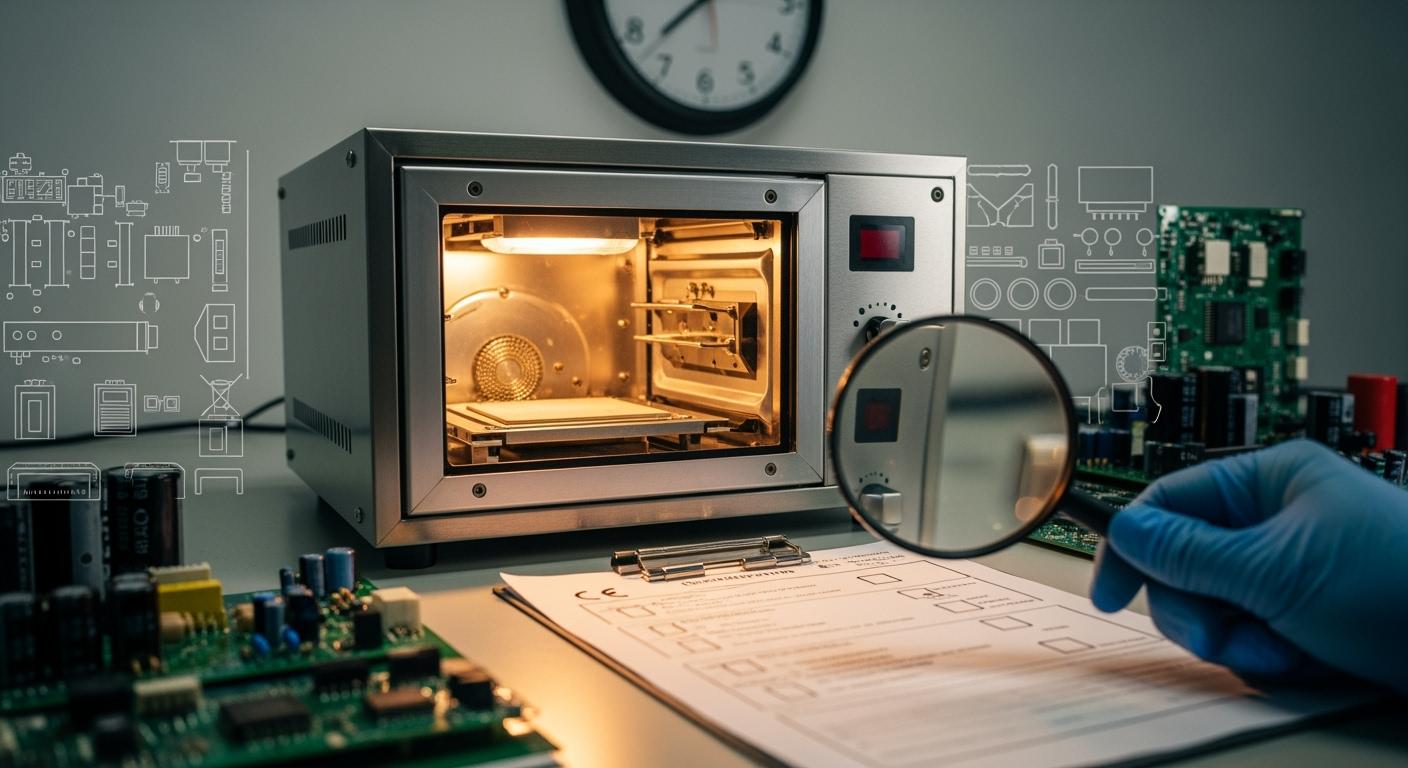

Imagine you are in charge of buying things for a high-tech electronics factory. You need a mini-led reflow oven that meets tough quality rules. If you do not check certifications early, you might have delays and problems with rules. S&M’s nitrogen reflow ovens need exact paperwork. You can stop problems and expensive errors by using a good certification process.

Principais conclusões

Always check certifications like RoHS, REACH, and CE before you buy a mini-led reflow oven. This makes sure the oven is safe and follows rules. It also stops problems that can slow down your work.

Ask for and look at all papers from the maker, like test reports and technical manuals. This helps you know if the oven is right for your work.

Use S&M’s help to get certification papers fast and get answers to your questions. This keeps your assembly line working well.

Keep checking if the oven follows rules by looking at how it works and writing down what you find. This helps stop problems with quality in your work.

Make good connections with suppliers so you can talk easily and get help. This makes sure you get news and support for your assembly needs on time.

Certification Verification for Mini-LED Reflow Ovens

Importance of Certification in Reflow Processes

You should check certifications before buying a mini-led reflow oven. This step keeps your assembly line safe from problems. Certifications prove the oven follows safety and environmental rules. You want your assembly schedule to stay on track. If you skip checking, you could have pcb quality issues or legal trouble. S&M cares about quality. The company checks every oven for compliance. You feel better knowing your equipment meets standards.

