When you pick a wave soldering machine for your SMT line, you look at more than just the price. Many hidden things affect how well your assembly works over time. These things can change your costs and the quality of your products. Research shows that advanced wave soldering machines help make soldering more accurate. They also lower the number of mistakes and make solder joints stronger. You get better product quality, faster soldering, and a bigger advantage if you notice these things.

Soldering accuracy helps make products better.

Fewer mistakes mean less fixing and less waste.

Strong solder joints help products last longer.

Do not just look at what you see first. Think about all the value a machine gives during its life.

Hal-hal Penting yang Dapat Dipetik

Do not only think about price when picking a wave soldering machine. Check the design, what it is made of, and how long it will last.

Good materials and smart design mean fewer repairs and better work. Pick machines that use strong metals.

Watch the temperature and other settings closely. This keeps the soldering good and stops mistakes.

Take care of your machine often. Clean it and change old parts to stop big repairs and lost time.

Get training and help from your supplier. This helps you use your machine well and fix problems fast.

Machine design and build quality

Materials and durability

You want your wave soldering machine to work for a long time. The frame, solder tank, and conveyor system need good materials. Stainless steel does not rust and keeps the machine strong. Aluminum makes the machine lighter but still tough. Good materials help protect your money and keep results steady. If you pick a machine with strong parts, you will fix it less. You also get better automation and fewer times when it breaks.

Tip: Always look at what materials the maker uses. Strong metals and good plastics help your machine do daily jobs well.

Engineering precision

Good engineering means every part fits and moves right. Tight spaces in the conveyor, nozzles, and heating zones help you solder well. If the machine is not made well, you might see bad solder joints or missed spots. High precision helps the machine work smoothly and keeps soldering steady. You get better results when the machine moves PCBs with care.

Good engineering helps:

Lower soldering mistakes

Make automation faster

Keep solder joints strong

S&M’s robust construction

S&M makes wave soldering machines that are strong and exact. Their models have tough aluminum frames and stainless steel parts. The company uses smart automation when building the machines. This gives you steady soldering and less fixing. S&M’s machines use good motors and control systems for smooth work. You get steady soldering and good results, even when you make many products.

Catatan: S&M’s strong build and smart automation help you get great soldering and value for a long time.

Process compatibility in SMT

PCB design challenges

Designing a pcb for smt can be hard. The way you place parts matters a lot. You need to match the machine’s needs. Good spacing helps stop soldering problems. If big parts block small ones, it causes trouble. Multi-pin parts should face the solder wave. Planning the layout helps the process work well. This also makes your product more reliable.

Putting parts in the right place helps wave soldering.

Good spacing and direction lower mistakes.

Big parts should not cover small ones.

Multi-pin parts should face the solder wave.

Component density impact

Adding more parts to a pcb makes things harder. When there are many parts, you must slow the conveyor. If it goes too fast, solder joints may not form right. Some parts could get hurt. For crowded pcbs, use a speed of 0.8 to 1.2 meters per minute. You need to balance speed and heat for strong joints. The number of parts changes what the machine must do. You need a machine that can handle these tough jobs.

S&M selective wave soldering adaptability

S&M’s selective wave soldering machines help with tricky pcb designs. They use small nozzles to solder exact spots. These machines work with boards that mix surface mount and through-hole parts. You can solder heat-sensitive spots without hurting other parts. The small solder area lowers heat stress and makes boards last longer. You also use less solder and flux, which saves money for busy boards.

Feature/Advantage | Deskripsi |

|---|---|

Precision Soldering | Small nozzles put hot solder on exact spots. |

Hybrid Technology Compatibility | Works with boards that have both surface mount and through-hole parts. |

Heat-Sensitive Area Soldering | Solder in spots with sensitive parts for hard designs. |

Small Solder Contact Area | Less heat stress and stronger pcbs. |

Reduced Solder and Flux Consumption | Saves materials for busy pcbs and lowers costs. |

You fix many smt wave soldering problems with S&M’s machines. You get good results even with hard layouts and lots of parts.

