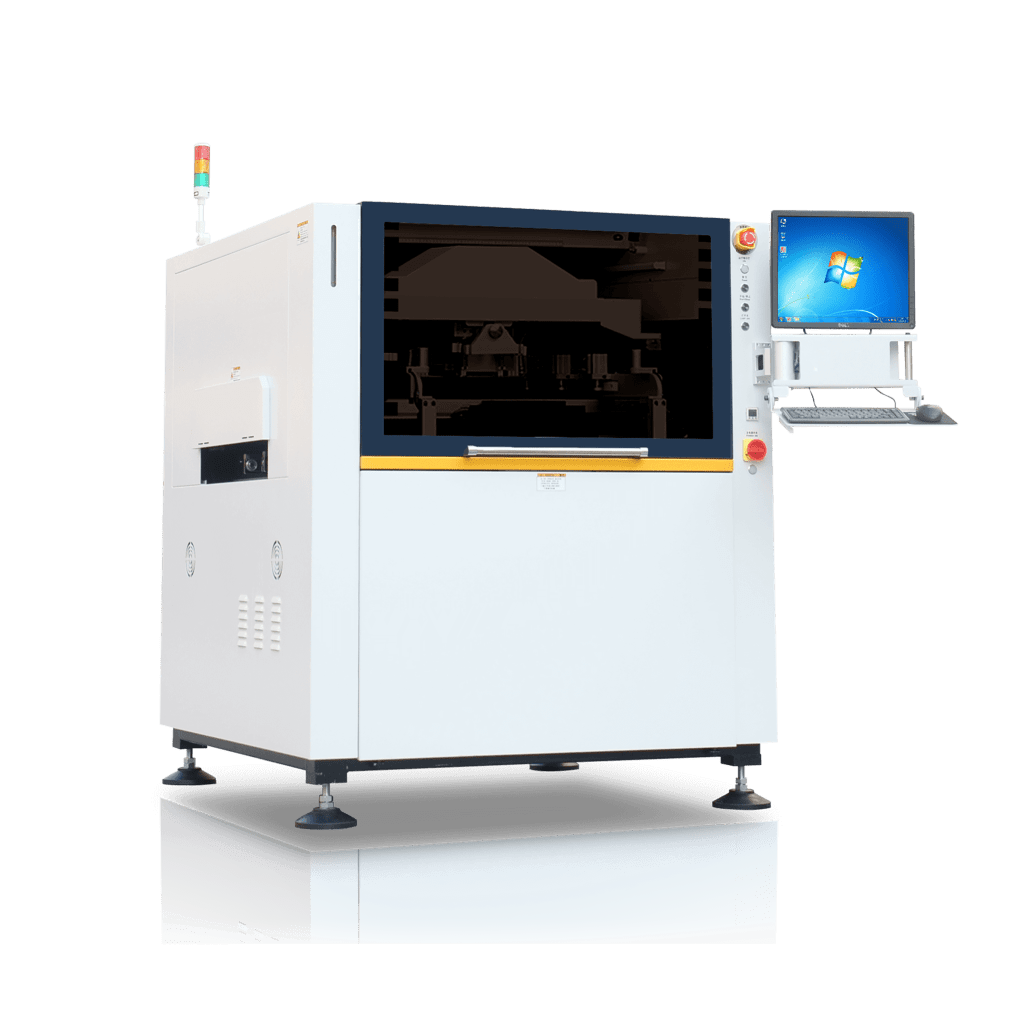

Product Overview

1. Function Overview

CP500 is a high-speed and high-precision solder paste printing machine with a repetition accuracy of ± 12 μ m and a printing accuracy of ± 25 μ m. The printing production cycle is a total of 8 seconds (excluding solder paste printing and cleaning). It can handle PCB boards ranging from 50mm × 50mm to 500mm × 350mm, and it only takes 2 minutes from installing the steel mesh to starting production, making the work simpler. Improve the speed of wire changing while ensuring quality.

2. Basic features of the product:

2.1. The PCB size compatibility range is wide, and it can support PCBs with different thicknesses ranging from 50mm × 50mm to 500mm × 350mm; 2.2. High precision printing resolution;

High positioning accuracy, with a repeat positioning accuracy of ± 12 μ m; Printing accuracy ± 25 μ m; Support adhesive printing;

2.3 Fully automatic control can improve production efficiency, control quality, and save costs;

Automatic steel mesh positioning; Automatic PCB calibration;

Software pressure closed-loop feedback system;

Automatic steel mesh cleaning (dry cleaning, wet cleaning, vacuum cleaning);

2.4. Adopting the suspended printing head independently developed by Huanchengxin Company, the pressure of the scraper is automatically balanced, and the pressure control is precise, which can achieve perfect solder paste forming effect;

2.5. Programmable motor controls the separation speed and stroke of scraper and steel mesh, which can flexibly achieve multiple demolding methods; 2.6. Multi functional PCB fixed positioning system, PCB positioning is convenient, fast, and accurate;

2.7.上下視覚位置決めシステム; 2.8.インテリジェント画像処理システム;

2.9. Supports 2D, SPI online, and SPC functions;

3. Solder paste printing range

3.1 Production and processing of surface mount components such as resistors, capacitors, inductors, diodes, transistors, etc. using SMT technology:

01005, 0201, 0402, 0603, 0805, 1206, and other specifications and dimensions;

3.2. IC: Supports packaging such as SOP, TSOP, TSSOP, QFN, etc., with a minimum pitch of 0.3mm;

Support BGA, minimum ball diameter (Ball) 0.3mm;

3.3 Printing size: 50mm × 50mm -500mm × 350mm; 3.4 PCB specifications: thickness 0.4mm-6mm;

3.5 FPC specifications: Thickness below 0.4mm (with fixture).

4. Application scope

The production and manufacturing of mobile phones, communications, LCD TVs, set-top boxes, home theaters, in car electronics, medical power equipment, aerospace and other products/equipment, as well as the production and processing of general electronic products.

