How to Use a Reflow Oven: A Comprehensive Step-by-Step Guide

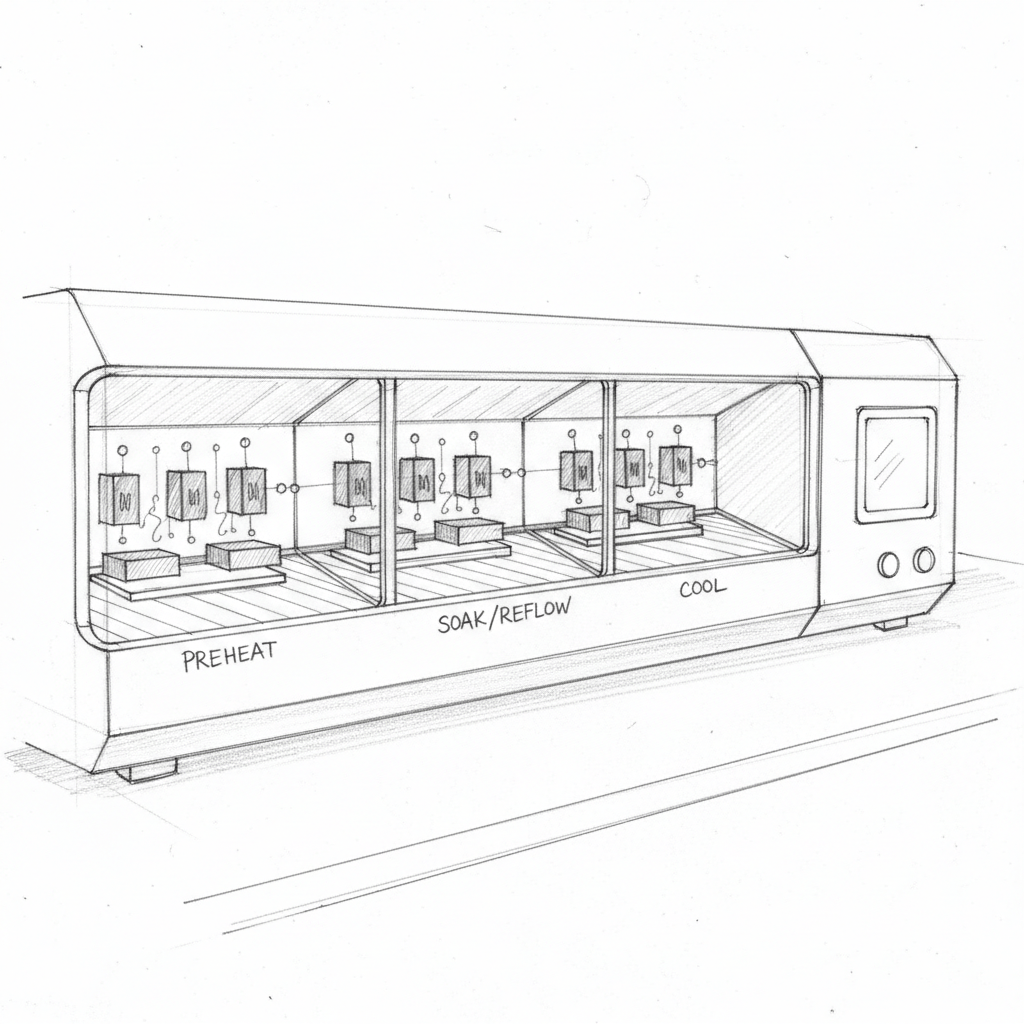

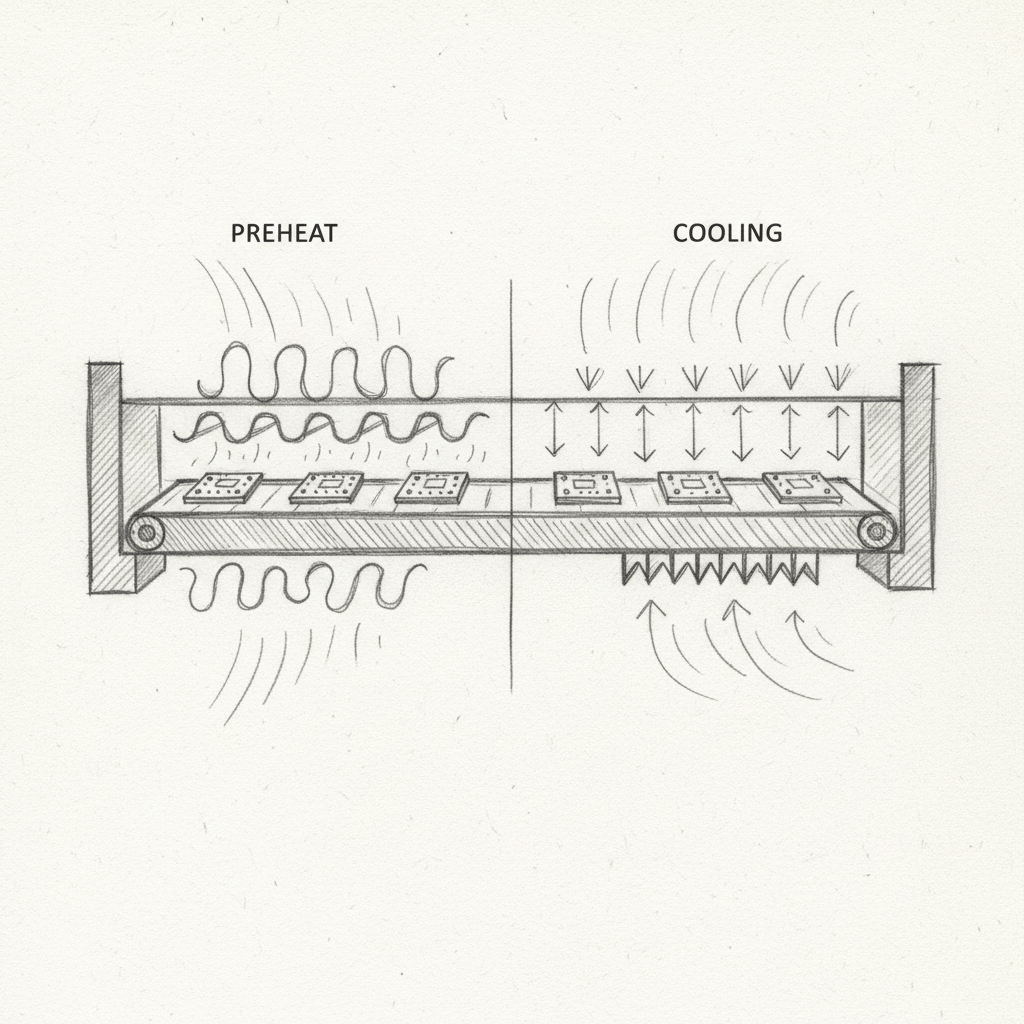

Reflow ovens are crucial in electronics manufacturing, particularly for Surface Mount Technology (SMT), providing precise soldering on PCBs through phases like preheating and cooling. Advanced multi-zone heating and controls facilitate efficient and defect-free production, supporting lead-free soldering at high volumes. Key considerations for optimizing reflow oven setup include configuring temperature profiles, maintaining ventilation, and performing initial tests for quality control. Monitoring critical parameters like temperature uniformity and adjusting operational settings in real-time ensures high-quality solder joints and meets industry standards. Regular maintenance, adapting to material changes, and engaging with industry insights are essential practices for maximizing efficiency and sustaining competitive advantages in SMT operations.