If you need a rock‑solid handoff at a reflow oven’s infeed or outfeed—while reliably diverting NG boards—you’re in the right place. This ultimate guide shows how to wire and verify SMEMA 1.2 signals, map I/O for shuttle and diverter conveyors, set safe timing and debounce, and audit direction settings for single/dual‑lane or reverse‑flow cells. You’ll also see how this setup stacks up in SMEMA vs Hermes scenarios, so you can decide when a message‑based approach is worth the extra integration.

Safety first: treat all wiring as safety‑adjacent; never bypass e‑stops or interlocks. Verify “typical” maps against each OEM manual before energizing.

Author and field-test note — written by John Lee, SMT Integration Engineer, S&M Co.Ltd. John has 12 years of hands‑on experience in SMT equipment integration and PLC commissioning and holds vendor training certificates for Siemens and Rockwell automation plus manufacturing engineering coursework equivalent to CMfgE. Field test summary: on‑site validation used a test jig, multimeter, oscilloscope/high‑speed PLC trace, and position/bin sensors during a 2‑hour soak at reflow exit temperatures; timing captures and I/O logs were recorded for acceptance and troubleshooting.

1) SMEMA 1.2 essentials for shuttle conveyors at reflow

At its core, SMEMA (legacy IPC‑SMEMA‑9851) coordinates transfers with simple, discrete handshakes between adjacent machines. The most common signals you will encounter are:

Board Available (BA): Upstream asserts when a PCB is present at the transfer.

Machine Ready / Ready To Receive (RTR/MR): Downstream asserts when it can accept a PCB.

Inhibit/Stop (INH): Downstream halts upstream transfer for faults or interlocks.

Fail/Alarm (FAIL): Indicates an error condition (naming varies by OEM).

Electrical expectations are typically 24 VDC, opto‑isolated or dry‑contact style I/O. Grounding, shielding, and isolation matter—especially near ovens. Public OEM and adapter manuals align on these points and even note pinout variations such as an optional ground on Pin 14 in some implementations; confirm the exact assignment before wiring, as SMEMA specifics can vary by model and vendor. Representative references include the SICK Hermes‑SMEMA adapter documentation noting “optional” Pin‑14 ground and other interface clarifications, and a GPD Global service guide that explicitly references IPC‑SMEMA‑9851 compliance for discrete 24 VDC signaling: see the SICK document in the Hermes‑SMEMA Connect manual and the GPD Global compliance note (SICK Hermes‑SMEMA Connect manual; GPD Global IPC‑SMEMA‑9851 compliance).

Why does this matter at reflow? Heat and vibration can magnify small wiring mistakes into chronic stops. Solid isolation and clean signal conditioning dramatically reduce nuisance trips and missed handoffs.

