Reflow oven specifications are very important in advanced PCBA manufacturing. These details help decide how good, reliable, and successful reflow soldering will be. Complex assemblies need exact temperature control and special features. This makes sure every solder joint is up to industry standards. S&M’s new reflow solutions use real-time monitoring, automated inspection, and process tracking. These features help make soldering better. The table below shows how these important features help make high-quality reflow soldering:

Funktion | Fordel |

|---|---|

Precise temperature control | Stops problems by keeping the best heating and cooling for PCBs. |

Real-time monitoring | Warns workers about changes, so there are fewer mistakes. |

Automated inspection | Checks for rules and keeps records for each PCB made. |

SPC charts | Finds patterns and possible problems early. |

Barcode capability | Stops people from making mistakes by using the right programs and PCBs. |

Process traceability | Follows reflow temperature steps, making things more reliable and ready for checks. |

De vigtigste pointer

Reflow oven specifications are very important for making good solder joints in advanced PCBA manufacturing.

Accurate temperature control stops problems like tombstoning and cold joints. This makes solder connections stronger.

Real-time monitoring and automated inspection make the soldering process better. They help reduce mistakes and make things more reliable.

Flexible zone configurations in reflow ovens help with complex parts. This gives more consistent results.

Data logging and traceability features help keep quality high. They also make the whole soldering process better.

