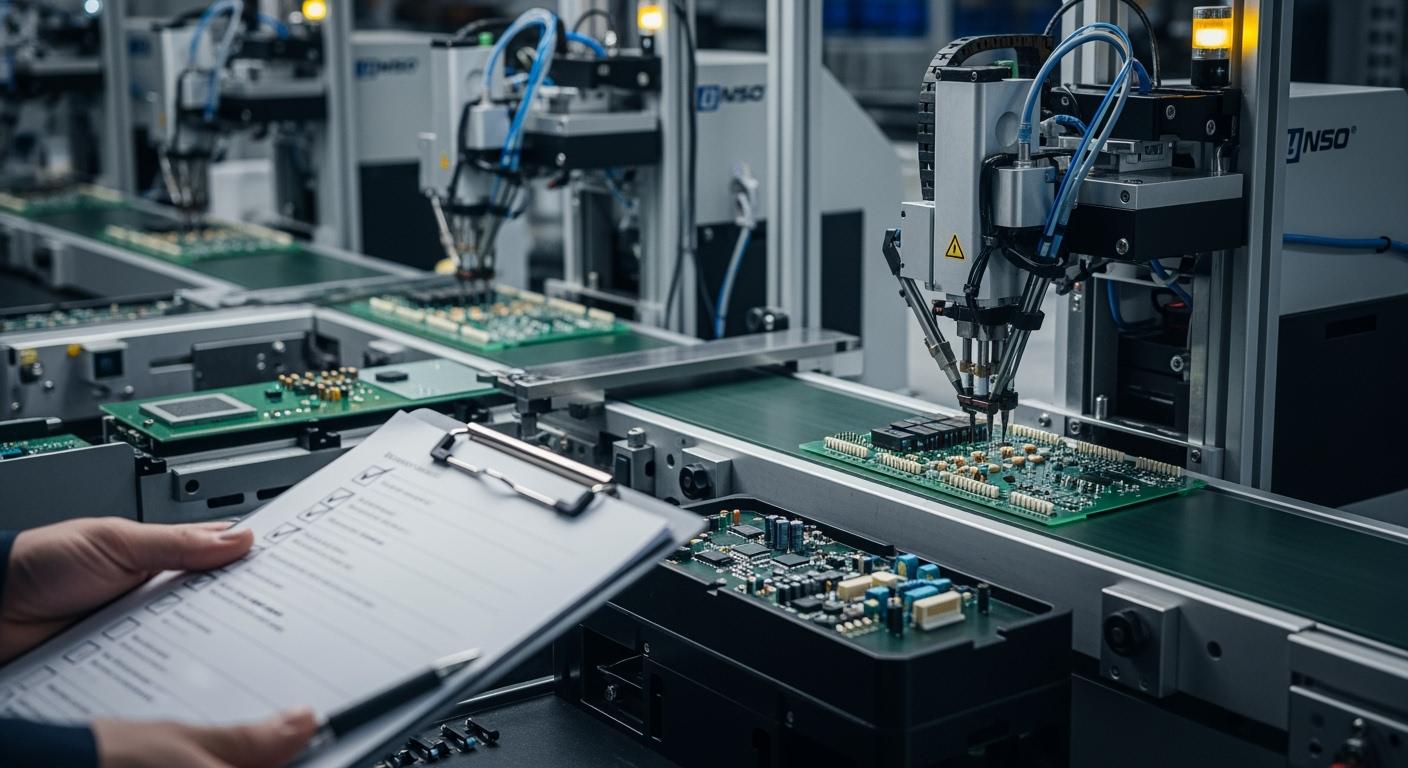

You want your factory to do even better. A smart upgrade to your smt line gives you better surface mount technology and makes assembly quality higher. You get more work done and get ready for new problems. Picking the right partner like S&M helps you get good solutions you can trust. Use the smt line guide to make good choices that help you reach your goals.

要点

Find slow spots in your SMT line by looking at how work moves and checking important numbers. This helps you make things faster and better.