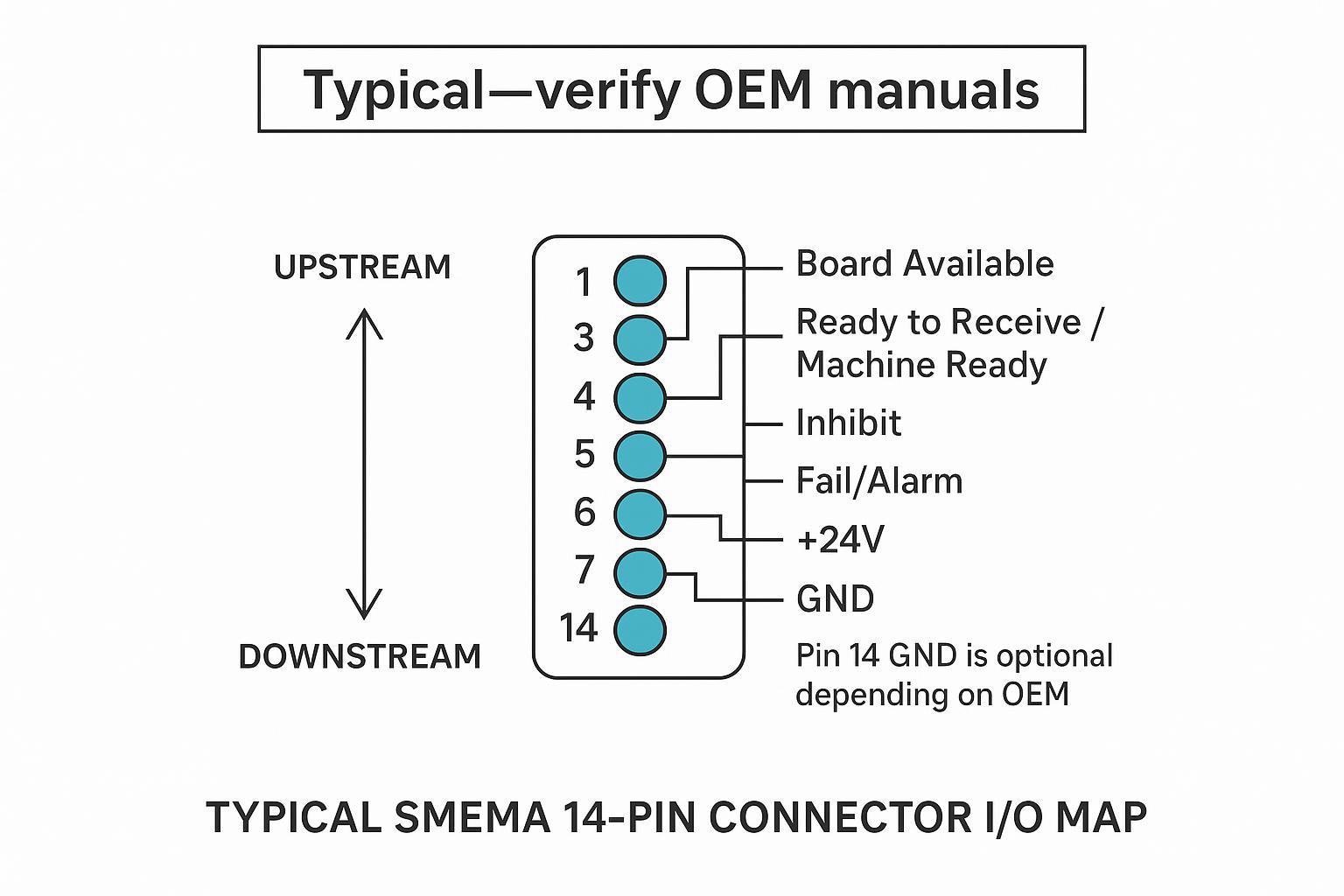

2) Typical 14‑pin I/O map (vendor‑agnostic; verify against manuals)

The following diagram shows a “typical” SMEMA 14‑pin connector arrangement used on shuttle or diverter conveyors. Pin labels and polarity are not universal—always verify the actual machine manual before energizing the line.

Practical wiring notes you can apply immediately:

Use shielded, twisted‑pair for signal runs. Terminate shields properly and maintain earth bonds.

If the OEM calls for dry‑contact style inputs, keep the circuits floating relative to logic common to prevent ground loops.

Label both ends of the harness with the verified pinout and direction (upstream vs downstream) to avoid pin‑reversal during maintenance.

For deeper context on SMEMA electrical style and optional pin assignments, consult the SICK Hermes‑SMEMA Connect manual and the GPD Global service guide cited above.

3) Handshake timing and debounce you can trust

Getting BA and RTR edges clean isn’t just about logic—it’s also about mechanical motion, sensor chatter, and PLC scan time. Here’s a field‑proven approach that balances responsiveness and noise immunity near hot, vibrating reflow exits.

Recommended baseline settings (tune during commissioning):

Hardware input filtering: use module‑level filters largely to kill high‑frequency noise.

Siemens example ranges (device/module dependent): roughly 0.4–20 ms class inputs with selectable delays. See ET 200SP F‑DI HF documentation for the menu location and options (Siemens ET 200SP input filter manual).

