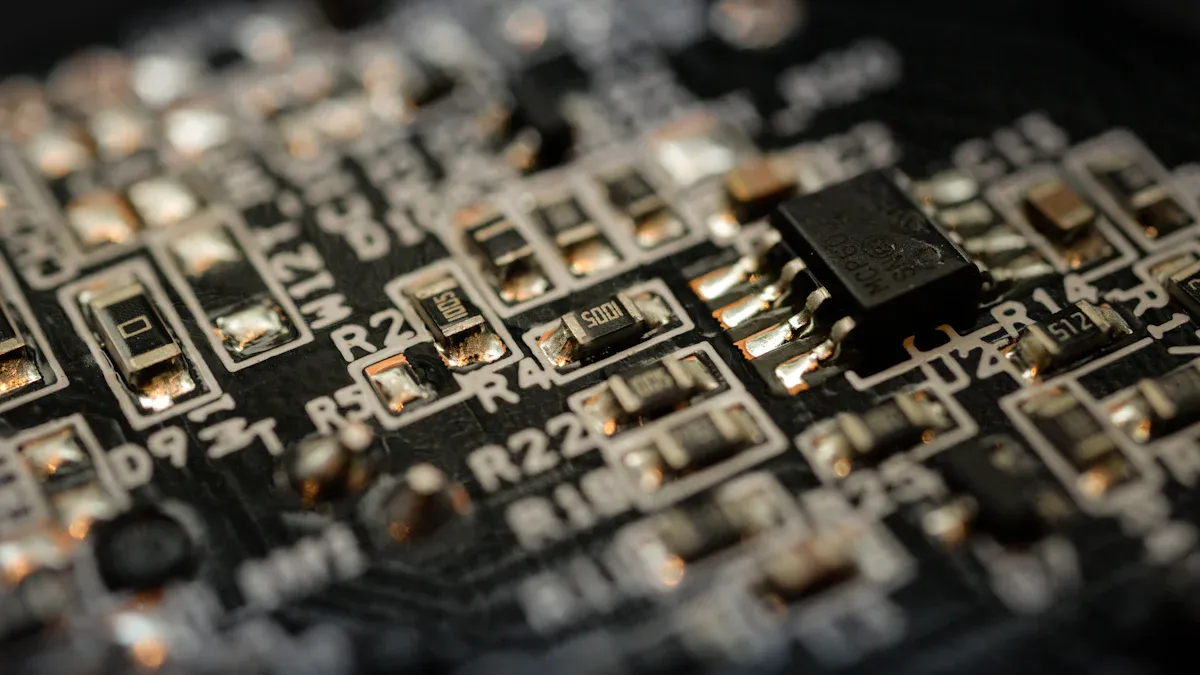

Utilizați transportoare NG/OK pentru a sorta plăcile cu circuite imprimate (PCB) în funcție de rezultatele inspecției în linia SMT. Aceste mașini deplasează PCB-urile bune la pasul următor și le separă pe cele defecte pentru revizuire. Îmbunătățiți eficiența și reduceți erorile atunci când automatizați acest proces. Conectați aceste mașini cu echipamente de inspecție, ceea ce vă ajută să reduceți deșeurile și să mențineți standardele de calitate ridicate.

Principalele concluzii

-

Transportoare NG/OK automatizează sortarea plăcilor cu circuite imprimate (PCB), îmbunătățind eficiența și reducând manipularea manuală.

-

Aceste mașini ajută la menținerea unei calități ridicate prin separarea plăcilor bune de cele defecte, minimizând erorile și deșeurile.

-

Integrarea transportoarelor NG/OK cu echipamentele de inspecție permite sortarea în timp real pe baza rezultatelor inspecției, sporind precizia.

-

Întreținerea regulată și formarea personalului sunt esențiale pentru a menține funcționarea fără probleme a transportoarelor NG/OK și pentru a evita întârzierile în producție.

-

Monitorizarea parametrilor de performanță precum viteza de sortare și ratele de eroare ajută la identificarea timpurie a problemelor și sprijină îmbunătățirea continuă.

