Essential Safety Precautions in PCB Handling for Advanced Manufacturing

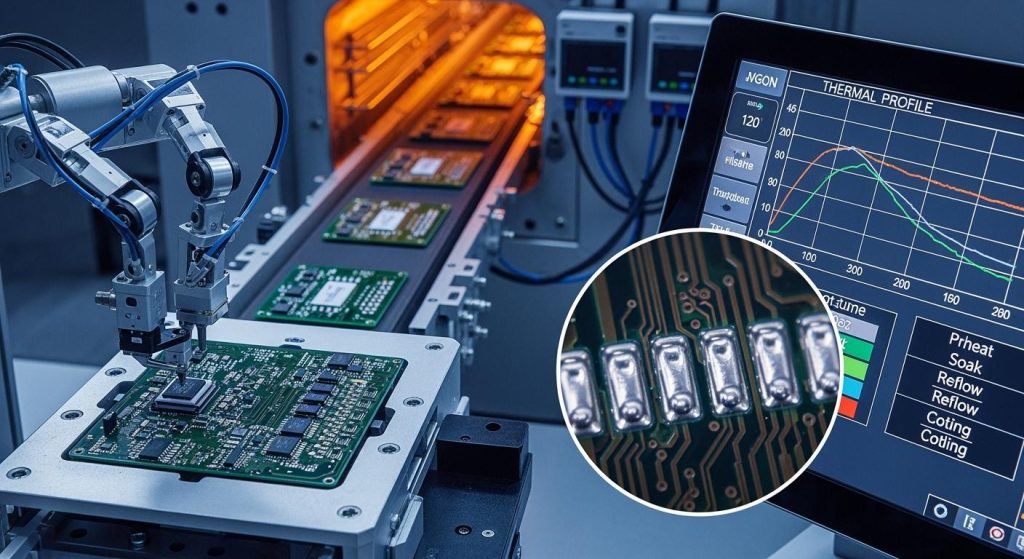

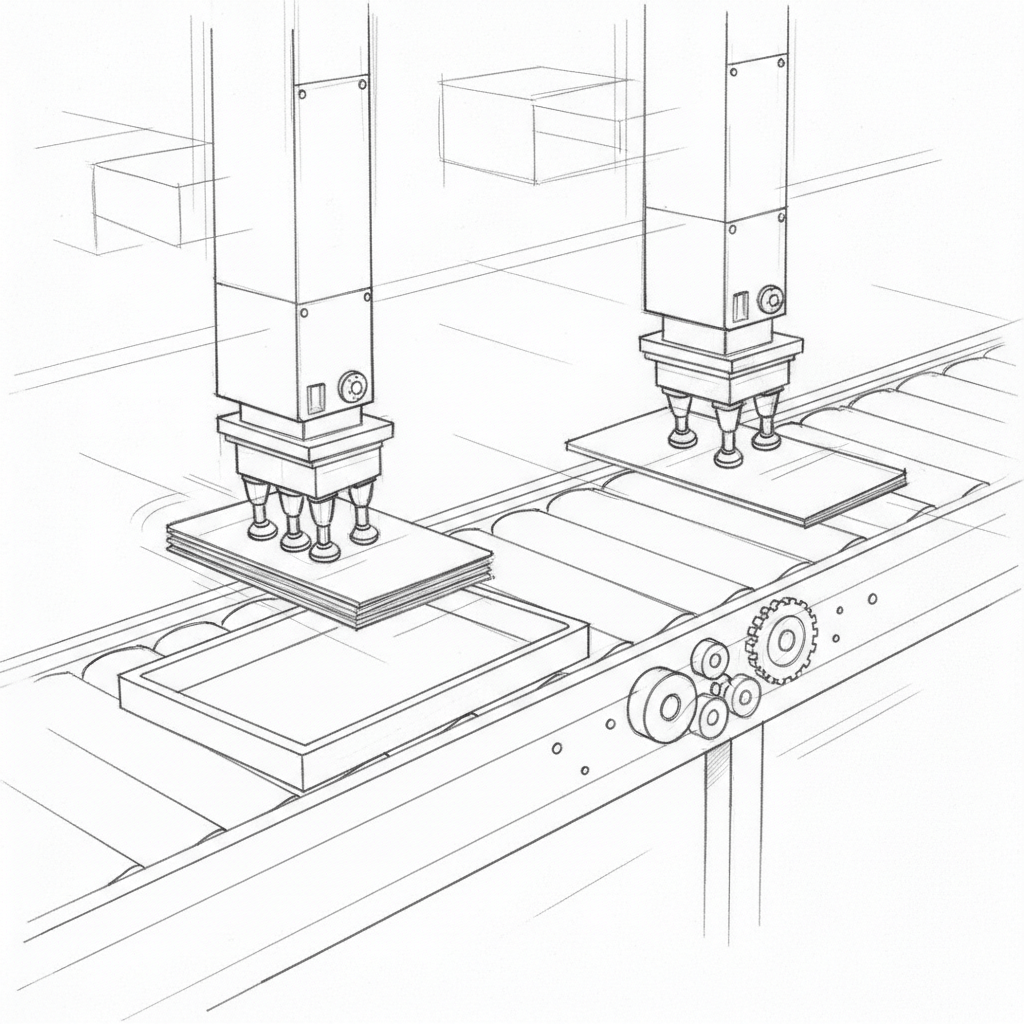

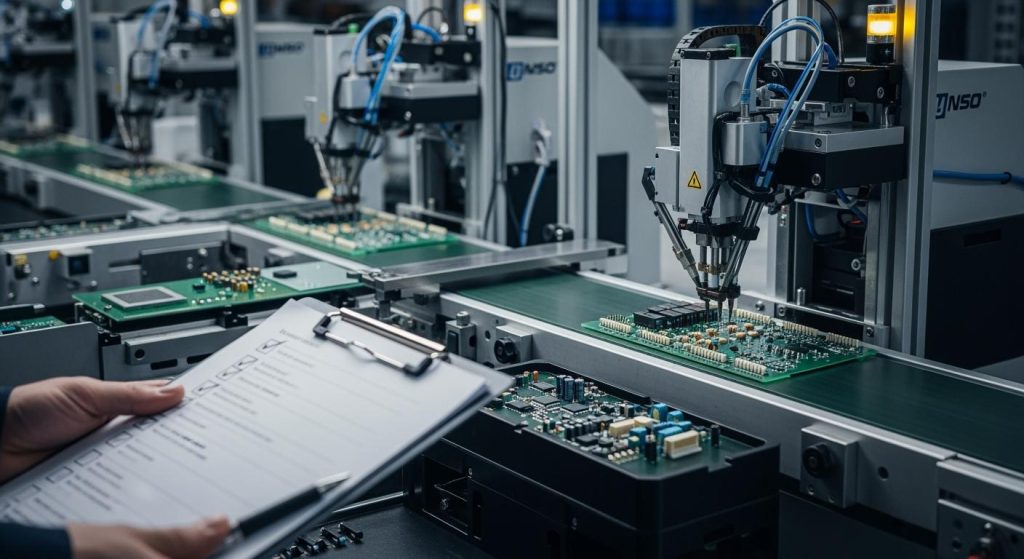

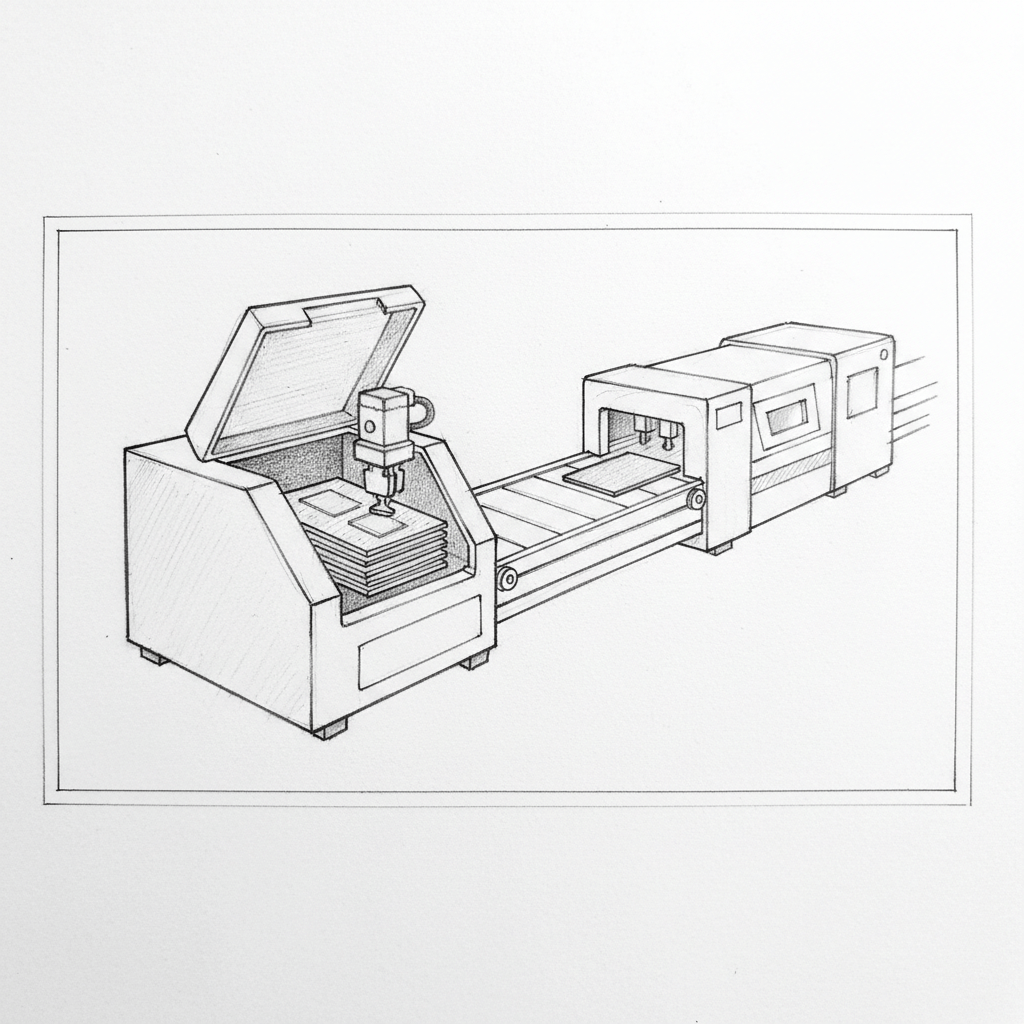

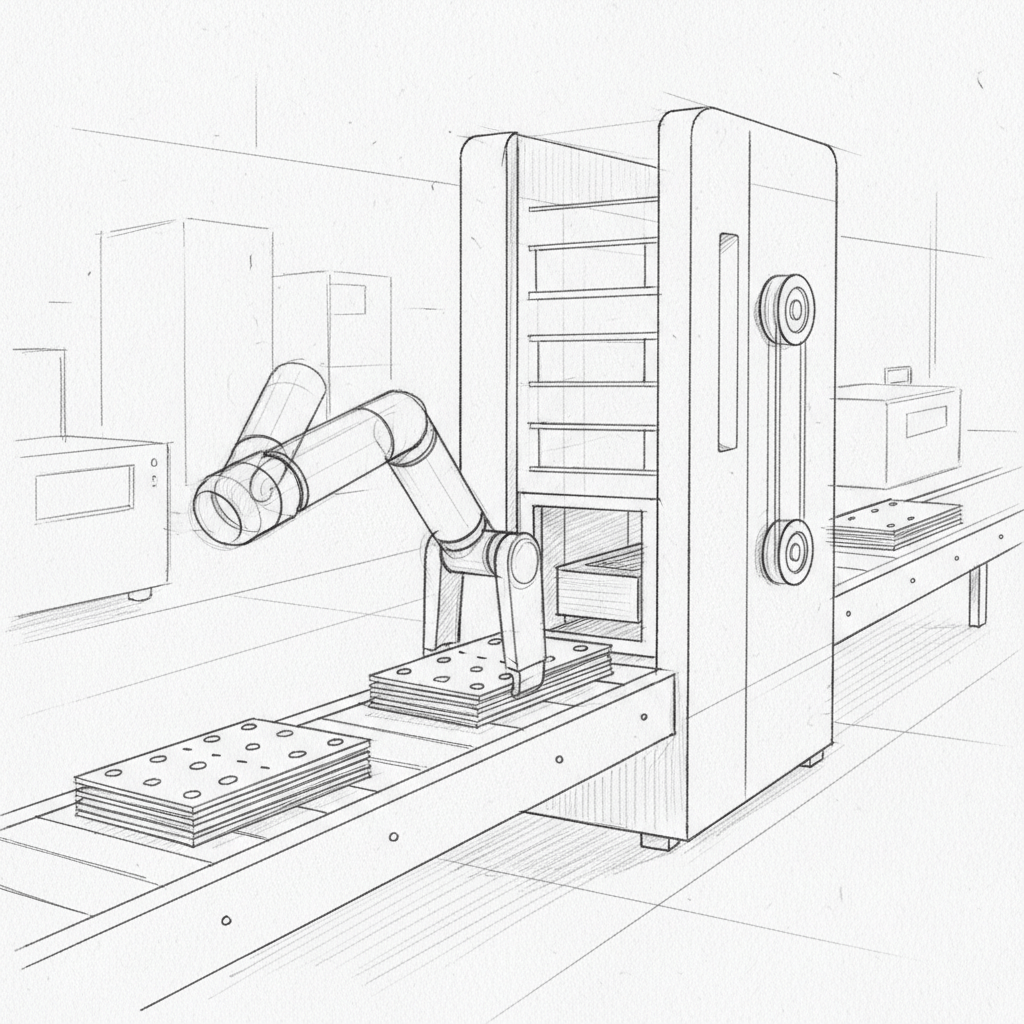

Printed Circuit Boards (PCBs) are integral components in advanced manufacturing processes, where safety and precision play pivotal roles in ensuring quality and reliability. Improper handling of PCBs can introduce various risks, such as mechanical damage, contamination, Electrostatic Discharge (ESD), and microcracks, which subsequently lead to failures including reduced solderability and latent defects, adversely affecting both production efficiency and product reliability. Industry reports highlight the common risks such as bending, contamination, and ESD-induced failures that manufacturers must mitigate for optimal outcomes [Overview of PCB/PCBA Reliability and Failure Analysis](https://resources.altium.com/p/overview-pcbpcba-reliability-and-failure-analysis).