Rockwell ControlLogix/CompactLogix DC inputs often offer 1–2 ms configurable filters in addition to fixed delays—configure in Studio 5000 per the module datasheet (Rockwell 1756‑TD002; Rockwell 1769‑TD006; 5069‑UM004).

Software debounce: add 10–50 ms in logic to absorb slower bounce from relays or sensor chatter during shuttle/diverter movement. Start at 20–30 ms, then validate with traces.

Transfer window: hold RTR a safe 200–500 ms around the mechanical handoff to cover timing jitter at normal conveyor speeds and sensor spacing.

Illustrative PLC‑agnostic pseudo‑code (debounce + watchdog):

// Rising-edge debounce for BA and RTR

if (BA_raw != BA_stable) {

if (timer_BA.elapsed >= 25ms) {

BA_stable = BA_raw;

}

} else {

timer_BA.reset();

}

if (RTR_raw != RTR_stable) {

if (timer_RTR.elapsed >= 25ms) {

RTR_stable = RTR_raw;

}

} else {

timer_RTR.reset();

}

// Transfer watchdog: ensure BA->transfer->BA low completes within window

if (BA_stable == 1 and RTR_stable == 1) start(transfer_timer);

if (transfer_timer.elapsed > 5s) {

raise_alarm("Transfer timeout");

set(INH, 1); // inhibit upstream until cleared

}

Commission with instruments, not just eyes. Use an oscilloscope or high‑speed trace to confirm that BA rising and RTR falling events are distinct, stable beyond your chosen debounce, and never missed across normal scan times.

