsolatos késések száma 30%-vel csökkent, ami javította az általános termelékenységet.

3. Fokozott ellenőrzési hatékonyság egy PCB-gyártónál

Egy nagy PCB-gyártó a Fancort szállítószalagjait alkalmazta a PCB-ellenőrzési folyamat hatékonyságának javítása érdekében. A szállítószalagok pontossága és a fejlett ellenőrzési rendszerekkel való integrálhatósága zökkenőmentesebb ellenőrzési folyamatot tett lehetővé, több mint 15%-vel csökkentve a hibaarányt. Ez a fejlesztés magasabb minőségbiztosítást és nagyobb ügyfélelégedettséget eredményezett. Tudjon meg többet az SMT-folyamatok fejlesztéséről.

Ügyfelek beszámolói

“Változást hozó tényező gyártósorunkban”

Egy elektronikai szerződéses gyártó vállalat üzemeltetési vezetője dicséri a Fancort SMT szállítószalagok megbízhatóságát, és kijelenti: “A Fancort szállítószalagok beépítése óta termelési hatékonyságunk ugrásszerűen megnőtt. Az egyszerű integráció és a minimális karbantartási igény jelentős hatással volt eredményünkre.”

“Zökkenőmentes integráció és kivételes teljesítmény”

Egy másik ügyfél, egy kis méretű elektronikai szerelőcég így nyilatkozott: “A Fancort szállítószalagjai könnyen integrálhatók voltak a meglévő SMEMA-kompatibilis berendezéseinkbe. A teljesítményük kivételes, így a szállítószalagokkal kapcsolatos zavarok miatt nem kell aggódnunk, és a működésünk bővítésére koncentrálhatunk.”

Gyakorlati előnyök

- Megnövekedett átviteli sebesség: A Fancort SMT szállítószalagjainak használatának egyik legjelentősebb előnye a megnövelt áteresztőképesség. Az alkatrészek következetes és megbízható szállításának biztosításával ezek a szállítószalagok hozzájárulnak a gyártósorok teljesítményének maximalizálásához.

- A leállási idő csökkentése: A Fancort szállítószalagok tartóssága és megbízhatósága kevesebb meghibásodást eredményez, ezáltal csökken a leállás ideje és a gyártási ütemterv lendülete megmarad.

- Költséghatékonyság: A leállási idő és a karbantartási igények minimalizálásával a Fancort szállítószalagok idővel jelentős költségmegtakarításhoz is hozzájárulnak. Ez a hatékonyság a gyártók számára jobb eredményeket jelent.

- Fokozott ellenőrzési pontosság: A Fancort SMT szállítószalagjai precíz műszaki megoldásokkal biztosítják a alapos ellenőrzési folyamatokat, garantálva a hibák gyors felismerését és kijavítását. Ez jobb minőség-ellenőrzést és kevesebb visszaküldést eredményez.

- Rugalmasság és kompatibilitás: A Fancort szállítószalagok úgy lettek kialakítva, hogy zökkenőmentesen integrálhatók legyenek a meglévő berendezésekbe, beleértve az SMEMA-kompatibilis eszközöket is. Rugalmasságuknak köszönhetően könnyebben alkalmazkodnak a változó gyártási igényekhez.

Következtetés

A Fancort SMT szállítószalagjainak valós alkalmazásai és előnyei egyértelműen kiderülnek a vizsgált esettanulmányokból és ajánlásokból. Legyen szó a termelékenység növeléséről, az állásidő csökkentéséről vagy a vizsgálati folyamatok fejlesztéséről, a Fancort megoldásai az elektronikai gyártás szigorú követelményeinek megfelelően vannak kialakítva. A szállítószalagokba való befektetés nemcsak a működési hatékonyságot javítja, hanem a termelés folyamatos kiválóságát is biztosítja.

Az SMT szállítószalagok hatékonyságát bemutató videók és az integrációs beállításokat bemutató interaktív diagramok és egyéb multimédiás elemek beépítése tovább gazdagíthatja az olvasó élményét és megértését. Vegye fel a kapcsolatot a Fancorttal egy bemutató vagy konzultáció céljából, hogy megismerje, hogyan tudnak szállítószalag-megoldásaik konkrétan kielégíteni gyártási igényeit.

Karbantartás és hibaelhárítás

A Fancort SMT szállítószalagok hatékonyságának fenntartása rendszeres karbantartást és proaktív megközelítést igényel a hibaelhárítás terén. Ez a szakasz bemutatja a karbantartás legjobb gyakorlatait, a gyakori hibaelhárítási technikákat, valamint a garancia és a technikai támogatás szolgáltatásainak részleteit, amelyek biztosítják, hogy szállítószalag-rendszerei továbbra is optimálisan működjenek.