Check your machines and how you work by using numbers like First Pass Yield and Overall Equipment Effectiveness. This helps you choose the best upgrades.

Think about growing in the future by looking at how much space and computer systems you need. This stops problems when you add new machines or technology.

Make your work steps better to cut down on waste and help people get more done. Ask your team to help so you get the best results.

Watch your SMT line all the time and fix things before they break. This keeps everything working well.

Assess SMT Line Performance

Identify Bottlenecks

You want your smt line to work well. Bottlenecks make things slow and less efficient. First, draw out each step in your process. This lets you see where things get stuck. You can check numbers like cycle time and throughput. These numbers tell you which machines or steps are slowest.

Here are some ways to find bottlenecks:

方法 | 説明 |

|---|---|

Analyze the Workflow | Draw the whole process to see how it works and how long it takes. |

Measure Key Metrics | Watch numbers like Cycle Time, Throughput, and Utilization Rate to find slow spots. |

Use Data Visualization Tools | Use tools like Gantt charts and value stream maps to see the process and spot problems. |

Conduct Time Studies | Time how long tasks take and compare to what is normal. |

Interview Employees | Ask workers for their ideas about delays and problems. |

Simulate Production Scenarios | Try out different situations with software to find possible bottlenecks. |

You can also ask your team for help. Workers often see problems before bosses do. Try using simulation software to test new ideas. This can help you find hidden problems in your smt line.

Evaluate Equipment and Processes

You need to see how well your smt equipment and steps work. Look at important numbers to check how good things are. These numbers help you know what to fix.

First Pass Yield (FPY): Shows how many assemblies pass all tests the first time.

Defect Per Million Opportunities (DPMO): Counts mistakes in a million chances.

Placement Accuracy: Checks if parts are put in the right place.

Solder Joint Quality: Measures how strong and good the solder joints are.

Line Utilization: Tells you how much you use your smt line.

Overall Equipment Effectiveness (OEE): Finds losses from breakdowns, setup problems, and bad quality.

Overall Resource Effectiveness (ORE): Looks at if you have enough materials and workers.

You can use a table to keep track of what you find:

Metric | 説明 |

|---|---|

First Pass Yield | Shows the percent of products that pass checks the first time; high FPY means things work well. |

Defect Density | Number of mistakes per area of PCB; helps find quality problems. |

スループット | Number of items made in a set time; shows how fast the line works. |

Machine Utilization | How well machines are used; high use means more work gets done. |

生産効率 | Looks at waste, downtime, and labor costs; helps you see how well production goes. |

You can make your line better by watching these numbers. High efficiency means you need fewer workers and can place more parts. When you know your numbers, you can make better choices for your smt line.

SMT Line Upgrade Planning

Space and Expansion Needs

You want your smt line to grow as your business grows. Planning for space is very important in the smt line guide. Look at your current setup and think about what you might need later. If you add new machines, you might need more room for materials and workers to move. S&M gives you smt line solutions that can fit many factory sizes. These solutions help you get ready for growth.

Impact Type | 説明 |

|---|---|

Expanding costs a lot because of building, permits, and stopping work. It can be hard to find more space close by. | |

Not enough space can slow down how materials move. This makes handling take longer and lowers how much you make. |

Use the smt line guide to see if your building can fit new equipment. Planning for enough space now helps you avoid problems later. This keeps your production smooth and working well.

IT Infrastructure and Software

Your smt line guide should check your IT systems. New smt lines need strong IT to run new software and automation. You want to see data right away so you can make quick choices. This helps you keep production on track. Smart factory tools let you watch dashboards from anywhere. S&M’s smart equipment connects easily to these systems.

Evidence Type | 説明 |

|---|---|

You get live data to help you make fast choices. | |

Smart Factory Integration | You can link your smt line to dashboards and control systems far away. |

Automation Software | Better software helps you make production better and guess less. |

Predictive Maintenance with AI | AI tools warn you about machine problems before they stop work. |

Think about using cloud tools and fixing problems from far away. These features help you stop downtime and keep your smt line working. Yearly checks and software updates help your systems stay strong. The smt line guide helps you match your upgrade to future goals and new tech.

