When you pick a reflow oven manufacturer, you should check throughput and stability. These things affect how well you make products and their quality. If you make stability better, you can lower defects by up to 37%. This also helps you save money every year. If you improve throughput, you can make 22% more products. The table below explains why these numbers are important:

Metric | คำอธิบาย | Impact on Manufacturing |

|---|---|---|

OEE | Traditional Overall Equipment Effectiveness | Often misses key operational parts |

MOEE | Modified Overall Equipment Effectiveness | Gives real-time data for better work |

Studies show that stable reflow oven work gives long-term value and trust. If you focus on these things, you get steady results and good value from your reflow process.

ประเด็นสำคัญ

Pay attention to throughput and stability to make products better and have fewer mistakes. – Pick a reflow oven that has the right heating zones and conveyor systems to work better. – Check and take care of the oven often and watch the settings to stop problems and help it work well. – Choose a manufacturer that people trust and who gives good help for success over time.

Throughput and stability in reflow ovens

Understanding throughput in solder reflow oven

It is important to know how throughput affects making electronics. Throughput tells you how many boards your oven can finish in a certain time. If you make throughput higher, you can produce more items and fill bigger orders. You also spend less on keeping extra products and make planning easier.

Throughput time shows how well your production works and helps you make it better.

If you lower throughput time, you save money on inventory and earn more profit.

Handling throughput needs helps you use resources wisely and keep spending down.

When your oven matches your throughput needs, you get better results. S&M ovens have different models for many types of production lines. You can pick the oven size and heating zones that fit your throughput. This helps you keep up with fast changes in electronics manufacturing.

Defining stability and its impact on performance

Stability in a solder reflow oven means the oven keeps temperature and airflow steady every time it runs. Stable ovens help stop defects and make products more reliable. If your oven is not stable, you might get uneven heating or cooling, which causes bad solder joints.

Uneven heating can happen if parts have different thermal capacities.

The edges of the conveyor or heater can change how heat spreads.

Putting too many boards in at once can change temperature profiles.

You should watch important settings to find problems early. S&M ovens use smart control systems to keep temperature steady. Automatic checks help you get even cooling and strong solder joints. This makes more good products and fewer mistakes in your electronics process.

Key Aspect | Impact on Defect Rates and Reliability |

|---|---|

Watching important settings | Helps find problems and fix temperature curves. |

Looking at data | Shows how welding defects connect to process settings. |

Better production efficiency | Makes more good products and fewer defects. |

If you pay attention to throughput and stability, you can make your production faster and better. S&M reflow ovens help you reach these goals with steady performance in every electronics process.