Karbantartási bevált gyakorlatok

A rendszeres karbantartás elengedhetetlen a felesleges leállások megelőzéséhez és az SMT szállítószalagok élettartamának meghosszabbításához. Íme néhány fontos karbantartási gyakorlat:

- Ütemezett ellenőrzések: Végezzen rendszeres ellenőrzéseket a lehetséges kopás és elhasználódás azonosítása érdekében. A rendszeres ellenőrzések segítenek a problémák korai felismerésében, mint például az ékszíj eltérése, a motor meghibásodása vagy a túlzott rezgés. A mélyebb megértéshez hasznos lehet a Végső útmutató: SMT gépek és szállítószalagok hasznos.

- Kenés: A mozgó alkatrészek rendszeres kenése elengedhetetlen. Ez megakadályozza a mechanikai meghibásodásokat és biztosítja a szállítószalag zökkenőmentes működését.

- Tisztítás: Tartsa a szállítószalagokat tisztán, por és szennyeződések felhalmozódásától mentesen. Használjon olyan tisztítószereket, amelyek nem károsítják az öveket vagy az elektronikus alkatrészeket.

- Alkatrészellenőrzések: Rendszeresen ellenőrizze az öveket, görgőket és motorokat, hogy nincsenek-e rajtuk sérülések. Cserélje ki az elhasználódott alkatrészeket, hogy elkerülje a váratlan meghibásodásokat. A mi Átfogó útmutató az SMT szállítószalag cseréjéhez értékes forrás lehet.

- Kalibrálás: A rendszer megfelelő kalibrálásának biztosítása segít a pontosság és a hatékonyság fenntartásában.

Gyakori hibaelhárítási tippek

A karbantartás során tett legjobb erőfeszítései ellenére is előfordulhatnak problémák. Íme néhány általános hibaelhárítási tipp:

- Övkövetési problémák: Ha az öv nem követi megfelelően a pályát, ellenőrizze az igazítást és a feszességet. Állítsa be a feszítőket a megfelelő pálya követéséhez.

- Motorproblémák: Ha a motor nem működik, ellenőrizze az áramellátást és keresse meg az esetlegesen kioldott biztosítékokat. Ha a probléma továbbra is fennáll, olvassa el a kézikönyvet vagy vegye fel a kapcsolatot a műszaki támogatással.

- Zaj és rezgés: Szokatlan zaj vagy rezgés laza alkatrészekre vagy rosszul beállított alkatrészekre utalhat. Húzza meg az összes csavart, és ellenőrizze, hogy minden alkatrész megfelelően van-e beállítva.

- Sebességingadozások: Ha sebességeltérések lépnek fel, ellenőrizze a vezérlő beállításait és vizsgálja meg a motort elektromos problémák szempontjából.

- Integrációs hibák: Győződjön meg arról, hogy az SMEMA-val vagy más berendezésekkel való összes kapcsolat biztonságos és helyesen van konfigurálva, hogy elkerülje a kommunikációs hibákat. További információkat az integrációról az útmutatónkban talál. SMT-folyamat és felületi szerelési technológia.

Garancia és műszaki támogatás

A Fancort átfogó garanciális szolgáltatásokat és szakértői technikai segítséget kínál minden szállítószalag-rendszerünkhöz. Technikai támogató csapatunk készen áll a mélyreható technikai kérdésekben való segítségnyújtásra és karbantartási tanácsok adására.

- Garanciális szolgáltatások: Szállítószalagjainkra meghatározott feltételek mellett alkatrészekre és munkadíjra vonatkozó garancia vonatkozik. További részletekért olvassa el garanciális feltételeinket.

- Szakértői támogatás: Technikai támogatás online és telefonon is elérhető, hogy segítséget nyújtson az Ön által tapasztalt problémák megoldásában. Támogatásunk lépésről lépésre nyújt útmutatást és segítséget a hibaelhárításban.

- Képzés és források: A Fancort hozzáférést biztosít olyan oktatóvideókhoz és kézikönyvekhez, amelyek részletes utasításokat tartalmaznak a szállítószalag-rendszereink karbantartásáról és hibajavításáról.

A multimédiával való interakció javítása

A jobb megértés érdekében javasoljuk, hogy tekintse meg multimédiás forrásainkat, beleértve az interaktív diagramokat és oktatóvideókat. Ezek a források vizuális útmutatást nyújtanak, és rendkívül hasznosak lehetnek mind az SMT szállítószalagok új, mind a tapasztalt felhasználói számára.

Ezen karbantartási és hibaelhárítási gyakorlatok betartásával, valamint a Fancort dedikált szolgáltatásainak támogatásával SMT szállítószalagjai továbbra is hatékonyan működnek, minimalizálva az állásidőt és maximalizálva a termelékenységet.

