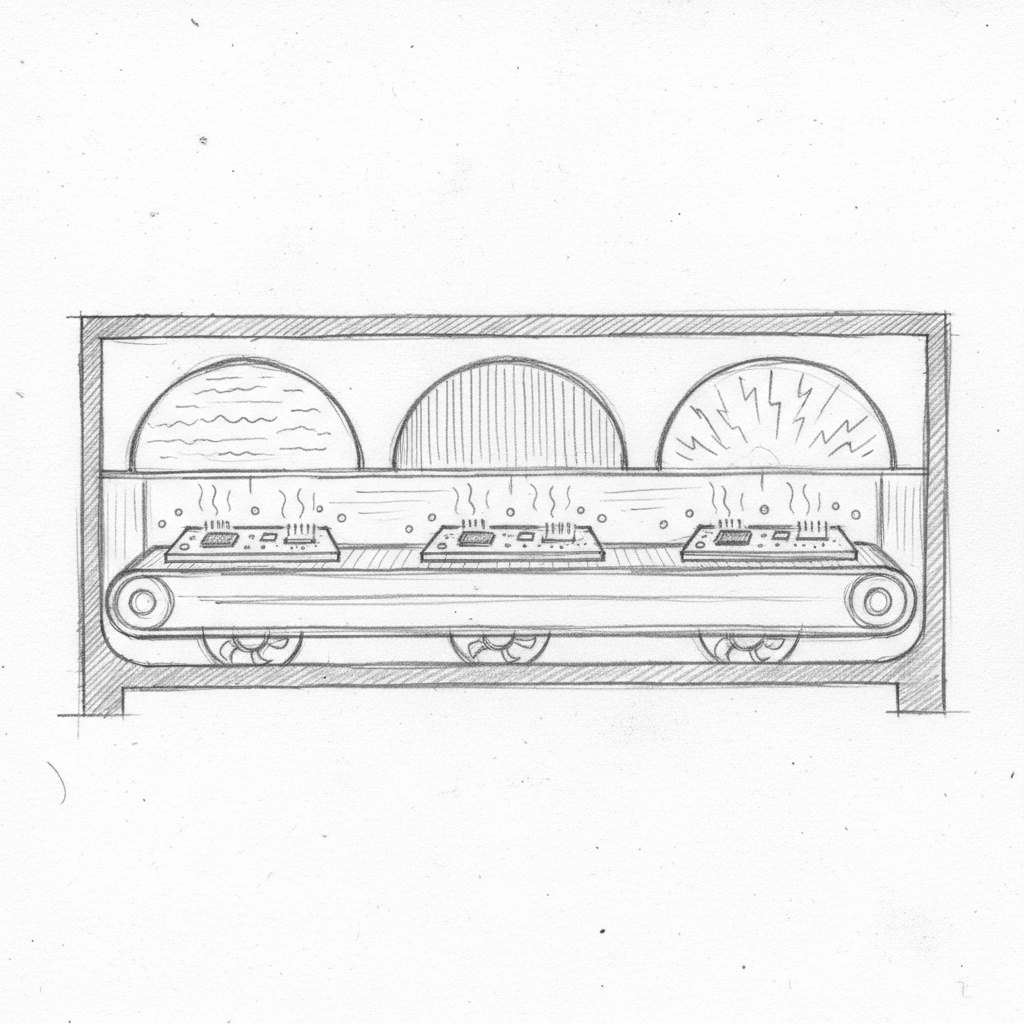

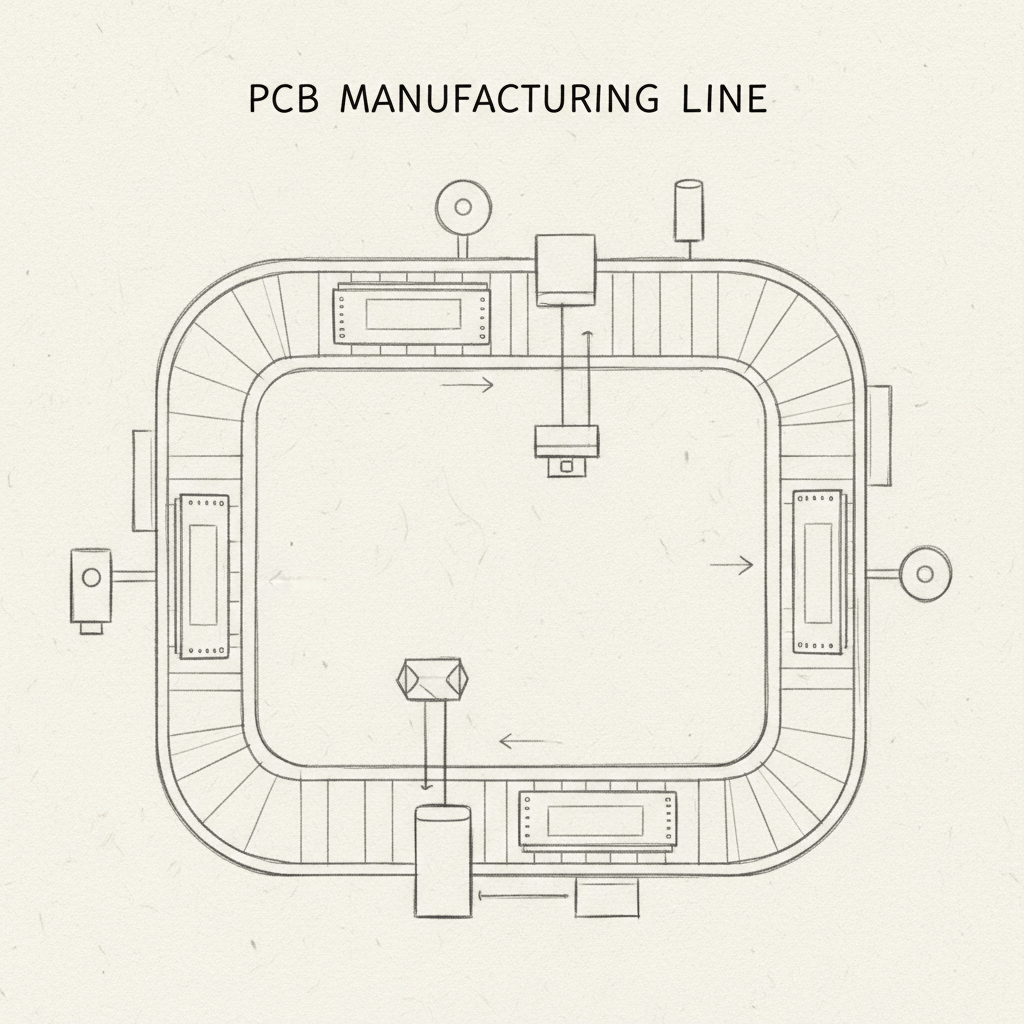

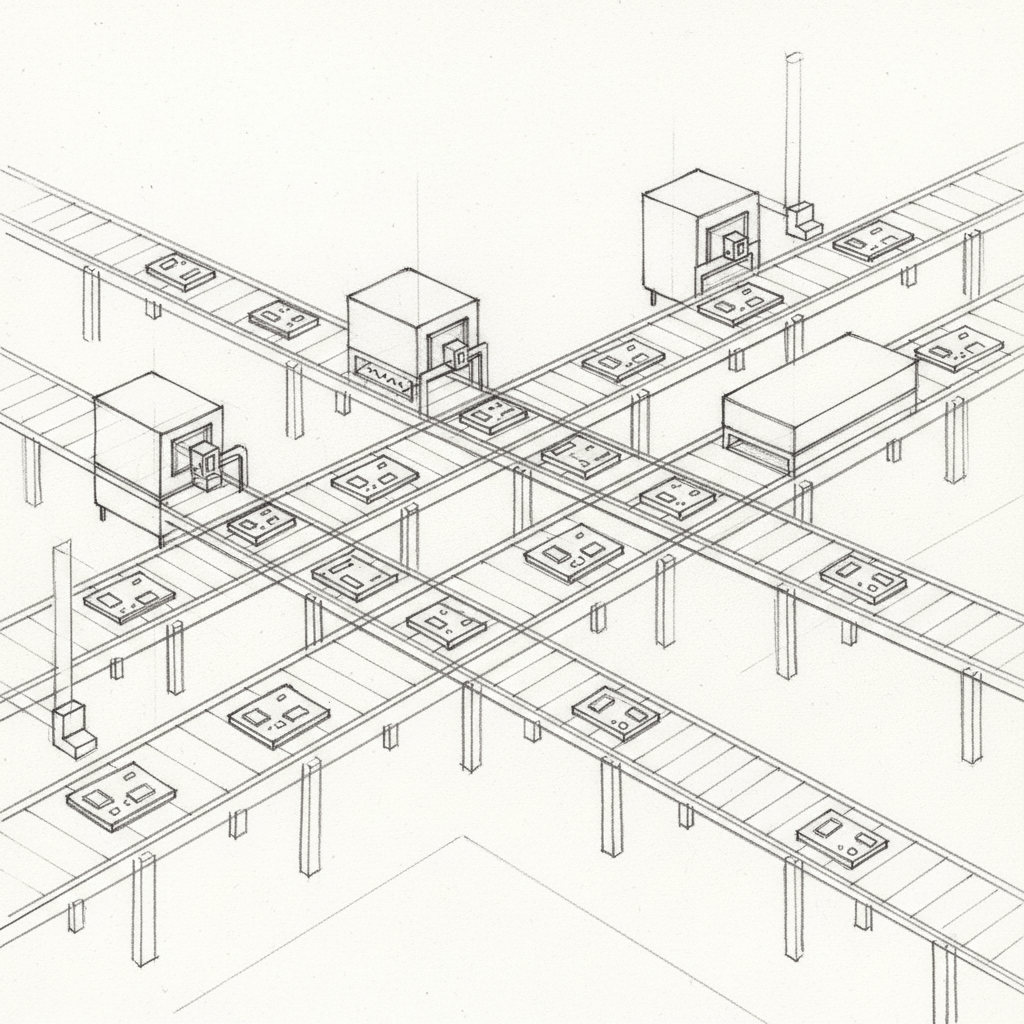

