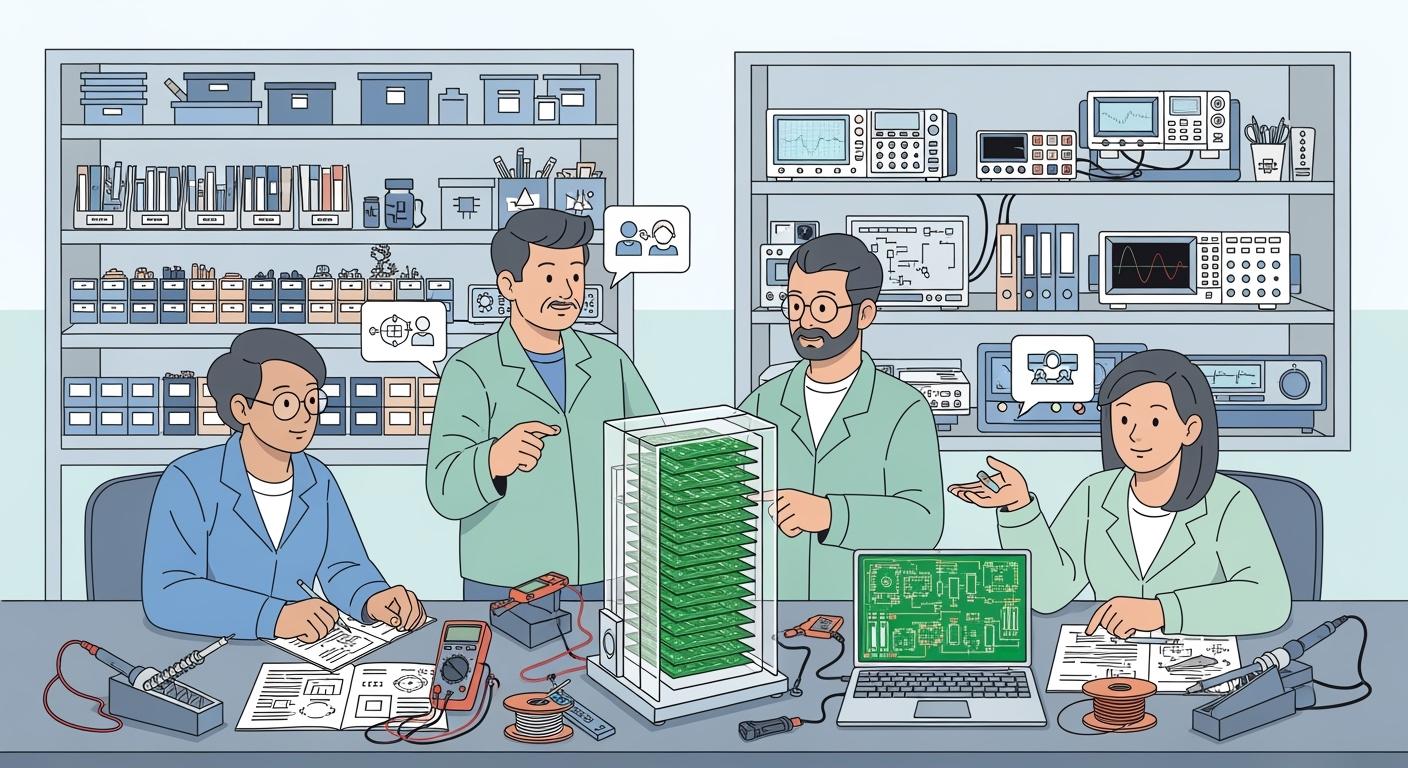

You can boost efficiency in your SMT production line by using PCB stackers. Experts agree that these machines help you move boards faster, protect them from damage, and keep your process steady. S&M always brings new ideas and high standards to SMT equipment. You get reliable results and save costs when you choose advanced solutions from S&M.

ประเด็นสำคัญ

PCB stackers help SMT production go faster. They let you load and unload boards quickly. This means you can make more boards each day.

When you use PCB stackers, you need less manual labor. This can make your output go up by 40%. It can also lower labor costs by 25%.

Stackers make your work smoother. They stop slowdowns and keep boards moving. This helps your production stay on time.

Advanced stackers lower the chance of PCB damage. This saves money on replacements. It also keeps your products good quality.

