You will see many big upgrades in the newest wave soldering machines:

Advanced process control uses closed-loop temperature control and real-time checks.

Automated defect detection helps make more good boards and fewer bad ones.

Industry 4.0 ideas are used for better maintenance and process improvement.

These upgrades help you get fewer defects, like tin bridging going down from 5.8% to 0.7%. They also make sure every board checked meets tough quality rules. The table below shows how new technology, rules, and market needs make these machines more flexible, reliable, and ready for the future.

Фактор | Impact on Flexibility, Reliability, and Future-proofing |

|---|---|

Technological Evolution | Better accuracy, saves energy, and more automation. |

Regulatory Environment | Equipment is safer and better for the environment. |

Pricing Dynamics | Smarter choices for long-term spending. |

Global Economic Factors | More people want reliable solutions. |

С&М is a leader in SMT equipment innovation. Selective wave soldering from S&M gives you what you need to meet high standards in today’s electronics production.

Кључне поруке

New wave soldering machines use better technology to lower mistakes. This helps quality go from 5.8% to 0.7%.

Real-time monitoring systems tell you about problems right away. This helps keep production good and stops delays.

Programmable settings let you change jobs fast. This makes results stay the same and saves time when making things.

Energy-saving designs use less power. This saves money and helps the environment.

Flexible alloy support lets you use different solder types. This follows world rules and meets what customers want.