Cost factors in wave soldering machines

Upfront vs. operational cost

You might think the price is the biggest cost in smt assembly. But how you use the wave soldering machine every day matters more. Upfront cost is what you pay to buy the machine. Operational cost is what you spend to keep it working. You should think about both when planning your pcb assembly line.

Upfront cost pays for the machine, setup, and training. Operational cost means paying for power, cleaning, repairs, and spare parts. If you only look at the price, you could miss hidden costs that make smt assembly more expensive. Machines that work better can save you money over time. They use less energy, break less, and help you finish more pcb assemblies with fewer errors.

Tip: Always check how much you will spend each year on power, cleaning, and repairs. This helps you know the real cost of your smt assembly project.

Maintenance and spare parts

Maintenance keeps your wave soldering machine working well. If you skip regular checks, the machine can break more and parts can cost more. You need to clean the soldering area, change old parts, and check the conveyor system. Some machines have modular design. This means you can change parts fast. You spend less time fixing and more time making products.

Machines with tool-free maintenance are easier to use. You do not need special tools to open the machine or change a part. This means less downtime and more money saved. Auto-calibration and CCD alignment help keep soldering steady. You do not need to adjust things by hand as much. This means fewer mistakes in pcb assembly and lower part costs.

Fitur | Manfaat |

|---|---|

Modular design | Fits any production line, allowing for quick integration and upgrades. |

Tool-free maintenance procedures | Simplifies maintenance, reducing time and costs associated with repairs. |

Auto-calibration and CCD alignment | Enhances quality and reduces the need for manual adjustments. |

Note: Regular maintenance and easy-to-find spare parts help you control the cost of smt assembly. You keep your assembly line moving and avoid expensive delays.

Efisiensi energi

Energy efficiency is a hidden thing that changes the cost of smt assembly. Machines that use less power help you save money every month. Smart factory features let you watch energy use in real time. You can find problems before they stop your assembly line. Predictive maintenance helps you fix things early. This means less downtime and your pcb assembly stays on track.

Many owners say their electricity bills drop by 40-50% with energy-efficient machines. These machines often use only 7kW when running. They use precision nozzles for even flux coating. This helps you get better soldering and lower part costs.

Manfaat | Deskripsi |

|---|---|

Electricity Bill Reduction | Owners report a drop of 40-50% in electricity bills due to energy efficiency. |

Enhanced Process Efficiency | The machine’s design contributes to overall operational efficiency. |

Fitur | Deskripsi |

|---|---|

Energy Consumption | Operates at only 7kW during normal operation. |

Precision Nozzle | Uses Japanese Kuroda precision nozzle for uniform flux coating. |

Tip: Energy-efficient machines help you save money. You spend less on power and get better results in your assembly line.

S&M’s cost-effective solutions

S&M makes wave soldering machines that help you lower smt assembly costs. Their modular design fits any assembly line. You can upgrade or fix parts fast. Tool-free maintenance means you do not need special tools. You save time and money on repairs. S&M uses hot air preheating and strong insulation. These features cut heat loss and make the machine work better. You spend less on energy and keep your assembly line running well.

S&M gives you optional protection devices. These help the machine last longer and need less fixing. The company’s machines use smart factory ideas. You get real-time monitoring and predictive maintenance. This helps you avoid big breakdowns and keep your pcb assembly on schedule.

Fitur | Manfaat |

|---|---|

Hot air preheating | Long service life reduces maintenance downtime. |

Internal reinforcement insulation | Minimizes heat loss, improving efficiency and reducing operational costs. |

Optional external protection device | Enhances durability and reduces maintenance needs. |

S&M’s cost-saving solutions help you control part costs, lower running expenses, and make your assembly work better. You get good soldering, fewer repairs, and better results in every pcb assembly.

Note: When you pick S&M, you get a wave soldering machine that helps you save money. You get strong performance, easy care, and lower costs for your smt assembly project.

Quality control and monitoring

Temperature control importance

You need to watch temperature closely in wave soldering. Temperature is one of the main soldering quality factors. If you keep the solder pot at the right heat, you get strong joints. If the solder wave is too cool, the solder does not stick well. This can cause cold joints that break easily. If the wave is too hot, you might see solder bridges or too much intermetallic growth. These problems weaken the joint and lower welding quality.

