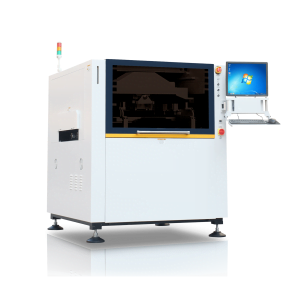

| Modelo | KL-650 |

| Applicable production range | Curing after dispensing or pasting of consumer electronincs |

| Dimensões (mm) | 2150(L)*2050(W)*2150(H) |

| weight(Kg) | <2000KG |

| Tempo de aquecimento | 10minute |

| Temperature setting range | Room temperature – 200°C |

| Control method | ±1.0°C |

| Number of temperature zones | 4 |

| Heating mode | Large circulation of hot air, two sides blowing and top return air |

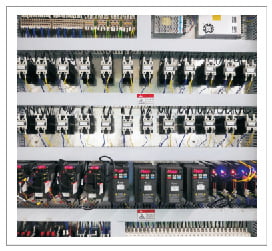

| Control method | PID closed-loop control +SSR drive |

| PCB boad temperature distribution deviation | ±3.0°C |

| Min beat | 15S |

| PCB maximum size(mm) | 650(L)×460(W) |

| Gama de ajuste da largura da calha | 80~460mm |

| Track width adjustment | Automatic width adjustment, and fixed track near the operating surface |

| Product flow | From left to right |

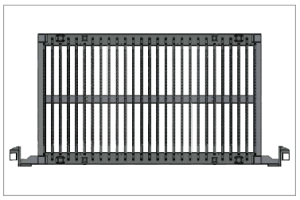

| Layer spacing | 20mm |

| Transport height(mm) | 950±30mm |

| Number of layers | 60 layers |

| Installed power | 67KW |

Estrutura do material Forno de cura vertical de ar quente

Product number: KL-650

- The transmission design is more scientific, and the risk of jamming is minimized: the internal transmission has no connection point, and the transportation is smooth.

- Intelligent shielding fault layer to improve operation efficiency: during equipment operation, when the support bar of a certain layer or several layers in the vertical furnace is in fault, the shielding of the plate passing layer can be selected in the operating system, which will not affect the use of the equipment. However, the general vertical furnace in the market does not have this function.

- Adjustable operation range, more energy saving and consumption reduction: the vertical furnace with material frame can realize small cycle action, and the product does not need to pass through the top layer.

- Innovative needle roller active transportation and rejection of jamming and plate damage: when using(vehicles)will stop when they are stuck, while the vertical furnace where the traditional chain drives the products (fixtures)to move will act forcefully when they are stuck, resulting in the products when they are stuck, resulting in the products.