You use wave soldering in electronics to connect parts to printed circuit boards quickly and accurately. If you pick the right wave soldering machine, you can make more boards and have fewer mistakes in each solder joint. These machines have automatic flux applicators and settings you can program, which help you keep good soldering quality. Good soldering equipment breaks down less and keeps your production line working well. S&M is a trusted brand that gives you advanced answers for every soldering problem.

Önemli Çıkarımlar

Pick a wave soldering machine that matches your PCB sizes. This stops jams and keeps the machine running well.

Keep the solder pot temperature within ±5°C. This makes sure the solder joints are always good. It also helps stop weak connections.

Set the conveyor speed and dwell time for your PCBs. This helps the solder go in well and makes strong joints.

Do regular maintenance. Clean the machine every day. Check the parts every week. This lowers downtime and helps the machine work better.

Train your operators. Workers who know what to do make fewer mistakes. This also makes the soldering better.

Dalga Lehimleme Genel Bakış

What Is Wave Soldering?

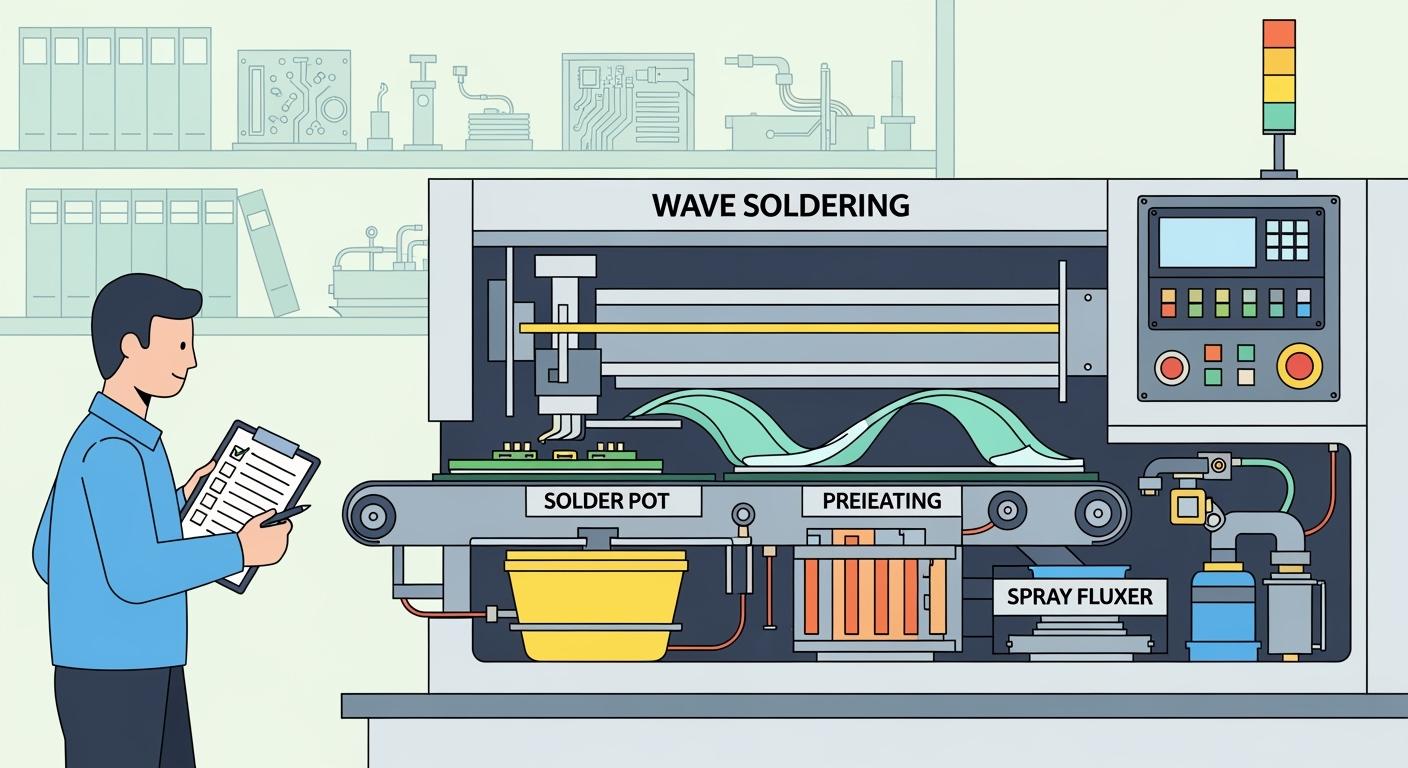

Wave soldering joins smt components and through-hole parts to a pcb. The machine pushes melted solder into a steady wave shape. The pcb moves over this wave at a certain speed and angle. The solder touches the leads and copper pads that are not covered. Flux cleans the metal before solder sticks to it. The solder flows onto the metal and bonds with it. Capillary action helps fill holes and make strong connections. Wave soldering is best for making lots of boards fast. You can solder many boards quickly and keep the quality high.

Wave soldering makes a steady wave of melted solder. The pcb slides through this wave. The solder touches the leads and pads and forms a strong joint.

Applications in Electronics

Wave soldering is used in many electronic products. It works for smt components and through-hole parts. You can solder chip resistors, capacitors, and connectors. It is also used for big power devices and connectors with many pins. Big appliances often need wave soldering because they have large parts. Wave soldering helps make sure every solder joint is strong and works well.

Large power devices

High pin count connectors

Chip resistors

Capacitors

Connectors

Major appliances

S&M’s Role in the Industry

S&M is a leader in wave soldering technology. Their advanced machines and smt solutions help you a lot. S&M makes machines that let you control soldering settings and keep your line running well. You can set the solder temperature, wave height, and conveyor speed. S&M’s machines are used in many fields like LED, smart display, new energy, and medical devices. You can trust S&M to give you great soldering results for every pcb and smt component.

