| Model | KT-400/KT-280 | Notă |

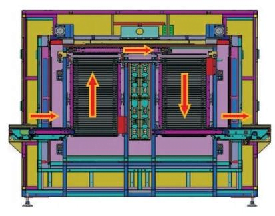

| Gama de producție aplicabilă | Producția de întărire PCBA după acoperirea produsului | |

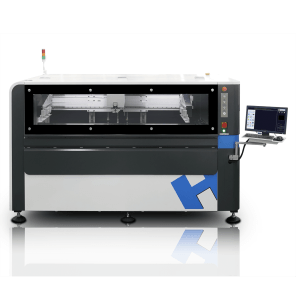

| Dimensiuni (mm) | 2500(L)x1740(w)x2240(H) 2500(L)x1580(w)x2450(H) |

Înălțimea și greutatea patului mașinii vor crește în funcție de cerințele stratului personalizat |

| greutate (Kg) | Aproximativ 1800/ 1650 | |

| Timp de încălzire | Aprox.30minute | |

| Intervalul de setare a temperaturii | Cameră Temp.180 ℃ | |

| Precizia controlului temperaturii | ±1.0°C | |

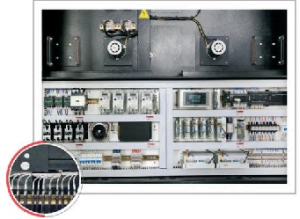

| Metoda de control | Control PID în buclă închisă + unitate SSR + ecran tactil | |

| Abaterea distribuției temperaturii plăcii PCB | ≤±3.0°C | |

| Timpul cuptorului | În funcție de setarea parametrilor cererii produsului | |

| Dimensiunea maximă PCB (mm) | 400(L)*400(W) 300(L)*280(W) |

Plăcile mici pot fi utilizate de tăvi de întărire, dimensiunea non-standard poate fi personalizată |

| Interval de reglare a lățimii șinei | 100 ~ 400mm | |

| Spațiu de bord | PCB spațiu superior = 25.4mm grosime placă - sub înălțimea componentei | Poate fi personalizat cu un multiplu integral de 25,4 spațiere palet sau alte specificații ale lanțului, în funcție de dimensiunea lanțului, spațiul de bord va fi diferit |

| Înălțimea transmisiei (mm) | 900±20mm | Echipament de distribuție de referință pentru clienți |