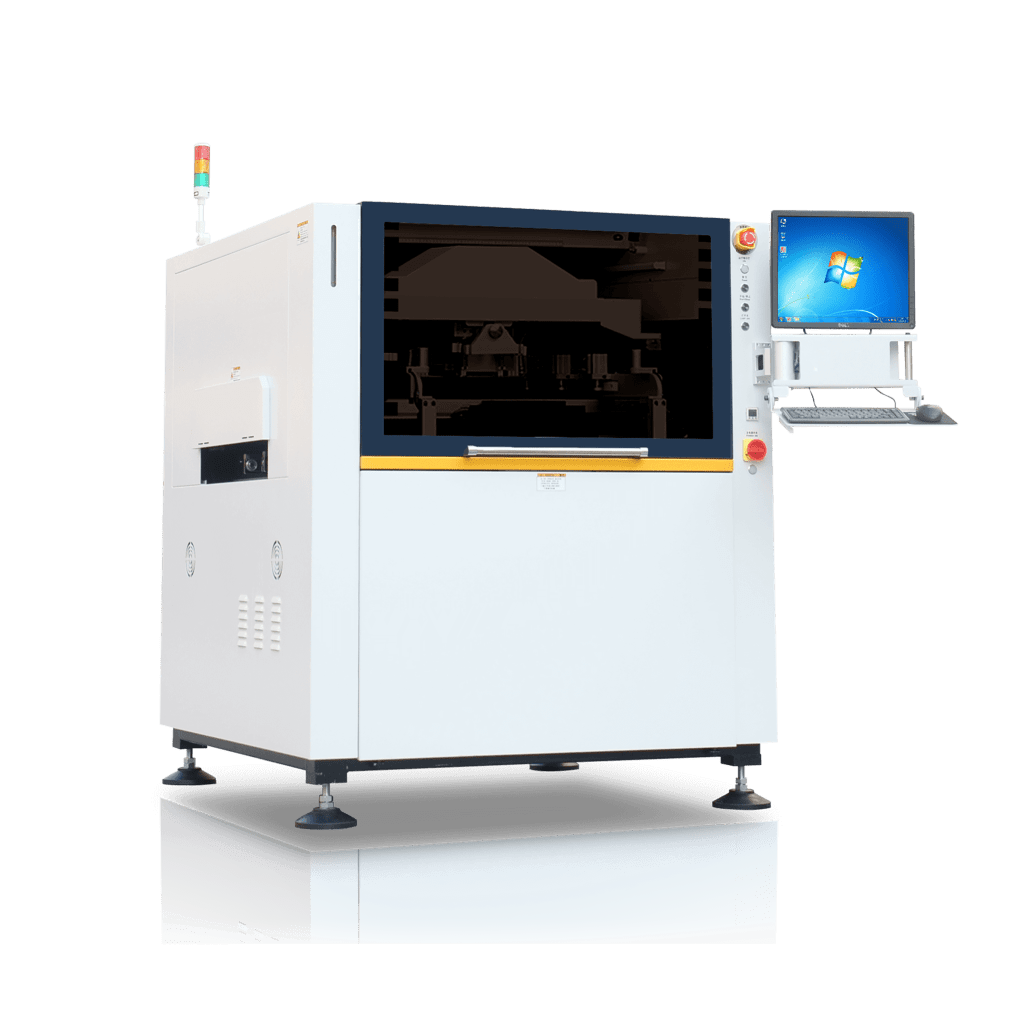

Product Overview

1. Function Overview

CP500 is a high-speed and high-precision solder paste printing machine with a repetition accuracy of ± 12 μ m and a printing accuracy of ± 25 μ m. The printing production cycle is a total of 8 seconds (excluding solder paste printing and cleaning). It can handle PCB boards ranging from 50mm × 50mm to 500mm × 350mm, and it only takes 2 minutes from installing the steel mesh to starting production, making the work simpler. Improve the speed of wire changing while ensuring quality.

2. Basic features of the product:

2.1. The PCB size compatibility range is wide, and it can support PCBs with different thicknesses ranging from 50mm × 50mm to 500mm × 350mm; 2.2. High precision printing resolution;

High positioning accuracy, with a repeat positioning accuracy of ± 12 μ m; Printing accuracy ± 25 μ m; Support adhesive printing;

2.3 Fully automatic control can improve production efficiency, control quality, and save costs;

Automatic steel mesh positioning; Automatic PCB calibration;

Software pressure closed-loop feedback system;

Automatic steel mesh cleaning (dry cleaning, wet cleaning, vacuum cleaning);

2.4. Adopting the suspended printing head independently developed by Huanchengxin Company, the pressure of the scraper is automatically balanced, and the pressure control is precise, which can achieve perfect solder paste forming effect;

2.5. Programmable motor controls the separation speed and stroke of scraper and steel mesh, which can flexibly achieve multiple demolding methods; 2.6. Multi functional PCB fixed positioning system, PCB positioning is convenient, fast, and accurate;

2.7. 상하 시각 위치 결정 시스템; 2.8. 지능형 영상 처리 시스템;

2.9. Supports 2D, SPI online, and SPC functions;

3. Solder paste printing range

3.1 Production and processing of surface mount components such as resistors, capacitors, inductors, diodes, transistors, etc. using SMT technology:

01005, 0201, 0402, 0603, 0805, 1206, and other specifications and dimensions;

3.2. IC: Supports packaging such as SOP, TSOP, TSSOP, QFN, etc., with a minimum pitch of 0.3mm;

Support BGA, minimum ball diameter (Ball) 0.3mm;

3.3 Printing size: 50mm × 50mm -500mm × 350mm; 3.4 PCB specifications: thickness 0.4mm-6mm;

3.5 FPC specifications: Thickness below 0.4mm (with fixture).

4. Application scope

The production and manufacturing of mobile phones, communications, LCD TVs, set-top boxes, home theaters, in car electronics, medical power equipment, aerospace and other products/equipment, as well as the production and processing of general electronic products.

