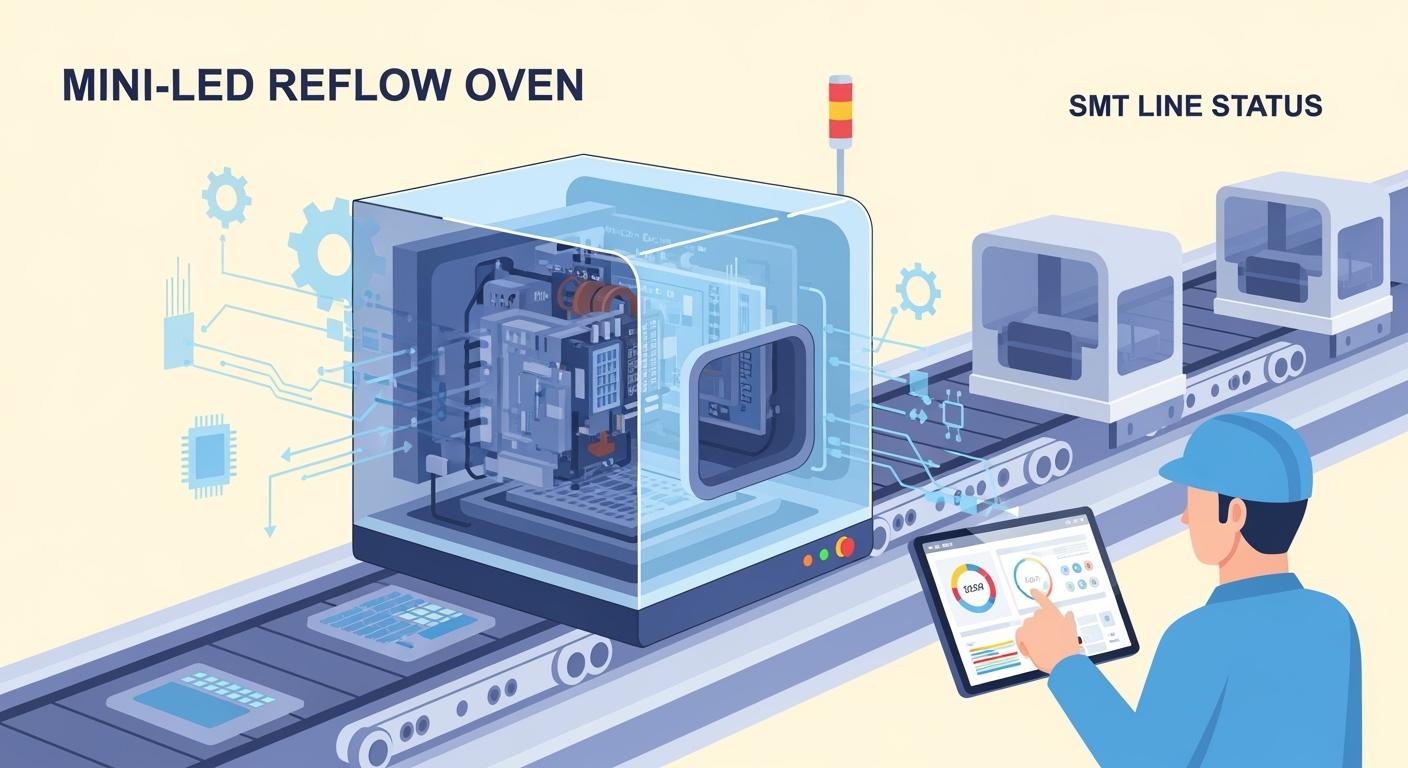

You usually see basic details when you pick a mini-led reflow oven for smt. Many hidden things change how well it works and how steady your process is. If you ignore these things, your production can fail. This can hurt quality and your role in making electronics. When you pay attention to equipment settings and quality checks, you make sure electronics are good. You can stop problems and make smt production better by knowing what really affects results.

Punti di forza

Calibrate your mini-LED reflow oven often. This keeps temperature and airflow steady. Good calibration helps make better solder joints. It also lowers the chance of defects.

