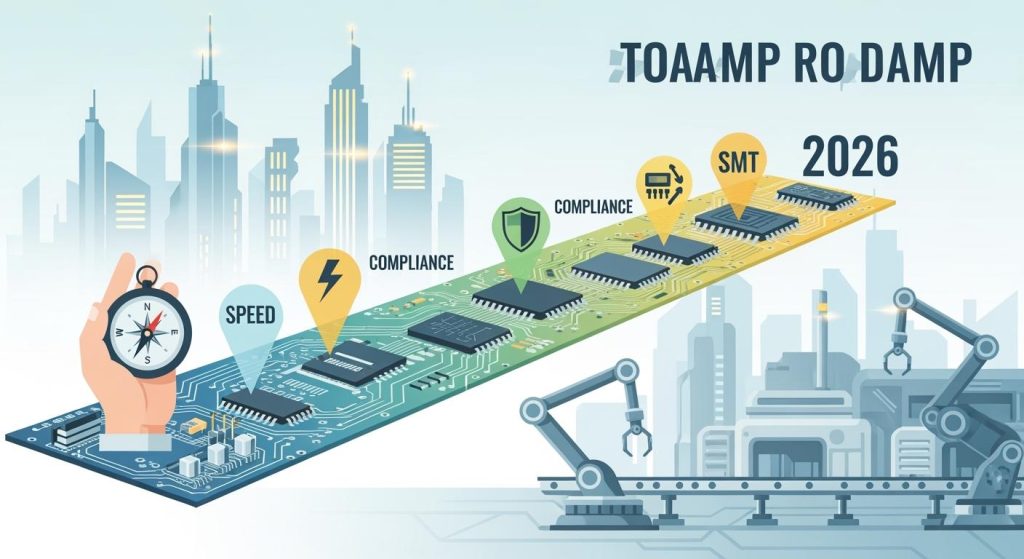

Automatic PCB Conveyors Compliance: Interconnect, Traceability, and Damage Reduction for Higher FPY

Standards‑anchored ultimate guide on automatic PCB conveyors compliance—SMEMA, IPC‑HERMES‑9852, IPC‑2581—and damage‑reduction practices to improve FPY. Read now.