Prezentare generală a transportoarelor NG/OK

Ce sunt ele

Utilizați Transportoare NG/OK pentru a sorta plăcile cu circuite imprimate (PCB) după inspecție în linia dvs. SMT. Aceste mașini vă ajută să separați plăcile care trec de inspecție de cele care nu trec. Transportatorul NG/OK acționează ca un gardian automat, asigurându-se că numai plăcile de calitate merg mai departe. Acestea au un design compact, astfel încât le puteți integra în majoritatea liniilor de producție fără a ocupa mult spațiu.

Iată o scurtă privire asupra principalelor componente și caracteristici de design ale acestora:

|

Caracteristică/Specificație |

Detalii |

|---|---|

|

Panou de control |

Panou de control cu membrană ușor de utilizat |

|

Tip curea |

Curele antistatice rezistente la uzură |

|

Moduri de operare |

FIFO, LIFO, Pass-through |

|

Reglarea lățimii |

Paralelă și netedă (șurub principal) |

|

Design de siguranță |

Design închis pentru siguranță |

|

Compatibilitate |

Compatibil cu SMEMA |

|

Durata ciclului |

Aproximativ 10 secunde |

|

Dimensiunea PCB (MM) |

5050-530460 (în funcție de model) |

Cum funcționează

Așezați transportorul NG/OK imediat după echipamentul de inspecție. Mașina primește semnale de la tester, apoi sortează fiecare PCB în calea "OK" sau "NG" (No Good). Acest proces are loc automat, astfel încât nu trebuie să deplasați plăcile manual. Transportatorul utilizează un sistem tampon fiabil pentru a stoca plăcile și a preveni blocajele.

|

Caracteristică |

Descriere |

|---|---|

|

Scop |

Folosit pentru salvarea și rejudecarea plăcilor PCB pe linia de producție SMT. |

|

Funcționalitate |

Sortează și stochează separat PCB-urile NG și OK pentru a eficientiza procesul de asamblare și a preveni erorile. |

|

Eficiență |

Oferă un sistem tampon fiabil și ușor de utilizat pentru producătorii de electronice. |