How Wave Soldering Machines Work

Process Steps

A wave soldering machine connects smt components and through-hole parts to a pcb. The process has several steps.

PCB Hazırlama: First, you clean the pcb and get it ready.

Akı Uygulaması: Next, you put flux on the bottom of the pcb. Flux helps solder stick and cleans the metal.

Preheating: Then, you warm up the pcb. This keeps smt components safe from heat shock and makes the flux work.

Solder Wave Contact: After that, you move the pcb over melted solder. The solder touches the leads and pads and makes strong joints.

Cooling: You let the solder cool down and get hard. This holds the smt components and through-hole parts in place.

Cleaning: Last, you clean off any extra flux or dirt. This stops rust and keeps the pcb and solder joints in good shape.

Tip: Every step in wave soldering helps you make strong connections and good products.

Key Components

A wave soldering machine has many important parts.

The machine holds melted solder in a big tank.

Bu fluxer puts flux on the pcb before soldering.

The preheater warms up the pcb and gets the flux ready.

The conveyor moves the pcb through each step.

The solder pump makes the wave that touches the smt components and leads.

The cooling system helps the solder get hard fast.

All these parts must work together for smooth soldering. Preheating and using flux are very important for strong joints and good quality.

S&M Machine Features

S&M makes wave soldering machines with smart controls. You can set the temperature, time, and flow rate for each job. These controls help you make better solder joints and keep smt components safe. S&M machines watch key things like solder temperature, wave height, and preheating time. If something is wrong, you get a warning so you can fix it fast. S&M selective wave soldering machines have two platforms. This helps you work with tricky pcbs with lots of smt components. You can program the solder path with pictures or GERBER files. The machine uses special motors and steel rollers to move smoothly. S&M’s focus on control and smart monitoring helps you get good soldering every time.

Parametre | Fayda |

|---|---|

Welding Temperature | Makes welding better |

Zaman | Helps make solder joints more exact |

Flow Rate | Keeps parts safe from too much heat |

You can count on S&M soldering machines to give you steady wave soldering for surface mount technology and through-hole assembly.

Key Specifications for Wave Soldering Machines

When you pick a wave soldering machine, you should check some key things. These details help you find a machine that fits your needs. They also help you get strong solder joints on every pcb. S&M makes machines with features for good smt assembly and strong soldering.

