Navigating the Landscape of PCB Loader Manufacturers: Insights for Electronics Manufacturers

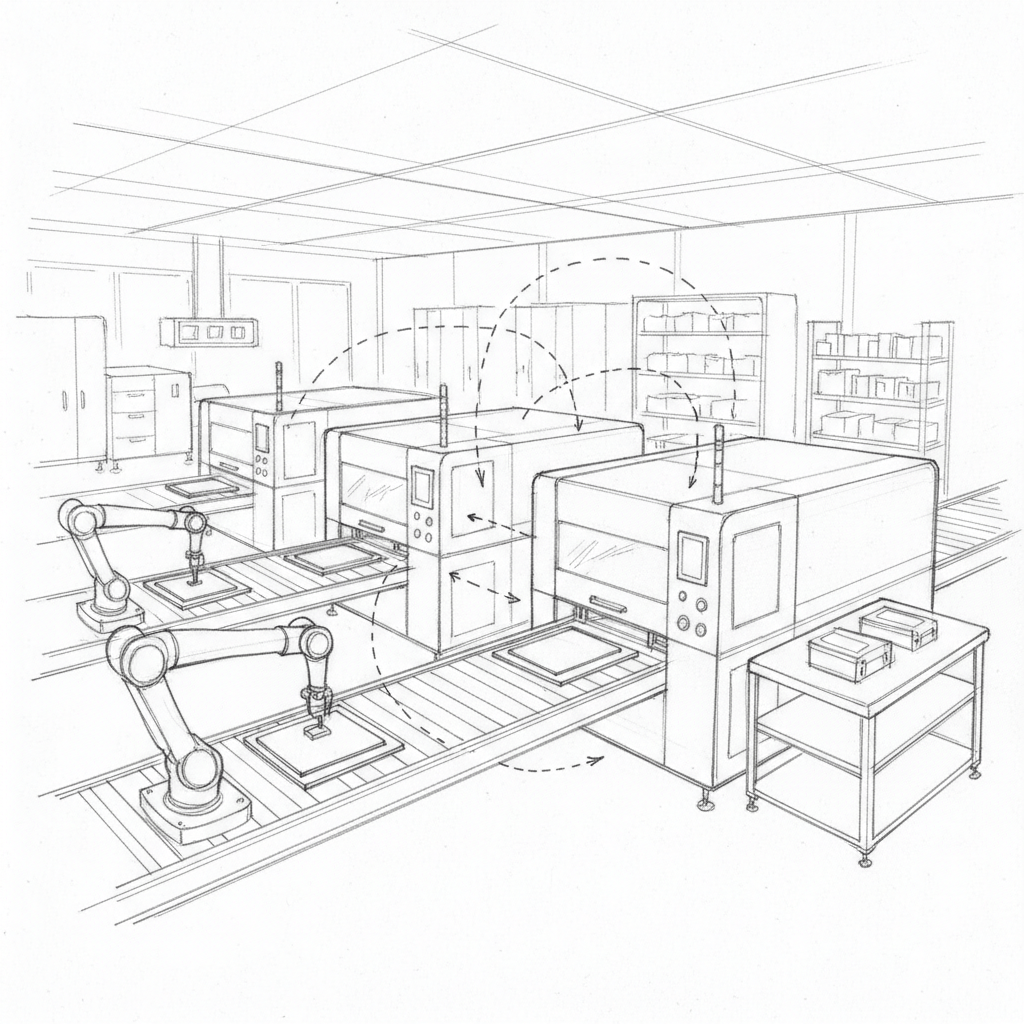

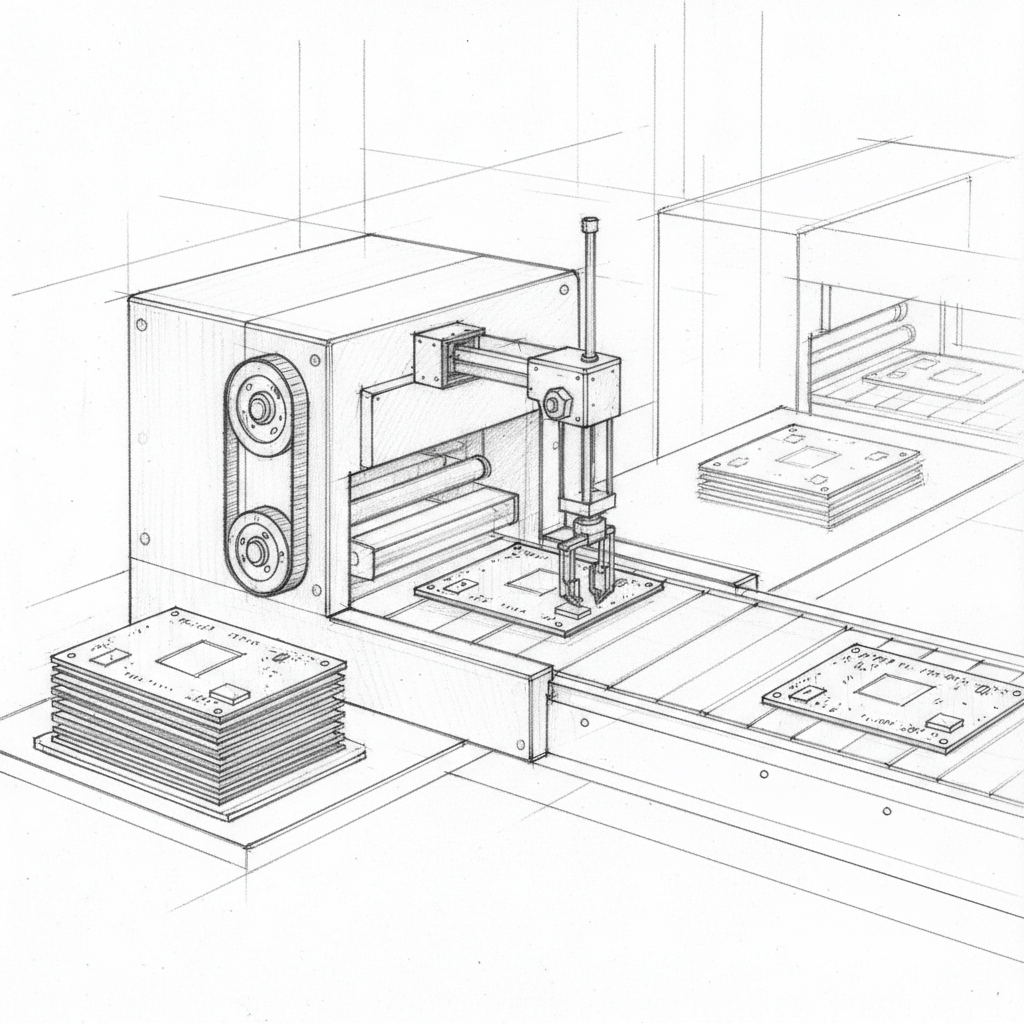

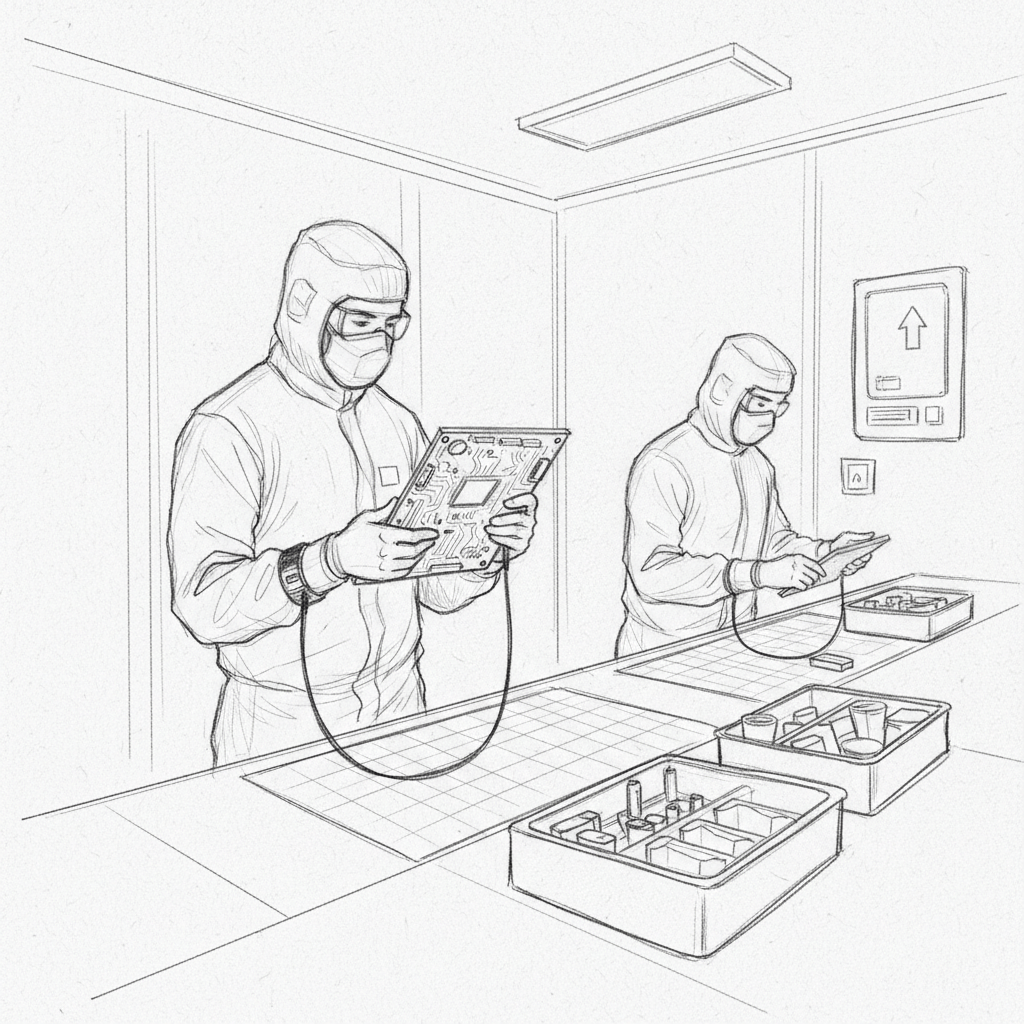