Tip: Always plan your smt line upgrade for what you will need later. Use the smt line guide to make sure your space, IT, and software are ready for new work.

Equipment Selection for SMT Line

Compatibility with Existing Systems

When you pick new machines for your smt line, they must work well together. You should check if the machines fit in your space. Make sure your power setup matches what the machines need. Your pcb assembly area needs the right ESD setup and good HVAC conditions. If you do not check these things, you could have problems later. S&M gives you solutions that help you add new machines easily. You can look at technical details and interface needs before buying. Manufacturers can help you check if everything works together. You can talk to vendors about any problems with connecting new machines.

Make sure your new machines fit in your space.

Make sure your pcb assembly area has the right ESD setup.

Check the HVAC conditions for your smt line.

You want everything to connect without trouble. S&M gives you advice and smart machines that connect easily. This helps your pcb assembly keep running well.

High-Speed and Advanced Equipment

You want your smt line to be faster and better. High-speed machines help you finish more pcb assemblies quickly. S&M has advanced pick-and-place machines, stencil printers, and reflow ovens. These machines make solder paste printing better and help you make more products.

Equipment Type | Impact on Production Throughput |

|---|---|

Pick-and-Place Machines | Help put parts on boards fast and right |

Stencil Printers | Make putting on solder paste quicker and easier |

リフロー炉 | Make soldering better and improve quality |

Inspection Systems | Check for mistakes and help stop defects |

You can pick high-speed machines with special imaging technology. You can use 3D inspection to check things faster. Some inspection systems can check up to 150 cm² every second. Faster and more accurate smt machines help your line grow and handle more work.

When you choose a vendor, look for one with a good name and lots of experience. You want strong support and easy ways to get spare parts. S&M has a good history and meets industry rules. You can ask other customers what they think. Good vendors help your pcb assembly line work with less downtime.

Tip: Always check if you can get long-term help and service when you upgrade your smt line. This keeps your pcb assembly strong and ready for new work.

Process Optimization for Productivity

Lean Workflow Improvements

You can help your smt line work better with lean workflow changes. Lean methods help you find waste and remove it from your process. First, plan with your team. Make sure everyone knows the goal. Ask your team to share ideas. Next, take action and watch what happens. After you finish, look at what worked. Celebrate when you make progress.

Here are steps for lean workflow improvements:

Give value to your customer.

Find waste in your smt line and remove it.

Make small changes often to get better.

Train your team and include everyone.

Watch for these seven types of waste:

Transportation

Inventory

Motion

Waiting

Overproduction

Overprocessing

Defects

Set up clear steps and checkpoints for your process. Standard procedures help keep quality high. Training helps your team use equipment well. It also helps them spot problems early. Lean methods help you see real improvements in your smt line.

Tip: Teamwork and talking openly help lean upgrades work better. Celebrate small wins to keep your team happy.

Material Handling and Automation

You can make your smt line more productive by improving how you move materials. Automated systems like conveyors and robots move parts fast and safely. These systems lower mistakes and help you finish assembly faster.

Benefit of Automation | How It Helps Your SMT Line |

|---|---|

Fewer manual errors | Automated systems deliver materials just in time. |

Faster material flow | Robots and conveyors reduce extra movement. |

Better tracking and control | Smart software keeps materials organized. |

Automated material handling cuts down on waiting and wasted steps. Advanced smt lines use smart shelves and robots to bring parts when needed. This keeps assembly moving and helps you reach higher productivity. Automation also makes it easier to track materials and plan upgrades.