Key Reflow Oven Specifications for Advanced PCBA

Temperature Control and Reflow Oven Temperature Settings

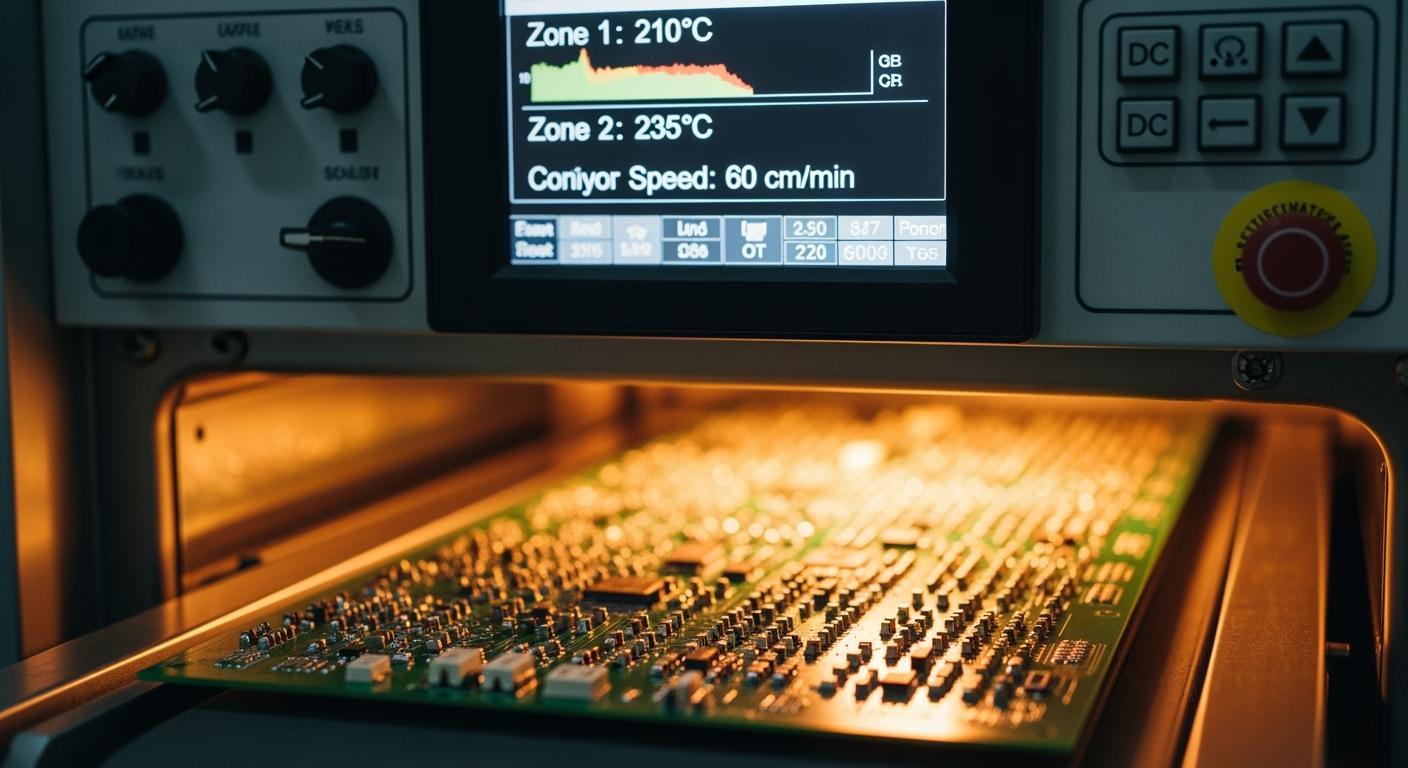

Having the right reflow oven temperature is very important. S&M’s reflow oven uses Siemens PLC and PID closed-loop control. This keeps the temperature steady. It helps every pcb get the same heat each time. Good settings stop problems like tombstoning, cold joints, and voids. Each part of the process needs careful changes. These parts are preheat, soak, reflow, and cooling. Good thermal profiling melts the solder paste. It also makes strong solder joints. S&M ovens watch the temperature all the time. This helps make the process better.

Zone Configuration and Process Flexibility

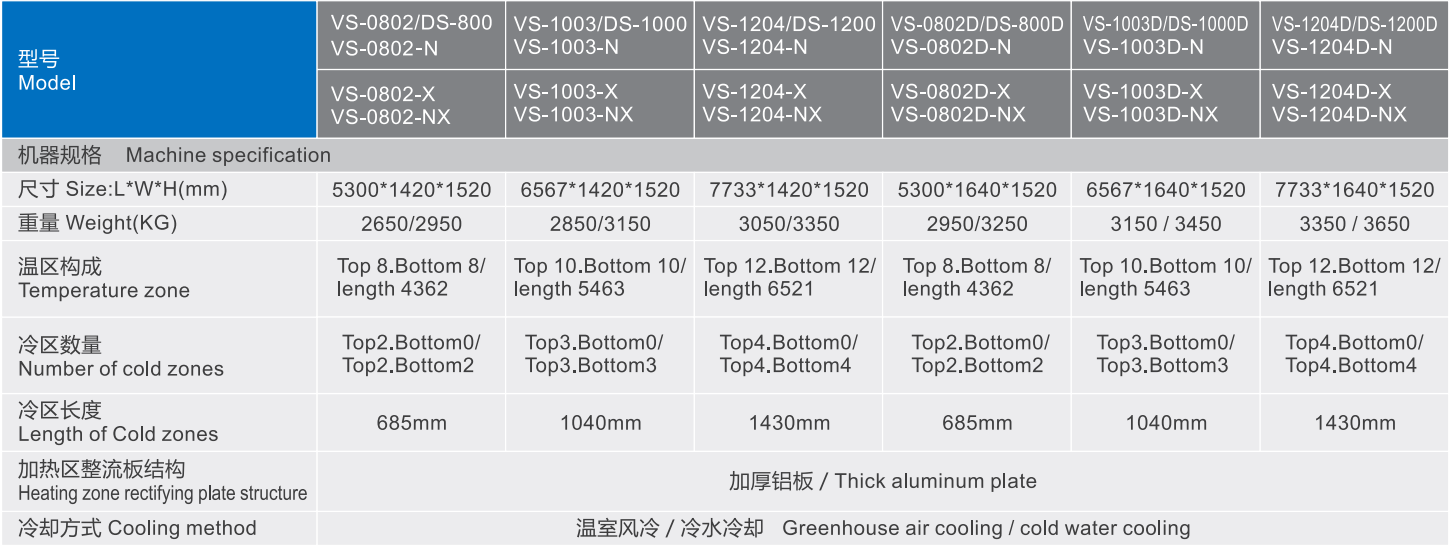

Modern reflow ovens have many zones. These zones help control the reflow process. S&M’s VS Series has up to 10 top and 10 bottom zones. More zones give better control over the smt reflow soldering profile. Some printed circuit boards are complex. They need flexible thermal zones for different parts and solder paste. Flexible zones help make the process better. They also help make good soldering for advanced surface mount technology.

Conveyor and Transport System

A strong conveyor system moves pcb assemblies through each zone. The speed and steadiness of the conveyor matter a lot. They affect the smt reflow soldering profile and how well soldering works. If the conveyor is too fast, the pcb may not get hot enough. If it is too slow, parts can get too hot and break. S&M’s rail surface is tough and has automatic oiling. This makes the transport smooth and solder joints strong.