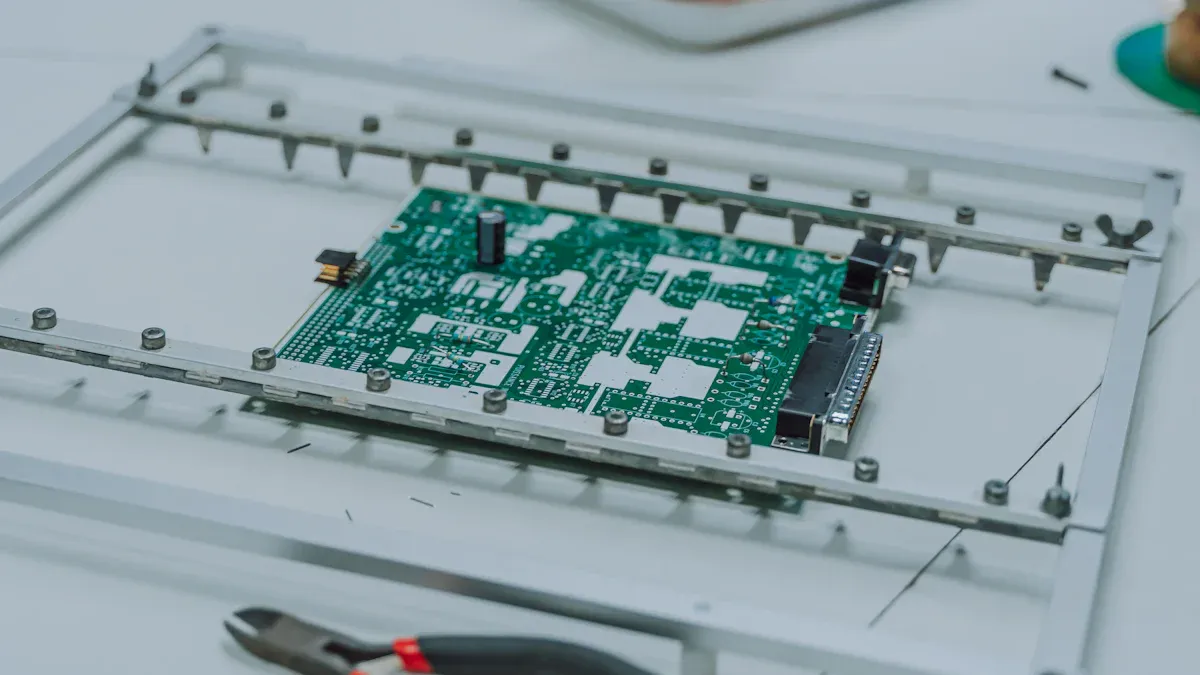

Board Size and Compatibility

You need to know what board sizes the machine can handle. Pcbs come in many shapes and sizes. Some machines work with small boards. Others can handle big or odd-shaped pcbs. If you use lots of smt components, you need a machine that fits many pcb types. S&M machines let you change settings for different board sizes. This helps you solder many kinds of pcbs without trouble.

Works with small and large pcbs

Guides can be moved for different board widths

Dual platforms help with tricky assemblies

Tip: Always check your pcb size before using the machine. This stops jams and keeps your smt components safe.

Solder Pot Temperature Control

The solder pot temperature is very important in wave soldering. You must keep the solder bath close to your target temperature. Try to stay within ±5°C. This helps you get the same results every time and strong solder joints. If the temperature changes too much, you might get weak joints or mistakes.

Preheat should be 120°C to 150°C for lead-free solder

Nozzle temperature should be 20°C–30°C above the solder’s melting point

If you make the solder hotter, it flows faster and fills holes better. When the solder is hotter than 230°C, you get fewer problems like bridging. Setting the temperature to 235°C and the conveyor speed to 1000 mm/min can help fix soldering issues.

Conveyor Speed and Dwell Time

The conveyor moves your pcb through the machine. You need to set the right speed so smt components get enough time in the solder wave. Most machines run from 0.5 to 2 meters per minute. For lead-free solder, use 2.5 to 3.5 feet per minute. For leaded solder, you can go up to 5 feet per minute.