Key factors for reflow oven performance

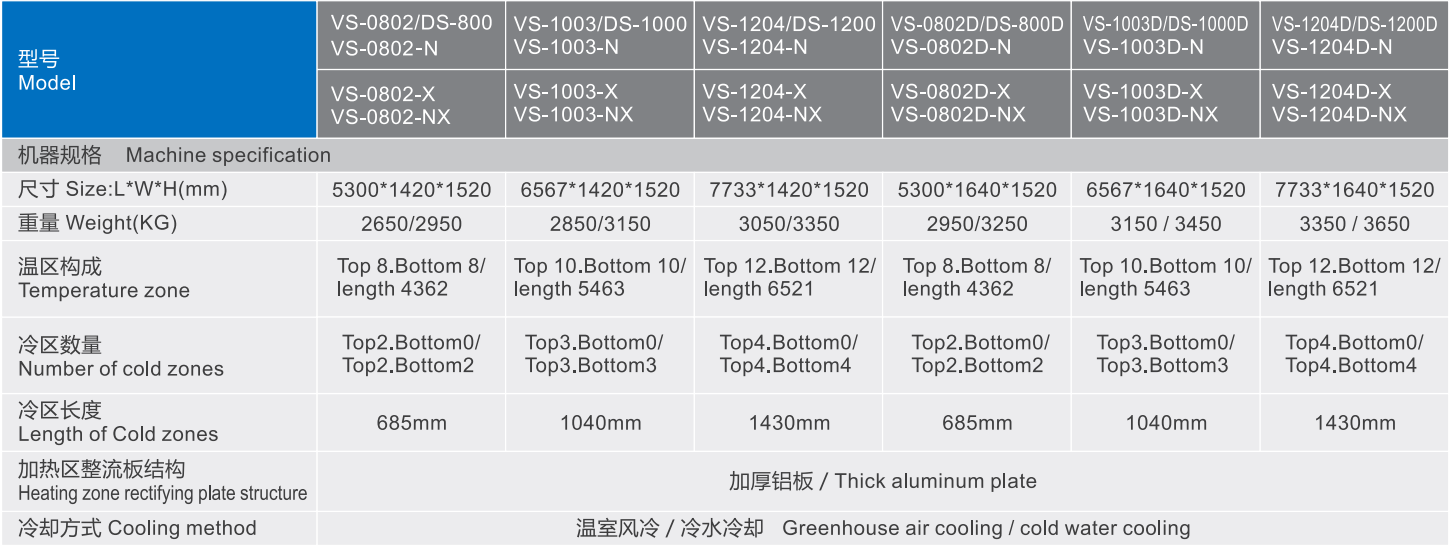

Heating zones and tunnel length

When you pick a reflow oven, check the heating zones. More heating zones help you control the temperature better. This lets you work with many types of printed circuit boards. S&M’s Nitrogen reflow oven has up to 10 top and 10 bottom heating zones. You can set each zone for your soldering needs. A longer tunnel means you can process more boards at once. This makes your work faster and more efficient. You can choose the tunnel length that fits your production line.

Conveyor systems and board handling

Conveyor systems move boards through the oven. Automation helps by reducing manual work. This keeps your boards safe from damage. It also makes the process steady and lowers mistakes. You have less risk of contamination and defects. S&M ovens use advanced conveyor systems for ESD safety and smooth movement. This means fewer defects and better efficiency. Automated conveyors can lower defect rates by up to 30%. Your process stays steady and your results improve.

Conveyor systems move PCBs automatically.

They keep sensitive parts safe.

Automation lowers mistakes and defects.

Cooling zones and joint quality

Cooling zones are important for solder joint quality. The cooling zone hardens the solder. If you cool too fast, joints can crack or break. If you cool too slow, joints may look dull or grainy. S&M ovens let you control how fast you cool. With the right settings, you get strong and shiny solder joints. Your products last longer and work better.

Tip: The best cooling rate is not too fast or slow. This helps you get strong and reliable solder joints.

Energy efficiency and insulation

Energy efficiency helps save money and the environment. S&M reflow ovens use good insulation and smart controls. You can change fan speeds and zone temperatures to use less energy. This lowers costs and helps green manufacturing. Efficient ovens keep heat inside and the temperature steady. This helps your reflow process stay the same every time.

Good settings use less energy.

Strong insulation keeps heat in the oven.

Energy-efficient ovens help with sustainability.

Always pick oven features that match your production needs. This helps you get the best results for your products and business.

Temperature control precision and stability

Advanced control systems in S&M ovens

Good temperature control helps your reflow oven work well. S&M ovens use Siemens PLC and PID closed-loop control systems. These systems have sensors that watch the temperature. They change the heat if it is too high or low. This lets you follow the right thermal profiles for each board. PID controllers help stop slow changes in temperature. They keep things steady and stop big changes. This helps you avoid cold joints or overheating. These problems can hurt your PCBs. Good control means better soldering and protects your money.

Closed-loop control checks and fixes temperature right away.

PID controllers keep the temperature close to what you set.

Good temperature control means fewer mistakes and better products.

Consistency and repeatability in soldering

You want every board to have the same solder joints. When reflow profiles are the same, your products are more reliable. S&M ovens help you do this with smart controls and modular design. You can make each step better and keep track of quality for every batch. The table below shows why being consistent is important:

Aspect | คำอธิบาย |

|---|---|

Process Optimization | Controlling settings makes sure solder joints are always good. |

Reflow Profile Development | You need to balance melting, intermetallics, and heat damage. |

Statistical Process Control | Watching settings all the time helps you find problems early. |

Equipment Maintenance | Cleaning and checking parts often keeps the oven working well. |

You can use solderability tests to see if surfaces take solder well. This helps you find problems like rust or dirt before they cause trouble.

Maintenance and downtime reduction

You need to keep your reflow oven working to make products fast. Doing regular maintenance stops surprise breakdowns and keeps soldering good. Daily checks and weekly cleaning help your oven last longer. A modular design makes it easy to change parts and start again fast. If you follow a maintenance plan, your equipment works better and you make more products. This saves money and keeps your line moving.

Tip: Make a checklist for daily and weekly care. This easy step can help your oven work better and more precisely every time.

You get the best from your reflow oven when you focus on temperature control, stability, and regular care. These steps help you work faster, make better products, and keep quality high for every board.

Evaluating reflow oven manufacturer options

Manufacturer reputation and certifications

You want to trust the company that makes your reflow oven. A good reputation means they make good products and help customers. Companies with many years in business are usually more reliable. S&M has helped many people since 2000. They are known as a national high-tech business.

Certifications are important because they show the company meets rules. These rules help you know the oven will work well for you. You can use the table below to see what to check:

Indicator/Certification | คำอธิบาย |

|---|---|

Quality Assurance | Look for strong quality checks, testing steps, and ISO certificates. |

Technical Specifications & Standards | Check for heating zones, top temperature, and IPC standards. |

Industry Compliance Requirements | Make sure the company follows IATF 16949 and RoHS rules. |

Always ask for proof of these certificates. This helps you feel sure about the oven’s quality and if it will last.