Certifications are important for every part of assembly. When you use a reflow oven, you need exact temperature control. The oven must work well with solder paste and flux. If the oven fails standards, pcb connections can be weak. Sensitive parts might get damaged during assembly. S&M’s nitrogen reflow ovens help your line run smoothly. You avoid expensive fixes and keep pcb production moving.

Tip: Always ask for certification papers before ordering. This step saves time and keeps your assembly safe.

Common Certification Types (RoHS, REACH, CE)

You will see many certification types in electronics. The most common for mini-led reflow ovens are RoHS, REACH, and CE. Each one covers a different rule. You should know what each means for your assembly and pcb work.

Here is a quick overview:

Compliance Standard | Descrição |

|---|---|

RoHS | Restriction of Hazardous Substances |

REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals |

CE | European Conformity (European Conformity) |

RoHS makes sure your oven has no harmful chemicals. REACH checks that chemicals in oven parts are safe. CE shows the oven meets European safety and performance rules. Using a certified oven protects your pcb and assembly from bad substances. You also make sure your flux and solder paste work right. These certifications help you pick the best flux for soldering. You also learn what flux does in soldering.

S&M’s Approach to Certification

S&M takes certification very seriously. The company tests every mini-led reflow oven before shipping. You get all the papers for RoHS, REACH, and CE. S&M uses strict checks for every assembly and pcb. The team looks at flux types and solder paste to make sure they meet standards. You can ask for test reports and certificates anytime.

S&M’s process helps you plan your assembly schedule. You do not wait for missing papers. The company gives fast help if you need more documents. You save time on pcb production and assembly. S&M’s nitrogen reflow ovens come with easy instructions for flux and solder paste. You get help with calibration and profiling. The support team answers your questions about assembly, flux, and pcb handling.

You can trust S&M to send certified mini-led reflow ovens. The company’s focus on compliance keeps your assembly line safe. You avoid delays and keep pcb production running well.

How to Verify Reflow Oven Certifications

Reviewing Manufacturer Documentation

First, ask the manufacturer for all certification papers. These papers prove the oven is safe and follows rules. Look for RoHS, REACH, and CE certificates. Each paper should match your oven’s model and serial number. Check if the papers show the oven is good for mini-led assembly.

Read the technical manual too. The manual tells you how to use the oven for pcb work. It explains how to handle flux and put on solder paste. See if it talks about temperature settings and thermal profiling steps. These details help you set up the oven right. Look for instructions about flux types, solder paste, and pcb loading. S&M gives full papers for every oven. You can ask for more papers if you need them for audits.

Tip: Keep digital copies of all certificates and manuals. This makes sharing easy with your team or for pcb checks.

Third-Party Testing and Validation

You can ask for test reports from outside labs. These reports show the oven passed independent checks. A trusted lab tests the oven for temperature profile accuracy. They also check flux compatibility and pcb safety. The lab looks at how the oven handles solder paste and assembly cycles. Find reports that talk about thermal profiling and flux performance.

Third-party checks give you extra confidence. You know the oven works well with your assembly process. You see proof that pcb quality stays high and flux residue is low. S&M shares test results from outside labs. You can use these reports to show partners or customers that your oven meets all rules.

Note: Third-party checks can help you get assembly approval faster and avoid delays in pcb production.

Ensuring Traceability and Authenticity

You need to make sure every certificate is real and traceable. Check serial numbers and match them to your oven. Look for time-stamped data and part identification. This helps you track each oven in your assembly and pcb process.

S&M uses smart systems for traceability. You get tools that watch oven performance, flux use, and pcb results. These systems save data for every assembly run. You can look up this data for audits or quality checks. The table below shows how S&M’s traceability works:

Tier | Descrição | Caraterísticas principais |

|---|---|---|

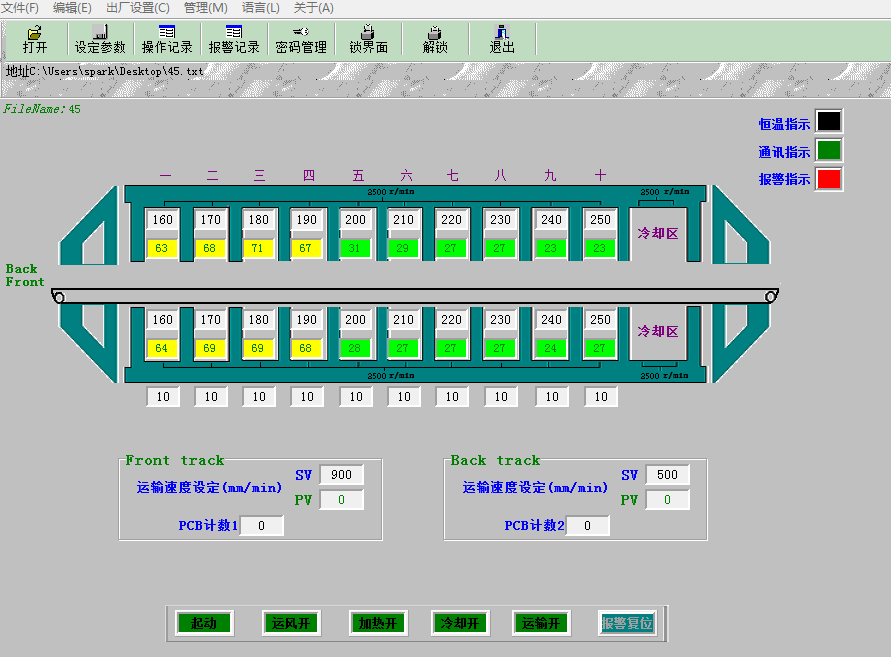

1 | Oven CPK | Continuous temperature monitoring, automatic Cpk calculation, real-time feedback on oven performance |

2 | Process Cpk with Oven Watch System | 24-hour monitoring, dynamic profile generation, SPC analysis and alert reporting |

3 | Product Traceability | Time-stamped data storage, positive part identification, recall for audits |

You get alerts if the oven’s temperature profile changes or if flux levels shift. You see notifications on your PC. This helps you keep your assembly and pcb work on track. You can test the oven every day without stopping production. This keeps your flux and solder paste use efficient and your assembly line moving.

Finds process changes right away from oven loading and settings.

Shows notifications for operators using PC software.

Makes daily testing easy without stopping production.

You make sure every step in your assembly meets high standards. You keep your oven’s certification current. You protect your assembly from mistakes and keep your pcb production safe.

Certification and Lead Time for Mini-LED Reflow Ovens

Factors Affecting Certification Lead Time

You need to think about several things that can slow down certification for a mini-led reflow oven. If you do not check the reflow oven’s paperwork early, you might wait longer for your assembly to start. Missing or incomplete certificates can stop your pcb production. Sometimes, you need extra tests for flux or solder paste. If the reflow oven does not match the rules for flux or pcb, you must fix problems before you begin assembly. You also need to check if the oven works with your solder paste and flux. Each step in the reflow process can add time if you do not plan well.

Fator | Impact on Lead Time |

|---|---|

Missing certificates | Delays assembly start |

Extra testing needed | Slows pcb production |

Poor documentation | Stops reflow process |

Wrong flux or solder paste | Causes rework |

Reducing Delays with S&M’s Support

S&M helps you avoid delays in certification. The team gives you all the reflow oven documents you need for your assembly. You get fast answers if you have questions about flux, solder paste, or pcb. S&M checks every reflow oven before shipping. You receive clear instructions for assembly, flux use, and solder paste application. The support team helps you set up the reflow oven for your pcb and assembly line. You can ask for extra help with flux or solder paste if you need it. S&M’s quick response keeps your assembly moving and your pcb production on schedule.

Tip: Contact S&M’s support team early to get all your reflow oven paperwork. This step helps you avoid waiting for certificates and keeps your assembly on track.

Maintenance, Calibration, and Profiling Tools

You must use the right tools to keep your mini-led reflow oven certified. Maintenance and calibration tools help you measure the reflow oven’s thermal profile. You need to test the oven with your actual pcb and flux. There is no standard test board, so you must use your own assembly products. Thermal profiling makes sure your solder paste melts correctly and your flux works well. Reliable profiling helps you keep your reflow oven certified and your assembly safe.

Maintenance tools check the reflow oven’s temperature zones for your pcb and flux.

Calibration tools help you set the right heat for solder paste and flux during assembly.

Profiling tools show you how the reflow oven handles flux and solder paste on your pcb.

You keep your assembly line running smoothly when you use these tools. Your reflow oven stays certified, and your pcb production meets high standards for flux and solder paste.

Buyer’s Checklist for Fast Certification Verification

Pre-Purchase Verification Steps

You should plan before buying a mini-led reflow oven. First, write down all certifications you need for assembly. Make sure the oven has RoHS, REACH, and CE. Look at every paper for the oven’s model and serial number. Ask S&M for test reports about how the oven works with flux, pcb, and solder paste. Check if the oven fits your assembly needs and matches your soldering quality. Ask for instructions on flux handling, pcb loading, and solder paste use. Learn how the oven’s reflow process affects your assembly.