Watch your thermal profile carefully. Keeping temperature even during soldering is important. It stops weak joints from forming. This makes your electronics work better.

Check airflow and heat spread in your oven. Good airflow stops cold spots from happening. It helps make strong solder joints. This is very important for mini-LED parts.

Use the correct solder paste for your parts. The right match helps make strong joints. It also stops problems during production.

Do regular maintenance and checks. This helps you find problems early. It keeps your reflow oven working well. This makes sure you get good quality products.

Calibration and Mini-LED Reflow Oven Performance

Importance of Accurate Calibration

You need to calibrate your mini-led reflow oven the right way. Calibration helps set the correct temperature and timing for each step. If you skip calibration or do it wrong, your soldering will not be good. This can make your electronics low quality. Good calibration stops problems in your production. It helps your SMT manufacturing stay steady and work well. When you calibrate, every PCB gets the same heat and airflow. This makes your results better and gives you fewer mistakes.

Detecting Calibration Issues

You can find calibration problems by looking at how soldering turns out. Some problems are uneven heating, parts coming off pads, and cold solder joints. These issues can cause mistakes and slow down your work. The table below lists common calibration problems, what they mean, and how to fix them:

Calibration Issue | Descrizione | Soluzione |

|---|---|---|

Inconsistent heating | Hot/cold spots on PCB | Adjust airflow and repeat profiling |

Component tombstoning | Parts lift off pads | Balance airflow and conveyor speed |

Giunti di saldatura a freddo | Solder does not melt fully | Slow down conveyor or increase zone temp |

Voiding defects | Gas pockets in solder | Fine-tune airflow and profile |

Tip: Check your oven often to find problems early. You can use tools to watch the temperature and airflow in your reflow oven.

S&M Solutions for Calibration Consistency

S&M gives you smart control systems to keep your reflow oven set right. The VS Series Lead-Free Nitrogen Type Hot Air Reflow Oven uses Siemens PLC and PID closed-loop control. This system keeps the temperature steady and the same every time. You can use Chinese or English on the Windows 10 screen, so it is easy to set up and check your oven. S&M’s design also makes fixing things simple, so you do not waste time on repairs. With these features, you get good calibration, better SMT results, and higher quality electronics.

Thermal Profile Uniformity in Reflow Ovens

Impatto sulla qualità della saldatura

It is important to keep the thermal profile even in your reflow oven. This helps make strong solder joints and good qualità della saldatura. When you control the temperature at each step, every part gets the right heat at the right time. Good thermal profiling gives you many benefits. Every part gets enough heat for strong soldering. The cooling step shapes the solder joint’s grain structure. Small grains make the bond strong and reliable. Fast cooling helps the solder joint stay tough and last longer. You can stop cold solder joints, tombstoning, and thermal voids. These problems can make solder joints weak and cause electronics to fail. If you do not use the right thermal profile, solder joints can be weak and soldering quality can drop. This can hurt your smt production and lower how well you make things.

Identifying Profile Variations

You can find thermal profile changes by checking important settings in your reflow oven. Use the table below to help you set up your reflow profile and get better soldering quality:

Descrizione | |

|---|---|

Temperatura di picco | The highest temperature during reflow soldering process. It melts the solder for good joints. |

Tempo sopra la liquidità (TAL) | How long the solder stays melted. This affects wetting and voiding in the solder joint. |

Velocità di rampa | How quickly the temperature rises. It controls the release of gases and helps avoid defects. |

Tempo di ammollo | Time at a set temperature before peak. It balances oxidation and voiding for better soldering. |

You should watch these numbers every time you do reflow soldering. This helps you find problems early and keep solder joints strong.

S&M Nitrogen Reflow Oven Advantages

S&M’s forno di rifusione ad azoto gives you better control for even heating. The VS Series uses Siemens PLC and PID closed-loop control. You get exact temperature control and the same soldering quality each time. The oven’s modular design makes fixing it easy, so your equipment works well. The new gas system helps heat move better and supports lead-free reflow profile setup. You can use Chinese or English on the Windows 10 screen, so setup is simple. With S&M, you get stronger solder joints, fewer failures, and better smt manufacturing.