Atmosphere Control in Nitrogen Reflow Ovens

Nitrogen reflow ovens make a special air for soldering. This air stops solder paste, leads, and copper pads from rusting. S&M’s nitrogen system covers the pcb. This makes solder joints better and more reliable. Nitrogen reflow ovens are used in places with strict rules. These places include car and medical device factories. They help keep solder connections clean and strong.

Data Logging and Traceability

Advanced reflow ovens must keep track of data for every pcb. S&M’s ovens collect data all the time. They make SPC charts and use barcode traceability. This means each board’s smt reflow soldering profile is saved. Alarms and links to quality systems help keep things working well. Traceability helps with checks and makes the process better over time.

Note: The table below shows important reflow oven specifications for advanced PCBA.

Specification Type | Detaljer |

|---|---|

Cooling is controlled at 2 to 4°C per second. This helps solder joints get solid without shock. | |

Heating Methods | Most ovens use conveyor-type convection for both sides. |

There are preheat, soak, reflow, and cooling zones. Each has its own temperature limits. | |

Kontrol af atmosfæren | |

Moisture Sensitivity Limits | The highest temperature depends on the part and pcb. |

Impact of Reflow Oven Specs on Soldering Process

Soldering Quality and Defect Reduction

Reflow oven specifications are important for soldering results. Each setting, like airflow and temperature, can change how many defects happen. If the airflow is not steady or a heating zone breaks, solder joints can be weak. This means more scrap and wasted boards. If the conveyor moves at different speeds, or the temperature changes too much, more defects and damage can happen.

Keeping the reflow temperature just right helps heat and cool the board evenly. This stops thermal shock and helps make good solder joints. The S&M nitrogen reflow oven uses special controls to keep the temperature perfect. This lowers problems like tombstoning, solder balls, and open joints.

Impact on Soldering Defects | |

|---|---|

Inconsistent Airflow | Bad solder joints, more repairs, and more waste. |

Heating Zone Failure | Uneven solder, broken parts, and fewer good boards. |

Conveyor Speed Fluctuations | Bad soldering, thermal shock, and more defects. |

Temperature Gradient Issues | Uneven soldering, more defects, and possible board damage. |

Hot Air Distribution Issues | Solder joints are not reliable and more products fail. |

Cooling System Failure | More broken parts, more failures, and expensive repairs. |

The S&M reflow oven uses Siemens PLC and PID closed-loop control. This keeps the temperature and airflow steady. It helps lower defects and makes better boards.

Handling Complex Components in Reflow Soldering

Some boards use tiny and packed parts like BGAs and QFNs. These parts are hard to solder. Problems like voids and tombstoning can happen. Voids are air or gas bubbles in the solder joint. Tombstoning is when one end of a part lifts up from uneven heat.

A reflow oven with good zone control can heat certain spots very well. The S&M nitrogen reflow oven lets you change the temperature for each part. This helps stop defects and keeps parts safe. The oven also uses a smart gas system to stop oxidation. This makes solder joints stronger.

Beskrivelse | |

|---|---|

Præcision | Heats small spots very accurately, so there are fewer defects. |

Fleksibilitet | Can solder different types of parts on one board without extra setups. |

Reduceret termisk belastning | Keeps heat away from sensitive parts, so they do not get hurt. |

Cost-Effectiveness | Fewer repairs and defects save money, even if it takes longer. |

Forbedret pålidelighed | Good solder joints help boards last longer and work better. |

The S&M reflow oven has a modular design and watches the process in real time. This helps make strong solder joints for tricky boards.

Supporting High-Mix, Low-Volume Production

Factories that make many types of boards in small amounts need flexible ovens. The soldering process must change for different boards and solder pastes. Ovens with programmable heating zones and real-time temperature checks are helpful. The S&M nitrogen reflow oven can save up to 100 profiles. This makes switching between products fast and keeps soldering quality high.

Funktion | Beskrivelse |

|---|---|

Programmable Heating Zones | Lets you set up heating for each board, making the oven flexible. |

Real-time Temperature Profiling | Shows the temperature right away, so you can control it well. |

Compatibility with Solder Types | Works with both lead and lead-free solder, so it fits many jobs. |

Changing from one product to another takes time in high-mix factories. Smart ovens like S&M’s make this faster and help improve the process. This means more boards can be made and resources are used better.

Ensuring Repeatability and Reliability

It is important for the oven to give the same results every time. Good thermal profiling and temperature control are needed. The S&M nitrogen reflow oven keeps the heat steady and makes strong solder joints. This lowers defects and makes boards more reliable.

