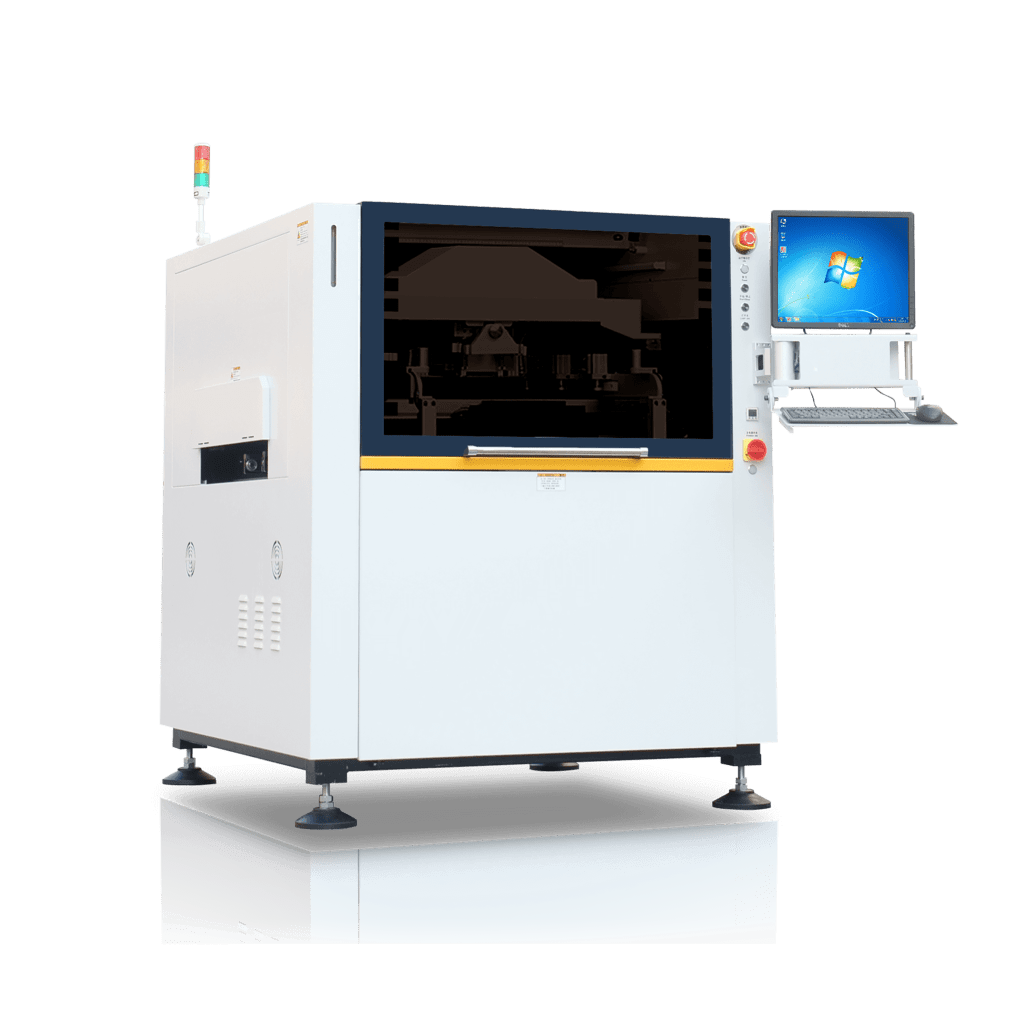

Product Overview

1. Function Overview

CP500 is a high-speed and high-precision solder paste printing machine with a repetition accuracy of ± 12 μ m and a printing accuracy of ± 25 μ m. The printing production cycle is a total of 8 seconds (excluding solder paste printing and cleaning). It can handle PCB boards ranging from 50mm × 50mm to 500mm × 350mm, and it only takes 2 minutes from installing the steel mesh to starting production, making the work simpler. Improve the speed of wire changing while ensuring quality.

2. Basic features of the product:

2.1. The PCB size compatibility range is wide, and it can support PCBs with different thicknesses ranging from 50mm × 50mm to 500mm × 350mm; 2.2. High precision printing resolution;

High positioning accuracy, with a repeat positioning accuracy of ± 12 μ m; Printing accuracy ± 25 μ m; Support adhesive printing;

2.3 Fully automatic control can improve production efficiency, control quality, and save costs;

Automatic steel mesh positioning; Automatic PCB calibration;

Software pressure closed-loop feedback system;

Automatic steel mesh cleaning (dry cleaning, wet cleaning, vacuum cleaning);

2.4. Adopting the suspended printing head independently developed by Huanchengxin Company, the pressure of the scraper is automatically balanced, and the pressure control is precise, which can achieve perfect solder paste forming effect;

2.5. Programmable motor controls the separation speed and stroke of scraper and steel mesh, which can flexibly achieve multiple demolding methods; 2.6. Multi functional PCB fixed positioning system, PCB positioning is convenient, fast, and accurate;

2.7. Sistem de poziționare vizuală sus și jos; 2.8. Sistem inteligent de prelucrare a imaginii;

2.9. Supports 2D, SPI online, and SPC functions;

3. Solder paste printing range

3.1 Production and processing of surface mount components such as resistors, capacitors, inductors, diodes, transistors, etc. using SMT technology:

01005, 0201, 0402, 0603, 0805, 1206, and other specifications and dimensions;

3.2. IC: Supports packaging such as SOP, TSOP, TSSOP, QFN, etc., with a minimum pitch of 0.3mm;

Support BGA, minimum ball diameter (Ball) 0.3mm;

3.3 Printing size: 50mm × 50mm -500mm × 350mm; 3.4 PCB specifications: thickness 0.4mm-6mm;

3.5 FPC specifications: Thickness below 0.4mm (with fixture).

4. Application scope

The production and manufacturing of mobile phones, communications, LCD TVs, set-top boxes, home theaters, in car electronics, medical power equipment, aerospace and other products/equipment, as well as the production and processing of general electronic products.