Product specifications

*다음 테스트 데이터는 주변 온도 25°C 및 상대 습도 60%를 기준으로 합니다.

| 프로젝트 | 매개변수 | |

| 반복 위치 정확도 | ±12μm(@6σ Cmk≥2.0) | |

| 인쇄 정확도 | ±25μm(@6σ Cmk≥2.0) | |

| 인쇄 속도/사이클 (사이클 시간) | <8s (excluding printing and cleaning time) | |

| 제품 전환 | <5분 | |

| 스크린 스텐실 크기/최소 (X×Y) | 470mm × 370mm | |

| 스크린 스텐실 크기/최대 (X×Y) | 780mm × 737mm | |

| 스크린 스텐실 크기/두께 | 20mm – 40mm | |

| PCB 인쇄 크기/최소 (PCB 크기/최소) (X×Y) | 50mm × 50mm | |

| PCB 인쇄 크기/최대 (PCB 크기/최대) (X×Y) | 500mm × 350mm | |

| PCB 크기/두께 | 0.4 – 6mm (a jig is required for diameters below 0.4mm) | |

| PCB 휨률 | <1% (대각선 길이를 기준으로) | |

| 보드 하단 크기 | 13mm, 23mm (선택 사항) | |

| 보드 가장자리 크기 | 3 mm | |

| 운송 고등 | 900±20(mm) | |

| 운송 방향 | 좌우;우좌;좌좌;우우 | |

| 운송 속도 | 100-1500(mm/초) 프로그래머블 제어 | |

| PCB positioning

(Board Location) |

지원 체계 | 자기식 이젝터 핀/가장자리 지지대 |

| 클램핑 시스템 | Elastic side clamp/Z-axis pressure plate/vacuum suction (optional) | |

| 프린트 헤드 | 전자 제어식 프로그래밍 가능 프린트 헤드 (표준) | |

| 스크레이퍼 속도 | 10 – 200(mm/초) | |

| 스크레이퍼 압력 | 0 – 15(kg) (software pressure closed loop) | |

| 스크레이퍼 각도 | 60°/55°/45° (선택 사항) | |

| 스크레이퍼 유형 | 강철 스크레이퍼, 고무 스크레이퍼, 기타 유형의 스크레이퍼는 맞춤 제작이 필요합니다. | |

| 스텐실 분리 속도 | 0.01 – 125 (mm/초) 프로그래밍 가능한 3단계 제어 | |

| 세척 방법 | 드라이클리닝, 웻클리닝, 진공청소 (모든 조합으로 프로그램 가능) | |

| 테이블 조정 범위 | X:±4mm;Y:±6mm; θ : ±2 ° | |

| 이미지 기준점 유형 | 표준 형상 기준점, 패드/개구부 | |

| 카메라 시스템 | 디지털 카메라/텔레센트릭 동축 비전 시스템/4방향 독립 동축/링형 LED 광원 | |

| CCD(카메라) | 1.3 million pixels, 6.4mm × 4.8mm upper and lower dual fields of view, pixel accuracy 5 μm (optional field of view 10mm × 8mm) | |

| 공기 압력 | 4 – 6(kg/cm²) | |

| 공기 소비량 | 약 0.007m³/min | |

| 제어 방법 | PC 제어 | |

| 전원 공급 장치 | AC:220-240V,50/60HZ 1 Φ 2.5KW,13A | |

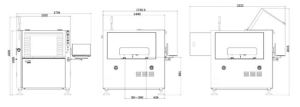

| 기계 치수 (길이×너비×높이) | 1250 × 1450 × 1510 (mm) (excluding the lighthouse height, see the product external dimensions) | |

| 기계 중량 | Approx:1100Kg | |

| 작동 온도 | -20℃ – +45℃ | |

| 작전명 습도 | 30% – 60% | |

기계 구성

1. 스크레이퍼 압력 조절을 위한 프로그래밍 가능한 전자 제어 장치 서스펜션 스크레이퍼 인쇄 헤드:

1.1. The scraper pressure can be adjusted by programmable method, and the pressure control is accurate;

1.2. The front and rear scraper pressures are adjusted independently to ensure that there is no pressure imbalance caused by the fatigue deformation of the scraper material, which will cause the difference in front and back printing;

1.3. The programmable motor controls the separation speed and stroke of the scraper and steel mesh;

2. Standard stainless steel scraper, unique design, longer blade life ;

3. Visual alignment system ;

4. Platform UVW automatic correction system ;

5. PCB clamping and supporting device:

5.1, Magnetic ejector pin;

5.2. Flexible clamping device on the PCB side to ensure that the PCB will not bend or deform when clamped; 5.3. Z-axis pressure plate;

5.4, strong vacuum suction (optional);

5.5, Flexible automatic ejector (optional);

6. CNC guide rails adjust the transport width and speed ;

7. Three programmable steel mesh cleaning systems: dry, wet and vacuum, which can be combined arbitrarily ;

8. Industrial control computer, Windows 7 operating system, Chinese/English interface;

9. Intelligent software diagnostic system ;

10. Support 2D, SPI connection, SPC software functions ;

11. Standard SMEMA connection interface.

Product peripheral placement structure size diagram

Disclaimers

Due to real-time changes in product batches and production supply factors, in order to provide accurate product information, specifications, and features as much as possible, Huanchengxin may adjust and revise the text expressions, image effects, and other content on the above pages in real time to match the actual product performance, specifications, parameters, components, and other information; In case of necessary modifications and adjustments to the above-mentioned pages, no special notice will be given;