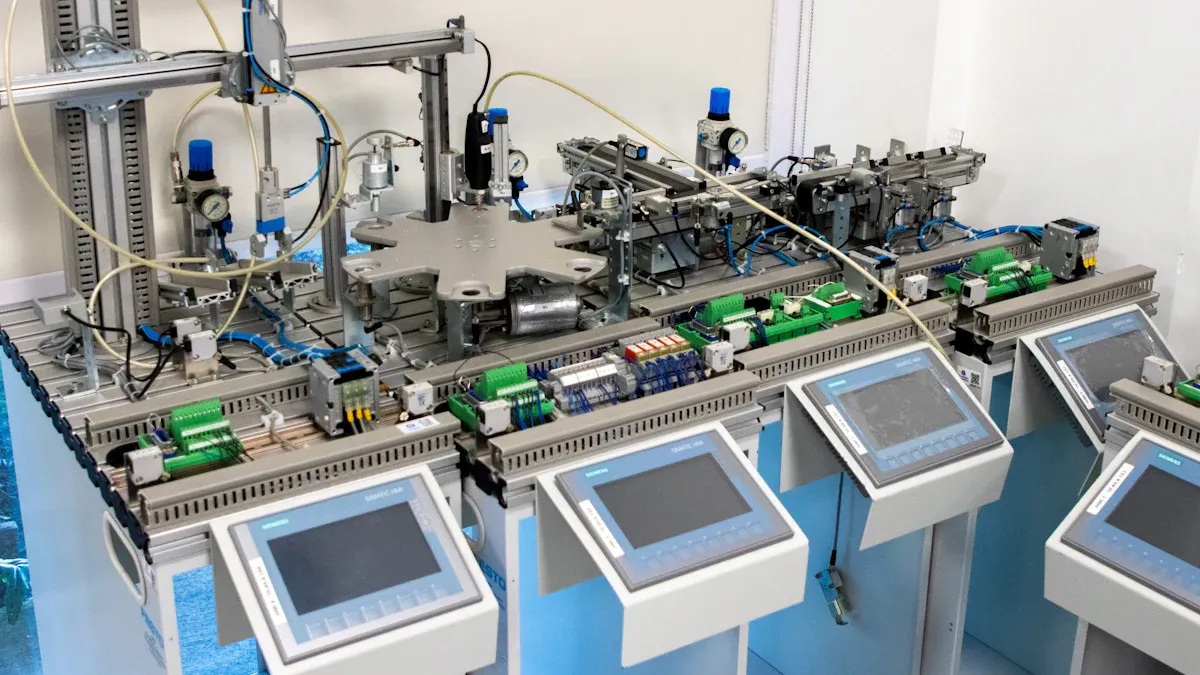

Rolul în liniile SMT

Vă bazați pe transportoarele NG/OK pentru ca linia dvs. SMT să funcționeze fără probleme. Aceste mașini, amplasate lângă echipamentul dvs. de testare, gestionarea calității PCB prin sortarea plăcilor pe baza rezultatelor inspecției. Puteți avea încredere în ei pentru a stoca plăcile NG și OK în zone separate, ceea ce vă ajută să evitați confuziile și să mențineți o calitate ridicată. Transportator NG/OK De asemenea, suportă diferite moduri de operare, cum ar fi FIFO sau pass-through, permițându-vă să le adaptați la fluxul dvs. de lucru.

Sfat: Prin utilizarea transportoarelor NG/OK, reduceți manipularea manuală și riscul de erori în linia dvs. de producție.

Aplicații în liniile SMT

Sortare automată după inspecție

Puteți utiliza transportorul NG/OK pentru a automatiza sortarea PCB-urilor imediat după inspecție. Atunci când plăcile dvs. părăsesc stația AOI (Automated Optical Inspection) sau ICT (In-Circuit Test), aceste mașini preiau controlul. Acestea primesc rezultatele inspecției și apoi sortează fiecare placă în calea corectă. Plăcile bune merg mai departe, în timp ce cele defecte merg într-o zonă separată pentru examinare. Acest proces reduce necesitatea manipulării manuale și vă ajută să evitați greșelile.

Iată o scurtă privire la modul în care aceste mașini improve your workflow:

|

Caracteristică |

Descriere |

|---|---|

|

Advanced Sorting Modes |

NG buffer machines automatically store and sort good and bad PCBs, reducing manual intervention. |

|

Efficiency Improvement |

The sorting process enhances inspection efficiency by minimizing the need for human oversight. |

|

Temporary Storage |

PCB buffers adjust the pace and temporarily store boards, preventing production line stoppages. |

You can see that NG/OK Screening Machines help you keep your line moving and reduce downtime.

Integration with Inspection Equipment

You connect Transportator NG/OK directly to your inspection equipment. This integration allows the machines to receive real-time inspection data. When a board passes or fails, the machine reacts instantly. You do not need to rely on workers to move boards or make decisions. This setup increases your accuracy and keeps your process consistent. You also lower the risk of mixing up good and bad boards.

Hierarchical Storage and Buffering

You benefit from hierarchical storage and buffering features in the NG/OK conveyor. These machines can store boards in different sections based on their inspection results. Good boards stay ready for the next step, while faulty ones wait for further analysis. This system prevents bottlenecks and keeps your production line balanced. You can also use the buffer to temporarily hold boards if the next process slows down. This flexibility helps you maintain a steady workflow and avoid unnecessary stops.

Tip: By using NG/OK conveyor, you can handle more boards with less effort and keep your quality control strong.

Benefits of NG/OK Conveyor

Efficiency and Throughput

Puteți boost your SMT line’s efficiency by using NG/OK conveyors. These machines sort NG and OK PCBs quickly and accurately. When you automate this process, you minimize errors and keep your production moving. The SMT PCB NG/OK Unloader Magazine helps you manage buffers better. This means you can handle more boards in less time and avoid slowdowns. You see higher throughput because the line does not stop for manual sorting or inspection delays.

Tip: Automated sorting keeps your line balanced and prevents bottlenecks, so you can meet production targets with less stress.

Error and Waste Reduction

You reduce mistakes and waste when you rely on NG/OK conveyors. Manual sorting often leads to errors, especially when workers get tired or distracted. Automation solves this problem by making sure each board goes to the right place every time. You also lower the risk of mixing good and bad boards, which protects your product quality.