Automation in Wave Soldering Machines

PLC and Robotics Integration

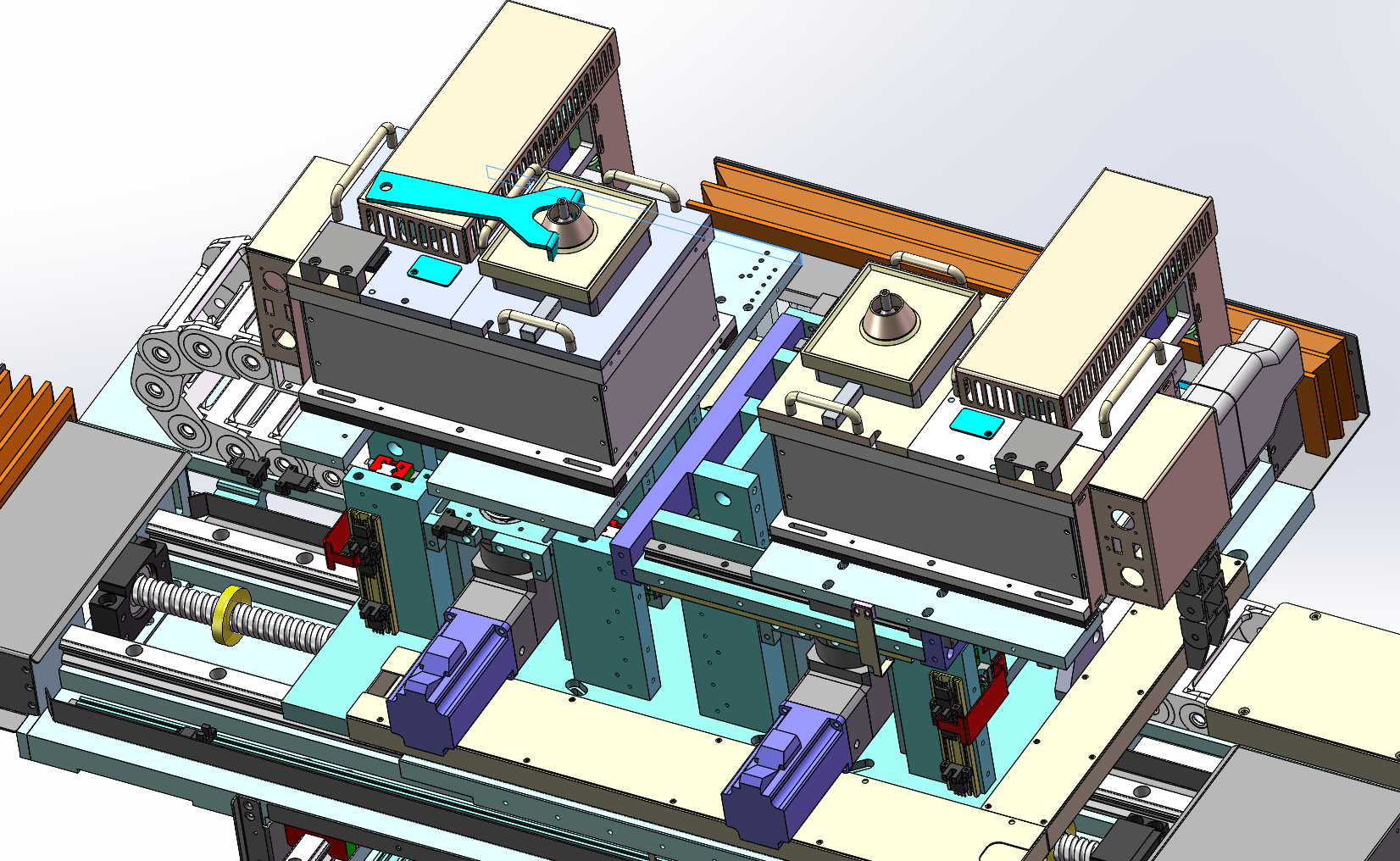

Wave soldering machines work differently now. Automation uses PLC controls and robotics. This makes production lines faster and more reliable. S&M’s SM-LⅡ Series shows these upgrades. The machine moves parts with high accuracy. You get better results with less work.

Auto-insertion and wave soldering equipment make things more precise, reliable, and fast.

Flux is placed exactly where needed. The solder wave stays steady. This means you get more good boards and almost no rework.

You can change jobs quickly. The machine keeps your work bridge-free and repeatable. It works well with many types of boards.

Modern wave soldering machines save you time. You fix fewer mistakes. You also make more good boards faster.

Real-Time Monitoring Systems

Real-time monitoring helps you work easier and safer. S&M’s SM-LⅡ Series uses smart monitoring. It watches every step. The system checks temperature, air pressure, and spray flow. If something is wrong, you get an alert right away.

Here is how these systems help you:

Monitoring System | Measurable Benefits |

|---|---|

Intelligent Condition Monitoring | |

Statistical Process Control | Alerts when trends get close to danger |

Predictive Models | Tells you how long parts will last |

Automated Work Orders | Makes maintenance requests with helpful details |

Priority Routing | Sends urgent alerts for important equipment problems |

False Positive Suppression | Keeps alerts accurate (85-90%) |

Real Implementation Example | Saved $340K in downtime and $85K in rework |

You can trust your wave soldering machine to keep working well. The system helps you avoid expensive problems. It keeps your boards at top quality.

Precision and Process Control by S&M

Intelligent Monitoring Features

You want every board to meet strict standards. S&M gives you intelligent monitoring in each машина за таласну заваривање. The system checks important details like temperature, spray flow, and air pressure. You see alerts if something changes. This helps you fix problems before they grow.

Tip: Smart monitoring means you spend less time checking by hand. You trust the machine to watch for errors.

You get more good boards and fewer mistakes. The machine records each step. You can look back at the data to find patterns. This helps you improve your process over time.

Here is what you can expect after using S&M’s next-generation wave soldering machine:

Metric | Value |

|---|---|

Defect Rate | |

Брзина производње | Hundreds of boards/hour |

Rework Reduction | Significant due to fewer defects |

You see fewer defects and less rework. Your line runs faster and smoother.

