You need a simple way to compare suppliers for a nitrogen reflow oven. Find companies that know a lot about the technology. Make sure they have big factories and many workers. Ask if they can keep oxygen levels under 100 ppm. Check if their temperature stays steady within ±1°C. Fast replies and delivery rates over 95% mean they are dependable. S&M gives advanced options because they have lots of experience and a big, new factory.

Criteria | What to Check For |

|---|---|

Technical Expertise | R&D, patents, control systems |

Production Capacity | Factory size, skilled staff |

Quality Verification | Test reports, stable temperature, low oxygen |

Service Metrics | Quick support, high delivery rate |

ประเด็นสำคัญ

Find suppliers who know a lot about the product and can make many ovens. This helps you get good quality and trust the supplier.

Decide how much money you can spend and when you need the oven. Do this before you look at different suppliers. This helps you pick ones that match your budget and schedule.

Search for important things in nitrogen reflow ovens. These include better solder joints and saving energy. These features help you work faster.

Look at supplier certificates and read what customers say. This helps you pick a company that is trusted and gives good service.

Check how fast the supplier can deliver and if they help after you buy. This keeps your work going and stops long breaks in your assembly line.

Define Your Needs for Reflow Ovens

Assess Production Volume and Product Mix

First, think about how many products you make. Count what you build each day or month. If your workshop is small, you may need a tabletop reflow oven. Desktop reflow ovens also work for small jobs. Big factories need larger reflow ovens. These ovens can handle more pcb boards. Check your assembly line to see what fits. Some industries need special settings. LED and medical device makers have unique needs. S&M has many nitrogen reflow ovens. You can pick a model that matches your work.

Set Budget and Timeline

Set your budget before you look at suppliers. The price of a nitrogen reflow oven changes with size and features. Here is a table that shows price ranges:

Category | Typical Price Range (USD) | คำอธิบาย |

|---|---|---|

Entry-Level Ovens | $5,000 – $20,000 | Basic, good for small-scale or prototyping |

Mid-Range Ovens | $20,000 – $50,000 | Balanced cost and features for most manufacturers |

High-End Ovens | $50,000 – $150,000+ | Advanced, for large-scale production |

Think about how long you can wait for delivery. Some ovens take weeks or months to arrive. Custom features may take even longer.

Identify Key Features for Nitrogen Reflow Ovens

Make a list of what matters most for your process. Nitrogen reflow ovens have many benefits. Nitrogen stops oxidation. This helps you get better solder joints. It also helps you work faster. You will have fewer solder balls and less rework. These ovens save money because they use less energy. They also finish jobs quicker. Here are some features buyers want:

Key Feature | คำอธิบาย |

|---|---|

Nitrogen prevents oxidation, leading to stronger solder joints. | |

Increased productivity | Reduces solder balling, minimizing the need for rework and enhancing overall productivity. |

Reduced costs | Lowers energy consumption and time for reflowing solder paste, making it cost-effective. |

S&M’s VS Series nitrogen reflow ovens have advanced features. They offer precise temperature control and modular design. Always choose an oven that fits your needs and meets industry standards.

Key Criteria for Comparing Nitrogen Reflow Oven Suppliers

When you want to pick the best supplier for reflow ovens, you should look at a few important things. These points help you make a smart choice and find the right company for your assembly line.

Product Quality and Certifications

You want a nitrogen reflow oven that works well and meets industry rules. Check if the supplier has certifications like ISO or high-tech enterprise status. These show the company follows strict quality rules. S&M has many certifications and a big, modern factory. This means you can trust their machines for your pcb assembly.

You should also check how often the ovens break and how much care they need. The table below lists common problems and ways to stop them:

Failure Type | ผลกระทบต่อการผลิต | Prevention Tips |

|---|---|---|

Nitrogen Supply System Failure | Poor solder quality, more rework | Regular maintenance, monitor gas flow |

Oxidized Solder Joints | Weakened mechanical bonds | Ensure proper nitrogen supply |

A supplier with good certifications and low failure rates will help your soldering process go smoothly.

