Batch Reflow Oven vs Inline: Key Differences in SMT Manufacturing

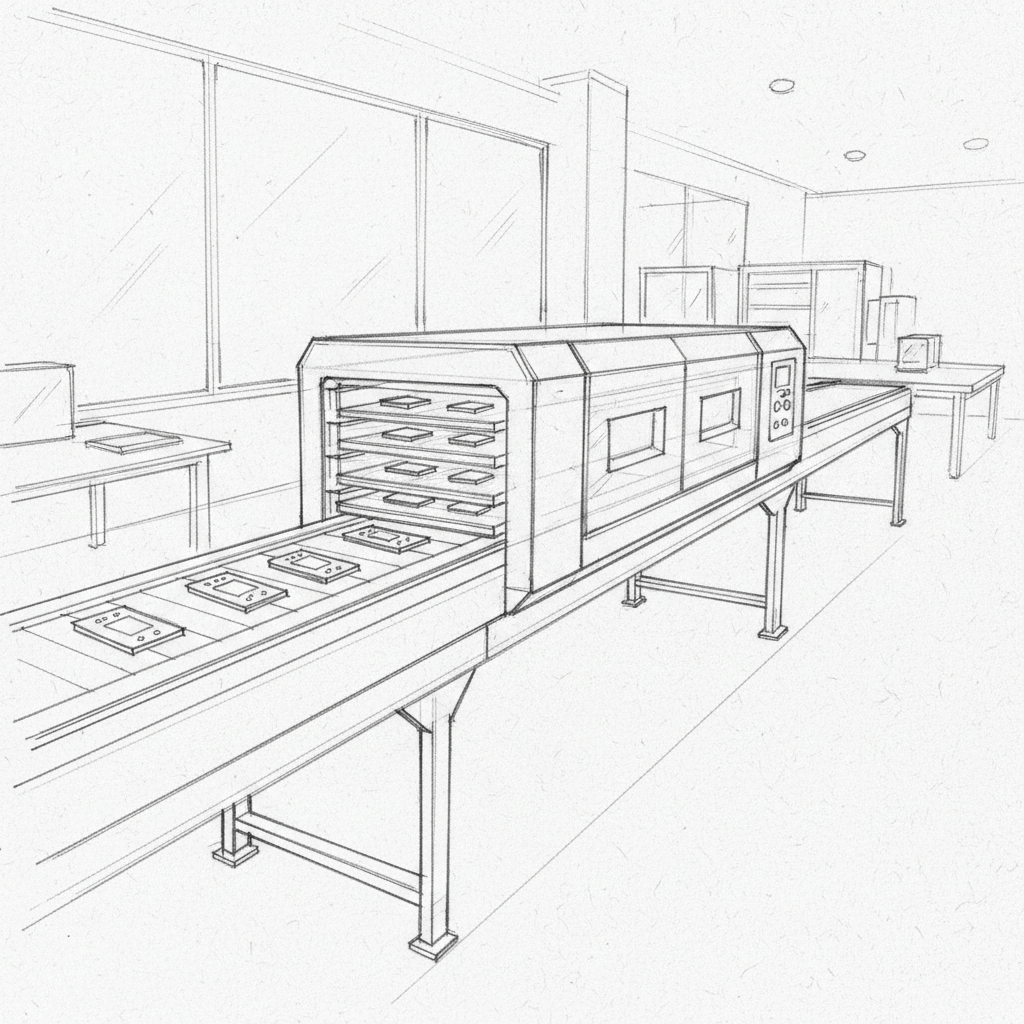

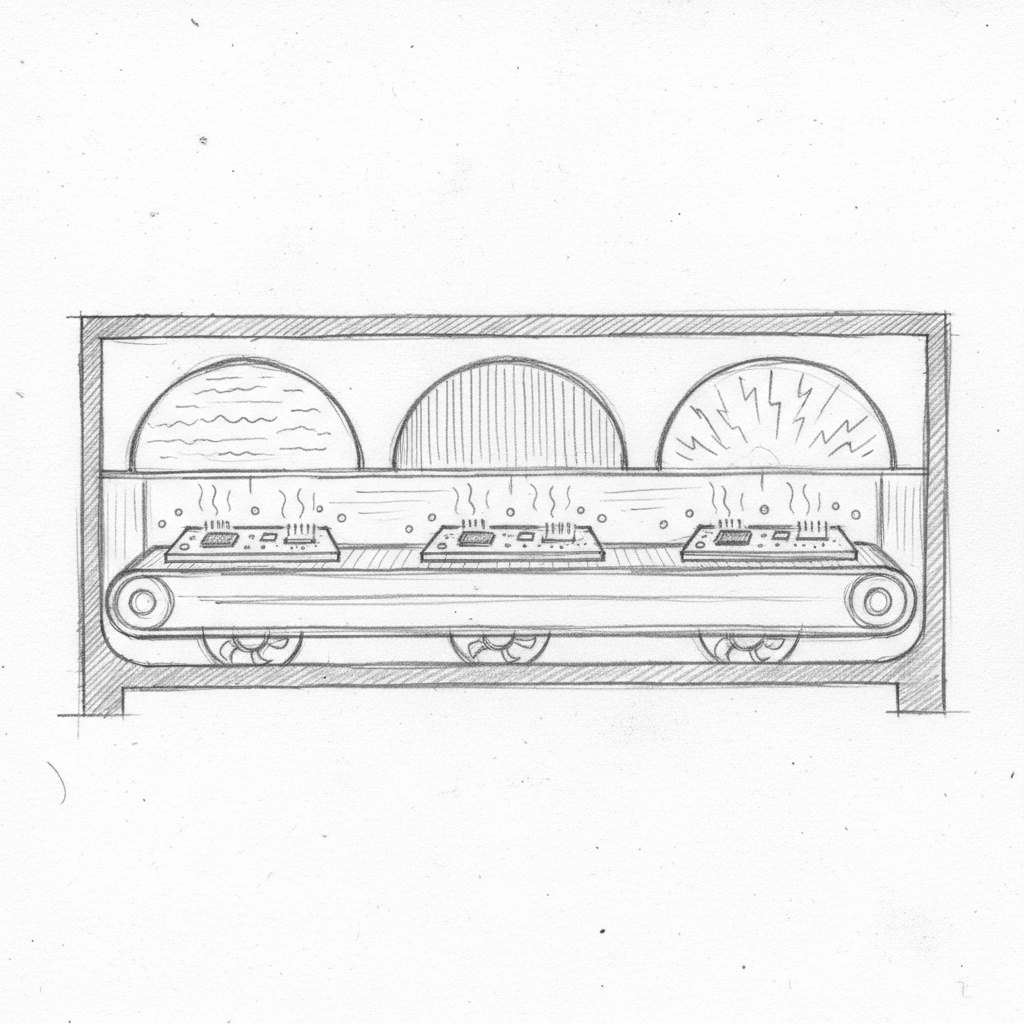

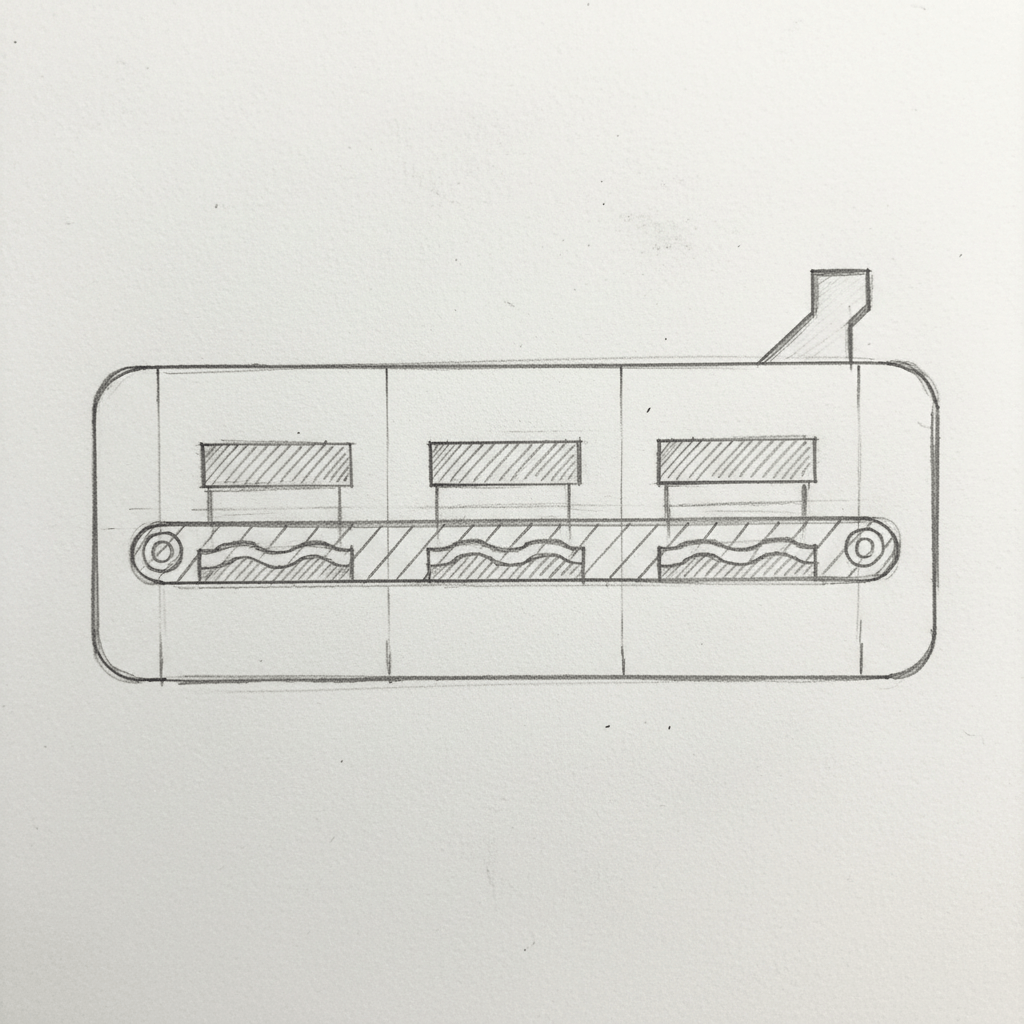

In the evolving landscape of Surface Mount Technology (SMT), reflow ovens are crucial for soldering electronic components to PCBs with precision and efficiency. Batch reflow ovens are ideal for low-volume or prototyping scenarios due to their flexibility and cost-effectiveness, while inline reflow ovens cater to high-volume production with continuous processing capabilities. Manufacturers must carefully assess production needs and space availability to choose the appropriate oven type, considering throughput, energy efficiency, and scalability. As technology advances with trends like automation, energy efficiency, and smart manufacturing, aligning reflow oven choices with strategic business objectives is essential for maintaining competitive advantage in electronics manufacturing.