Picking the right PCB stacker makes things safer and better. Your team can focus on checking quality, not just moving boards.

SMT Efficiency with PCB Stackers

Faster PCB Handling

You want your smt line to move quickly. PCB stackers help you do that. When you use stackers, you can load and unload boards in seconds. S&M designs its equipment to keep your smt process moving without delays. You see less waiting time between steps. Machines pass pcb boards from one station to the next with smooth transitions. This speed means you finish more products each day. Your team can focus on quality checks instead of moving boards by hand. S&M’s stackers use smart sensors to detect board positions. You get accurate placement every time. Fast handling keeps your smt line productive and helps you meet tight deadlines.

Reduced Manual Labor

You save time and money when you reduce manual work in your smt facility. PCB stackers take over the job of moving boards. Your workers do not need to lift or carry pcb boards from one machine to another. This change lowers the risk of mistakes and injuries. S&M’s automatic stackers make your smt line safer and more efficient. You can see big improvements in your labor costs. Many companies report up to a 40% increase in throughput after adding stackers. You may save around 25% on labor costs because machines handle most of the work. Your team can spend more time on important tasks like inspection and testing. S&M’s solutions help you build a smarter smt line with less manual effort.

You reduce manual handling.

You increase throughput by up to 40%.

You save about 25% on labor costs.

Streamlined SMT Workflow

You want your smt process to run smoothly from start to finish. PCB stackers help you organize your workflow. S&M’s equipment lines up boards in the right order and keeps them moving. You avoid bottlenecks and keep every step on schedule. Stackers work with other smt machines to create a steady flow. You do not need to worry about boards piling up or getting lost. Your operators can track progress easily. S&M’s stackers fit into many types of smt lines, including those for LED, smart display, and medical devices. You get a flexible system that grows with your needs. A streamlined workflow means you deliver products faster and keep your customers happy.

Tip: When you use S&M’s pcb stackers, you build a more efficient smt line. You finish jobs faster, save money, and keep your team focused on quality.

Reliability in Surface-Mount Technology

Minimized PCB Damage

You want your pcb boards to stay safe during every step of the smt process. PCB stackers help you protect your boards from scratches, bending, and other damage. When you use S&M’s advanced stackers, you see fewer broken boards. Machines handle each pcb gently and keep them in the right position. You do not need to worry about boards falling or getting crushed. S&M’s equipment uses sensors to detect the size and thickness of each pcb. This smart feature keeps your boards secure. You save money because you do not have to replace damaged boards. Your smt line runs better when you trust S&M’s solutions.

Note: PCB stackers from S&M help you lower the risk of damage. You keep your products strong and your customers happy.

Consistent Board Alignment

You need every pcb to line up perfectly in your smt line. PCB stackers make sure each board stays in the right spot. S&M’s machines use guides and sensors to keep boards straight. You get the same alignment every time. This helps you avoid problems with soldering and placement. When boards move smoothly, your smt machines work faster and make fewer mistakes. You do not waste time fixing errors. S&M’s stackers fit into many types of smt lines. You can use them for LED, medical devices, and more. Consistent alignment means your products look better and work better.

You get perfect board placement.

You avoid soldering errors.

You improve your smt process.

Enhanced Process Reliability

You want your smt line to work the same way every day. PCB stackers help you build a reliable process. S&M’s equipment keeps your boards moving without delays. You see fewer stops and less downtime. Machines handle each pcb with care and keep the workflow steady. You do not have to worry about missing boards or slow steps. S&M’s stackers help you meet high standards for surface mount technology. You deliver strong and safe printed circuit boards to your customers. When you use reliable equipment, you build trust in your products.

Tip: Reliable smt processes help you grow your business. S&M’s pcb stackers give you the tools you need for success.

Cost Advantages for Printed Circuit Boards

Lower Operational Costs

You want your smt line to cost less. PCB stackers help you save money. Automated stackers from S&M mean you need fewer workers. Machines move pcb boards fast and safely. You spend less on labor and make fewer mistakes. This means you waste less material. S&M’s stackers use smart technology to move each pcb gently. You see less damage and save money on replacements. Many companies pick S&M because their smt equipment helps them stay on budget.

Tip: Automated pcb stackers help you spend less and earn more.

