When you pick a reflow oven for lead-free work in your smt line, you need to think about more than just the main features. Do you know that calibration, airflow, and integration can affect your results in surface mount technology? You have to look past simple numbers to get the best price and performance. S&M is a trusted brand that helps you reach high standards in reflow processes.

주요 내용

Think about more than just the price when picking a reflow oven. Check if it has good temperature control and can change for different needs. These features help the oven work better.

Always check if calibration and airflow are correct. This keeps the heat even and makes solder joints strong. It also helps stop problems from happening.

Set your oven to match the solder paste you use. The right temperature stops problems like tombstoning and weak joints.

Use smart features like real-time monitoring and alarms for faults. These tools help you find problems early and keep things working well.

Make sure your reflow oven works well with your SMT line. When machines talk to each other, things run faster and there is less waiting.

Price-Performance in Lead-Free Reflow Oven Selection

What Price-Performance Means for SMT

When you think about price-performance in SMT, you have to look at both cost and what the reflow oven can do. Many engineers care about more than just how much the oven costs. They want ovens that work well and can handle different boards. Longer ovens with more zones give you better control. This lets you work with boards that need different heat at each step.

Good temperature control and even heating are very important for strong solder joints. Ovens with better temperature systems might cost more, but they help you get the same results every time and have fewer problems. Newer reflow ovens heat the PCB evenly and carefully. This makes solder joints stronger and lowers the risk of mistakes.

Here are some things engineers look at when thinking about price-performance:

Capacity vs. Space: The oven should fit your space and make enough boards.

Number of Zones and Temperature Control Precision: Harder boards need better temperature control.

Process Adaptability: The oven should work for both leaded and lead-free jobs, and maybe use nitrogen.

Intelligence and Usability: Find features that make the oven easy to use and help you get better results.

Budget & ROI: Think about how much value you get over time, not just the first price.

Why Hidden Factors Are Important

You may think the main specs are all that matter, but hidden things can change your results. The temperature profile is very important for good solder joints. The right profile means fewer problems and better joints. For lead-free soldering, you need even more control because there is less room for error. Smaller parts and mixed boards make this even harder.

The process window for lead-free soldering is small. If you do not control it, you can lose good boards.

Lead-free solders need careful heat because they melt at higher temperatures and do not flow as well.

If you watch these hidden things, you can get better results and more value from your reflow oven in your SMT line.

Temperature Profile Control in Reflow Oven Performance

Precision and Calibration for Lead-Free Soldering

When you do lead-free soldering in your SMT line, you must watch the temperature profile closely. The temperature profile is a list of heating and cooling steps your reflow oven follows. If you control the temperature at each step, your solder joints will be strong and last longer. Lead-free soldering needs higher heat and has a smaller safe range. This means you have to be more careful and cannot make many mistakes.

A good reflow profile keeps small parts safe from harm and protects your boards. Sensors and data loggers check the temperature all the time and help you find problems fast. This helps you keep your soldering good and stop defects before they happen.

Here are some reasons why calibration is important:

Good temperature control makes solder joints stronger.

그리고 right thermal profiles stop hidden damage to tiny parts.

New technology lets you work safely at higher heat.

Keeping the right temperature profile means fewer defects in lead-free soldering.

If you use the right tools and keep your oven set up well, your SMT line will work better. You will have fewer problems and your boards will be more reliable.