Anda harus monitor the solder pot temperature all the time.

Adjust the conveyor speed so the board touches the wave for 2 to 3 seconds.

Using nitrogen helps stop oxidation when you need higher temperatures.

Anda harus understand how wave height and temperature affect the board and its parts. This helps you keep soldering quality factors under control. You get better welding quality and fewer defects when you manage temperature well.

Process parameter stability

Stable process parameters help you avoid defects in smt assembly. You need to control wave height, contact time, conveyor speed, and cooling rate. Each one affects welding quality and soldering quality factors. If you let these change too much, you see more defects. You get weak joints, cracks, or bridges.

Effect on Defect Rates | |

|---|---|

Tinggi Gelombang | Affects solder coverage; too low means not enough solder, too high causes splashing or bridging. |

Contact Time | Not enough time makes weak joints; too much time overheats and damages the board. |

Kecepatan Konveyor | Fast speed gives weak joints; slow speed overheats the board. |

Tingkat Pendinginan | Fast cooling can cause cracks or weak spots in solder joints. |

You need to keep these settings steady. You should check them often. This helps you keep welding quality high and stop defects before they happen. You also improve solder paste quality and lower the risk of bad boards.

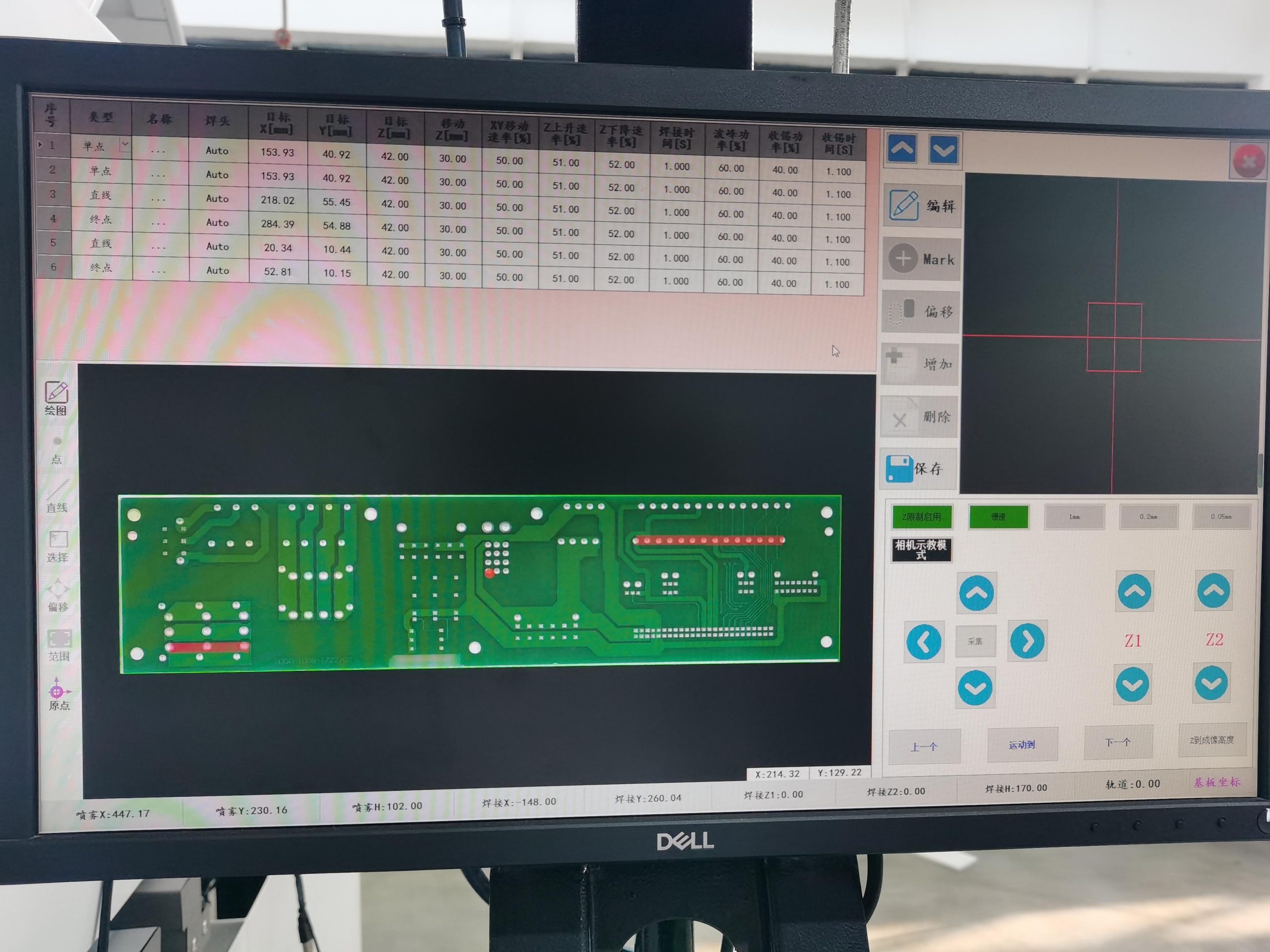

S&M’s intelligent monitoring system

S&M gives you advanced tools for quality control. Their wave soldering machines use built-in inspection and smart monitoring. You get alarms if something goes wrong. The system records key process parameters like temperature, nitrogen pressure, spray flow, and tin furnace heat. You can see these numbers in real time. This helps you spot defects early and fix them fast.

You get visual and automated inspections during production.

The system helps you catch defects like bridging and not enough solder before the board leaves the line.

S&M’s machines let you use AOI with rework steps. You can fix defects before the board reaches the end. This lowers scrap and saves time.

You can set up automatic testing for every board. The machine checks for defects and welding quality. You get alerts if something changes. You can adjust settings right away. This keeps welding quality high and stops defects from spreading.

Tip: Use S&M’s intelligent monitoring system to keep your smt line running smoothly. You get better quality control, fewer defects, and stronger welding quality.

You should test every board for soldering quality factors. You need to check temperature, wave height, and conveyor speed. You should use built-in inspection to find defects early. You can use AOI and rework to fix problems before they reach the end. You get better welding quality and lower costs.