Dwell time is how long the pcb touches the solder wave. This affects how well the solder fills holes and makes strong joints.

Aspect | Evidence |

|---|---|

Solder Penetration | Changing wave height or dwell time helps solder fill holes. |

Joint Reliability | Too long in the wave can cause problems. Too short can cause weak joints. |

Note: Set conveyor speed and dwell time for your pcb size and smt components.

Nozzle and Pump Quality

The nozzle and pump make the solder wave that touches your pcb and smt parts. These parts need to be made from good materials. Good nozzles move heat well and do not rust. They must handle high heat and last a long time. S&M uses special materials and coatings to keep nozzles strong and easy to wet.

Özellik | Açıklama |

|---|---|

Material | Special material moves heat well and does not rust. |

Temperature Resistance | Works in high heat during wave soldering. |

Hardness and Abrasion Resistance | Hard and tough for long use. |

Wettability | Coating helps solder stick and stops rust. |

Solder sticking to the nozzles is a tricky process. Good nozzles and pumps give you better solder waves, fewer problems, and less downtime.

Clean flux off the conveyor and nozzles every day. Check and set temperature sensors every week. Change the solder bath every month if it gets dirty.

Advanced Features (Selective Wave Soldering)

New wave soldering machines have smart features for better control. Seçici dalga lehimleme lets you set the solder path for each pcb. You can control how long, how hot, and how much solder goes to each smt part. S&M’s SM-LⅡ Series gives you full computer control and smart monitoring. You can use pictures or GERBER files to set the solder path.

Özellik | Fayda |

|---|---|

Programmability | Lets you control time, heat, and solder flow. |

Precision Control | Makes soldering better for each smt part and spot. |

Otomasyon | Makes results the same and cuts down on mistakes. |

Wave Height Control | Soldering works for tricky, crowded pcbs. |

Duration on Solder | Solder goes where you want, with fewer mistakes. |

Sıcaklık Ayarları | Keeps soldering just right. |

Nitrogen shrouds save solder and nitrogen.

Using less solder saves money and helps the planet.

S&M’s two-platform design and smart monitoring help you do hard soldering jobs with high trust.

Maintenance and Support

You should think about maintenance when picking a wave soldering machine. Cleaning and checking the machine often keeps it working well. Machines that need less cleaning cost less to use. S&M makes machines that are easy to clean and fix, so you spend less time on care.

Bakım Sıklığı | Impact on Cost of Ownership |

|---|---|

Haftalık | Costs more because of more downtime |

Quarterly | Costs less because of less downtime |

Maintenance costs add to your total spending.

Machines that need lots of care can cost more.

How often you clean the machine changes your costs.

Buyers now want to see data about how the machine works and how much care it needs. This helps you know the real cost and plan your money.

Good support from the maker is important for long use. Good support means training, help with the process, and software updates. S&M gives strong support to help you do better and keep up with new needs. This means better soldering and higher quality.

Tip: Pick a machine that is easy to care for and has good support. This helps you keep your line running and your smt parts soldered well.

Matching Machine to Production Needs

Assessing Throughput

Yapmanız gereken pick a wave soldering machine that fits your work goals. If you make lots of boards, you need a fast machine. There are a few things you should check:

Look at the equipment. Check how well it sprays flux, controls temperature, and keeps the conveyor belt steady. These things help your smt components get soldered right.

Think about the solder and flux you use. The type of solder bars and how active the flux is can change how strong each joint is.

Check your components and pcb boards. If there is dirt, rust, or water on them, you might get bad solder joints.

Tip: Always look at your machine and materials before you start a new batch. This helps you keep your soldering good.

PCB Complexity

If your pcb designs are hard, you need special machine features. Custom fixtures hold your pcb in place. These fixtures make sure only the right spots touch the solder. This keeps your smt components safe. If you have boards with both smt and through-hole parts, you need to be extra careful. You can use selective wave soldering to only solder certain places. This keeps your smt components safe and makes your soldering more exact.