Airflow and Heat Distribution in Reflow

Role in Mini-LED Soldering

It is important to know how airflow and heat work in the mini-led reflow oven. Airflow spreads heat over the PCB during soldering. Good airflow helps each solder joint get hot enough. If you control airflow, you stop uneven heating. This makes solder joints strong and safe. Mini-led soldering uses tiny parts that need even heat. If airflow is not managed, the temperature can change in different spots. These changes can make solder joints weak and lower the quality.

Detecting Airflow Imbalances

You can find airflow problems by looking at your soldering results. Watch for uneven heat or cold spots on the PCB. These signs can cause solder joints to fail. You might also see bridges or solder that is not finished. Use temperature sensors to check heat across the board. If you see temperature changes, you should fix your equipment. The table below shows what you should look for:

Symptom | Possible Cause | What to Do |

|---|---|---|

Uneven heating | Poor airflow | Adjust fan speed |

Weak solder joint | Cold spots | Check heater alignment |

Solder joint failure | Hot/cold zones | Re-profile temperature |

Tip: Check your oven often to find airflow problems early. This helps you stop issues before they hurt your smt production.

Optimizing with S&M Reflow Ovens

You can make your reflow oven work better with S&M equipment. S&M ovens use smart airflow control. This keeps heat even during soldering. You get strong solder joints and fewer mistakes. The system lets you change fan speed and zone settings. This helps you stop uneven heat and temperature changes. S&M ovens help you get good smt quality and steady production. You can trust your solder joints and lower the chance of problems.

Material Compatibility and SMT Performance

Solder Paste and Component Challenges

Choosing solder paste and surface-mount components is hard. The quality of solder paste changes how joints form. Some pastes work better with certain components. Using the wrong paste can make weak joints. This can cause your production to fail. Tiny components need the right paste to stop defects. You must check the solder paste type and each component’s material. Do this before you start reflow soldering. Good choices help you get strong joints and good smt performance.

Ensuring Compatibility in Reflow

You must make sure your materials fit your oven and process. You can use different ways to check solder joint quality. These tests help you avoid problems and failures. Here is a table that shows common ways to test material compatibility in smt:

Inspection Technique | Descrizione |

|---|---|

Visual Inspection | Operators look at solder joints under magnification to find defects. |

Automated Optical Inspection (AOI) | Cameras and software compare solder joints to design rules. |

X-Ray Inspection | Radiographic images show hidden solder joints and internal defects. |

Cut-Away Inspection | A sample component is cut open to see inside solder joints. |

Functional Testing | Electrical tests check if assemblies work as they should. |

You should use these tests during reflow soldering. They help you find problems with joints and components. Early checks stop defects and keep your production strong.

S&M’s Approach to Material Adaptability

S&M makes equipment that works with many pastes and components. Their reflow oven lets you control temperature and airflow. You can change settings for different materials. This helps you get strong solder joints. The oven supports advanced profiles for each paste and component. S&M’s system helps you stop defects and improve smt performance. You get good results and fewer failures in your production.

Environmental Controls for Reflow Oven Performance

Managing Ambient Conditions

You must control the area around your reflow oven. Room temperature, humidity, and airflow can change how soldering works. If the room is too hot or cold, the oven may not heat right. This can make solder joints weak and cause problems in smt production. High humidity makes soldering harder and can lower joint quality. Good airflow helps the oven work well and keeps the process steady.

Tip: Check room temperature and humidity every day. Use sensors to watch for changes that could hurt solder joints.

Monitoring and Control Strategies

You can use systems that watch the environment and oven in real time. These systems show changes in temperature and humidity right away. You can fix problems before they hurt solder joints. Real-time monitoring helps keep the soldering process steady. You can set alarms for quick changes. This helps stop defects and keeps joints strong. Use these ideas to make sure your smt process works well.

Real-time systems show temperature and humidity numbers.

Alarms warn you about changes that could hurt solder joints.

Quick action keeps the process steady and stops joint failure.