Software Integration in SMT Line Guide

MES/ERP Compatibility

You want your smt line to work well with your business systems. MES and ERP help you control production, inventory, and quality. When you link these systems, you can manage your smt process better. But connecting them can be hard. The table below shows some problems you might face:

Challenge | 説明 |

|---|---|

Disparate Systems and Data Formats | Different vendors use different data formats, making it hard to connect everything. |

Complexity of Manufacturing Processes | Each smt line may have unique steps, which makes integration more difficult. |

Compliance and Data Security | You must keep your data safe and follow rules when you combine systems. |

Resistance to Change | Some workers may not want to use new systems, slowing down the process. |

Lack of Skilled Personnel | You need trained people to set up and manage integration. |

Costs and Budget Constraints | Integration can cost a lot, especially for smaller companies. |

Scalability | Your systems must grow with your business. |

Customization Requirements | Tools that do not fit your needs can slow down your smt line. |

Data Accuracy and Duplication | Mixing data from different sources can cause mistakes or double entries. |

Dependency on Vendor Support | You may need help from vendors to keep your systems running well. |

Interoperability with Third-Party Applications | Your systems must work with other special tools you use. |

You also need to keep your data matching in all places. This helps you know what parts you have and plan your work. Security is important because you use private information. Real-time data helps you make fast choices and keeps your smt line working well.

Real-Time Monitoring

You can use real-time monitoring to watch your smt line as it works. This software collects data from your machines and shows you what is happening right now. You can spot problems early and fix them before they grow. Real-time monitoring helps you keep your smt line running at its best.

The Smart Inspect app finds defects as soon as they happen. It checks trends and helps you stop quality issues before they spread. This means fewer mistakes and less rework.

camLine MES makes sure each step in your smt process happens at the right time. This reduces errors and keeps your production reliable.

QualityLine brings together data from all your equipment. You can see where things slow down or go wrong. This lets you fix problems fast and improve your yield.

Tip: Use real-time monitoring to catch issues early and keep your smt line working smoothly. You will see better quality and higher output.

Operator Training and Change Management

Upskill for New Technologies

必要なのは skilled operators to run your smt line well. When you add new technology, your team must learn how to use it. Hands-on training helps the most. You can set up workshops for your products and processes. These workshops let your team practice with real equipment. Training that matches your factory’s needs works better.

A good training plan teaches the skills operators need most. You can check your team’s skills to find what they need to learn. Then, you make lessons for those skills. This way, you use your training budget wisely. Operators learn to spot problems and fix them fast. Supervisors also learn more about the smt process.

Tip: Custom workshops and hands-on practice help your team learn. People feel sure of themselves when they know how to use new machines.

Minimize Downtime

You want your smt line to keep working during upgrades. Downtime costs money and slows production. You can plan upgrades in steps to lower downtime. This lets you add new technology slowly. Your line keeps running while you make changes.

Software and hardware updates help stop problems. For example, new software can check itself for issues. These checks warn you before your line stops. Sometimes, you need extra hardware to keep things working well.

Here is a simple table to show ways to lower downtime:

Strategy | ベネフィット |

|---|---|

Keeps production moving | |

Software self-checks | Finds problems early |

Hardware improvements | Supports smooth operations |

You can train your team before you start upgrades. This way, operators know what to do if something goes wrong. You keep your smt line working and avoid long stops.

Measures to Improve SMT Assembly Quality

Quality Control Upgrades

You want your smt assembly to be the best it can be. S&M works hard to keep quality high. They have certifications like ISO 9001 and SMTA. These show S&M follows strict rules for smt assembly. You can trust their solutions to help you reach your goals.

Strong quality control helps your smt line do better. 自動光学検査 (AOI) checks each board for mistakes. AOI finds parts in the wrong place and spots defects early. Use Statistical Process Control (SPC) to watch for problems. Calibrate pick-and-place machines often to keep them accurate. This lowers defects in solder paste printing. Clean surfaces and careful soldering stop soldering defects. Follow DFM guidelines and pick good components to avoid errors.

Tip: Keep your smt line clean and teach your team to find problems. This keeps quality high and cuts down on rework.

Certification | メリット |

|---|---|

ISO 9001 | Makes sure quality management is strong and standards are high. |

SMTA | Helps engineers learn more and sets a high bar for quality. |

Inspection and Testing Solutions

You need good tools to check your smt assembly for quality. AOI uses 3D imaging to check polarity, orientation, and soldering. X-ray inspection finds hidden problems in solder joints. In-circuit testing checks if every part works and is in the right spot. Flying probe testing helps with small batches and prototypes. Thermal imaging finds hot spots that show bad soldering. Boundary scan testing works for boards with hard-to-reach places. Functional testing makes sure your assembly works in real life.

