Client Introduction

Tiandi Weiye Technology Co., Ltd. was founded in 1994 and is a global provider of intelligent security solutions. With “builder” as its core value, the company is committed to serving artificial intelligence, blockchain, cloud computing, big data, information technology, and other technologies in various fields. With large laser models as the technical foundation, relying on technological innovation and precision quality, it provides the world with intelligent, efficient, and safe security applications.

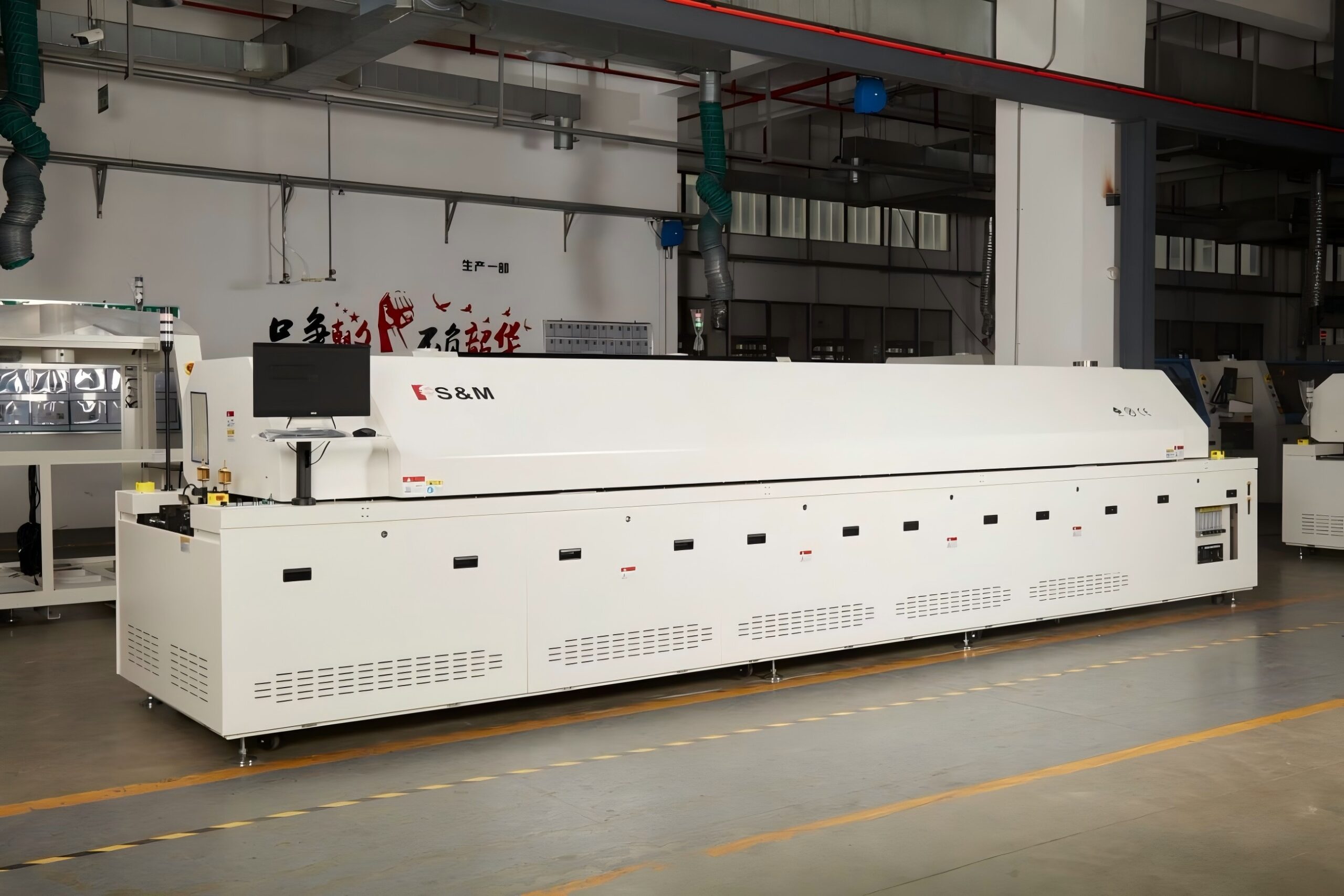

About Equipment

S&M Equipment Features

- Windows 10 operating system, can realize the free switching of the operation interface in Chinese and English.

- Siemens PLC+PID closed-loop control to achieve highly precise temperature control and repeatable profiles.

- Модульная конструкция, удобное и быстрое обслуживание, сокращение времени и стоимости обслуживания.

- The rail surface is treated with a hardening process to make it more stable.

- Sound and light alarm and information prompt function with various faults, including temperature deviation, speed deviation, detention board and drop board, wind fault, error operation, etc.

- Новая система управления газом позволяет повысить эффективность обмена горячим газом в печи, добиться лучшей термокомпенсации и тепловой эффективности, а также полностью удовлетворить требования различных процессов бессвинцовой пайки.

Customer workshop

S&M After Sales Team

- Обучение и интеграция: Наши специалисты обеспечивают беспрепятственную интеграцию нового оборудования в существующую производственную линию и проводят комплексное обучение персонала.

- Наша забота о вашем успехе выходит за рамки продажи. Наша послепродажная поддержка направлена на то, чтобы ваша линия SMT работала с максимальной производительностью.

- Программы расширенной гарантии: Регулярное техническое обслуживание имеет решающее значение для долговечности вашего оборудования. Мы предлагаем программы профилактического обслуживания, чтобы свести к минимуму время простоя.

Equipment Installation

- Install the computer in the reflow oven, install the rosin inlet and outlet, recycle the filter, and the oil tray, power on with UPS, open the oven box, remove the red fixed track bracket on the track, and confirm whether the track has a flared mouth.

- For reflow soldering, it is necessary to confirm that the input voltage is 380V, whether the phase sequence of the customer’s wiring N, R, S, and T is normal, power on the machine for a test, and confirm whether the fan direction and the temperature rise to a constant temperature are normal.

- Debug the process according to customer requirements, debug the process curve to achieve the required state, and test 2PCS boards to confirm whether the board passing effect is normal and whether the signal is normal.

Our Service Highlights

- Perfect Service: Establishing customer satisfaction with our services is the standard concept for testing the quality of our service work.

- High-standard service quality: standardized service process, regular skills training, on-site service order signing

implementation of a customer rating mechanism. - Efficient response speed: Response within 2 hours

On-site processing is within 12 hours within the province and 24 hours outside the province. - High-level service requirements: 7*24 hours all-weather service.