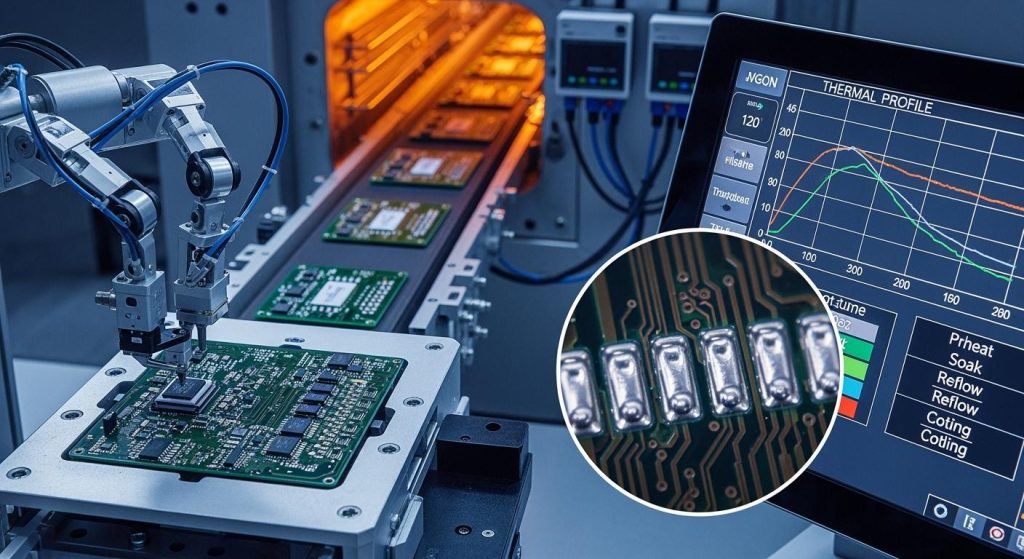

In the intricate environment of electronics manufacturing, PCB loaders play a pivotal role by significantly influencing production efficiency, precision, and throughput rates. PCB loaders are specialized machines designed to automate the process of feeding printed circuit boards (PCBs) into various stages of surface mount technology (SMT) assembly lines, thereby facilitating seamless integration and enhancing operational productivity.