Product support and after-sales service

Support is very important when picking a reflow oven company. Good support helps you fix problems quickly. It also keeps your line working well. S&M gives strong support with tech help, training, and quick answers. The table below shows why support matters:

Key Point | คำอธิบาย |

|---|---|

Customer Satisfaction | Good service keeps you happy and helps you trust the company. |

Brand Loyalty | Good support makes you want to tell others about the brand. |

Product Longevity | Regular care and repairs help your oven last longer. |

Reduced Returns | Fast help means fewer returns and less trouble. |

Technical Assistance | Support is needed to keep your oven working, especially when you are busy. |

Check if the company gives training, spare parts, and help from far away. These things help you use your oven better and protect your money. When you have good support, you can focus on making great products.

Tip: Ask about the warranty and how fast they answer before you buy. This helps you avoid problems later.

Customer references and sample runs

You can learn a lot by talking to other people who use the ovens. Ask the company for names of customers you can talk to. These people can tell you how the ovens work in real life. You can ask about speed, quality, and if the oven is reliable. You should also ask for a sample run. A sample run lets you see how the oven works with your own boards.

When you look at different companies, remember these things:

Ask for customer names and talk to them.

Ask for a sample run with your own boards.

See if the company can change the oven for your needs.

Changing the oven can help it fit your line better. This also helps you get more value from your oven. When you use real feedback and try a sample run, you make a smart choice. You get an oven that works well and has good support for your business.

Practical comparison tips for reflow ovens

Creating a feature checklist

You can make a good choice by using a checklist. First, write down the most important features for your work. Check things like how many heating zones the oven has. Look at the tunnel length and what kind of conveyor it uses. Think about how the oven cools the boards. Add things like temperature control, energy use, and safety. Make sure to include if you can set different temperatures for different solder pastes. This list helps you see which oven fits your needs best.

Tip: Bring your checklist when you meet with manufacturers. Ask them to show how their ovens match each thing on your list.

Aligning oven size with throughput needs

Picking the right oven size is very important. If the oven size matches your needs, your line runs smoothly. The right size oven helps you finish work on time. It also lets you grow in the future. You do not want to stop work or buy a new oven too soon.

Matching oven size to needs stops slowdowns.

The right size oven helps you finish on time.

Planning for growth saves money and trouble later.

Think about how many boards you need to make now and later. This helps you pick an oven that can handle more work if needed.

Considering industry-specific requirements

Different industries need special things from reflow ovens. You should check if the oven has the right heating type and board mover. Some jobs need nitrogen to stop oxidation and make better joints. Good control systems help keep the heat steady and stop mistakes. Being able to change the process is important if you make different products often.

Factor | คำอธิบาย |

|---|---|

Heating Technologies | Different types change how heat spreads and how well soldering works. |

Methods of Board Transport | How boards move in the oven can change how well soldering works. |

Inerting Systems | Nitrogen helps stop oxidation and makes joints better. |

Control Methods | Good controls keep the heat right and stop mistakes. |

You should also look for ovens that save energy and have good temperature control. These things help you keep up with new trends and help the environment.

Note: Always ask if the oven can change for new products or ways of working. This helps you get more value and makes your process stronger for a long time.

You can make a smart choice by following key steps when you pick a reflow oven manufacturer. Start with tests and data checks to see how the oven performs:

ขั้นตอน | คำอธิบาย |

|---|---|

1 | Run no-load tests for temperature control. |

2 | Try full-load tests for real production. |

3 | Record and study the results. |

4 | Use feedback from actual production. |

Match oven features to your goals and quality needs. This helps you save money, reduce defects, and keep your process safe. S&M gives you advanced technology, strong support, and custom solutions. You can ask for a demo or talk to other users to see how the oven works for real jobs.

คำถามที่พบบ่อย

What does throughput mean in a reflow oven?

Throughput shows how many boards you can process in a set time. You can boost your production by choosing an oven with the right size and heating zones. S&M ovens help you reach your target output with flexible models.

How does oven stability affect product quality?

Stable ovens keep temperature and airflow steady. You get fewer defects and better solder joints. S&M ovens use smart controls to keep every run consistent. This helps you make reliable products every time.

Why should you care about temperature control precision?

Precise temperature control stops overheating and cold joints. You protect your boards and get strong solder connections. S&M ovens use Siemens PLC and PID systems for exact temperature management.

What support can you expect from S&M after buying an oven?

You get technical help, training, and fast answers. S&M offers spare parts and remote support. You can keep your line running smoothly and fix problems quickly.