Technology and Performance Metrics

Modern reflow ovens use new technology to work better. You should look for features like good temperature control, energy saving, and automation. These features help you get even heat and make more products.

Good temperature control keeps the soldering process steady.

Energy-saving designs help you spend less and waste less.

Automation lets the oven change settings for each pcb.

Smart sensors and data help you control the process.

The number of heating zones is important too. More zones give you better control and let you make different things. Here is a table that compares popular models:

แบบจำลอง | Heating Zones | Nitrogen Consumption |

|---|---|---|

1809 MK7 | 9 | Reduced nitrogen consumption |

1913 | 13 | Reduced nitrogen consumption |

1936 | 10 | Reduced nitrogen consumption |

2049 MK7 | 15 | Reduced nitrogen consumption |

2156 MK7 | 17 | Reduced nitrogen consumption |

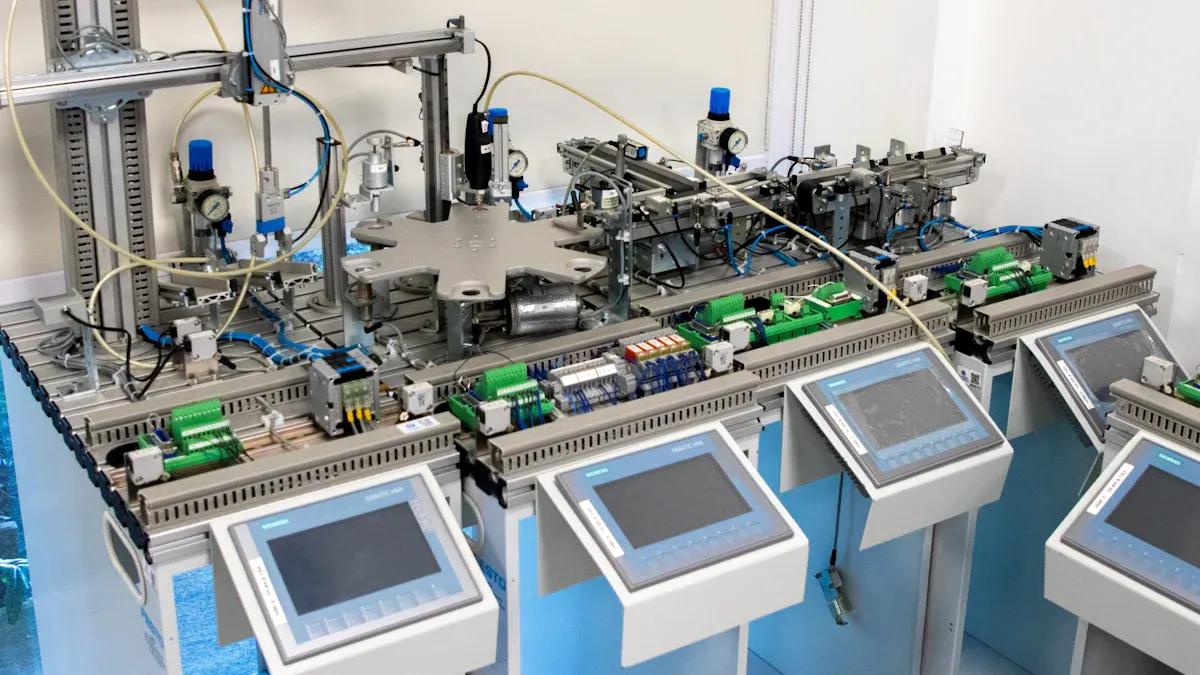

S&M’s VS Series reflow oven uses Siemens PLC and PID closed-loop control. This gives you good temperature control and even heat. The modular design also makes it easy to fix.