-

The NG/OK Unloader Machine automates the sorting of PCBs, reducing the need for manual labor.

-

This automation minimizes human error, enhancing production accuracy.

-

Increased production efficiency leads to lower labor costs in SMT manufacturing.

You save money because you need fewer workers for sorting tasks. You also waste fewer boards since the system catches defects early and keeps them separate from good products.

Data and Traceability

You gain better control over your production data with NG/OK conveyors. These machines work well with your inspection and control systems. You can track each board as it moves through the line. This traceability helps you find problems faster and fix them before they affect more products. You also collect valuable data for quality reports and audits.

|

Beneficii |

Descriere |

|---|---|

|

Real-time Tracking |

You monitor each PCB’s status instantly. |

|

Quality Reports |

You generate accurate records for every batch. |

|

Fast Problem Solving |

You identify and address defects quickly. |

NG/OK conveyor supports your quality goals by making it easy to trace every board and keep your records up to date.

Implementation Considerations

Equipment Compatibility

You need to check if your Transportator NG/OK matches your current SMT line equipment. Most NG/OK conveyor supports SMEMA standards, which makes integration easier. You should look at the size of your PCBs and the conveyor’s width adjustment features. Some machines work best with specific inspection systems, such as AOI or ICT. You can use the table below to compare key compatibility factors:

|

Compatibility Factor |

What to Check |

|---|---|

|

PCB Size Range |

Fits your board dimensions |

|

Signal Interface |

Matches AOI/ICT output signals |

|

Conveyor Height |

Aligns with your line setup |

|

Control Protocol |

Supports your automation system |

Tip: Always review your equipment manuals before installing a new conveyor. This helps you avoid connection issues and downtime.

Customization and Scalability

Puteți customize NG/OK conveyors to fit your production needs. Many manufacturers offer options for belt type, buffer size, and operation modes. You may want to add extra storage for NG boards or change the sorting logic. If your production volume grows, you can scale up by adding more conveyors or expanding buffer capacity. You should plan for future changes when choosing your machine.

-

Choose an adjustable width for different PCB sizes.

-

Select operation modes like FIFO or pass-through.

-

Add extra buffer sections for high-volume lines.

Note: Customization lets you adapt quickly to new products or process changes.

Maintenance Needs

You must keep your NG/OK conveyor in good condition to ensure reliable performance. Regular cleaning of belts and sensors prevents jams and errors. You should inspect moving parts for wear and replace them as needed. Most machines have simple maintenance routines, so your staff can handle basic tasks. You can set a schedule for checks and cleaning to avoid unexpected breakdowns.

-

Clean belts and sensors weekly.

-

Check for loose screws or worn parts monthly.

-

Update software and control settings as needed.

Maintenance keeps your conveyor running smoothly and protects your investment.

Cele mai bune practici

System Integration

You should connect your NG/OK conveyor with your inspection and automation systems for the best results. Start by checking that your conveyor supports SMEMA or other standard interfaces. This step helps you avoid connection problems. Use the same communication protocols across your equipment. You can work with your equipment supplier to set up the integration. Test the system with a few boards before running full production. This approach lets you catch issues early.

Tip: Keep a wiring diagram and software settings handy. This information helps you troubleshoot quickly if problems come up.

Staff Training

Trebuie să train your staff to use and maintain the NG/OK conveyor. Begin with a hands-on demonstration. Show your team how to load boards, read the control panel, and respond to alarms. Use simple checklists for daily and weekly tasks. Encourage your staff to ask questions during training. You can also create quick reference guides for new operators.

Key training topics:

-

Safe operation of the conveyor

-

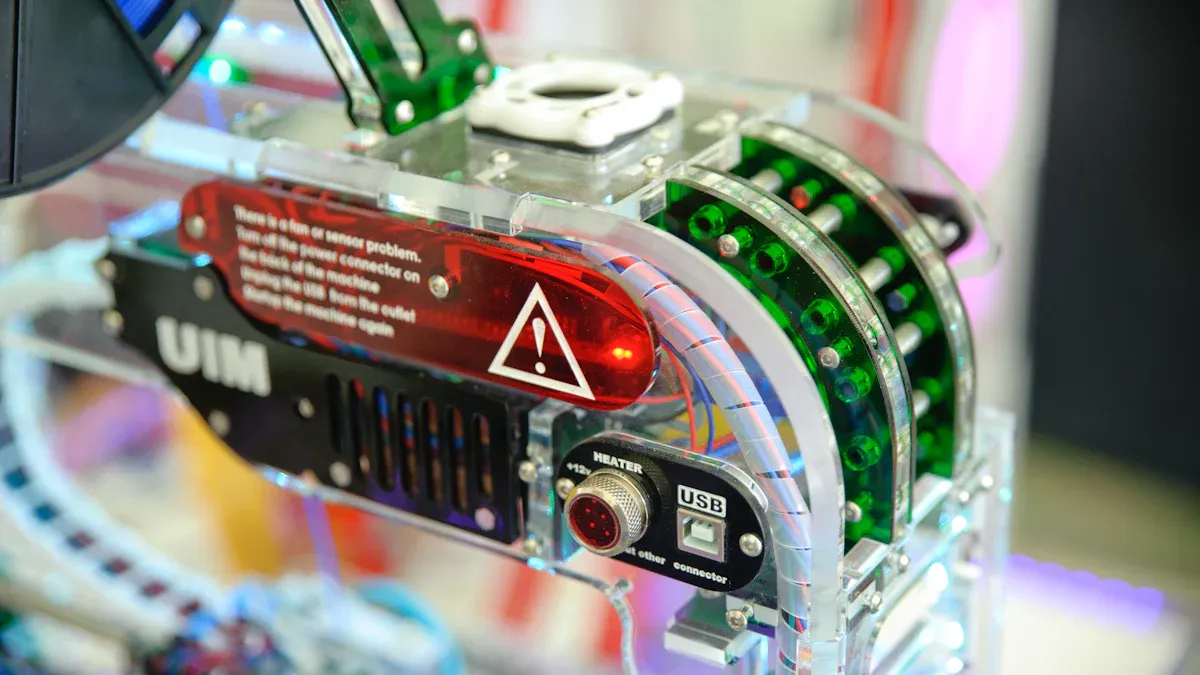

Recognizing and responding to error messages

-

Basic cleaning and maintenance steps

Note: Well-trained staff help you avoid downtime and keep your line running smoothly.

Performance Monitoring

You should monitor your NG/OK conveyor’s performance to keep your SMT line efficient. Track the number of boards sorted, error rates, and downtime. Use the conveyor’s built-in data features if available. Review this data weekly to spot trends or problems. Set clear targets for sorting speed and accuracy.

|

Metric |

What to Watch For |

|---|---|

|

Sorting Speed |

Boards per hour |

|

Error Rate |

Incorrect sorting of events |

|

Downtime |

Minutes per week |

Regular monitoring helps you catch small issues before they become big problems. This practice supports your quality goals and keeps your production on track.

You can strengthen your SMT line quality control by using NG/OK Screening Machines. These machines help you boost efficiency, cut errors, and keep your product quality high. Review your current process and see where you can improve. If you want to learn more, reach out to equipment suppliers or research new solutions for your production line.

ÎNTREBĂRI FRECVENTE

What does NG/OK mean in SMT production?

NG stands for “No Good,” and OK means “Good.” You use these terms to sort PCBs after inspection. NG boards need review or repair. OK, boards move to the next process.

How do NG/OK conveyors connect to inspection machines?

You connect NG/OK conveyors using standard interfaces like SMEMA. The conveyor receives inspection results directly from AOI or ICT machines. This setup lets you automate sorting and reduce manual handling.

Can you adjust the NG/OK conveyors for different PCB sizes?

Yes, you can adjust the conveyor width for various PCB sizes. Most machines use a lead screw or similar mechanism. This feature helps you handle different products without changing equipment.

What maintenance do NG/OK conveyors need?

You should clean the belts and sensors regularly. Check for loose screws or worn parts each month. Follow the manufacturer’s maintenance schedule to keep your conveyor running smoothly.

Do NG/OK conveyors store data for traceability?

Many NG/OK conveyors support data collection. You can track each board’s status and generate quality reports. This feature helps you find defects quickly and improve your process.