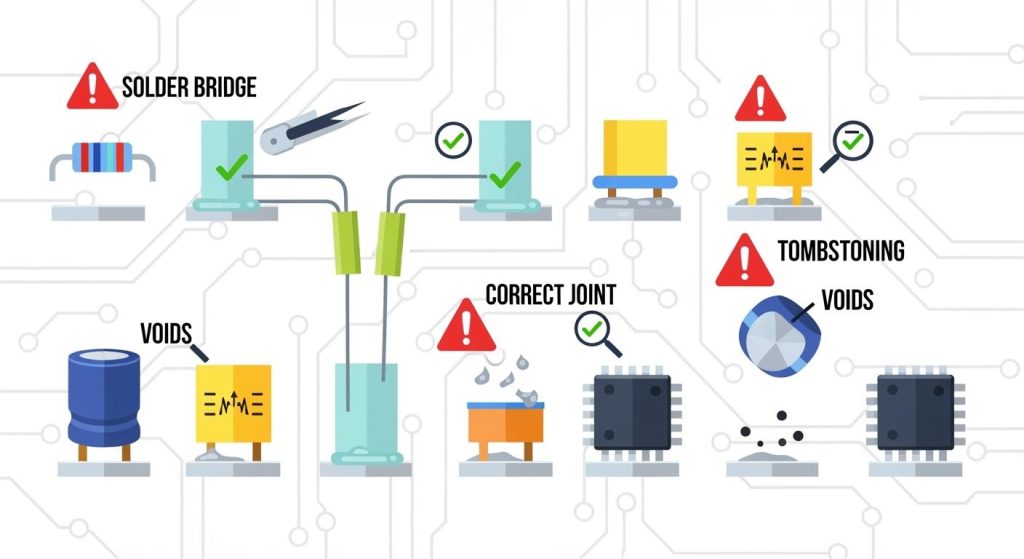

Основные причины дефектов пайки SMT и способы их предотвращения

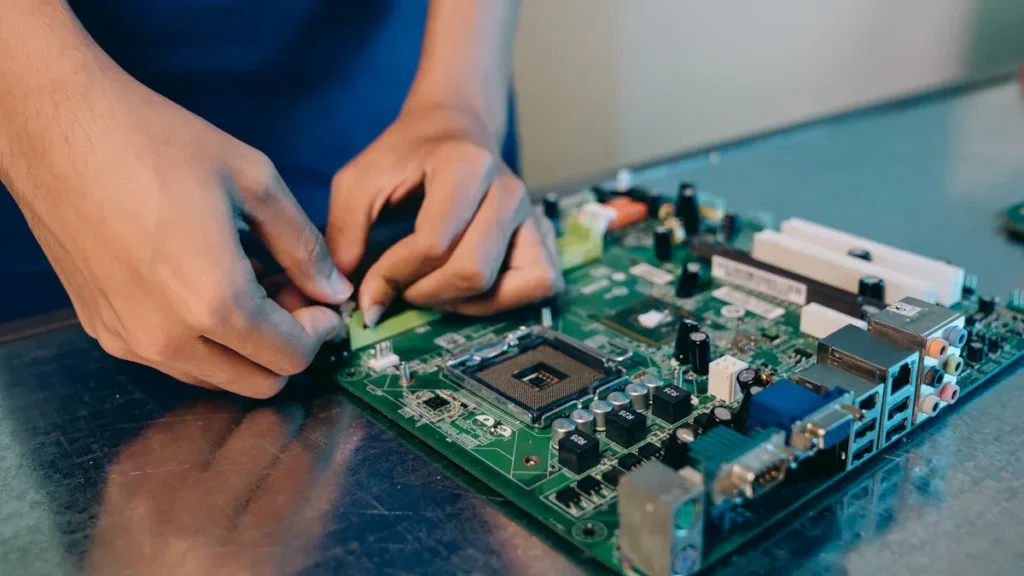

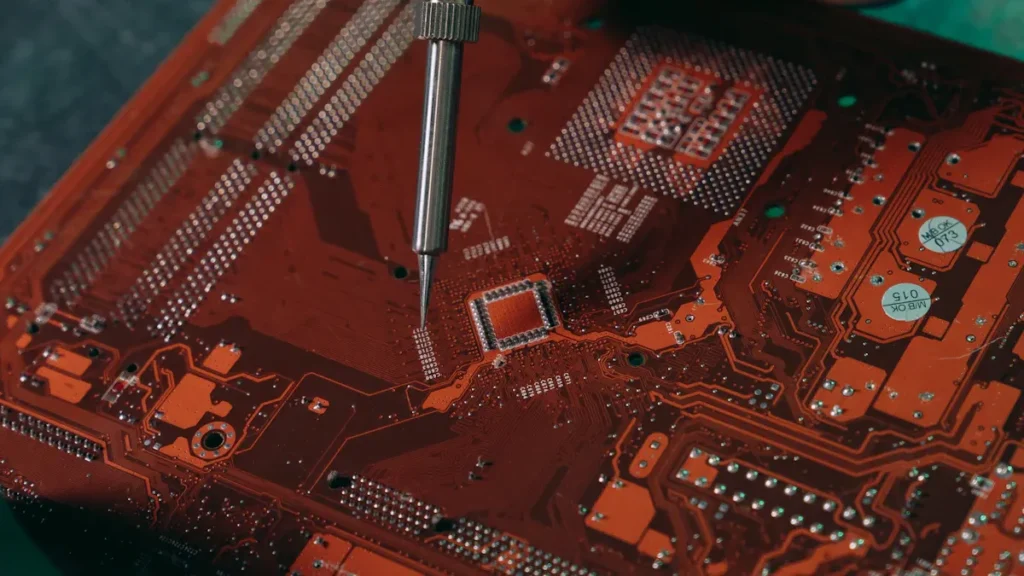

Дефекты пайки SMT, такие как перекрытия и наплывы, возникают из-за проблем с пастой, размещением и оплавлением. Предотвратите их с помощью контроля процесса и качественного оборудования.