Pricing, Warranty, and Value

You need to look at the price, warranty, and value of each nitrogen reflow oven. Some suppliers give longer warranties and better help after you buy. This can save you money and trouble later.

Supplier | Warranty Period | After-Sales Service |

|---|---|---|

HTGD (GDK) | 2 years | Technical support, lifelong maintenance, software upgrades, training, door-to-door |

Charmhigh | 1 year | Online Q/A, troubleshooting, technical advice, one-to-one after-sale service |

A longer warranty and good support make your investment better. S&M gives strong support and cares about customers for a long time.

Supplier Reputation and Experience

You should always check how well-known and experienced the supplier is. Look for companies that have been in business for many years. Top suppliers often have more than 25 years of experience. S&M started in 2000 and is known for quality and new ideas.

Customer reviews and how often people buy again can tell you a lot. High reorder rates mean customers trust the supplier. You can also ask for references from other assembly lines.

Technical Support and After-Sales Service

Good technical support is important for smooth work. Fast answers help you fix problems quickly. The table below shows how fast some suppliers reply:

Supplier | Response Time |

|---|---|

Dongguan Kingsun Automation Technology Co. | ≤1h |

Dongguan ICT Technology Co. | ≤2h |

You should also check how happy customers are. High ratings show the supplier cares about your success.

Supplier Name | Key Metrics |

|---|---|

Shenzhen Eta Technology Co., Ltd. | Perfect on-time delivery record, highest revenue volume |

Dongguan ICT Technology Co., Ltd. | 67% reorder rate, strong client retention |

Wuxi KAYO Automation Equipment Co., Ltd. | Balanced excellence across all metrics |

S&M gives good after-sales service, training, and quick help for all reflow oven models.

Delivery and Lead Times

Fast and steady delivery is important for your work schedule. On-time delivery rates show if a supplier is dependable.

Supplier Name | On-Time Delivery Rate | Customer Impact |

|---|---|---|

Zhejiang Huaqi Zhengbang Automation Technology Co., Ltd. | Perfect | High reliability and operational efficiency lead to increased customer satisfaction and retention. |

Dongguan ICT Technology | 95% | Slight risk for time-sensitive projects may affect customer trust and satisfaction levels. |

S&M has a big factory and a high on-time delivery rate. This helps you keep your assembly line running without delays.

Tip: Always ask how long custom features will take, like vacuum reflow oven options or special pcb handling systems.

When you use these points to compare, you can find the right nitrogen reflow oven supplier for your needs. Focus on quality, technology, support, and delivery to get the best results for your assembly process.

How to Gather and Verify Supplier Information

Request Quotes and Proposals for Nitrogen Reflow Ovens

Always ask each supplier for a full quote. The proposal should have more than just the price. It needs to show what support you get. It should list oven features and company history. Use the table below to see what a good proposal has:

Proposal Component | คำอธิบาย |

|---|---|

Training, installation, and help for your nitrogen reflow oven. | |

Customer Feedback | Comments from users about soldering and support. |

Certifications | Proof of safety and quality like CE, RoHS, or ISO9001:2015. |

Company Background | Years in business and number of customers. |

คุณสมบัติของสินค้า | Details about nitrogen support, thermal precision, and technical advantages. |

This helps you compare suppliers and find the best value.

Arrange Product Demos and Factory Visits

You learn a lot by watching the oven work. Ask for a demo online or in person. S&M’s VS Series demo shows how the nitrogen system works. It also shows how easy it is to use. When you visit a factory, check if it is bigger than 6,000 m². Bigger factories have more inventory and faster delivery. Look for certifications like IPC-9850, ISO 9001, and CE or UL. These prove the supplier meets high standards.

Tip: During your visit, ask for test data on temperature uniformity (±1°C), oxygen levels, and nitrogen use. This shows the oven can handle your pcb and reflow jobs.

Check References and Customer Reviews

Contact other customers and ask about their experience. Find out how fast the supplier fixes problems. Ask if they deliver on time. Review scores and reorder rates show trust. You can check Alibaba Business+ for real buyer feedback.