S&M Environmental Solutions

S&M gives you smart ways to control the oven’s environment. Their ovens use real-time systems to watch temperature and humidity. You can see numbers on the screen and change settings fast. S&M ovens help keep the process steady and improve joint quality. The design saves energy, lowers costs, and helps the planet. S&M supports green practices in smt making. You get strong joints, better quality, and steady performance.

Energy-saving ovens lower costs and help the planet.

Good temperature control makes soldering reliable for mini-LEDs.

S&M supports green production with smart technology.

Maintenance and Common Reflow Oven Faults

Preventive Maintenance Best Practices

You can keep your reflow oven working well by doing regular care. This helps stop sudden breakdowns and keeps solder joints strong. Clean the nozzles often so heat spreads evenly. Use thermal profilers to check the temperature on the PCB. This lets you fix hot or cold spots before they cause trouble. Keep the room at the same temperature and humidity. This helps your oven work better and makes good solder joints. Check and clean your oven in steps. Use X-ray inspection to find hidden problems in solder joints. Clean off flux with the right methods, especially for lead-free parts.

Preventive Maintenance Practice | Descrizione |

|---|---|

Ensure uniform heating | Clean nozzles and use multi-zone control to prevent hot/cold spots. |

Monitor in real time | Track temperature with thermal profilers and adjust as needed. |

Control Environmental Conditions | Keep room temperature and humidity steady for best performance. |

Rigorous Inspection and Cleaning | Inspect in stages and use X-ray for hidden solder joint defects. |

Clean thoroughly | Remove flux residues, especially for lead-free soldering. |

Tip: Make a cleaning and inspection schedule. This helps you find problems early and keeps solder joints strong.

Identifying and Addressing Faults

You should know the common problems that can happen with reflow ovens. If the blower fan breaks, airflow gets uneven and solder joints get weak. If the heater fails, the temperature changes and solder joints can break. If the conveyor is not set right, PCBs move wrong and soldering mistakes happen. Thermal spill problems mess up the heat and can hurt solder joints. If airflow is not even, heat does not spread right and joints get bad. If the cooling system fails, parts cool too fast or slow and can break. If the conveyor chain wears out, PCBs do not line up and solder joints shift. If the nitrogen supply stops, solder joints can get oxidized and need more fixing.

Fault | Descrizione | Impact |

|---|---|---|

Guasto al ventilatore | Inconsistent airflow, uneven heating. | Poor solder quality, more rework, higher rejection rates. |

Guasto al riscaldamento | Temperature inconsistencies. | Damaged components, reduced yield, weak solder joints. |

Deriva della calibrazione del trasportatore | PCB movement speed changes. | Solder bridging, cracked components, solder joint defects. |

Problema di fuoriuscita termica | Temperature gradient disruption. | Inconsistent soldering, increased defects, PCB damage. |

Incoerenze nel flusso d'aria | Uneven heat distribution. | Unreliable soldering quality, more product failures. |

Guasto al sistema di raffreddamento | Rapid or uneven cooling. | Component damage, costly rework, rejected units. |

Conveyor Chain and Sprocket Wear | Inconsistent PCB movement. | Solder defects, misalignment, component shift, production delays. |

Nitrogen Supply System Failure | Oxidized solder joints in nitrogen ovens. | Reduced solder quality, more rework, product failure. |

Note: Watch for these problems when you run smt production. Fixing them fast helps keep solder joints strong.

S&M’s Maintenance Features

S&M reflow ovens are easy to fix and keep working well. The modular design lets you change parts fast, so repairs take less time. You get alarms with sound and light for common problems. These alarms warn you if the blower fan, heater, or conveyor has trouble. Real-time systems show you temperature and airflow changes right away. You can change settings quickly to protect solder joints. S&M ovens let you do online maintenance, so you can clean and check things without stopping work. These features help you keep soldering steady and your smt line running well.

S&M’s smart tools help you stop failures and keep solder joints strong. You get better results and fewer problems in your work.

Automation and Process Consistency in Mini-LED Reflow

Benefits for SMT Performance

Utilizzo automation in your mini-led reflow oven helps smt work better. Automation keeps each step the same every time. Automated controls make sure temperature and airflow do not change. This helps solder joints stay strong and have fewer problems. You do not have to worry about people making mistakes or forgetting steps. Automated systems watch the oven and change settings fast if needed. This gives you strong solder joints and makes your smt line work well.