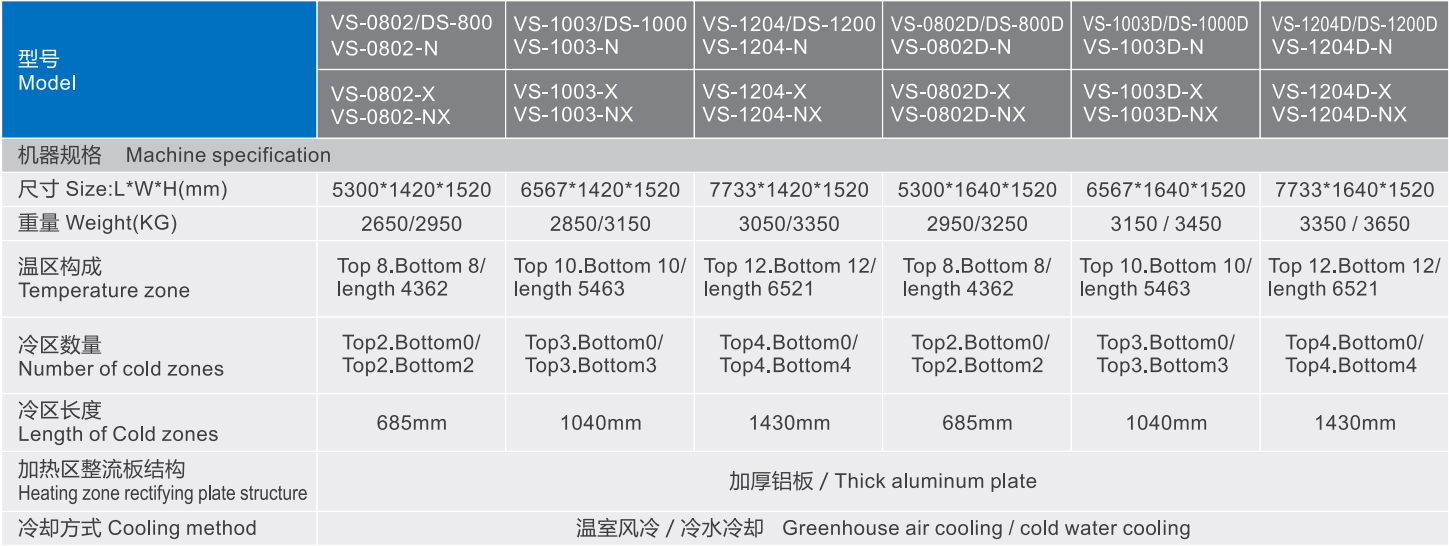

S&M Nitrogen Reflow Oven: Advanced Temperature Management

You can get better soldering results with the S&M nitrogen reflow oven. This oven uses Siemens PLC and PID closed-loop control to keep the temperature just right. Every board gets the same steady heat. The oven also has a Windows 10 system, so you can change languages and settings easily.

The S&M nitrogen reflow oven gives you these good things:

You can set and keep the right temperature for lead-free jobs.

The oven has smart sensors that check the temperature all the time.

Its modular design makes fixing it easy and saves time.

The new gas system helps hot gas move better, which saves heat.

When you use the S&M nitrogen reflow oven, you can trust your soldering process. You get strong solder joints, fewer problems, and better results in your SMT work.

If you want to do a great job in electronics, you need a reflow oven that gives you control and works well. S&M helps you reach your goals with smart temperature control and easy setup.

Oven Zone Design and Airflow in SMT Reflow

Heating Zone Configuration and Air Distribution

When you look at a reflow oven, you see many heating zones. Each zone heats the board in a special way. The number and setup of these zones change how heat spreads across your PCB. If your board is thick or has many layers, it needs more careful heating. The type of solder paste and the number of parts on your board also matter.

More heating zones give you better control over the temperature profile.

Boards with lots of parts or layers need more zones to keep heat even.

At least five vertical zones work for simple lead-free jobs. For harder boards, you should use eight or more zones.

Good air distribution helps heat move across the board. Forced convection ovens use fans to push hot air around. This method keeps the temperature steady and helps all parts of the board heat up the same way.

Airflow Impact on Solder Quality

Airflow plays a big role in solder quality. If air does not move well, some parts of your board may get too hot or too cold. This can cause weak solder joints or defects. Forced convection technology helps keep the temperature even between the board and the hot air. When airflow is strong and steady, you get better performance and fewer problems.

Tip: Clean nozzles and good airflow design help your oven work better. If nozzles get dirty, heat transfer drops and solder joints may fail.

Fluid dynamics modeling helps engineers design ovens that move air in the best way. This makes sure every part of your board gets the right heat.

S&M Reflow Oven: Optimized Zone Design

S&M reflow ovens use advanced insulation and airflow control. You get a new thermal insulation structure that keeps heat inside and saves energy. The oven uses inverters to adjust fan speed in each zone. This means you can set airflow for different boards and solder paste types. The design helps you keep a stable temperature profile for lead-free soldering.

The oven’s modular zones let you change settings for each job.

Airflow control helps you avoid defects and get strong solder joints.

S&M ovens support real-time monitoring, so you can check temperature and airflow during reflow.

If you want high-quality results in your smt line, you need an oven with smart zone design and airflow control. S&M gives you the tools to reach top solder quality every time.

Material Compatibility and Lead-Free Solder Paste

Matching Oven Settings to Solder Materials

You have to set your reflow oven to match your solder paste. Lead-free soldering needs more heat, so your oven must get hot enough. Each solder paste melts at a certain temperature. If your oven cannot reach this, your boards may have problems. The oven’s size, how it heats, and how well it keeps the right temperature all matter for different solder pastes.

Lead-free solder pastes need more heat, so weak ovens may not work.

Every solder paste melts best at a certain heat. You need to check if your oven can do this.

Ovens with more zones and better control help stop problems like tombstoning or bad wetting.