Gyakran feltett kérdések

Ebben a részben a potenciális vásárlók és a jelenlegi felhasználók leggyakoribb kérdéseire válaszolunk a Fancort SMT szállítószalagjaival kapcsolatban. Ez a GYIK gyors, egyértelmű válaszokat nyújt, hogy a felhasználók magabiztosak és jól tájékozottak legyenek gépeikkel kapcsolatban.

1. Mi a Fancort SMT szállítószalagok telepítési folyamata?

A Fancort SMT szállítószalagokhoz részletes telepítési útmutató és videó bemutató tartozik, amelyek lépésről lépésre végigvezetik Önt a beállítási folyamaton. Általában a telepítés néhány óra alatt elvégezhető ezeknek az erőforrásoknak a segítségével. Ezen felül a Fancort helyszíni telepítési szolgáltatásokat is kínál, ha Ön professzionális segítséget szeretne igénybe venni az optimális beállítás érdekében.

2. Milyen garanciát kínál a Fancort az SMT szállítószalagjaira?

A Fancort minden SMT szállítószalagjára egyéves átfogó garanciát biztosít, amely fedezi az esetleges gyártási hibákat és garantálja a megbízható működést. A nagyobb biztonság érdekében kiterjesztett garanciális tervek is rendelkezésre állnak, amelyek akár három évig is fedezetet nyújtanak.

3. Ha problémám adódik a szállítószalaggal, kaphatok technikai támogatást?

Igen, a Fancort rendelkezik egy dedikált technikai támogató csapattal, amely bármilyen működési problémával kapcsolatban segítséget nyújt Önnek. A támogatás telefonon, e-mailben vagy online támogatási portálunkon keresztül érhető el. Ezenkívül az ügyfelek hozzáférhetnek egy hibaelhárítási videókból álló könyvtárhoz és egy interaktív felhasználói kézikönyvhöz, amelyek célja a gyakori problémák gyors megoldása.

4. Hogyan integrálhatók ezek a szállítószalagok az SMEMA-val és más berendezésekkel a létesítményemben?

A Fancort SMT szállítószalagjai SMEMA kompatibilisek, így zökkenőmentesen integrálhatók a gyártósoron található egyéb SMT berendezésekkel, például reflow kemencék vagy hullámforrasztó gépek. Könnyen összekapcsolhatók a fel- és lefelé irányuló gépekkel, minimalizálva a beállítási időt és csökkentve a technikai problémákat.

5. Melyek azok a valós alkalmazások, ahol ezeket a szállítószalagokat sikeresen alkalmazták?

SMT szállítószalagjaink széles körben használatosak különböző iparágakban, például az elektronikai gyártásban, az autóiparban és a távközlésben. Növelik a termelési hatékonyságot, különösen azokon a szerelősorokon, ahol a NYÁK-ok gyors szállítása szükséges. Például jól integrálhatók szelektív fluxálás és egyéb kritikus SMT-folyamatok.

6. Milyen karbantartás szükséges ezeknek a szállítószalagoknak?

A Fancort SMT szállítószalagok rutin karbantartása magában foglalja a kopás és elhasználódás rendszeres ellenőrzését, a mozgó alkatrészek kenését és a kalibrációs ellenőrzéseket. Részletes karbantartási útmutatók és videók állnak rendelkezésre, hogy segítsék a felhasználókat a rendszeres karbantartás elvégzésében, és így meghosszabbítsák berendezéseik élettartamát. Érdemes megnézni a útmutató a szállítószalag cseréjéhez további konkrét tanácsokért.

Ez a GYIK szakasz segít eloszlatni az esetleges bizonytalanságokat, hogy megalapozott döntést hozhasson a közelgő vásárlásáról. További kérdések vagy pontosítások esetén forduljon ügyfélszolgálatunkhoz, vagy látogasson el átfogó online információs központunkba.

Következtetés és cselekvésre való felhívás

A Fancort SMT szállítószalagokról szóló átfogó útmutatónkat lezárva egyértelművé válik, hogy ezek a rendszerek páratlan hatékonyságot és alkalmazkodóképességet kínálnak a felületi szerelés technológiájának világában. Javasoljuk, hogy mélyebben is ismerkedjen meg azzal, hogyan lehet ezeket a kifinomult szállítási megoldásokat az Ön egyedi gyártási igényeihez igazítani.

A Fancort hírlevelének előfizetésével exkluzív betekintést nyerhet esettanulmányokba és átalakító iparági innovációkba. Legyen mindig egy lépéssel előrébb a legújabb fejlesztéseket bemutató rendszeres frissítésekkel, amelyek megvalósítható stratégiákat kínálnak gyártási folyamatainak optimalizálásához.