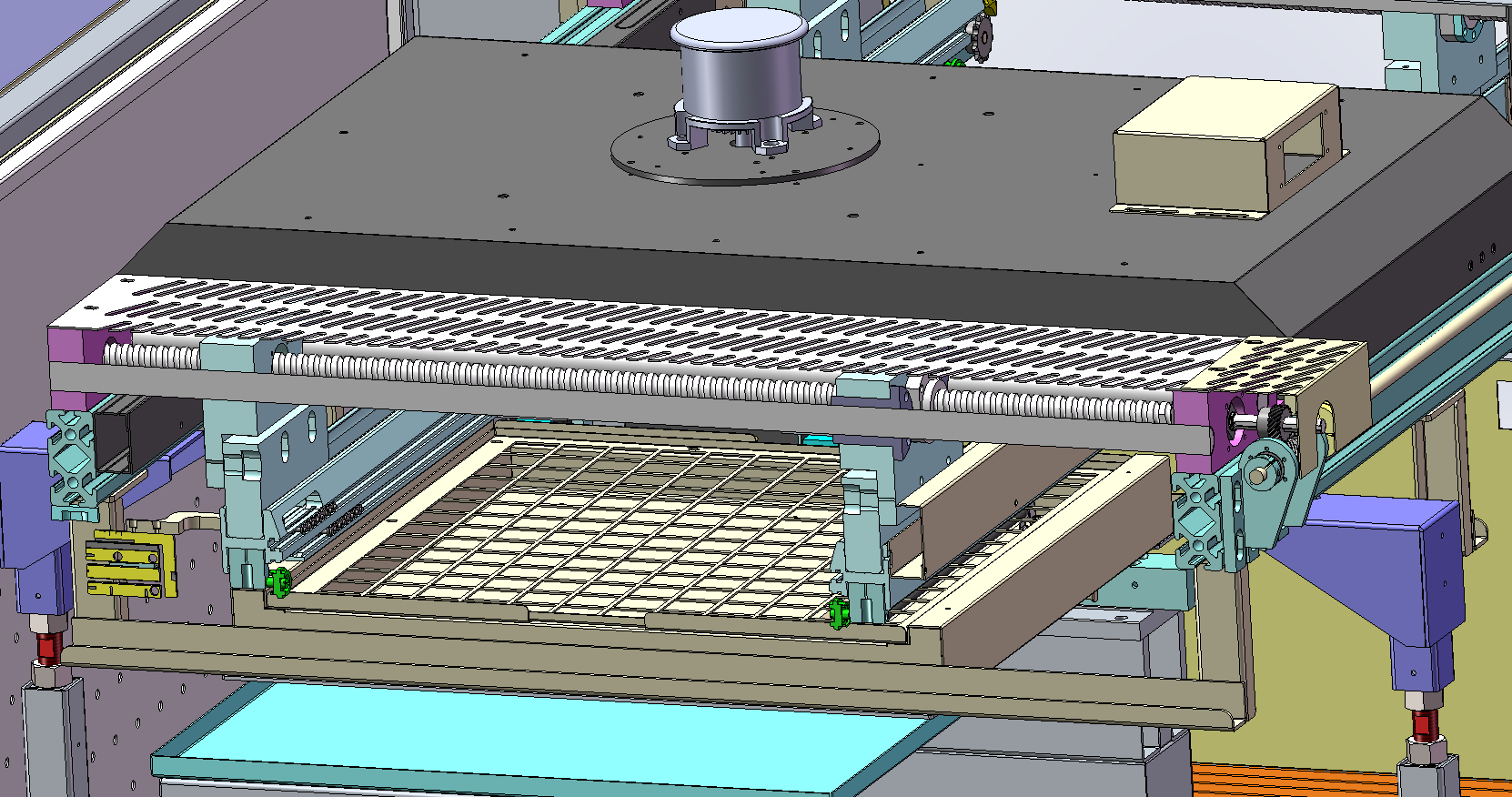

Programmable Parameters and Recipes

You control every part of the soldering process. S&M lets you set and save recipes for each job. You choose the temperature, time, and solder wave height. The machine remembers your settings. You switch jobs quickly without mistakes.