You can see how changing oven settings helps your smt line in the table below:

Evidence | 설명 |

|---|---|

Fine-Tune Reflow Profiles | Change the settings for each solder paste to keep soldering steady and lower problems. |

Monitor Oven Zones | Watch oven zones and conveyor speed to make sure heat spreads the same everywhere. |

Adjust Reflow Profile | Fix the settings to stop cold solder joints and make more good boards. |

Avoiding Contamination and Defects

You need to watch out for contamination and defects with lead-free solder paste. If the heat is not even, parts can lift or tombstone. Wetting problems can happen if the solder paste or oven settings are wrong. If parts and pads do not line up, solder joints can be weak. Gases trapped during reflow can make holes in the solder. Oxidation can stop wetting and make more holes. If you do not handle or store solder paste right, it can get too thick and cause problems. Solder balls can form if there is too much flux or oxidation.

Source of Contamination/Defect | 설명 |

|---|---|

Can make tombstoning because of different heat across the board. | |

Uneven Wetting | Can cause tombstoning, depending on part shape and solder paste. |

Component and Pad Misalignment | Makes solder uneven and raises tombstoning risk. |

Outgassing | Trapped gases make holes in solder joints. |

Oxidation | Oxide layers stop wetting and make holes. |

Solder Paste Handling and Storage | Bad handling makes paste too thick, causing holes. |

납땜 볼링 | Too much flux or oxidation makes unwanted solder balls. |

Tip: Always check your oven settings and solder paste before you start your smt process. This helps you stop defects and keeps your results good.

In-Process Controls and Smart Features in SMT Reflow

Real-Time Monitoring and Fault Alarms

You need smart features to keep your reflow oven running smoothly. Real-time monitoring lets you watch the temperature profile as your boards move through the oven. You can see if the heat matches your lead-free soldering needs. If something goes wrong, fault alarms warn you right away. You can fix problems before they affect your boards. This helps you keep high performance and strong reliability in your smt line.

Smart alarms protect your process. They alert you to issues like overheating, fan failures, or temperature drops. You can act fast and avoid bad solder joints or wasted boards.

You can use these features to:

Track the temperature profile for every board.

Get alerts for faults and errors.

Make quick changes to keep your process safe.

S&M Reflow Oven: Intelligent Process Control

S&M reflow ovens give you advanced control for your smt process. The Windows 10 system makes it easy to switch settings and languages. You can connect the oven to your MES interface. This lets you monitor equipment status, process parameters, and quality data in real time.

You get full traceability for every board you make.

You can spot problems quickly and improve your process.

You can keep your lead-free soldering reliable and efficient.

Real-time temperature monitoring helps you keep the right temperature profile. You can see trends and make changes to boost performance. S&M ovens help you stay competitive by making your process smarter and safer.

Tip: Use the MES system and real-time monitoring to track every step. This helps you find and fix problems fast, so your boards meet high standards.

Maintenance, Reliability, and Cost of Ownership

Modular Design for Easy Maintenance

It is important for your reflow oven to be easy to fix. A modular design makes this possible. You can change parts fast without stopping your whole smt line. This saves time and keeps your work going. With a modular oven, you do not need special tools for most fixes. Your team can learn repairs quickly. This means fewer errors and less time when the oven is not working.

Tip: Clean your oven often and swap parts quickly to keep it running well.

Reliability and Downtime Reduction

Reliability is very important in every smt process. If your oven breaks, your whole line can slow down or stop. You want to stop this from happening. Smart ovens have sensors and alarms to warn you about problems early. You can fix small issues before they get worse. This keeps your boards safe and your work smooth.

Using advanced controls cuts oven downtime by 35%. You spend less time fixing things.

Technicians spend 40% less time checking for defects by hand. They can use their time to make your process better.

Your oven works better, so your products are more reliable. Your team can make more good boards and spend less time fixing mistakes.

S&M Reflow Oven: Operational Efficiency

S&M reflow ovens help you work faster and better. The modular design lets you change parts quickly. The oven uses smart alarms and real-time checks to keep your process safe. You can watch every step and find problems early. This means you fix things faster and spend more time making boards.

기능 | 혜택 |

|---|---|

Modular Design | Fast maintenance |

Smart Alarms | Early problem detection |

Real-Time Monitoring | Better process control |

Stable Performance | Fewer defects |

You get strong lead-free solder joints and results you can trust. S&M ovens help you save money and make your smt line more reliable.

Integration with SMT Line and Upstream/Downstream Processes

Conveyor and Board Handling Compatibility

Your reflow oven should fit your smt line well. Good board handling keeps your process smooth. It also protects your products from harm. Many ovens have conveyor systems with 8 to 12 heating zones. These zones help you control temperature for lead-free soldering. Look for conveyor belts that stop static electricity. This keeps sensitive parts safe. Your oven must connect easily with other machines. If you pick the right system, you avoid problems. Your line keeps moving without trouble.