Product specifications

* Următoarele date de testare se bazează pe o temperatură ambientală de 25 grade Celsius și umiditate 60%.

| proiect | parametru | |

| Repetarea poziției Precizia | ±12μm(@6σ Cmk≥2.0) | |

| Acuratețea imprimării | ±25μm(@6σ Cmk≥2.0) | |

| Viteza de imprimare/ciclu (Durata ciclului) | <8s (excluding printing and cleaning time) | |

| Schimbarea produselor | <5Min | |

| Dimensiunea șablonului ecranului/Min (X×Y) | 470mm × 370mm | |

| Dimensiune ecran Stencil / Max (X × Y) | 780mm × 737mm | |

| Ecran Stencil dimensiune / grosime | 20mm - 40mm | |

| Dimensiunea / minimul imprimării PCB (dimensiunea / minimul PCB) (X × Y) | 50mm × 50mm | |

| Dimensiune imprimare PCB / Max (Dimensiune PCB / Max) (X × Y) | 500mm × 350mm | |

| Dimensiune / grosime PCB | 0.4 – 6mm (a jig is required for diameters below 0.4mm) | |

| Raport de deformare PCB | <1% (pe baza lungimii diagonalei) | |

| Partea de jos a plăcii Dimensiune | 13mm, 23mm (opțional) | |

| Marginea dimensiunii plăcii | 3 mm | |

| Transport ridicat | 900 ± 20 (mm) | |

| Direcția de transport | stânga-dreapta;dreapta-stânga;stânga-stânga;dreapta-dreapta | |

| Viteza de transport | 100-1500 (mm/sec) Control programabil | |

| PCB positioning

(Board Location) |

Sistem de sprijin | Pini de ejecție magnetici/suporturi pentru margini |

| Sistem de prindere | Elastic side clamp/Z-axis pressure plate/vacuum suction (optional) | |

| Cap de imprimare | Cap de imprimare programabil controlat electronic (standard) | |

| Viteza racletei | 10 - 200 (mm/sec) | |

| Presiunea racletei | 0 – 15(kg) (software pressure closed loop) | |

| Unghiul racletei | 60°/55°/45° (opțional) | |

| Tip racletă | Oțel răzuitor, răzuitor de cauciuc, alte tipuri de răzuitoare trebuie să fie personalizate | |

| Viteza de separare a șablonului | 0,01 - 125 (mm/sec) control programabil în trei trepte | |

| Metoda de curățare | Curățare uscată, curățare umedă, aspirare (programabile în orice combinație) | |

| Interval de reglare a mesei | X:±4mm;Y:±6mm; θ : ±2 ° | |

| Imagine tip fiducial | Coordonate geometrice standard, tampoane/deschideri | |

| Sistem de camere video | Cameră digitală/sistem de vedere coaxial telecentric/sursă de lumină LED independentă coaxială în patru direcții/în formă de inel | |

| CCD(Camera) | 1.3 million pixels, 6.4mm × 4.8mm upper and lower dual fields of view, pixel accuracy 5 μm (optional field of view 10mm × 8mm) | |

| Presiunea aerului | 4 - 6 (Kg/cm2) | |

| Consumul de aer | Aproximativ 0,007m³/min | |

| Metoda de control | Control PC | |

| Sursă de alimentare | AC:220-240V,50/60HZ 1 Φ 2.5KW,13A | |

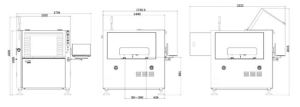

| Dimensiunile mașinii (L×W×H) | 1250 × 1450 × 1510 (mm) (excluding the lighthouse height, see the product external dimensions) | |

| Greutatea mașinii | Approx:1100Kg | |

| Temperatura de funcționare | -20℃ - +45℃ | |

| Umiditatea de funcționare | 30% – 60% | |

Configurația mașinii

1. Control electronic programabil pentru reglarea presiunii răzuitorului Cap de imprimare răzuitor suspendat:

1.1. The scraper pressure can be adjusted by programmable method, and the pressure control is accurate;

1.2. The front and rear scraper pressures are adjusted independently to ensure that there is no pressure imbalance caused by the fatigue deformation of the scraper material, which will cause the difference in front and back printing;

1.3. The programmable motor controls the separation speed and stroke of the scraper and steel mesh;

2. Standard stainless steel scraper, unique design, longer blade life ;

3. Visual alignment system ;

4. Platform UVW automatic correction system ;

5. PCB clamping and supporting device:

5.1, Magnetic ejector pin;

5.2. Flexible clamping device on the PCB side to ensure that the PCB will not bend or deform when clamped; 5.3. Z-axis pressure plate;

5.4, strong vacuum suction (optional);

5.5, Flexible automatic ejector (optional);

6. CNC guide rails adjust the transport width and speed ;

7. Three programmable steel mesh cleaning systems: dry, wet and vacuum, which can be combined arbitrarily ;

8. Industrial control computer, Windows 7 operating system, Chinese/English interface;

9. Intelligent software diagnostic system ;

10. Support 2D, SPI connection, SPC software functions ;

11. Standard SMEMA connection interface.

Product peripheral placement structure size diagram

Disclaimers

Due to real-time changes in product batches and production supply factors, in order to provide accurate product information, specifications, and features as much as possible, Huanchengxin may adjust and revise the text expressions, image effects, and other content on the above pages in real time to match the actual product performance, specifications, parameters, components, and other information; In case of necessary modifications and adjustments to the above-mentioned pages, no special notice will be given;