Applications of Reflow Soldering in Electronics: A Comprehensive Guide

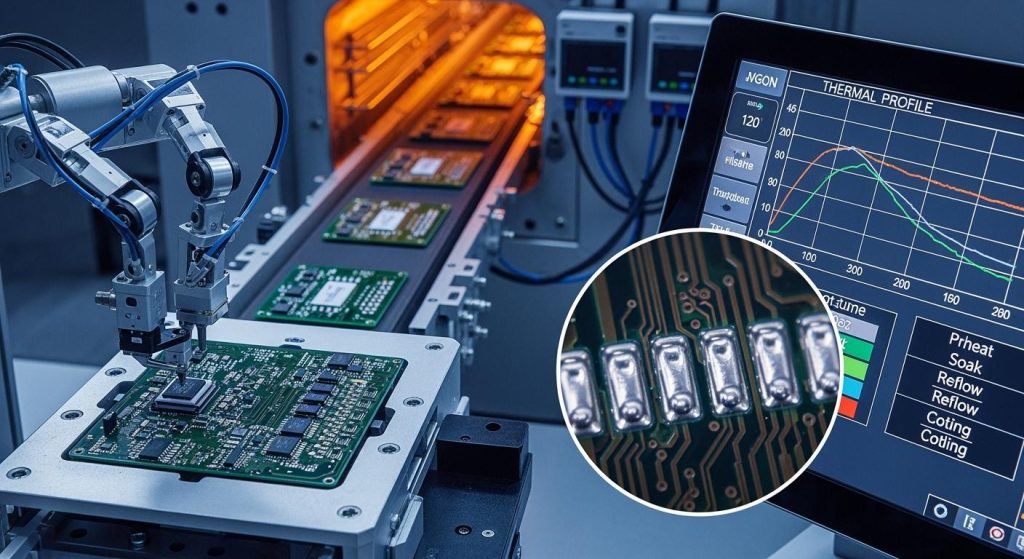

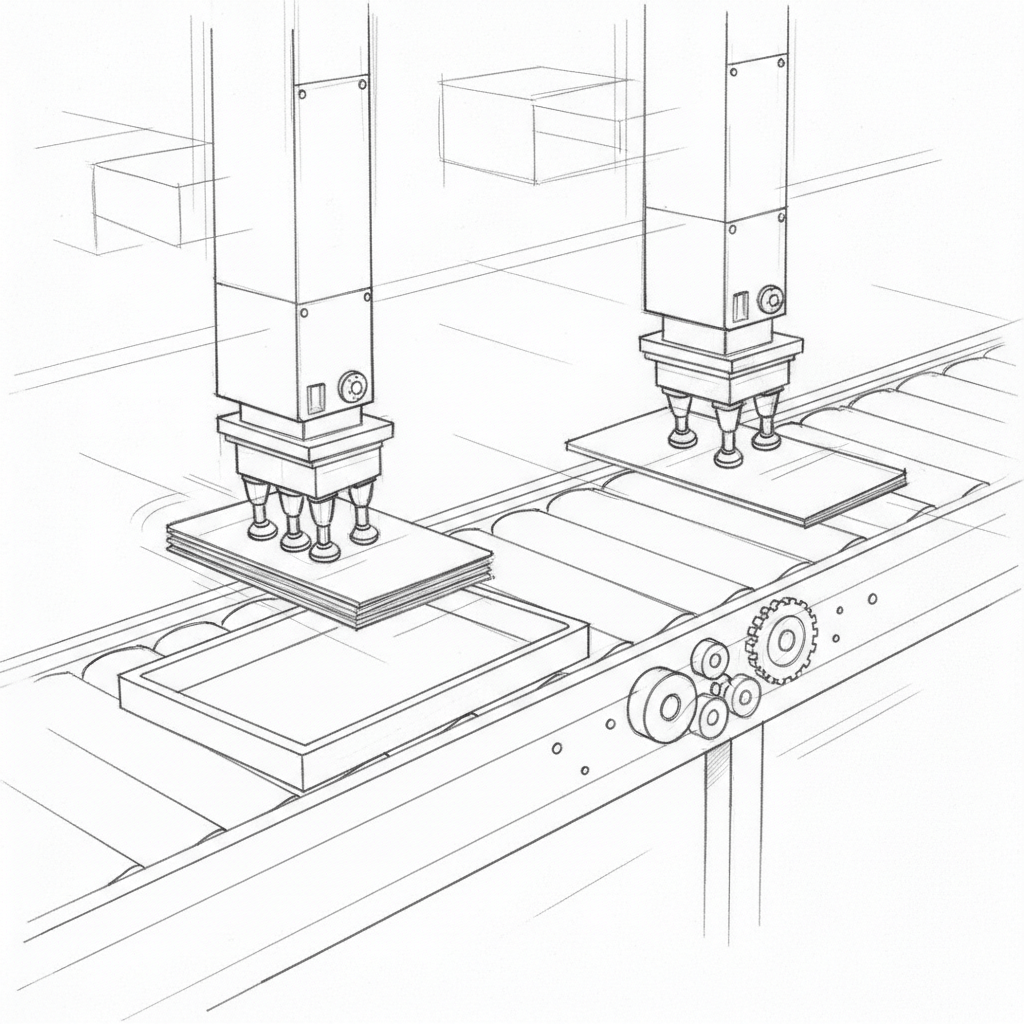

Moreover, the integration of cutting-edge SMT equipment into manufacturing operations is essential for meeting challenges such as reducing time-to-market, enhancing scalability, and adapting to technological changes. Consequently, reflow soldering serves not only as a technical procedure but as a strategic component facilitating the alignment of production goals with technological advancements.