Supplier Name | Review Score | Response Time | |

|---|---|---|---|

Zhejiang Huaqi Zhengbang Automation | 100% | 4.8 | ≤1h |

Wuxi KAYO Automation Equipment Co., Ltd. | 100% | 5.0 | ≤2h |

Shenzhen Eta Technology Co., Ltd. | 100% | 5.0 | ≤2h |

Review Documentation and Certifications

Ask for all important documents and certifications before you choose. These prove the oven meets safety and quality rules. Look for IPC-9701, SEMI S2/S8, ISO 9001, and CE marking. International standards make sure your nitrogen dual-rail reflow soldering oven is safe. This step protects your investment and saves money over time.

Making the Final Supplier Selection

Score and Rank Reflow Oven Suppliers

You can use a scoring system to help you choose. First, write down what you want in a nitrogen reflow oven supplier. Give each supplier a score for each thing on your list. This makes it easy to see which company fits your needs best. Use a table to compare things like certifications, how skilled the staff are, how many ovens they can make, and how many customers stay with them.

Importance | |

|---|---|

IPC-9850 compliance | Temperature profiling accuracy |

ISO 9001 certification | Quality management practices |

Staff expertise in thermal engineering | Effective nitrogen support |

Production capacity | Handles bulk orders, high throughput |

Third-party test reports | Verifies uniformity and energy efficiency |

On-time delivery rates | Reliable supplier performance |

Client retention rates | Strong after-sales service |

Add up the scores for each supplier. The one with the highest score is the best match for your assembly line and reflow oven needs.

Evaluate Trade-Offs and Risks

You should think about the good and bad points before you pick. Some suppliers have better vacuum reflow oven choices. Others have lower prices or cheaper long-term costs. Decide what is most important for your pcb and soldering work. Even heat and good pressure control help your solder joints. Flexible settings and nitrogen support let you do more types of jobs.

คำอธิบาย | |

|---|---|

Vacuum Level Control | Adjustable for specific assembly needs |

Temperature Uniformity | Consistent soldering results |

Pressure Control and Monitoring | Real-time for desired outcomes |

Process Flexibility | Handles diverse reflow and solder tasks |

Maintenance and Support | Minimizes downtime |

Think about how many boards you need, the price, and the help you get. Choose the supplier that fits your long-term plans.

Tip: Always ask if the supplier gives good technical help and fast repairs. S&M is known for quick and reliable service.

Negotiate Terms and Confirm Support

After you pick your top supplier, talk about the details. Ask how long the warranty lasts and what service you get. Make sure you know what is included. Good support saves you time and money. Ask if they will train you and help set up the oven. Make sure they will help if you have problems with your nitrogen reflow oven or vacuum reflow oven. Good after-sales service keeps your assembly line working well.

Note: A clear deal on warranty and support keeps your investment safe and helps you make more products.

You get better results if you use a simple checklist to compare nitrogen reflow oven suppliers.

You make good choices when you follow each step in this guide.

S&M’s advanced ovens and helpful support show what good quality looks like.

Remember: Picking the right supplier helps you build a strong assembly line and meet your production goals.

คำถามที่พบบ่อย

What certifications should you check when choosing a nitrogen reflow oven supplier?

You need to look for ISO 9001, CE, and RoHS certifications. These show the supplier follows safety and quality rules. S&M has these certifications, so you can trust their products.

How do you know if a supplier offers good after-sales support?

Read customer reviews and check how fast they reply. Ask about training, installation, and repair help. Quick answers and clear support plans mean you get help when you need it.

Why does temperature control matter in a nitrogen reflow oven?

Good temperature control keeps solder joints strong and stops defects. This gives you better product quality and fewer problems when you make things.

What features help reduce nitrogen consumption in reflow ovens?

Find ovens with smart gas systems and good heating zones. These features use less nitrogen and help you save money over time.