Inspection Method | 説明 | Effectiveness |

|---|---|---|

自動光学検査 (AOI) | Checks placement, polarity, and soldering with 3D imaging. | Finds problems early and makes accuracy better. |

X-Ray Inspection | Finds hidden flaws in solder joints. | Spots inside defects with high accuracy. |

In-Circuit Testing (ICT) | Tests placement and function of components. | Makes sure all parts work and connect. |

Flying Probe Testing | Uses probes for small runs and prototypes. | Fast checks for small batches. |

サーマルイメージング | Finds heat problems and bad soldering. | Spots issues while working. |

Boundary Scan Testing | Uses built-in features for complex boards. | Works well for hard-to-reach spots. |

Functional Testing | Simulates real use to check performance. | Finds problems in real conditions. |

You can use these steps to make smt assembly quality better and keep production strong. S&M’s advanced equipment and focus on accuracy help you get great results.

Maintenance and Reliability

Preventive Maintenance

You want your smt line to work well every day. Preventive maintenance helps stop machines from breaking down suddenly. It also helps your machines last longer. When you check your machines often, you can find problems early. This means you fix small things before they get worse. You save money because you do not have to fix big problems.

Preventive maintenance stops surprise breakdowns and keeps machines running.

Cleaning and adjusting your smt equipment helps it last longer.

You do not have to pay for big repairs that stop your work.

If you skip maintenance, you might spend a lot of money. For example, if a machine breaks, you could lose 80,000 RMB on parts and 20,000 RMB on wasted material. If you plan ahead, you only spend about 20,000 RMB on spare parts. You also do not lose much time. Doing regular maintenance helps you avoid big losses and keeps your smt line working well.

You can use predictive maintenance tools to watch your machines. These tools tell you about problems before they happen. You can control your production better and keep your assembly moving.

Tip: Make a schedule for preventive maintenance. Use predictive maintenance software to find problems early.

Spare Parts and Service

You need the right spare parts to keep your smt line working. Good spare parts management helps you fix machines quickly. This stops long delays. You can use past data to guess what parts you will need. Build good relationships with suppliers so you get parts fast.

Keep important motors and parts in your factory or with your vendor.

Think about the cost of storing parts and the cost of downtime. Pick what works best for your business.

Check your spare parts often to make sure they are still good.

You can hire a company to manage your spare parts. This can help you save money and share risks.

Put spare parts in smart places to meet service needs. This helps you get parts when you need them. It also keeps your smt line working well. Predictive maintenance helps you know when to order new parts before something breaks.

Spare Parts Practice | ベネフィット |

|---|---|

In-house or consignment stock | Fast repairs and less downtime |

Regular monitoring | Stops parts from going bad |

Supplier relationships | Get parts when you need them |

Strategic stocking | Meets service agreements |

When you take care of maintenance and spare parts, your smt line stays strong. Your assembly keeps moving and does not stop.

Cost and ROI Analysis

Total Cost of Ownership

You want to know how much your smt line will cost over time. The total cost of ownership is more than just buying new equipment. You need to think about direct and indirect costs. Direct costs are things like the price, spare parts, and items you use up. Indirect costs are things like how often your line works, how much time you spend setting up, and how reliable your machines are. You also need to think about maintenance, training, and how many products you make. Here is a table that shows these costs:

Cost Type | Examples |

|---|---|

Direct | Purchase price, Depreciation, Spare parts, Consumables |

Indirect | Uptime, Programming costs, Setup/changeover costs, Reliability, Maintenance costs, Training, Actual throughput |

You should look at all these costs before you upgrade. If you only think about the price, you might miss other costs. These hidden costs can hurt your production and assembly. Making a smart choice saves money and keeps your smt line working well.