SMT Reflow Oven Basics Every Engineer Should Know

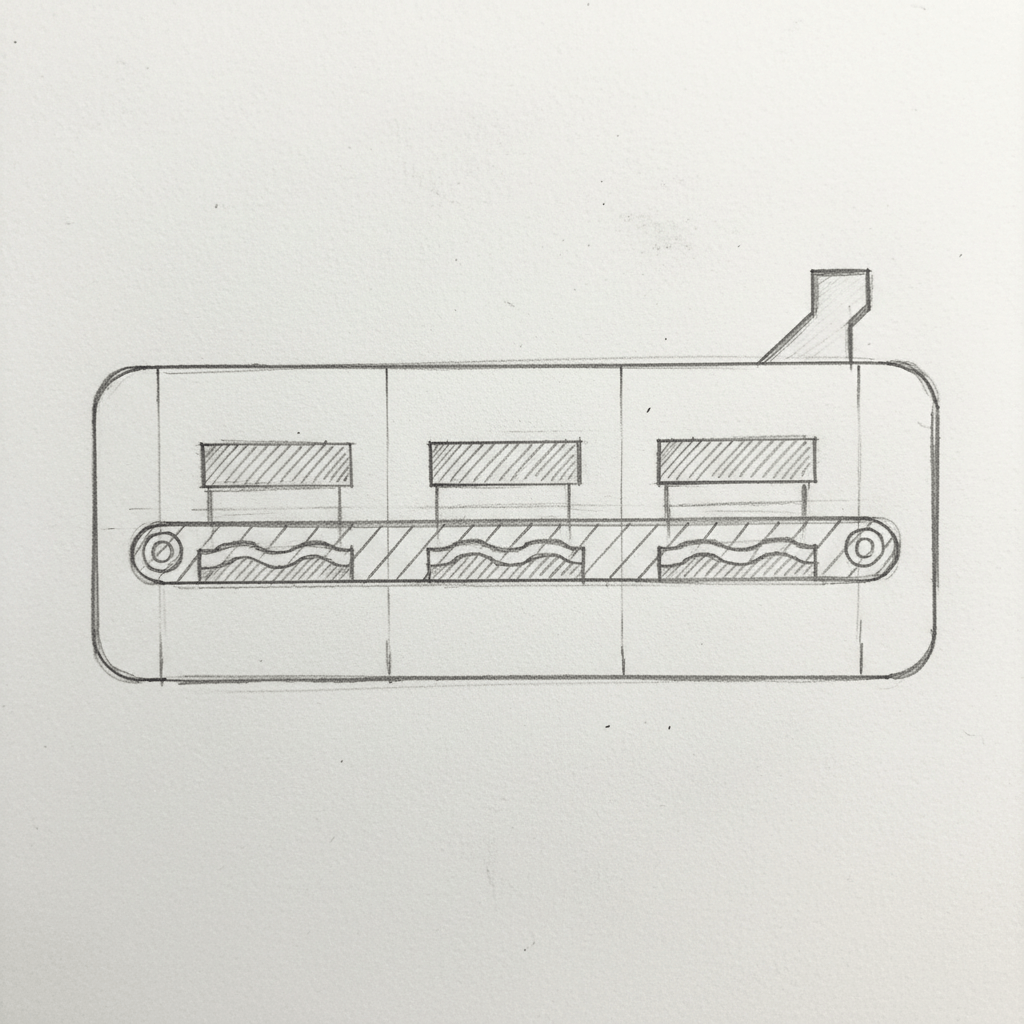

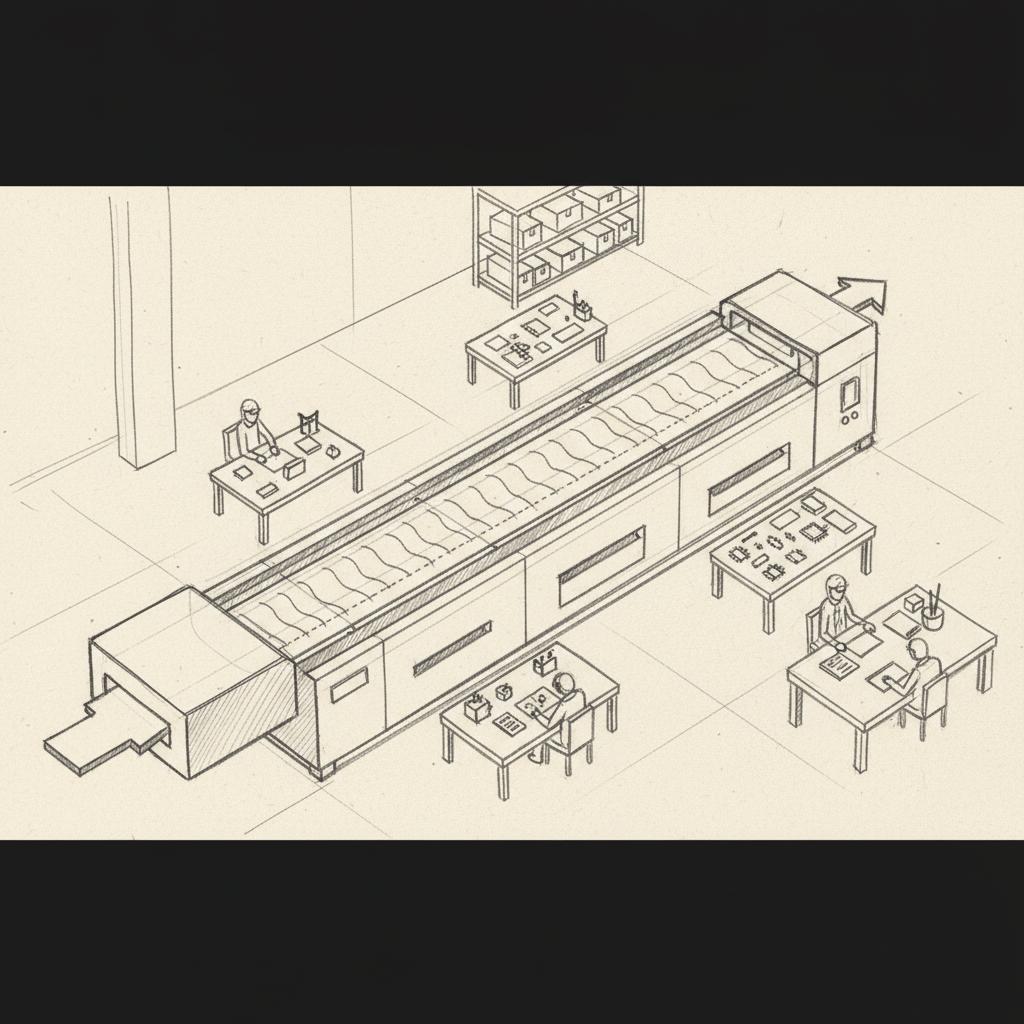

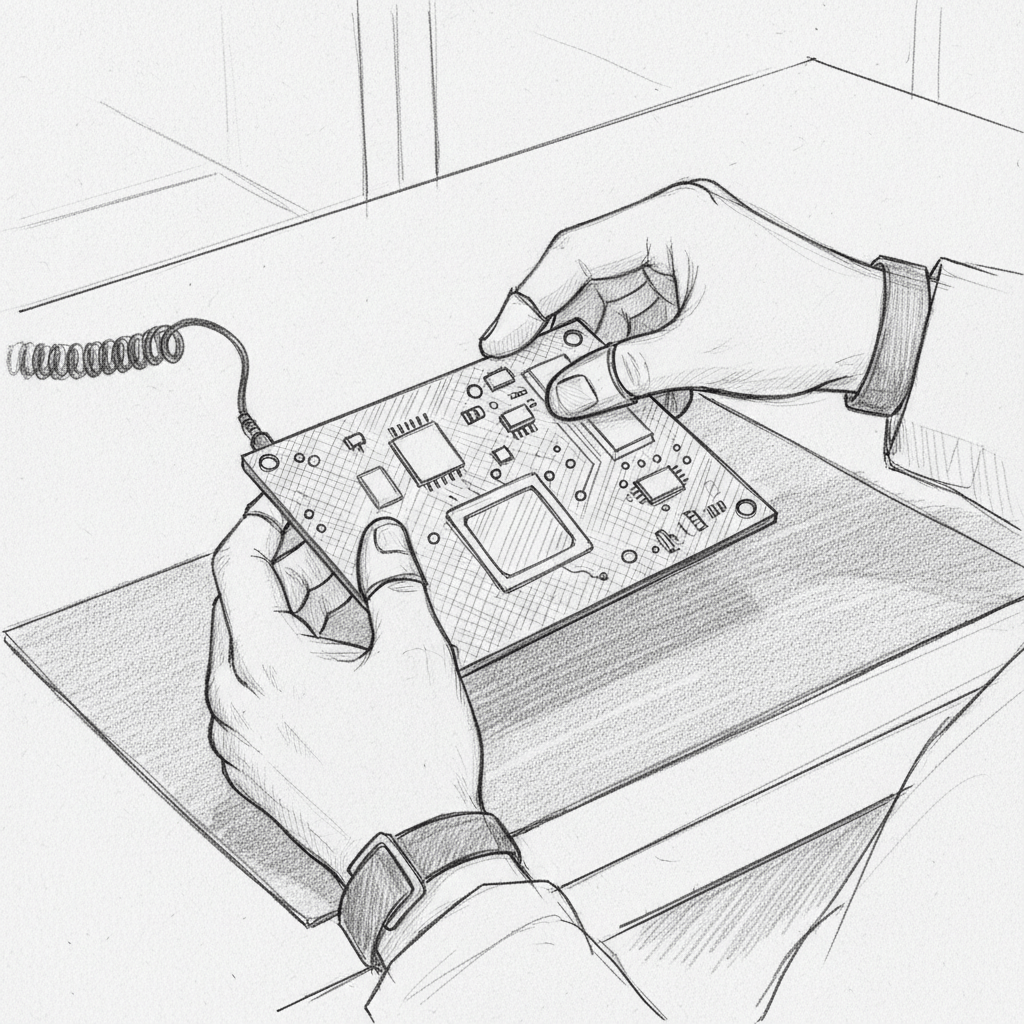