Testing is important for quality control. You should test for defects at every step. You need to check solder paste quality, soldering quality factors, and welding quality. You should use automated testing and visual checks. You get better quality and fewer defects.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You need to test for defects often. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing is key for quality control. You should test for defects, soldering quality factors, and welding quality. You need to use automated and visual testing. You get better quality and fewer defects.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

You should always focus on quality control. You need to test for defects and welding quality. You should use S&M’s intelligent monitoring system for real-time testing. You get alerts and can fix problems fast. You keep welding quality high and stop defects from spreading.

You need to test for defects at every step. You should use built-in inspection and AOI. You can fix defects before the board leaves the line. You get better welding quality and lower costs.

Testing helps you find defects early. You can fix them before they hurt welding quality. You should use S&M’s monitoring system for real-time testing. You get alerts and can adjust settings fast. You keep welding quality high and stop defects from spreading.

Ringkasan

You need strong quality control to get good results in smt. You should monitor temperature, keep process parameters steady, and use built-in inspection. S&M’s intelligent monitoring system helps you test for defects and keep welding quality high. You get better soldering quality factors, lower costs, and stronger boards.

Environmental and facility considerations

Ambient conditions

You have to watch the air and temperature in your work area. If the air is too wet, water can collect on your PCBs. This can make solder joints weak and hurt sensitive parts. Dust and chemicals in the air can also cause trouble. They might get inside your wave soldering machine and make cleaning harder.

Air pollution from soldering can make people sick and ruin products. These pollutants include gases from colophony and coatings. They can build up in the machine and make you clean it more often.

You should keep your work area tidy and use good fans. This helps your machine last longer and keeps your products safe.

Facility requirements

Your building must be ready for smt work. The floor should be strong enough for heavy machines. You need space for conveyors and inspection tools. Bright lights help you see problems early.