Tip: Always check both direct and indirect costs before you buy new smt equipment. This helps you avoid surprises and keeps your production strong.

Payback and Savings

You want to know how fast you get your money back. The payback period tells you how long it takes to earn back what you spent. Some companies get their money back in less than a year. Others need a few years. For example:

One company spent $450,000 and got it back in 3.88 years.

A communication equipment company spent about $700,000 and got it back in 10 months.

You can find your payback period by dividing the total cost by your average monthly savings.

Some companies use yearly energy savings to figure out payback.

When you upgrade your smt line, you can save money in many ways. You make more products, have less downtime, and get better quality. These savings help you reach your goals faster and make your assembly process better.

Note: Shorter payback periods mean you start saving sooner. Always look at your expected savings and compare them to what you spend.

Future-Proofing SMT Line

Technology Evolution

You want your smt line to use new technology. In five years, smt equipment will change a lot. Machines will use AI and big data to get smarter. They will learn and get better on their own. Parts will get much smaller, from micron to nanometer size. Machines will be more exact. Modular designs let you change your smt line fast for new jobs. Green manufacturing will help save energy and lower pollution.

Here is a table with important technology trends:

Trend | 説明 |

|---|---|

Intelligent Upgrade | AI, big data, and industrial Internet help machines learn and optimize smt line performance. |

継続的改善 | Precision increases as components shrink, reaching submicron and nanometer levels. |

Flexible Development | Modular design allows you to customize your smt line for high-mix, small-batch production. |

Green Manufacturing | Energy-saving modes and better design reduce waste and help the environment. |

You will see more smart tools like machine vision and IoT. These tools help you spot problems and check quality by themselves. Upgrades like these keep your smt line ready for new jobs.

Tip: Watch for new technology so your smt line stays strong and can compete.

Flexible Production

Your smt line needs to do many kinds of work. Customers want more choices and quick delivery. Flexible production lets you switch between products and batch sizes fast. You can change your smt line quickly to meet new needs.

Manufacturers use smart upgrades to change production quickly. You can fill orders for small batches or many types of products. Contract manufacturers help you make more or less without losing speed or quality. This flexibility keeps your assembly process working well and ready for anything.

Here is a table showing how flexible production helps you:

説明 | Source |

|---|---|

Customers want more personalized and diverse smt processing. | SMT assembly line integration boosts flexibility and capacity. |

Smart upgrades let you adjust production for multi-species, small batches. | Rapid response to market changes becomes possible. |

Contract manufacturers help you scale production and keep quality high. | You can change volumes without hurting turnaround times. |

You can get your smt line ready for the future by picking equipment and software that support flexible production. This helps you stay ahead when things change.

You can upgrade your smt line by using the smt line guide for each step. The smt line guide helps you test pilot batches and train your team. It also helps you set up real-time monitoring. You use the smt line guide to plan maintenance and handle materials. The smt line guide helps you when you start and as you keep improving. S&M gives you flexible production, good quality, and smart money choices. The smt line guide shows you how to use leasing, make production better, and get parts that save money. You can ask experts for help and use the smt line guide to keep your smt line strong. The smt line guide gives you easy steps, expert help, and solutions that work. If you want to upgrade, begin with the smt line guide and talk to S&M for a plan made just for you.

よくあるご質問

What is the first step when upgrading an SMT line?

You should start by checking your current SMT line. Look for slow spots and weak areas. Write down what works well and what needs help. This helps you plan your upgrade.

How do you choose the right SMT equipment?

Always match new machines to your current setup. Check size, power, and software needs. Ask your vendor for advice. S&M offers equipment that fits many lines and helps you grow.

Why is preventive maintenance important?

You keep your SMT line running longer with regular checks. You find small problems before they stop your work. This saves money and avoids big repairs.

Can you upgrade your SMT line without stopping production?

Upgrade Method | Downtime Risk | ベネフィット |

|---|---|---|

Phased Upgrades | 低い | Keeps line running |

Full Replacement | 高い | Fast, but stops work |

You can upgrade in steps to keep your line working.