You save recipes for different boards.

You change settings with a few clicks.

You keep results consistent every time.

This feature helps you avoid errors. You do not need to reset everything for each new job. You get reliable results, even with complex boards.

You see how S&M’s precision and process control make your work easier. You get better boards, faster production, and less waste.

Energy Efficiency and Maintenance

Low Power Consumption

You want to use less energy and save money. New wave soldering machines help you do this. These machines have smart designs that lower power use. For example, the preheater has its own temperature controls. You only heat the spots you need. This saves energy.

Here is how these machines use power:

Функција | Опис |

|---|---|

Forced convection hot air pre-heating | Heats boards fast and evenly. It does not waste much energy. |

Startup power | Uses 26 kW when you turn on the machine. |

Operational power consumption | Uses 12 kW during normal work. |

You also get low-flux use and local nitrogen inerting. These features make your process work better and waste less. You can set each preheating area by itself. This means you do not use extra power. The parts need little care, so you spend less time fixing things.

Tip: Using less power helps the planet and saves you money.

Quick-Release and Easy Cleaning

It is important to keep your wave soldering machine clean. S&M makes cleaning simple for you. The quick-release nozzle lets you take it off and clean it fast. You soak the nozzle in cleaner and dry it with air. This keeps the nozzle working well.

You should clean the machine based on how much you use it. If you use it a lot, remove dross every day. Do a deep clean each week. The nozzle design lets you take it apart quickly. You can clean tough stains and dirt easily.

Taking it apart is quick.

Cleaning is easy and saves time.

Regular care keeps your machine working well.

You get more time to work and better results. Your maintenance team will like the easy cleaning steps.

Lead-Free and Multi-Alloy Soldering

Flexible Alloy Support

You need a wave soldering machine for many solder types. S&M’s SM-LⅡ Series lets you use different alloys. You can pick lead-free solder or other alloys for your boards. This helps you work with many products. You can meet what customers want.

You change alloys fast without changing everything.

Your process stays steady, even with new materials.

You get strong joints and fewer defects.

S&M’s machine lets you set the temperature and time for each alloy. You control the solder wave height for every job. This means you get good results with any alloy.

Tip: Flexible alloy support helps you get ready for new jobs and new rules.

Industry Compliance

You must follow strict rules in electronics. Many countries have laws about dangerous substances. The European Union’s RoHS Directive says no lead in most electronics. REACH rules also say which chemicals you can use.

Here is a table that shows how solder types follow these rules:

Solder Type | Compliance Status |

|---|---|

Leaded Solder | Not RoHS-compliant; restricted globally |

Lead-Free Solder | Fully compliant with RoHS and REACH |

You see lead-free solder is best for global standards. S&M’s машина за таласну заваривање works with lead-free and multi-alloy soldering. You can trust your boards to pass checks and go to markets everywhere.

REACH affects which soldering materials you use.

Many places have rules about lead and other chemicals.

You keep workers and customers safe by following these rules. You can sell to more markets. S&M helps you stay ahead with machines that meet these tough standards.

Modular Design and Scalability

Dual Platform Structure

You need a wave soldering machine for your goals. S&M’s dual platform gives you more control. You can run two jobs at once. This design helps with different board sizes and types. The nozzle moves accurately. This means better solder joints and fewer mistakes.

The dual platform lets you switch tasks fast. You do not wait for one job to finish. Your line keeps moving. Your output stays high. The machine uses computer control. You set up each job with a few clicks. You get the same results every time.

Here is a table that shows how S&M’s modular design helps you:

Функција | Корист |

|---|---|

Accurate nozzle movement | |

Computer control | Easy path programming |

Automatic recipe | Fast setup and repeatable results |

Stable transmission | Reliable product flow |

Tip: Dual platform machines help you finish jobs on time. They also make hard jobs easier.