Az SMT szállítószalagok szélesebb gyártási környezetben való alkalmazásának mélyebb megértéséhez érdemes megismerkedni a következővel: Végső útmutató: SMT gépek és szállítószalagok amely részletes betekintést és összehasonlításokat nyújt.

Ne csak olvasson az összeszerelés jövőjéről, hanem legyen annak része! Vegye fel velünk a kapcsolatot még ma, és fedezze fel, hogyan forradalmasíthatják testreszabott megoldásaink gyártósorát. Akár a meglévő SMEMA szabványok integrálását, akár a jelenlegi rendszer fejlesztését tervezi, csapatunk készen áll a segítségére.

Felhívás cselekvésre

- Hírlevélre feliratkozás exkluzív tartalmakért és frissítésekért

- Kapcsolatfelvétel személyre szabott konzultációért

- Fedezze fel Interaktív diagramok és videók hogy jobban megismerje technológiánkat

A hatékonyabb gyártás felé vezető út egy egyszerű kattintással kezdődik. Engedje, hogy a Fancort segítse Önt az innováció és a gyártási kiválóság terén.

A modern gyártás területén a hatékonyság és a pontosság kulcsfontosságú. A Fancort Industries megérti az elektronikai szerelés bonyolult igényeit, és csúcstechnológiás SMT szállítószalag-megoldásokat kínál, amelyek célja a gyártási folyamatok racionalizálása. Ha megbízható és alkalmazkodó berendezésekkel szeretné javítani gyártósorának teljesítményét, itt az ideje cselekedni. Fedezze fel átfogó útmutatónkat az SMT szállítószalag cseréjéről a hatékonyság fenntartásával kapcsolatos betekintésért.

Vegye fel velünk a kapcsolatot egyedi megoldásokért!

Gyártási igényei egyediek, ezért berendezéseinek is azoknak kell lenniük. A Fancortnál büszkék vagyunk arra, hogy az Ön egyedi igényeinek megfelelő, testreszabott megoldásokat kínálunk. Akár meglévő rendszerek korszerűsítését, akár új technológiák bevezetését tervezi, szakértői csapatunk készen áll a szoros együttműködésre. Vegye fel velünk a kapcsolatot még ma, hogy megbeszéljük az Ön egyedi kihívásait, és lehetővé tegye számunkra, hogy olyan szállítószalag-rendszert tervezzünk, amely növeli a termelékenységet és pontosan megfelel az Ön gyártósorának specifikációinak.

Legyen tájékozott és járjon előre

Csatlakozzon növekvő iparági vezetőink közösségéhez, iratkozzon fel exkluzív hírlevelünkre. Legyen mindig egy lépéssel előrébb, és ismerje meg az SMT szállítószalag-technológia legújabb trendjeit és fejlesztéseit. Hírlevelünkben iparági szakértők értékes betekintései, sikeres megvalósításokat bemutató részletes esettanulmányok, valamint legújabb termékeinkről és innovációinkról szóló friss hírek találhatók.

Multimédiás és interaktív források kihasználása

A Fancort SMT szállítószalagok teljes potenciáljának megértéséhez nem elég csak elolvasni a leírásokat. Átfogó útmutatónk videókat tartalmaz, amelyek bemutatják a rendszer működését, valamint interaktív diagramokat, amelyek segítségével felfedezheti a konfigurációkat. Ezek az erőforrások részletes vizuális megértést nyújtanak, így könnyebben megértheti, hogyan illeszkednek megoldásaink zökkenőmentesen az Ön működésébe.

Legyen része a jövőnek!

A gyártási technológia gyorsan fejlődik, és a helyben maradás nem opció. Ha SMT szállítószalag-megoldásaihoz a Fancortot választja, akkor olyan partnerségbe fektet be, amelynek célja a gyártási kapacitásainak fejlesztése. Azok számára, akik szeretnék megismerni az SMT-folyamatot, A SMT-gépekről és szállítószalagokról szóló végső útmutatónk részletes betekintést nyújt.

Vegye fel velünk a kapcsolatot most

Ne hagyja ki ezt a lehetőséget! Személyre szabott tanácsadásért és a szállítószalagjaink működésének megtekintéséért vegye fel a kapcsolatot a Fancorttal még ma! Hívjon minket, küldjön e-mailt vagy töltse ki online érdeklődési űrlapunkat! Vegye kézbe gyártási jövőjét, és gondoskodjon arról, hogy üzeme a legjobb SMT szállítószalag-technológiával legyen felszerelve!.

A kiválóságra törekedve

Csatlakozzon a számtalan elégedett ügyfélhez, akik a Fancort Industries-t választották megbízható partnerüknek a gyártástechnológia területén. Segítünk Önnek a működési hatékonyság növelésében, az állásidők csökkentésében és a termékminőség javításában. Ne feledje, a kiválóság kulcsa az együttműködés; érjük el ezt együtt!.