Product specifications

*以下のテストデータは、周囲温度25℃、湿度60%でのものです。

| プロジェクト | パラメータ | |

| リピート位置精度 | ±12μm(@6σ Cmk≥2.0) | |

| 印刷精度 | ±25μm(@6σ Cmk≥2.0) | |

| 印刷速度/サイクル(サイクルタイム) | <8s (excluding printing and cleaning time) | |

| 製品切り替え | <5分 | |

| スクリーンステンシル寸法/最小(X×Y) | 470mm × 370mm | |

| スクリーン・ステンシル・サイズ/最大(X×Y) | 780mm × 737mm | |

| スクリーン・ステンシル・サイズ/厚さ | 20mm - 40mm | |

| PCB印刷サイズ/最小 (PCBサイズ/最小) (X×Y) | 50mm × 50mm | |

| PCB印刷サイズ/最大 (PCBサイズ/最大) (X×Y) | 500mm × 350mm | |

| PCBサイズ/厚さ | 0.4 – 6mm (a jig is required for diameters below 0.4mm) | |

| PCB反り率 | <1%(対角線の長さによる) | |

| ボード下部サイズ | 13mm、23mm(オプション) | |

| エッジ・オブ・ボード・サイズ | 3 mm | |

| 輸送高 | 900±20(mm) | |

| 輸送方向 | 左-右;右-左;左-左;右-右 | |

| 輸送速度 | 100-1500(mm/sec) プログラム制御 | |

| PCB positioning

(Board Location) |

サポート体制 | マグネットエジェクターピン/エッジサポート |

| クランプシステム | Elastic side clamp/Z-axis pressure plate/vacuum suction (optional) | |

| プリントヘッド | プログラム可能な電子制御プリントヘッド(標準) | |

| スクレーパーの速度 | 10〜200(mm/sec) | |

| スクレーパー圧力 | 0 – 15(kg) (software pressure closed loop) | |

| スクレーパー角度 | 60°/55°/45°(オプション) | |

| スクレーパータイプ | スチールスクレーパー、ゴムスクレーパー、他のタイプのスクレーパーはカスタマイズする必要があります。 | |

| ステンシル分離速度 | 0.01 - 125 (mm/sec) プログラマブル3段制御 | |

| 洗浄方法 | ドライクリーニング、ウェットクリーニング、バキューム(任意の組み合わせでプログラム可能) | |

| テーブル調整範囲 | X:±4mm;Y:±6mm; θ : ±2 ° | |

| 画像フィデューシャルタイプ | 標準形状フィデューシャル、パッド/開口部 | |

| カメラシステム | デジタルカメラ/テレセントリック同軸ビジョンシステム/4方向独立同軸/リング型LED光源 | |

| CCD(カメラ) | 1.3 million pixels, 6.4mm × 4.8mm upper and lower dual fields of view, pixel accuracy 5 μm (optional field of view 10mm × 8mm) | |

| 空気圧 | 4〜6(Kg/cm2) | |

| 空気消費量 | 約0.007m³/分 | |

| 制御方法 | PCコントロール | |

| 電源 | AC:220-240V,50/60HZ 1 Φ 2.5KW,13A | |

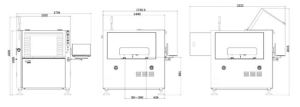

| 機械寸法(L×W×H) | 1250 × 1450 × 1510 (mm) (excluding the lighthouse height, see the product external dimensions) | |

| 機械重量 | Approx:1100Kg | |

| 動作温度 | -20℃ - +45℃ | |

| 動作湿度 | 30% – 60% | |

マシン構成

1.スクレーパーの圧力を調整するためのプログラム可能な電子制御は、スクレーパー印刷ヘッドを中断した:

1.1. The scraper pressure can be adjusted by programmable method, and the pressure control is accurate;

1.2. The front and rear scraper pressures are adjusted independently to ensure that there is no pressure imbalance caused by the fatigue deformation of the scraper material, which will cause the difference in front and back printing;

1.3. The programmable motor controls the separation speed and stroke of the scraper and steel mesh;

2. Standard stainless steel scraper, unique design, longer blade life ;

3. Visual alignment system ;

4. Platform UVW automatic correction system ;

5. PCB clamping and supporting device:

5.1, Magnetic ejector pin;

5.2. Flexible clamping device on the PCB side to ensure that the PCB will not bend or deform when clamped; 5.3. Z-axis pressure plate;

5.4, strong vacuum suction (optional);

5.5, Flexible automatic ejector (optional);

6. CNC guide rails adjust the transport width and speed ;

7. Three programmable steel mesh cleaning systems: dry, wet and vacuum, which can be combined arbitrarily ;

8. Industrial control computer, Windows 7 operating system, Chinese/English interface;

9. Intelligent software diagnostic system ;

10. Support 2D, SPI connection, SPC software functions ;

11. Standard SMEMA connection interface.

Product peripheral placement structure size diagram

Disclaimers

Due to real-time changes in product batches and production supply factors, in order to provide accurate product information, specifications, and features as much as possible, Huanchengxin may adjust and revise the text expressions, image effects, and other content on the above pages in real time to match the actual product performance, specifications, parameters, components, and other information; In case of necessary modifications and adjustments to the above-mentioned pages, no special notice will be given;