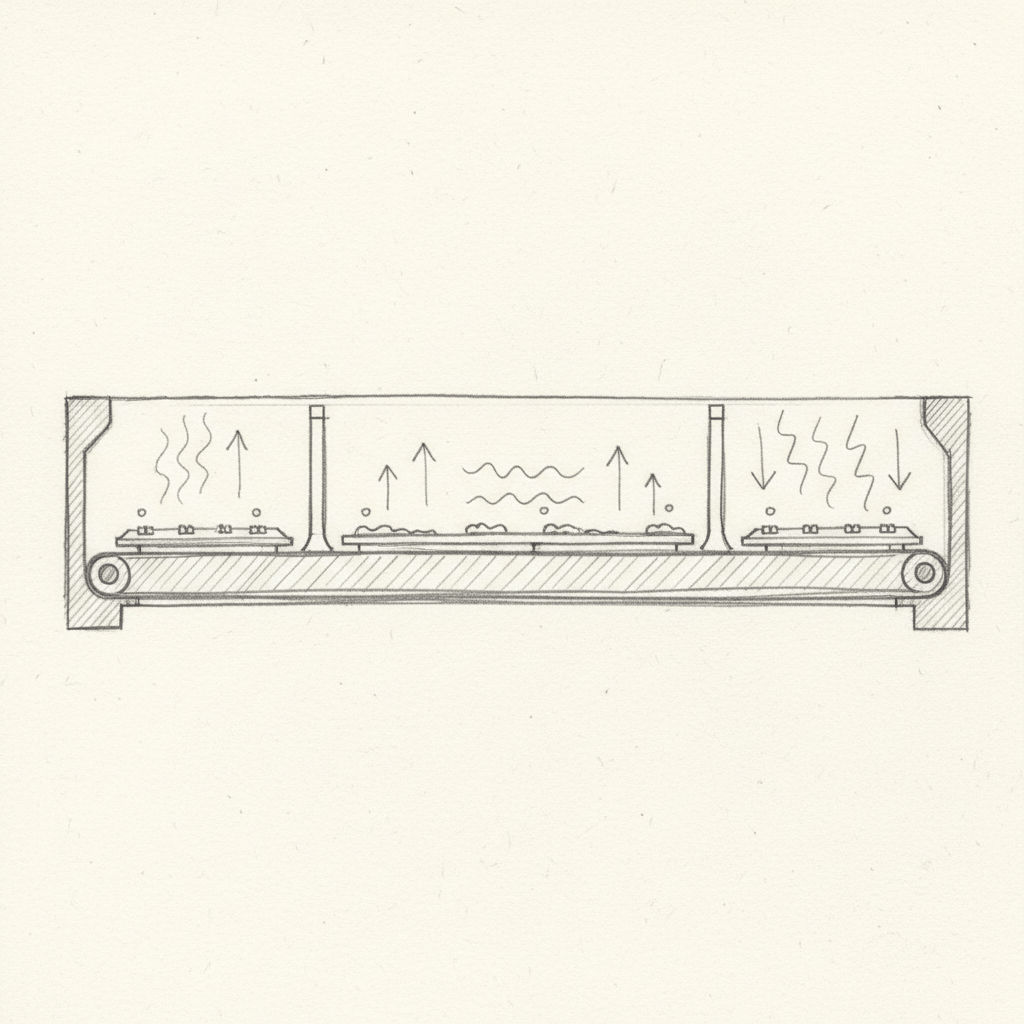

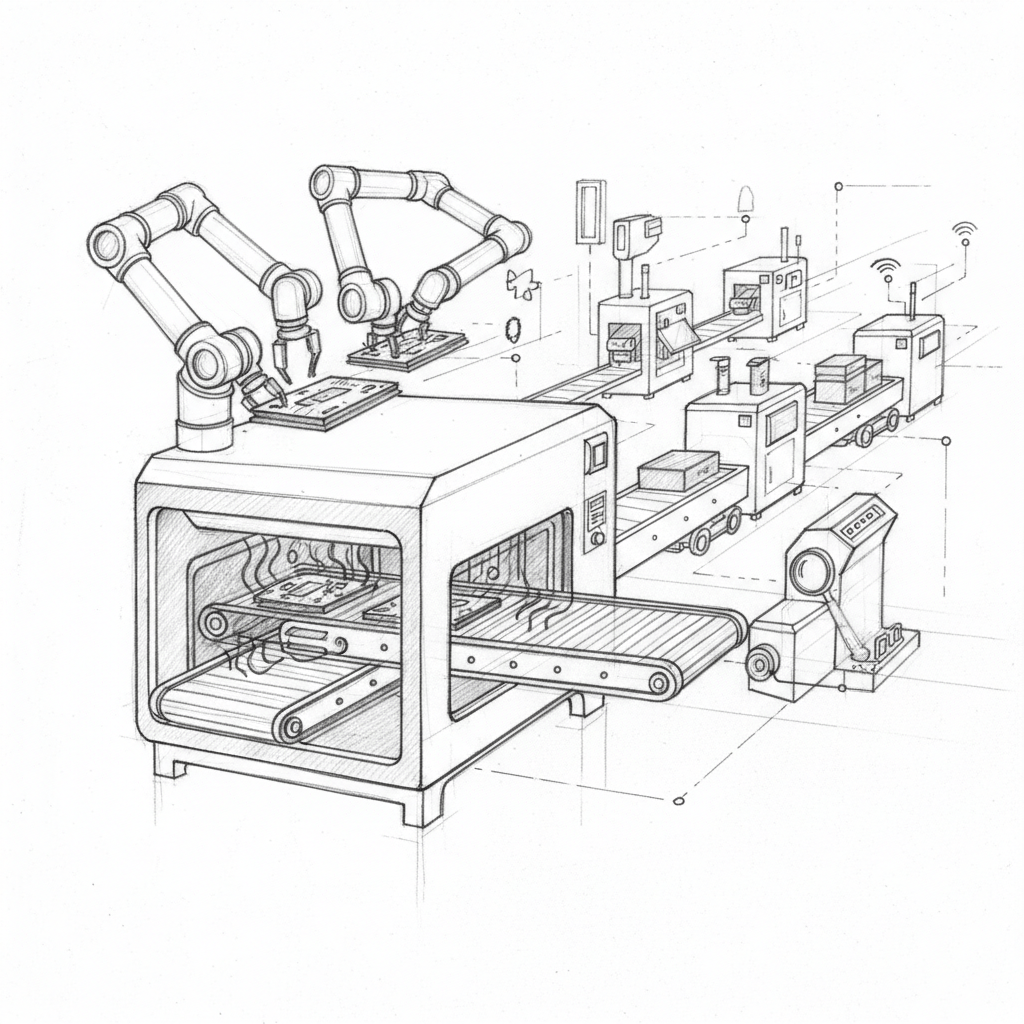

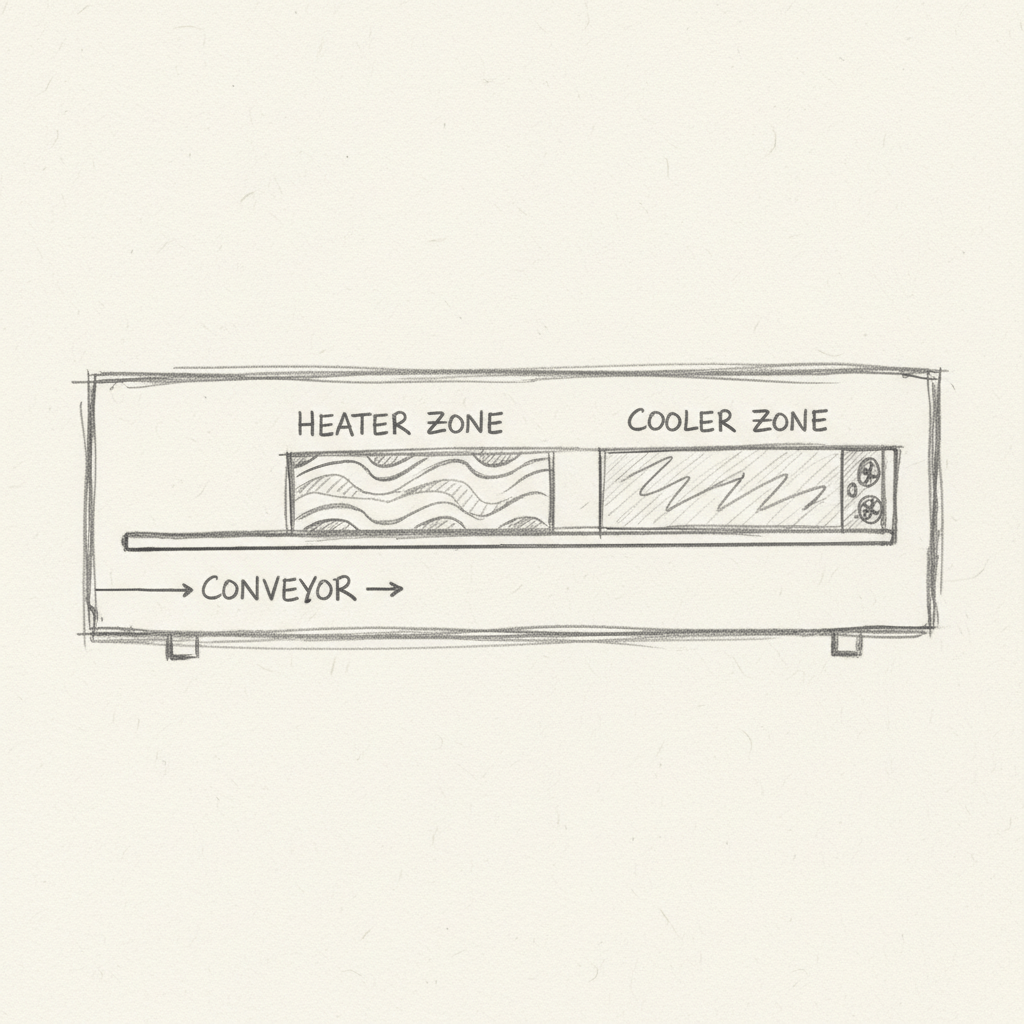

The blog article emphasizes the critical role of SMT reflow ovens in modern electronics manufacturing, highlighting their ability to enhance production quality and efficiency by automating the soldering process and reducing human error. It discusses the integration of AI and IoT technologies to enable smart features like predictive maintenance, aligning with Industry 4.0 standards. Key recommendations include focusing on precise temperature management and energy efficiency to minimize defects and operational costs. Manufacturers are encouraged to adopt advanced ovens, such as those from Shenzhen Chuxin Electronic Equipment Co., Ltd., to stay competitive and adaptable in the evolving market landscape.