Optimizing Reflow Oven Conveyor Speed for Precision in Electronics Manufacturing

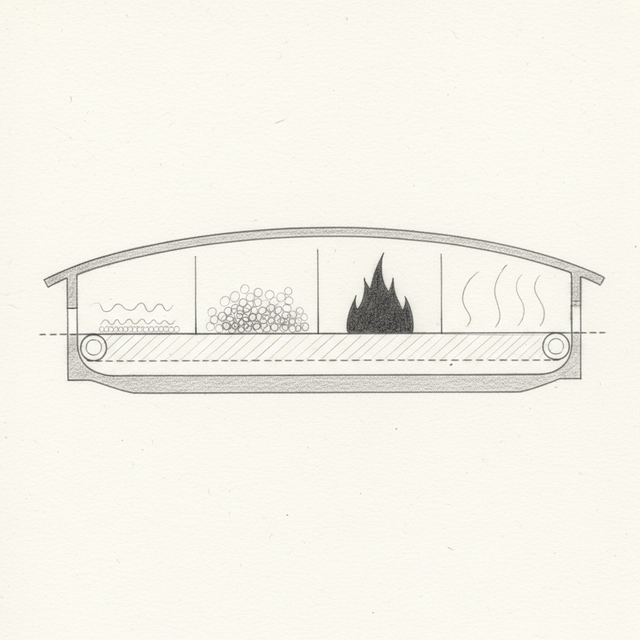

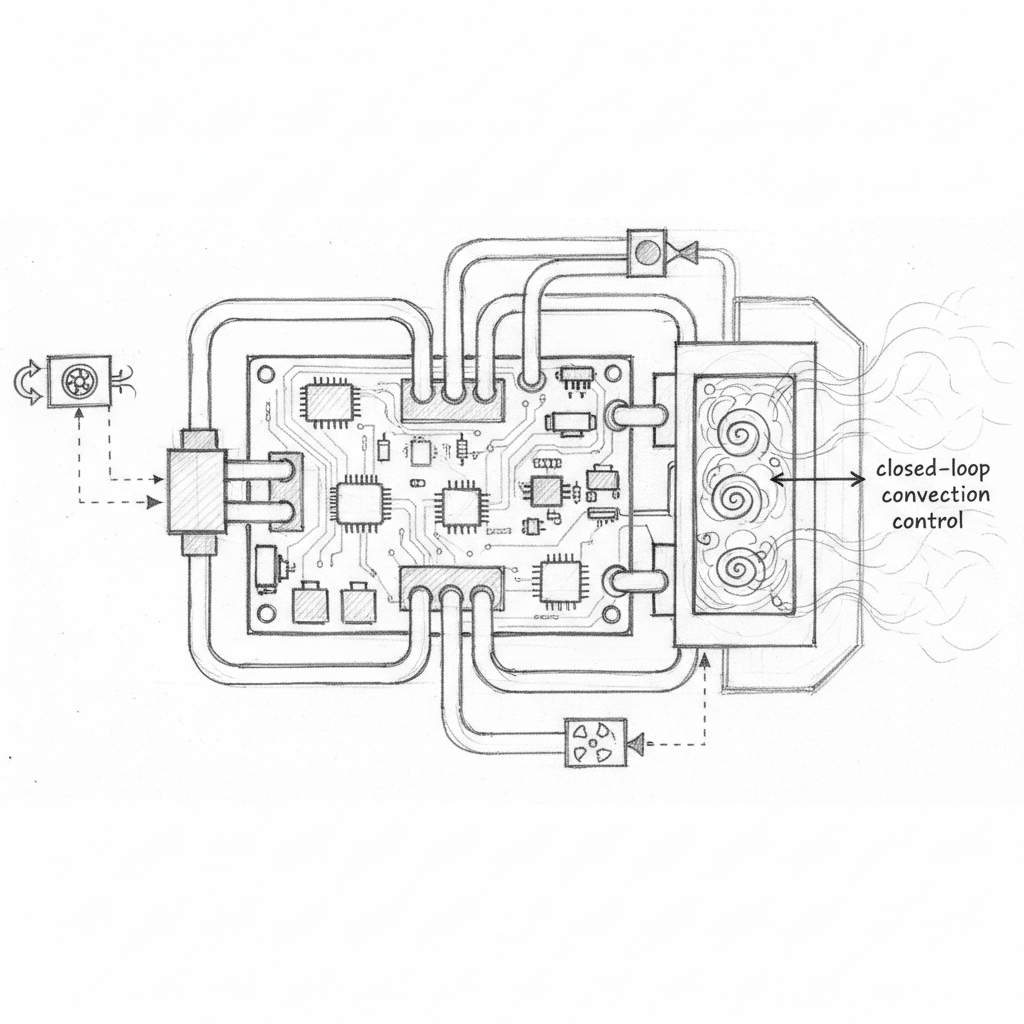

The article explores the critical role of reflow oven conveyor speed in SMT manufacturing, highlighting how it influences the thermal profile and impacts production efficiency. Key insights emphasize the need for precise alignment of conveyor speed with thermal profiles to avoid defects like soldering errors or overheating. Practical recommendations include using advanced calibration tools and thermal profiling technologies to refine conveyor settings. The article forecasts future trends, indicating the integration of AI and IoT for autonomous speed adjustments and predictive maintenance will be pivotal for enhancing manufacturing precision and efficiency. Implementing these innovations allows manufacturers to maintain competitive advantage in the evolving electronics market.