Esplorare le tendenze future nella tecnologia dei caricatori PCB

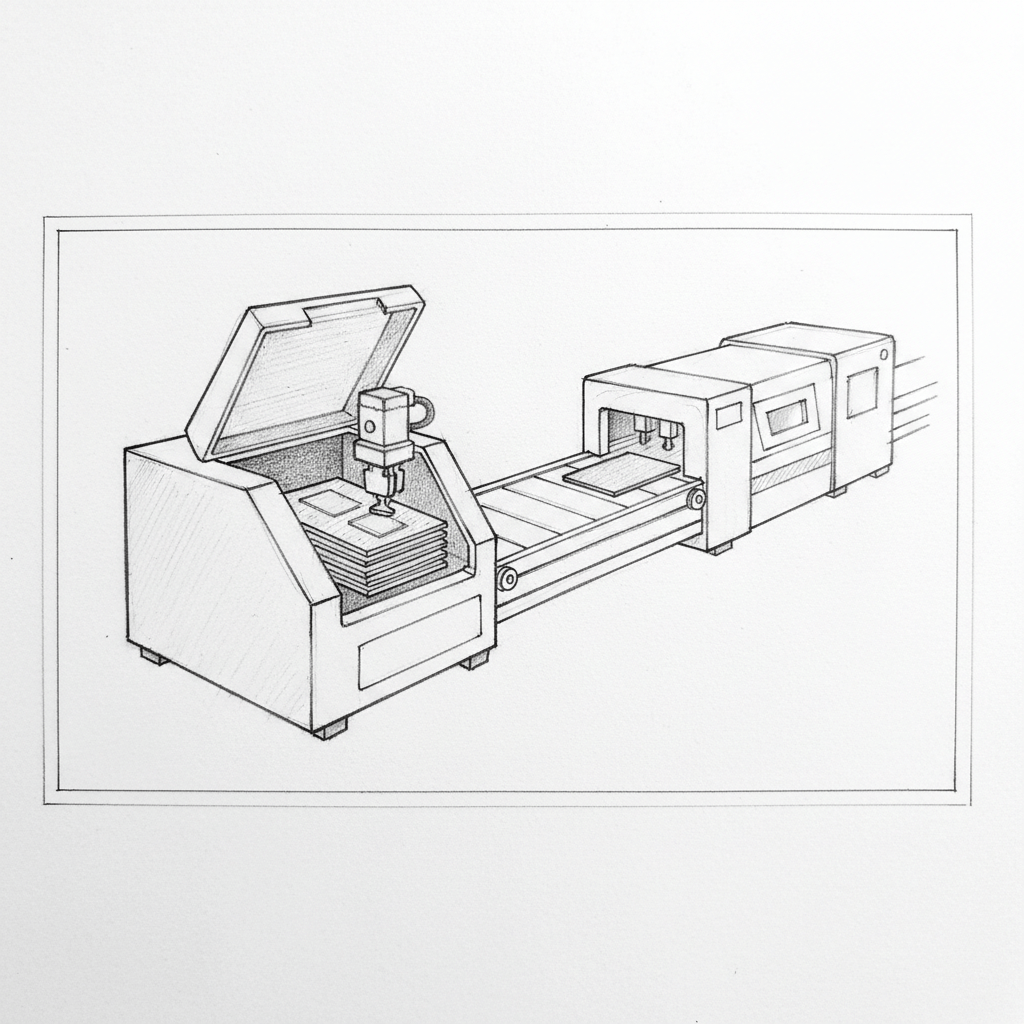

Printed circuit board (PCB) loader technology serves a pivotal role in the electronics manufacturing industry, particularly within Surface Mount Technology (SMT) lines. As of 2025, the demand for enhanced production efficiency and precision in electronics manufacturing underscores the importance of PCB loaders, crucial components that facilitate automated operations. By optimizing the feeding and alignment of PCBs, these systems significantly contribute to improved throughput, repeatability, and uptime, several key metrics of manufacturing success.