Checklist Table:

Etapa | Action | Why It Matters |

|---|---|---|

1 | List certifications | Makes sure your assembly follows rules |

2 | Match model/serial | Checks you have the right oven for pcb |

3 | Request test reports | Shows flux and solder paste work well |

4 | Review instructions | Helps you set up assembly the right way |

5 | Confirm reflow process | Keeps soldering quality high |

Tip: Save digital copies of your certification papers. This helps you find them fast for assembly and pcb checks.

Ongoing Compliance Monitoring

You need to keep checking after you set up your reflow oven. Make a schedule to check oven performance with flux, pcb, and solder paste. Use S&M’s traceability tools to watch assembly runs and flux use. Look for alerts about temperature or flux changes. Test the oven every day to keep your assembly line safe. Regular checks help stop problems with soldering quality and pcb defects. Write down every assembly cycle, flux batch, and solder paste lot.

Streamlining Documentation Requests

You can get your documents faster with S&M’s customer support. Ask for all flux, pcb, and solder paste certificates before assembly starts. Use online portals to download oven manuals and compliance papers. Share these documents with your team for quick assembly setup. Ask S&M for more help if you need extra flux or pcb data. Fast access to documents keeps your assembly line moving and helps you keep soldering quality high.

Note: Getting documents quickly helps you avoid waiting in assembly and pcb production.

Tips for Reliable and Efficient Procurement

Building Supplier Relationships

You need good supplier relationships for a smooth assembly. You talk with your supplier about what you need. You ask about reflow oven, flux, and pcb needs. You ask questions about your assembly schedule and certifications. You share your goals and pcb standards with your supplier. Your supplier gives you quick answers about flux and oven performance. You get updates on new features and pcb changes. You trust your supplier to help with flux problems. Your supplier helps keep your assembly line moving. S&M gives fast help and clear advice for setup. S&M helps with flux and pcb loading. You count on S&M’s experience for efficient and safe assembly.

Using Digital Tools for Certification

You use digital tools to manage your certificates. These tools help with reflow oven, flux, and pcb documents. You pick platforms that track compliance and store certificates. KeyTalk’s PKI Management Platform keeps your oven certificates safe. PSC Software’s ACE Platform helps with flux and pcb documents. This platform helps you follow assembly rules and check flux quality. You see real-time data for your assembly and pcb results. You use portals to check flux certificates and oven audits. You set up workflows for assembly and flux updates. You keep your documents ready for checks and inspections.

KeyTalk’s PKI Management Platform keeps oven certificates safe.

PSC Software’s ACE Platform helps with compliance and flux documents.

Staying Updated on Industry Standards

You keep up with RoHS, REACH, and CE rules. You use resources to track assembly and flux changes. You check dashboards for new rules and pcb standards. Acquis Compliance Platform gives real-time updates for flux and assembly. You see automated supplier help for oven and flux needs. You review dashboards for pcb and assembly management. You learn about compliance and use tech to track updates.

Resource | Descrição |

|---|---|

Despatch Laboratory Ovens | Follows REACH and RoHS rules for safety and health in manufacturing. |

Acquis Compliance Platform | Gives automated supplier help, tracks rules in real time, and has dashboards for easy compliance management. |

You check these resources often to keep your process safe. You avoid delays by knowing the latest oven and flux rules. You keep your assembly line ready for audits and pcb checks.

Tip: Work with trusted brands like S&M for support. You get help with oven certification, flux management, and pcb compliance. You save time and keep your assembly process running well.

You keep your production on track by checking certifications for mini-led reflow ovens. This helps you make better solder joints. You keep quality high on your assembly line. S&M’s help lets you avoid delays and control residue at every step. Use the checklist and tips to make buying easier. The table below shows how following rules and smart buying help your business over time:

Benefício | Descrição |

|---|---|

Uses less material and allows lead-free assembly, helping you follow rules like RoHS. | |

Reduced Electronic Waste | Products last longer, so you have fewer failures and less waste. |

Enhanced Operational Efficiency | SMT uses less energy and makes less waste than older ways. |

Supports Circular Economy and Regulatory Goals | Matches circular economy plans and makes it easier to follow rules like WEEE and REACH. |

You follow the rules and buy smarter when you work with trusted partners like S&M.

FAQ

What certifications should you check before buying a mini-led reflow oven?

You need to look for RoHS, REACH, and CE. These show the oven is safe and follows rules. Ask S&M for the right papers before you buy.

How can you verify the authenticity of certification documents?

Check if the oven’s serial number matches the certificate. Ask for time-stamped data and reports from outside labs. S&M gives you papers you can trace for every oven.

Does certification affect the delivery time of your oven?

Yes. If you do not have all the right papers, shipping can be slow. You can stop delays by checking with S&M before you buy.

What support does S&M offer for certification verification?

S&M gives you quick access to all needed papers. You get help with audits, tracking, and technical questions. The team answers fast so your work does not stop.