Infrastructure Component | Deskripsi |

|---|---|

Inspeksi Optik Otomatis (AOI) | Checks quality and helps stop mistakes during assembly. |

Inspeksi Pasta Solder (SPI) | Makes sure solder paste is put on right for good soldering. |

Automated Conveyorized Component Mounting | Moves parts quickly to make production faster and easier. |

Wave Soldering Machines | Needed for soldering parts to PCBs and need special room conditions. |

Quality Control Measures | Make sure finished products meet all rules and standards. |

Environmental Conditions | Must be controlled to stop water damage to sensitive parts. |

You should use drying ovens and storage for parts that do not like water. A Manufacturing Execution System (MES) helps you watch production and find problems fast.

Workplace safety

You need to keep your team safe from bad air and heat. Fume extraction systems pull out harmful gases from the air. These systems help you follow safety rules and keep workers healthy. Clean air means less sickness and better work.

Fume extraction systems keep air clean and protect workers from bad fumes.

These systems help you follow safety rules like OSHA and RoHS by removing dirty air.

Better air helps keep workers safe and makes production better.

S&M builds wave soldering machines that are safe and work well in many places. You get good safety features and steady performance, even if things change.

Supplier support and warranty

Training and technical support

You need more than just a machine to succeed in SMT assembly. You need the right training and technical support. Good suppliers offer training programs that help you use your wave soldering machine the right way. These programs teach you how to set process parameters, do preventative maintenance, and solve common problems. You learn how to keep your machine running smoothly and avoid mistakes.

Training helps you understand wave soldering process variables.

Workshops show you how to fix defects and improve your production line.

You learn how to make your SMT line more efficient and reliable.

When you know how to use your machine, you get better results. You make fewer mistakes and your products last longer.

Tip: Ask your supplier if they offer hands-on training and technical support. This can help you solve problems faster and keep your line running.

Warranty terms

Warranty terms matter when you buy a wave soldering machine. A good warranty protects you from unexpected costs. It covers repairs and replacement parts if something goes wrong. You should check how long the warranty lasts and what it includes.

Warranty Feature | Mengapa Hal Ini Penting |

|---|---|

Length of Coverage | Longer coverage means more protection. |

Parts and Labor | Covers repair costs and spare parts. |

Response Time | Fast help reduces downtime. |

A strong warranty gives you peace of mind. You know you can get help if you need it.

S&M’s customer service

S&M gives you full support after you buy your machine. You get training, technical help, and a clear warranty. S&M’s team helps you set up your machine and teaches you how to use it. If you have a problem, you can reach out for fast answers. The company’s after-sales service helps you keep your SMT line running with less downtime.

S&M’s support team has years of experience. They know how to solve problems and keep your machine working well. Many customers say S&M’s service makes their production smoother and more reliable.

Note: Good support and warranty help you save money and avoid long delays. S&M’s service gives you the confidence to focus on making great products.

When picking a wave soldering machine for your smt line, you should think about more than just what you see. The design, how it works with your process, cost, and help from the supplier all matter. These things change how much money you get back from your machine. Many factories get better quality and use their machines more when they fix both easy-to-see and hidden problems. S&M’s smart solutions help you handle these problems. This gives you steady performance and good results. You get the most out of your machine when you look at every detail, not just the first thing you notice.

PERTANYAAN YANG SERING DIAJUKAN

What is the main benefit of using a wave soldering machine in SMT?

You get faster and more reliable soldering for your circuit boards. The machine helps you make strong connections and reduces mistakes. This means your products work better and last longer.

How often should you maintain your wave soldering machine?

You should check and clean your machine every week. Replace worn parts as soon as you notice problems. Regular care keeps your machine running smoothly and helps you avoid costly repairs.

Can S&M wave soldering machines handle complex PCB designs?

Yes! S&M machines work well with boards that have many parts or special layouts. You can use them for both simple and advanced projects. The machines adapt to your needs.

What support does S&M offer after you buy a machine?

S&M gives you training, technical help, and a clear warranty. You can contact their team for fast answers if you have questions or need help with your machine.

How does energy efficiency affect your production costs?

Faktor | Impact on Costs |

|---|---|

Lower Power Usage | Saves money each month |

Less Heat Loss | Reduces energy waste |

You spend less on electricity and keep your production line running efficiently.