Reduced Downtime

You want your smt line to run without stopping. PCB stackers keep things moving. S&M’s stackers automate loading and unloading of pcb boards. This keeps a steady flow and stops bottlenecks. You do not need to stop the line to fix jams. You do not wait for manual handling. Machines feed each pcb into the smt line at the right time. You finish jobs faster and avoid delays. S&M’s solutions help you keep production on schedule.

ประโยชน์ | คำอธิบาย |

|---|---|

Less waiting | PCB stackers keep boards moving |

Fewer stoppages | Automation prevents bottlenecks |

More output | SMT lines finish jobs faster |

Improved Resource Utilization

You want to use your smt equipment and space well. PCB stackers from S&M help you do this. Their small design fits easily into your smt line. You can handle different pcb sizes with adjustable settings. Machines stack and destack boards smoothly. You get more work done in less space. S&M’s stackers improve throughput and keep safety high. You use your resources better and get high-quality pcb products every time.

PCB stackers automate stacking and destacking.

Small design saves space in your smt line.

Adjustable features handle many pcb sizes.

Machines improve productivity and reduce downtime.

Note: S&M gives cost-effective smt solutions for LED, medical devices, and smart displays. You get reliable equipment that helps you save money and grow your business.

Expert Insights and S&M Solutions

SMT Professional Experiences

You can learn a lot from other professionals who use smt equipment every day. Many factory managers say that adding PCB stackers changed their production lines. One manager shared, “We used to stop our smt line often to fix board jams. After installing S&M’s stackers, our line runs much smoother.” Another engineer said, “Our team spends less time moving boards and more time checking quality.” These stories show how real people solve problems with smart equipment. You can trust these results because they come from people who work with smt lines every day.

Challenges Solved by PCB Stackers

You face many challenges in smt production. PCB stackers help you solve these problems. They boost efficiency, connect each step, and cut down on bottlenecks. Stacking PCB Buffer Technology keeps your line moving and helps you finish more work with less downtime. You also deal with issues like board warping or misfeeds. S&M’s stackers use advanced features to fix these problems. The table below shows how these features help your smt line:

Benefit for SMT Lines | |

|---|---|

Real-time Warp Compensation | Fixes board warping by detecting and adjusting for bent boards. |

Z-tracking 3D Compensation | Measures boards in three ways to stop errors from slope or twist. |

You get a smoother process and better results when you use these smart solutions.

Choosing the Right PCB Stacker

You want the best fit for your smt line. Start by thinking about your board sizes and how fast you need to move them. S&M offers stackers with adjustable settings for different board types. Look for machines with smart sensors and safety features. These help you avoid mistakes and keep your team safe. You can ask S&M for advice on which stacker matches your needs. Their experts help you pick the right equipment for LED, medical, or smart display production. You get a solution that grows with your business and keeps your smt line strong.

Tip: When you choose S&M, you get support from a team that knows smt inside and out.

When you use PCB stackers in your smt line, you get big benefits. These machines help you finish jobs faster and save money. They also keep your boards safe from harm. Experts like stackers because they help you make more boards and have fewer mistakes. The table below shows how much better your line can get:

ประโยชน์ | Statistic |

|---|---|

Increased Efficiency | |

Reduced Labor Costs | Labor expenses reduced by 40% |

Enhanced Quality Control | Defects reduced by 30% |

Improved Safety | Reduced risk of workplace accidents |

คุณสามารถ trust S&M to help you get these results. Pick S&M’s solutions to make your process better and help your business grow.

คำถามที่พบบ่อย

What is a PCB stacker?

A PCB stacker is a machine that moves and organizes printed circuit boards in your production line. You use it to automate board handling and improve workflow.

How does a PCB stacker improve safety?

You reduce the risk of accidents when you use a PCB stacker. Machines handle boards instead of people. This keeps your team safe and lowers injury rates.

Can PCB stackers work with different board sizes?

You can adjust most PCB stackers to fit many board sizes. S&M offers models with flexible settings. You choose the right option for your production needs.

Why should you use PCB stackers in your smt line?

You boost speed and reliability when you add PCB stackers to your smt line. Machines keep boards moving and help you finish jobs faster.

How do you choose the best PCB stacker for your factory?

You look at your board sizes, speed needs, and safety features. S&M experts help you pick the right stacker for your workflow.