Customization Options

You want a machine that fits your needs. S&M gives you many ways to customize. You can add real-time data analytics. This helps you track your process. Predictive maintenance stops breakdowns before they happen. IoT monitoring lets you check your machine from anywhere. Advanced sensors and automated diagnostics keep things running well.

You can connect your machine to MES systems. This gives you full production transparency. Remote monitoring lets you know your machine works well. You do not have to be on site.

Here are some customization options you can pick:

Real-time data analytics

Predictive maintenance

IoT-enabled process monitoring

Advanced sensors

Automated diagnostics

Remote monitoring capabilities

MES integration for production transparency

Many industries use these features. You see them in aerospace, automotive, medical devices, and telecommunications. Your machine grows with your business. It adapts to new challenges.

Note: Customization makes your wave soldering machine fit your line perfectly.

User Interface and Connectivity

Touchscreen Controls

You want a machine that is simple to use. S&M’s selective wave soldering machines have a modern touchscreen. The menus are easy to read. The buttons are big and clear. You tap the screen to set up jobs. You can change recipes and check the machine’s status. The touchscreen helps you work faster. You make fewer mistakes.

You change temperature, time, and solder wave height by tapping.

You save recipes for different boards.

You load recipes quickly.

You see alerts and messages right away.

The touchscreen shows you live data. You watch the process as it happens. You see if something needs fixing. You do not need special training. The screen gives you steps to follow.

Tip: Touchscreen controls help you finish jobs fast. They keep your production line moving.

Here is a table that shows what you can do with the touchscreen:

Функција | Корист |

|---|---|

Recipe Management | Quick job setup |

Fast problem spotting | |

Easy Adjustments | Fewer mistakes |

Alert Notifications | Fast response |

MES/ERP Integration

You want your machines to talk to your factory systems. S&M’s wave soldering machines connect to MES and ERP platforms. You send and get data right away. You track production and manage inventory easily. You plan jobs without extra work.

You see production numbers on your computer.

You check machine status from your desk.

You get automatic reports for quality and output.

You link your machine to other systems for full control.

MES/ERP integration helps you make smart choices. You find problems early and fix them fast. You keep your factory neat and working well.

Note: Connecting your wave soldering machine to MES and ERP systems gives you more control and better results.

You use these features in places like car factories, airplane makers, and medical device companies. Your machine fits into your digital factory. You are ready for new jobs and growth.

S&M Selective Wave Soldering in Industry

Applications in Military and Aerospace

You need very reliable products for military and aerospace work. S&M’s selective wave soldering machines help you meet these hard needs. You can count on these machines to give the same good results every time. In these jobs, even a tiny mistake can be a big problem. That is why you need equipment that always works right.

Here is how S&M’s technology helps in these fields:

Application Area | Performance Requirements |

|---|---|

Aerospace and Defense |

You use selective soldering for boards that control flight, talking, and navigation. The machines make clean and strong joints every time. You also use less solder, so you save money and help the planet.

Selective soldering is good for PCBs with both through-hole and surface-mount parts. You can work on tricky boards without extra steps.

Manufacturers say they like S&M’s machines because they lower defects and keep quality high. You can trust these machines for the most important jobs.

Automotive and Medical Device Use

You need safe and reliable products for cars and medical devices. S&M’s selective wave soldering machines help you reach these goals. The machines follow strict rules for safety and quality. You get perfect solder joints with no mistakes allowed.

See the main features and where you use them:

Key Features of Class III | Typical Applications |

|---|---|

No room for error: Every solder joint, component placement, and surface must meet strict inspection criteria with no cosmetic imperfections allowed. | Medical devices (life-support systems, diagnostic equipment) |

Extended reliability and lifespan: Products must perform flawlessly in harsh environments, under continuous use or critical conditions. | Military electronics (communication systems, radar) |

Higher cost and longer production: The level of detail and inspection required increases both time and production cost. | Aerospace electronics (navigation, avionics) |

Automotive safety systems (airbags, braking systems) |

You use these machines for airbags, brakes, and life-support devices. The machines help you stop mistakes and keep people safe. You also save time because the process is fast and correct.