Metric | Beskrivelse | Impact on Reliability |

|---|---|---|

Pass Rates | Shows how many solder joints are good. | More good joints mean better reliability. |

Temperature Profiling | Controls solder heat during the process. | Makes strong joints and lowers defects. |

Compliance with Industry Standards | Follows quality rules in making boards. | Makes people trust the process more. |

Cooling Rates | Cools boards at the right speed to stop cracks. | Makes joints last longer and work better. |

Quality Checks | Uses SPC and other checks to keep quality high. | Lowers mistakes and makes results repeatable. |

The S&M reflow oven uses real-time checks and SPC charts to watch the process. This makes sure every board meets high standards. The oven works for both small and big boards, so it fits many uses. Good soldering results help products work well and make customers happy.

Comparing Standard vs. Advanced Reflow Requirements

Specification Differences in Reflow Ovens

Standard reflow ovens are used for simple pcb assemblies. They have fewer temperature zones and use basic thermal profiling. These ovens work with common parts and regular solder paste. Advanced reflow ovens are needed for special industries like aerospace and medical devices. These industries need very exact temperature control and cleanroom use. They also need advanced ways to watch the process. The reflow temperature must stay steady for every pcb, even with tricky parts and sensitive solder joints.

Standard ovens use simple profiles and do not change much.

Advanced ovens have more temperature zones and real-time checks.

Some industries need ovens that keep special air and track lots of data.

Unique Challenges in Advanced PCBA Process

Advanced PCBA has some tough problems during reflow soldering. The table below shows common problems and how to fix them:

Challenge | Beskrivelse | Løsning |

|---|---|---|

Cold Solder Joints | Solder does not melt all the way, so it is weak. | Make the oven hotter or keep it hot longer. |

Tombstoning | One end of a part lifts up during reflow. | Heat the board longer before reflow to even out heat. |

Loddebroer | Too much solder connects pads and makes shorts. | Use less solder paste and check the reflow settings. |

Medical device makers use reflow ovens for tiny and sensitive electronics. These ovens must pass hard quality tests and keep the right temperature. Aerospace needs ovens that make strong solder joints, even if there is shaking or big temperature changes.

Choosing the Right S&M Reflow Oven

S&M’s advanced reflow ovens help with these problems in many ways:

Automation makes the process faster and more even.

Exact temperature control helps every solder joint be strong.

Flexible profiles let you change settings for different parts and solder paste.

Real-time checks and data logs help make sure everything is right.

S&M’s ovens help companies get good reflow soldering for hard pcb assemblies. Their special features help make the process better, solder joints stronger, and results more steady. This makes them great for jobs that need the best quality and reliability.

Matching reflow oven specifications to advanced PCBA needs helps make good soldering, strong boards, and fast production. S&M gives new ways to help with careful reflow soldering for hard assemblies. Picking the right profile for each part makes solder joints better and lowers mistakes. For example, FBGA244-GND works well with a steady profile. QFN48 and QFP80 need special care with flux. The table below shows how different profiles change soldering results:

Component Type | Observations | Implications |

|---|---|---|

FBGA244-GND | Heat sink helps keep things steady and stops warping during reflow | Boards work better and last longer |

QFN48 | How flux and design work together changes solder joint quality | You must match the flux to the part’s design |

QFP80 | Good outgassing of flux means fewer problems, even though the part is big | Shows why flux is important for making good boards |

S&M tells factories to check their soldering steps and pick the best reflow oven for the best results.

OFTE STILLEDE SPØRGSMÅL

What does a reflow oven do in PCBA manufacturing?

A reflow-ovn heats up solder paste and parts on a PCB. The heat melts the solder and connects the parts to the board. This makes the joints strong and helps them last.

Why is temperature control important in a reflow oven?

Good temperature control helps each solder joint form the right way. It stops problems like cold joints or too much heat. S&M ovens use special controls to keep the heat steady.

How does nitrogen improve the reflow soldering process?

Nitrogen keeps the oven clean inside. It lowers oxidation on solder joints. This makes the connections stronger and more reliable.

Can S&M reflow ovens handle different PCB sizes and types?

S&M reflow ovens work with many PCB sizes and types. The ovens have flexible zones and adjustable conveyors. This helps with both small boards and big boards.

What features help track quality during reflow soldering?

S&M ovens use real-time monitoring, SPC charts, and barcode traceability. These tools help track each board’s process. They also help with quality checks and audits.