Ovens with many heating zones help you control temperature.

ESD safe conveyor belts protect boards from static.

Easy connections with other equipment keep your workflow steady.

Tip: Always check if your oven connects with your machines before buying.

Communication with SMT Equipment

You want your machines to share information. Communication protocols help equipment work together. If machines do not connect, you may have more downtime. You also see less of what is happening in your process. Standards like IPC-CFX and IPC-Hermes-9852 help different brands work together. Some factories use a Manufacturing Execution System (MES). MES brings all data into one place. This helps you make better choices and see how your line works.

Good communication between machines improves performance.

Bad connections can slow your process and hide problems.

MES systems help you track everything in real time.

Note: Strong communication keeps your smt line efficient and competitive.

S&M Solutions for SMT Line Integration

S&M gives you many ways to connect your reflow oven with your smt line. You get systems that focus on production integration and assembly. They also help with volume optimization. S&M designs ovens and conveyors for different materials and layouts. You can test and watch boards in parallel chambers. Advanced manufacturing links your PCB line with thermal testing. This checks quality and reliability under tough conditions.

Integration Solution | 설명 |

|---|---|

Production Integration | Tests and improves design, material, and layout for stress. |

Assembly Considerations | Picks solder paste and reflow settings, checks process quality. |

Volume Optimization | Uses parallel chambers for testing and monitoring. |

Connects PCB lines with thermal cycling for full quality checks. |

S&M helps you build a strong smt line. You get better results, fewer defects, and reliable lead-free soldering.

Common Pitfalls in Lead-Free Reflow Oven Selection

Overlooking Calibration and Airflow

Some people think their reflow oven is ready to use right away. But if you do not check calibration often, the temperature can change over time. This can make some boards too hot or too cold. Uneven heating happens when calibration is off. Airflow is also very important. If air does not move well, some parts of your PCB get too hot or too cold. These hot and cold spots can make solder joints weak. Your boards may not work as well. Always check calibration and airflow to keep your smt process steady. This helps your boards stay strong and reliable.

Tip: Make a schedule to check calibration and clean airflow paths. This helps you stop hidden problems before they start.

Ignoring Material Compatibility

You must set your oven to match your solder paste and board. Lead-free solder needs more heat than leaded solder. If you use the wrong settings, you can get problems like tombstoning or bad wetting. Some boards have parts that need extra care. Always look at what your materials need before you start reflow. This step helps you stop mistakes and keeps your work going well.

Mistake | What Can Happen |

|---|---|

Wrong temperature | Solder does not melt well |

Incompatible materials | Weak or cracked joints |

Skipped adjustments | More defects and waste |

Neglecting Smart Features and Maintenance

Sometimes people only look at the main features and forget about smart features or maintenance. This can make you spend more money later. If you do not take care of your oven, it can break down a lot. When this happens, you pay more for repairs and lose time making boards. Bad maintenance means you make fewer good boards, so you lose money. Emergency fixes and new parts cost even more. Doing regular checks keeps your oven working well and steady. You should also plan to get a new oven every 5 to 10 years. This helps you use new technology and get the most for your money.

Ovens that break a lot cost more over time.

Bad maintenance means you make less money.

Emergency fixes and new parts cost extra.

Regular checks keep your oven working right.

Getting a new oven every few years helps you stay ahead.

Note: Smart features like alarms and real-time checks help you find problems fast. This keeps your smt line working well and protects your money.

You get better SMT results when you check more than specs. Calibration helps your reflow oven work better. Airflow makes heat spread evenly on your boards. Material compatibility means your oven matches the solder paste. Smart features help you spot problems fast and fix them. Integration lets your oven work well with other machines. These things lower defects and save money. Lead-free reflow becomes more reliable. You get stronger solder joints and make more good boards. If you want great results, look at ovens like S&M’s for your next upgrade.

자주 묻는 질문

What hidden factor affects lead-free reflow oven performance the most?

You need to watch the temperature profile closely. Even small heat changes can make solder joints weak. Always check calibration and airflow to keep your boards safe.

How does S&M’s nitrogen reflow oven help with lead-free soldering?

S&M’s nitrogen reflow oven uses Siemens PLC and PID closed-loop control. This gives you very exact temperature control. It helps you make strong and reliable solder joints for lead-free jobs.

Why is airflow important in a reflow oven?

Airflow moves heat evenly across your PCB. Good airflow stops hot and cold spots. You get fewer problems and better solder joints.

Can I connect S&M reflow ovens to my SMT line easily?

Yes! S&M ovens work with MES interfaces and smart communication. You can connect them to other SMT machines for smooth work and real-time checks.