Unlocking the Benefits of Vacuum Reflow Ovens for High Reliability PCBs

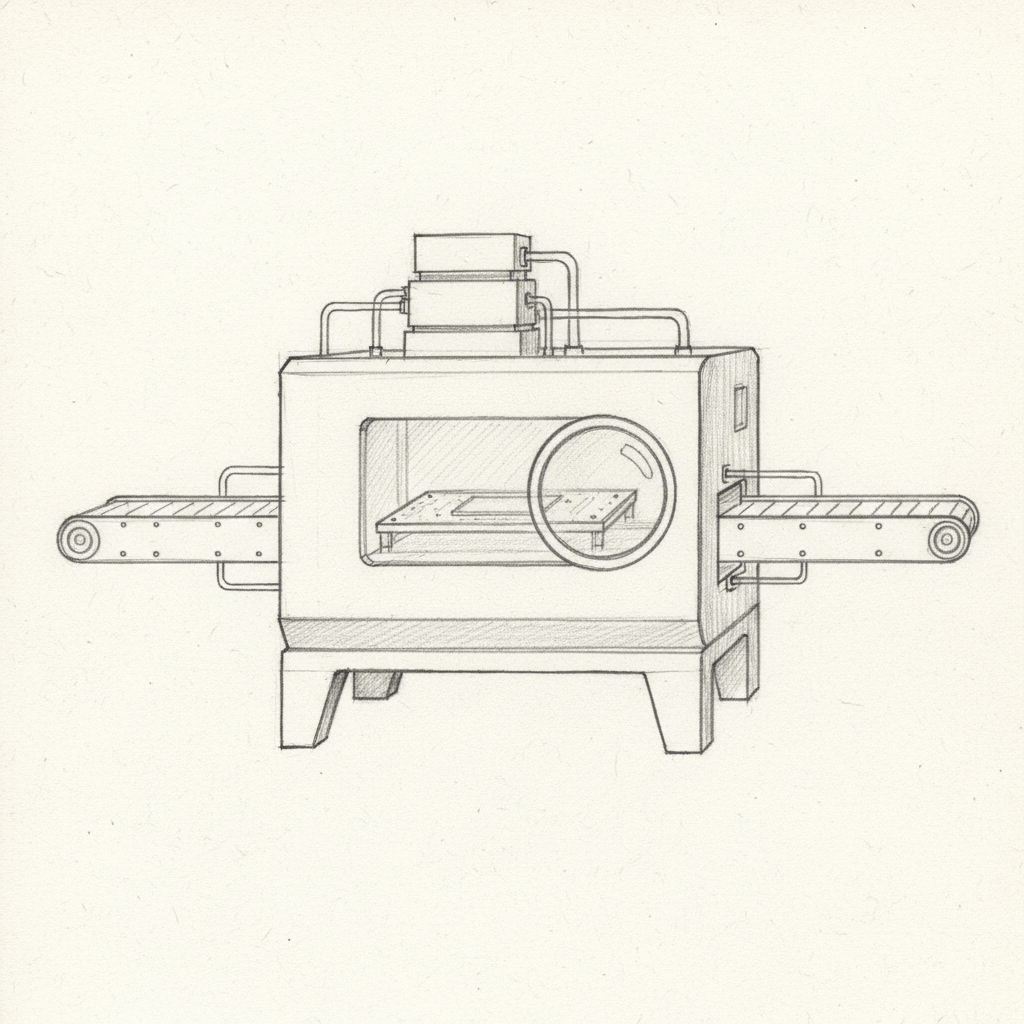

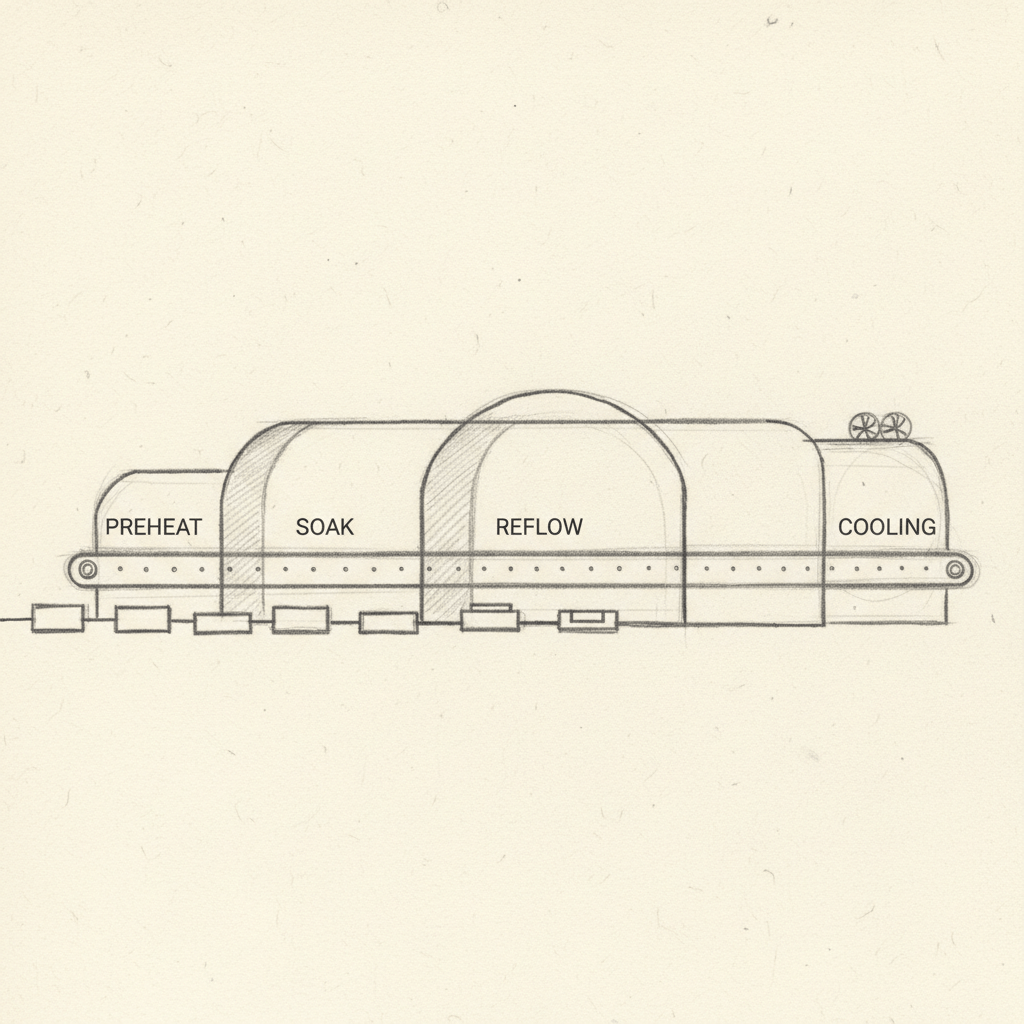

Vacuum reflow ovens have emerged as essential tools in PCB manufacturing, particularly for industries like automotive, aerospace, and medical devices that require high reliability. By implementing vacuum conditions during the soldering process, these ovens significantly reduce voids in solder joints, enhancing the mechanical and thermal integrity crucial for demanding applications. The integration of smart technologies such as AI-driven controls and real-time monitoring into these systems has increased production efficiency, optimized thermal management, and reduced defect rates. Manufacturers are advised to prioritize vacuum reflow technology for its long-term benefits, including cost efficiency and operational reliability, solidifying its role as a critical component in modern PCB production.