Selective soldering is great for small, crowded boards.

It keeps sensitive parts safe from too much heat.

It cuts your costs and lowers waste.

Now you see why S&M’s selective wave soldering is a smart pick for high-reliability industries. You get strong, safe, and long-lasting products every time.

Comparing Next-Gen Wave Soldering Machines

Technology Advancements

There are big changes in wave soldering machines. New machines use eco-friendly processes. They also use nitrogen atmosphere soldering. These upgrades help you make better joints. They also help you waste less. On-site nitrogen generation saves you money. Better compressor systems make your products higher quality. Real-time feedback checks the PCB as you work. This stops defects before they happen. Selective wave soldering gives you the same good results every time.

Here is a table that shows how these upgrades help:

Technological Advancement | Performance Improvement |

|---|---|

Eco-friendly processes | Less waste and fewer emissions |

Stronger, more reliable solder joints | |

On-site nitrogen generation | Lower costs for your operation |

Upgraded compressor systems | Better quality for your products |

Real-time PCB feedback | Fewer defects and higher build quality |

Selective wave soldering techniques | Consistent, high-quality joints |

These features help you follow strict rules. They also keep your line running well.

Performance and Value

You want to know if new machines are worth it. Next-generation machines cost more at first. But you save money later. They use less energy. They also need less fixing. You do not spend as much on repairs or downtime. New machines help you use lead-free soldering. This meets world rules and keeps people safe.

Here is a table that compares costs and benefits:

Аспект | Next-Generation Machines | Legacy Equipment |

|---|---|---|

Initial Purchase Price | Higher | Lower |

Operational Expenses | Lower | Higher |

Maintenance Costs | Lower | Higher |

Energy Consumption | Lower | Higher |

Lead-Free Soldering Costs | Higher | Lower |

More companies are picking new machines now. The market is growing quickly. Manufacturers want machines that save energy. They also want machines that can use many alloys. You see more smart features like real-time monitoring. Predictive maintenance is also popular. Small and modular designs help you change jobs fast.

Companies want machines that use less energy and work with many alloys.

More smart features like real-time monitoring and predictive maintenance are used.

Compact and modular designs help you switch jobs quickly.

Tip: Upgrading to next-generation machines helps you stay ahead in quality, efficiency, and following the rules.

You get lots of good things when you use a next-generation wave soldering machine. Here are the main benefits:

Корист | Опис |

|---|---|

High-Volume Production | You can make many boards fast and easily. |

Cost-effective | You spend less money because you waste less stuff. |

Consistent and Reliable | You get great quality every time with fewer errors. |

Versatile and Compatible | You can use many board shapes and sizes. |

Excellent Solder Joints | You make strong, neat connections with fewer problems. |

When picking a machine, check for lead-free support, smart controls, and Industry 4.0 features. These help you follow new rules and get ready for the future. S&M’s machines have advanced technology and are very dependable for your production line.

Често постављана питања

What makes S&M’s selective wave soldering machines different?

You can control the machine very well. It checks things as it works. You can change settings with easy recipes. The dual platform helps you finish hard jobs fast. S&M’s machines help you follow tough rules in many fields.

Can I use different solder alloys with these machines?

Yes, you can use lead-free and other alloys. You set the temperature and time for each alloy. You switch alloys fast and keep your work steady.

How does the machine help reduce defects?

The smart system watches important things like temperature and spray flow. You get alerts if something changes. This helps you fix problems early and keep defects low.

Is it easy to clean and maintain the machine?

Yes, you can take off the nozzle fast to clean it. The design makes regular care easy. You spend less time fixing and more time making good boards.