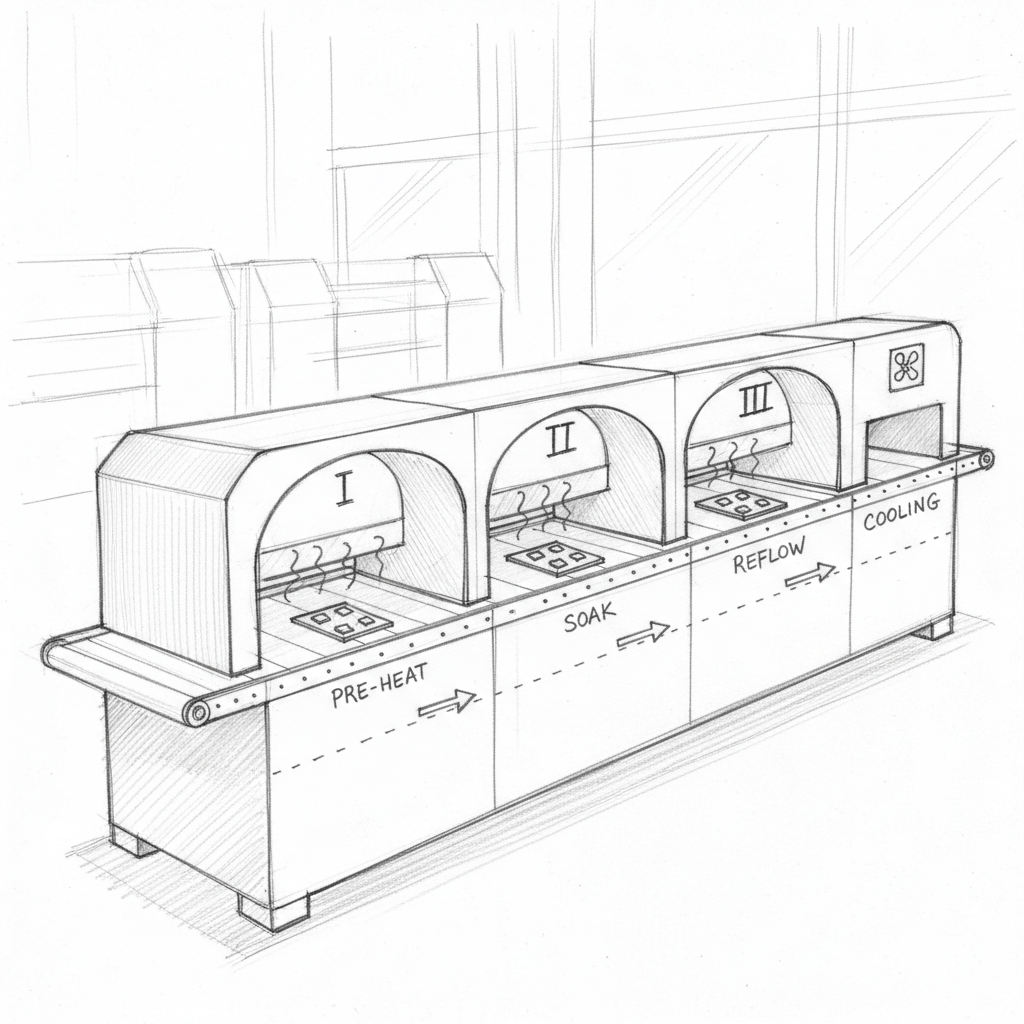

Understanding Inline Reflow Ovens for SMT Manufacturing Efficiency

Inline reflow ovens are essential in SMT manufacturing, providing advantages in precision, speed, and energy efficiency by moving circuit boards through controlled temperature zones for consistent soldering. Their adoption can lead to increased throughput, enhanced precision, and reduced operational costs through efficient energy use. Expert recommendations include ensuring regular calibration of temperature zones and optimizing conveyor speeds to balance quality and production efficiency. Selecting the right oven compatible with production scale and future growth needs is crucial for effective competition in the electronics market.