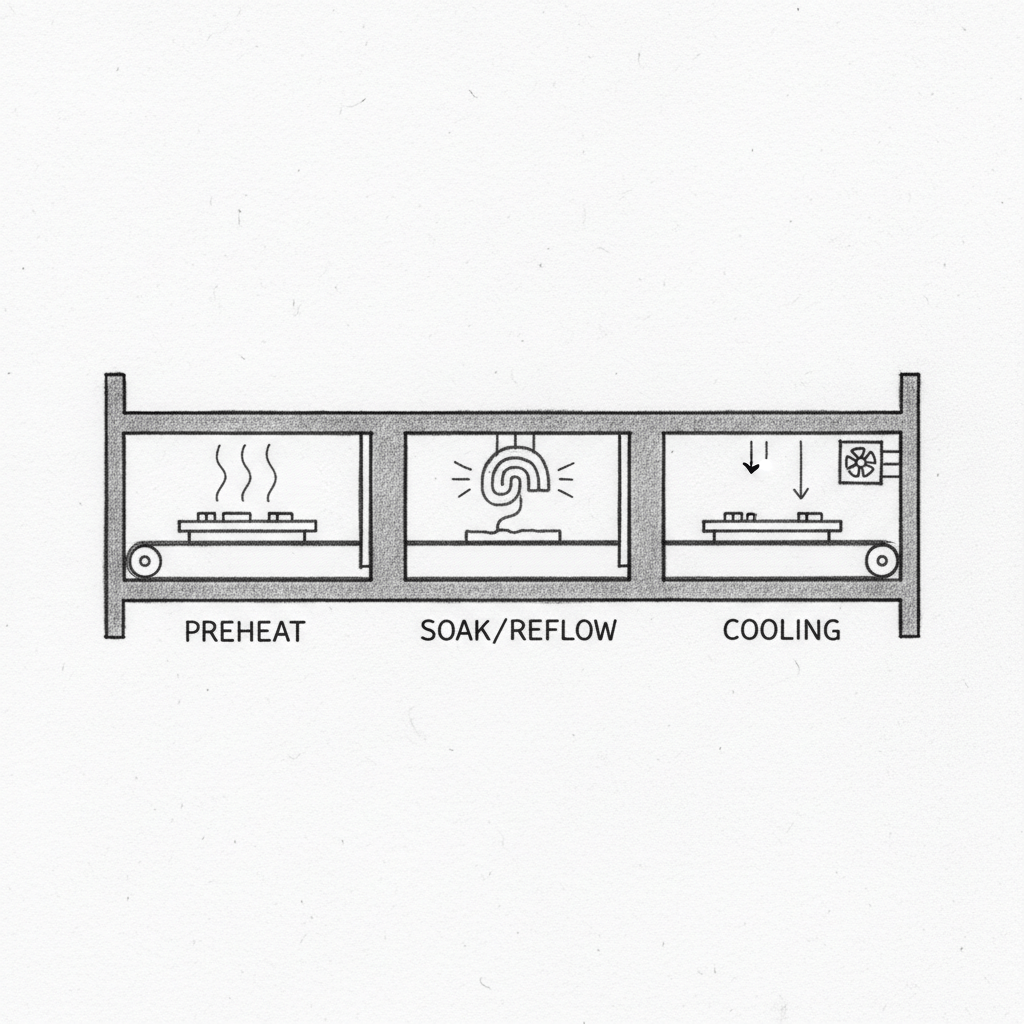

How Heating Zones Affect Reflow Oven Performance

Reflow ovens are crucial in SMT assembly, affecting both efficiency and quality in electronics manufacturing. Key insights include the importance of optimizing heating zones, which are distinct sections regulated to create specific time-temperature profiles for effective soldering, accommodating varied PCB designs, and enhancing solder joint quality. Expert recommendations focus on leveraging AI-driven control systems and thermal profiling tools to improve zone performance and energy efficiency, with potential energy savings of up to 40%. Practical takeaways emphasize investing in advanced technologies for real-time adjustments and enhanced adaptability, ensuring sustainability and competitive advantage in the electronics industry by 2026.