Studies show automation really helps keep the process steady. The table below shows how different automated features help your work:

Descrizione | Impact on Process Consistency |

|---|---|

Multi-zone reflow soldering ovens manage thermal gradients effectively | Ensures gradual and uniform heating, reducing thermal stress and defects |

BGA Rework Stations provide precise control over temperature and airflow | Maintains integrity and performance of electronic assemblies |

Advanced soldering technologies are crucial for automotive electronics | Ensures reliability and safety of electronic systems under various conditions |

Automated reflow ovens help stop thermal stress and keep solder joints strong. They also help with hard jobs and tough places.

Tip: Use automated monitoring to find problems early. This helps you fix things before they hurt solder joints.

S&M’s Automation Capabilities

S&M puts smart automation in every reflow oven. You can set up the oven with Windows 10 and pick your language. Siemens PLC and PID closed-loop control keep temperature and airflow steady. Alarms warn you about problems so you can fix them fast. You can change fan speed and zone settings for each job. Real-time monitoring lets you watch the process and make changes quickly. S&M’s automation helps you keep solder joints strong and avoid problems in smt work. You get better soldering, strong joints, and steady results every time.

Case Studies: S&M Reflow Oven Success Stories

Overcoming Hidden Factors

When you use a forno a rifusione, hidden things can change your results. Some people had problems with solder joints before using S&M ovens. One team saw weak solder joints and heat was not even. They checked their work and found airflow was not right. After they got an S&M reflow oven, they used smart controls to fix fan speed and heat zones. This made solder joints better and stronger.

Another group had trouble with solder joint problems during smt work. They could not keep the heat profile steady. S&M’s reflow oven helped them set the right temperature. They used real-time checks to spot changes fast. This cut down on problems and made solder joints better.

Note: You can fix many hidden problems by using smart features in your reflow oven. S&M ovens give you tools to watch and change your process.

Real-World Results in SMT

You can learn from real smt lines that use S&M reflow ovens. One factory wanted better solder joints for mini-LED boards. They set up the oven with special profiles for each solder paste. This gave them stronger solder joints and fewer problems. Another company needed better results for medical devices. They used S&M’s oven to keep things steady. Their solder joints got better and they had less rework.

S&M reflow ovens help you make strong solder joints.

You can get better solder joints and have fewer problems.

Real-time checks help you keep your smt line working well.

Tip: You can get great solder joints by using the right oven and watching your process closely.

You can make your SMT work better by looking at hidden things in your reflow oven. Good solder joints need the right thermal profiles, airflow, and materials. Check your oven often and use smart controls to keep things steady. Follow this checklist to help your work and stop mistakes:

Recommendation Type | Descrizione |

|---|---|

Design Optimization | Help clients with DFM to make spacing, heat flow, and alignment better. |

Controlled Processes | Watch solder paste thickness, oven temperature, and how parts are placed. |

Movimentazione dei materiali | Bake all PCBs to dry them and pick the right solder paste for your design. |

Inspection and Testing | Use AOI, X-ray, and tests to find problems early and make sure things are built right. |

Keeping your oven steady and settings right helps you get strong solder joints. Early checks let you fix issues before they get worse. Check your SMT process often to keep solder joints good and your production working well.

FAQ

How often should you calibrate your mini-LED reflow oven?

You should calibrate your oven every three to six months. Regular calibration helps you keep temperature and airflow steady. This practice reduces defects and improves solder joint quality.

What signs show your oven needs maintenance?

Look for uneven heating, strange noises, or error alarms. You may see weak solder joints or more failed boards. These signs mean you should check and clean your oven soon.

Can S&M reflow ovens handle different solder pastes?

Yes, S&M ovens let you adjust temperature and airflow for many solder paste types. You can set custom profiles for each paste. This flexibility helps you get strong solder joints.

Why does airflow matter in mini-LED soldering?

Airflow spreads heat across the PCB. Good airflow gives you even heating. Weak airflow causes cold spots and poor solder joints. You should check fan speed and zone settings often.