Scalability and Cost

You want your soldering to grow as your business grows. Scalability means your machine can handle more boards when you get more orders. Find machines that let you change conveyor speed, solder wave height, and temperature. These features help you save money and keep your smt line working well. Good wave soldering uses less work and saves solder and flux. This lowers your costs and keeps your quality high.

Faktör | Impact on Production |

|---|---|

Scalability | Handles more pcbs easily |

Cost Control | Reduces waste and labor |

Esneklik | Adapts to new products |

S&M Solutions for Industry Demands

S&M has wave soldering machines for today’s electronics factories. As devices get smaller and harder to make, you need machines that can handle tiny smt components and tricky pcb designs. S&M machines solder many smt components at once. This is good for making lots of boards fast. You also save on work and materials. S&M’s machines give you strong, steady solder joints and work with both through-hole and smt components. You can count on S&M to help you keep up with changes and make great products.

Common Challenges and Solutions

Compatibility Issues

You may face several challenges when using wave soldering machines. These problems can affect how well your soldering works and the strength of your connections.

Insufficient hole fill can happen if solder does not flow through the holes. This leads to weak joints.

Solder bridging creates unwanted connections between pads. This can cause short circuits.

Cold solder joints look dull and do not bond well. These joints are not reliable.

Solder balling leaves small solder balls on the board. These can cause shorts.

Lifted components may move or detach during soldering.

You can solve these issues by adjusting preheat temperature, cleaning leads, and changing wave height. For example, if you see insufficient hole fill, try raising the preheat or cleaning the component leads. Lowering the wave height can help prevent solder bridging. Always check your board design. Large copper planes can act as heat sinks. Add thermal relief to help solder flow better.

Maintenance and Downtime

Regular care keeps your wave soldering machine running well. You should set up a maintenance schedule and follow it closely.

Check the solder wave for smooth movement.

Make sure the fluxer works as it should.

Align the conveyor system often.

This routine helps you avoid downtime and makes your machine last longer. When you keep your machine clean and parts in good shape, you spend less time fixing problems and more time soldering.

Solder Quality Control

You need to check your soldering work to keep your products strong and safe. Use these steps to make sure your solder joints are good:

Look at solder joints under a magnifier. Good joints look shiny and smooth.

Use Automated Optical Inspection (AOI) to find defects like skips or low solder.

Try X-ray inspection for hidden problems inside joints.

Test solderability with dip-and-look or wetting balance tests.

You should also keep the solder bath mix close to the right alloy, set preheat temperature between 100°C and 120°C, and skim dross from the bath. Use thermal tools to check that the board heats evenly. Tracking defects helps you spot patterns and improve your soldering process. This keeps your quality high.

Operator Training

Training your team is key for safe and effective wave soldering. Well-trained operators can lower defect rates by up to 30%. Teach your team how to set up the machine, spot problems, and follow safety rules. When your operators know what to do, you get better soldering results and fewer mistakes.

Remember: Good training leads to better performance and safer work.

When you choose a wave soldering machine, focus on these top three specifications:

Conveyor width and speed. Make sure the machine fits your largest PCBs and lets you adjust speed for better soldering.

Preheating system. Look for zoned heaters to keep heat even across your boards.

Solder pump type. Pick a reliable pump for smooth solder flow.

S&M machines give you these features and strong support. Match machine features to your production needs. Talk with experts to get the best results.

SSS

What is selective wave soldering?

You use selective wave soldering to target specific areas on your PCB. This method helps you avoid soldering sensitive components. S&M machines let you program the solder path for each board.

How often should you clean your wave soldering machine?

You should clean your machine daily. Remove flux residue and check the solder bath. Regular cleaning keeps your machine working well and helps you avoid defects.

Can you use wave soldering for both SMT and through-hole components?

Bileşen Türü | Wave Soldering Use |

|---|---|

SMT | Evet |

Through-hole | Evet |

You can solder both types. You need to set the machine for each component.

Why does temperature control matter in wave soldering?

Temperature control helps you make strong solder joints. If the solder is too hot or too cold, you may get weak connections. S&M machines let you set and monitor temperature for better results.