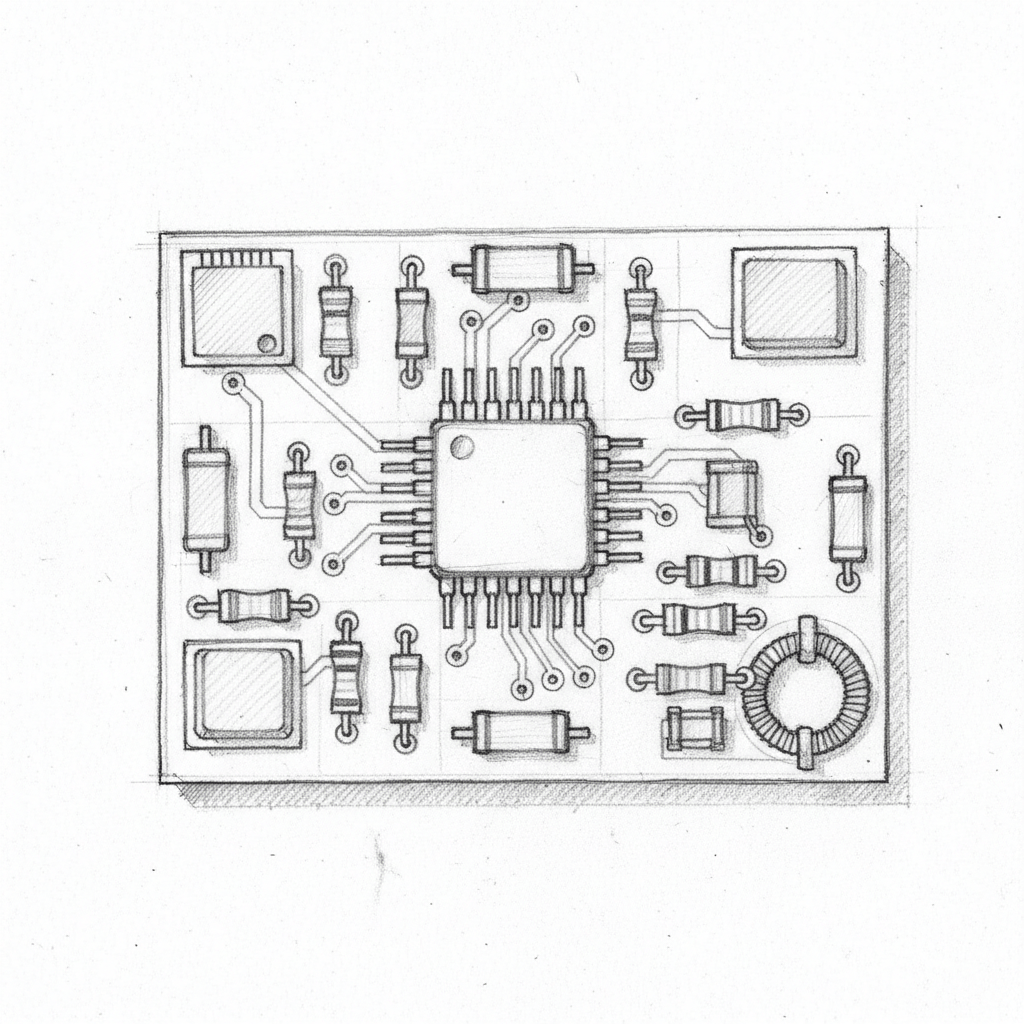

Comprehensive Overview of PCB Assembly Process

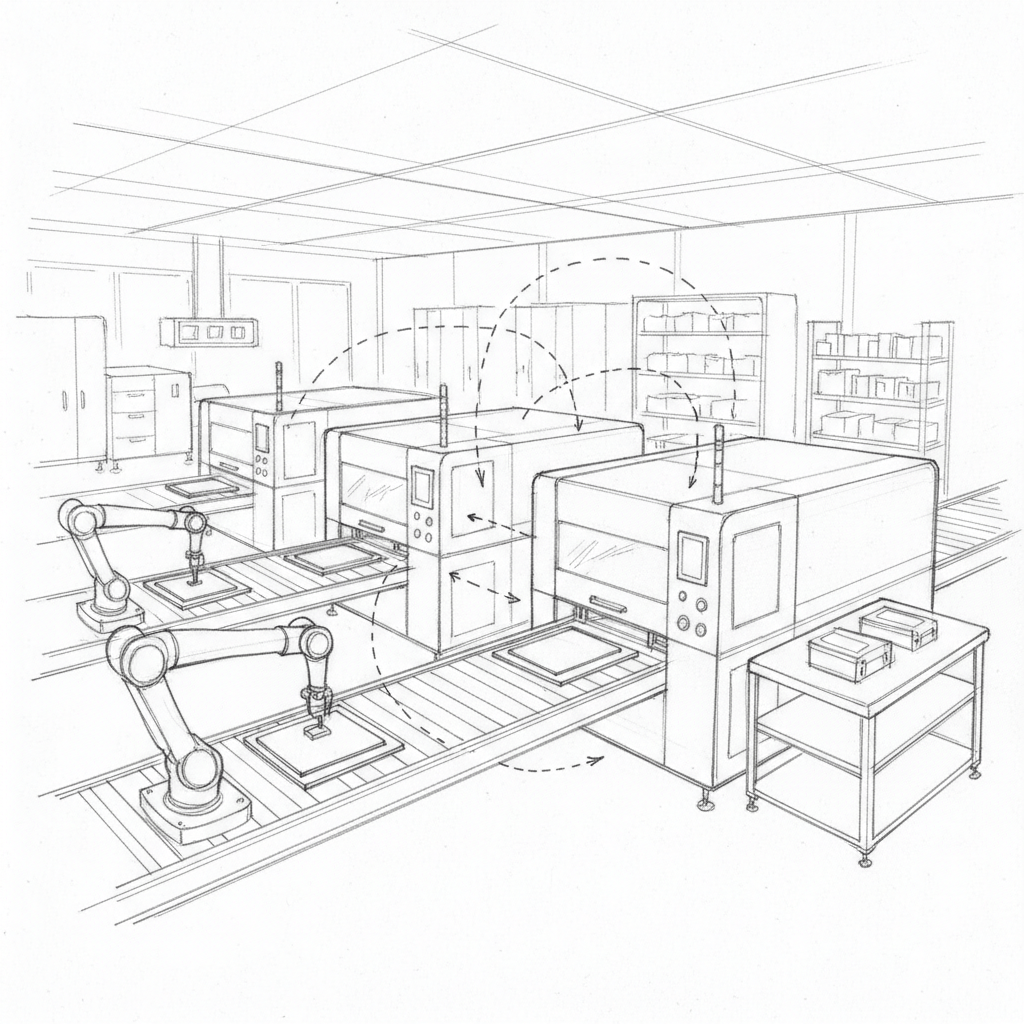

PCB assembly represents a crucial phase in electronics manufacturing, comprising methods and technologies essential for the creation of functional electronic devices. It involves placing components onto a printed circuit board (PCB) through processes such as surface mount technology (SMT). As of 2025, the importance of PCB assembly has only grown as electronics become increasingly complex and miniaturized, necessitating more sophisticated assembly techniques to maintain efficiency and quality.