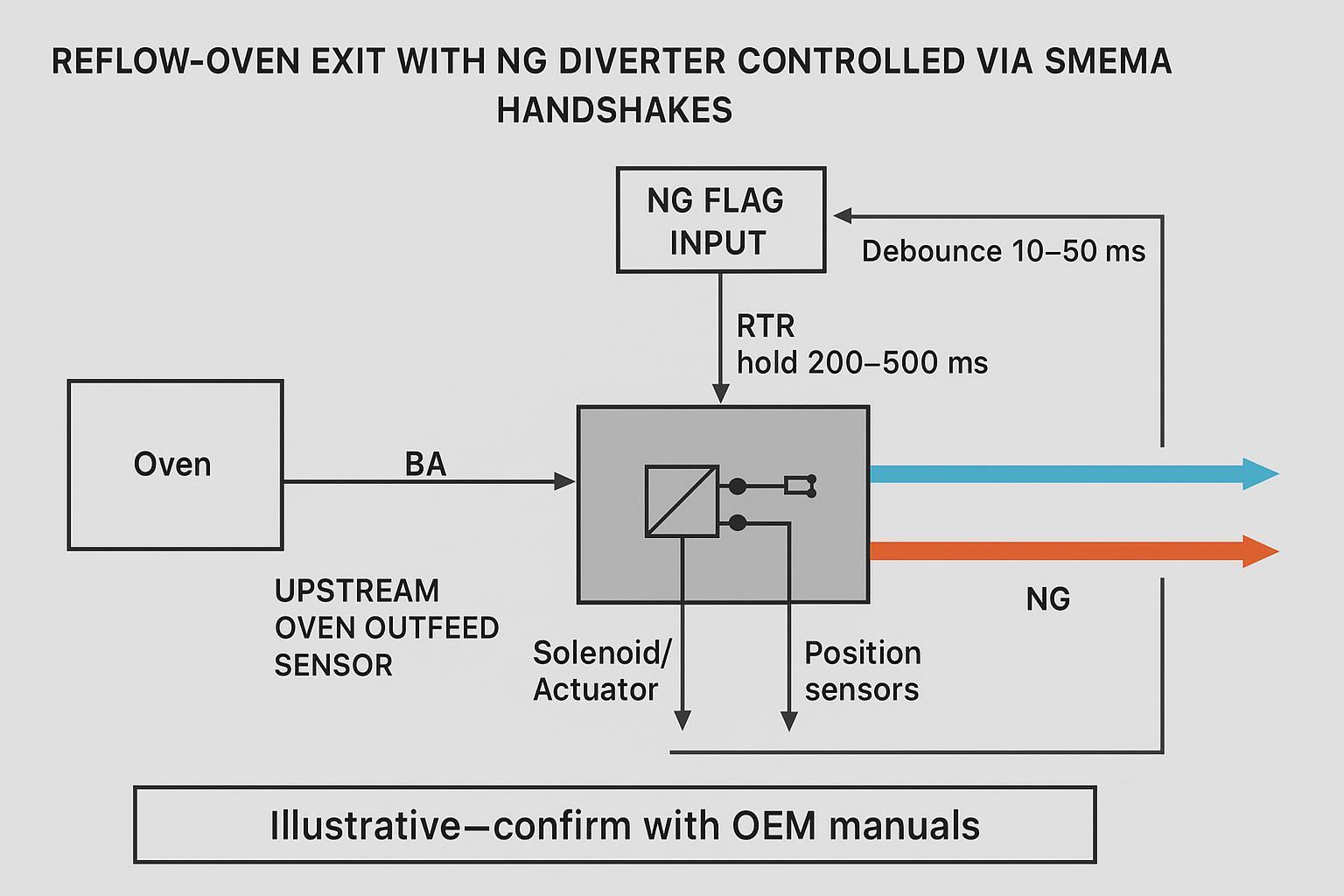

4) Reflow oven in/out with an NG diverter: wiring and logic that hold up under heat

At a reflow exit, you’ll typically route OK boards straight and divert NG boards to a reject lane/bin. Under SMEMA, NG context isn’t standardized in the handshake itself, so most lines bring an NG flag from AOI or upstream PLC I/O into the diverter logic.

Typical logic pattern you can adapt:

Downstream diverter/shuttle asserts RTR when the path is clear and actuators are in a safe state.

Upstream asserts BA when a board arrives at the transfer sensor.

If NG flag = 1, pre‑actuate the diverter to the reject path and wait for position confirmation before allowing the transfer. If NG = 0, keep the straight‑through path.

Assert INH if the reject bin is full, a position sensor isn’t confirmed, or safety interlocks are open.

Direction settings to document and test:

Single vs dual‑lane: each lane’s SMEMA chain should be explicit (Upstream‑L/R ↔ Downstream‑L/R). Keep lane signals independent to avoid cross‑talk.

Reverse‑flow declarations: on bidirectional shuttles, define and label the active flow direction at changeover; verify that BA/RTR role assignment matches the active flow.

For mechanical fundamentals of shuttles and handoff geometry, this explainer provides additional context: see the internal primer on shuttle mechanics and timing in the brand library under the shuttle conveyor principles (Shuttle conveyor working principles). For cooling and outfeed considerations after reflow, this guide offers a broader process view (PCB cooling conveyors guide).

5) SMEMA vs Hermes at the reflow exit (tailored to NG diverters)

Hermes (IPC‑HERMES‑9852) replaces discrete handshakes with TCP/IP messages that carry board‑level context such as a persistent Board ID. That changes what’s possible at a reflow exit, especially for NG routing and traceability. For implementation background and current specification details, see the official v1.6 spec and Siemens’ implementer overview (IPC‑HERMES‑9852 v1.6; Siemens Hermes overview).

Aspect | SMEMA (legacy) | Hermes (v1.6) |

|---|---|---|

Transport coordination | BA/RTR/INH discrete stop/go | Message states (NotStarted/Incomplete/Complete) |

Board identification | None | Persistent Board ID (GUID) end‑to‑end |

NG routing metadata | Local PLC/AOI I/O; ad‑hoc | Message‑level context for consistent NG routing |

Error handling | Basic via INH/FAIL | Structured error messages and recovery paths |

Retrofit complexity | Low; fast to commission | Higher; requires network + software mapping |

Best‑fit use | Simple conveyors/shuttles; basic interlocks | Traceability, flexible routing, MES connectivity |

When should you choose one over the other? If you need auditable board‑level NG routing and easy rework loopbacks, Hermes is hard to beat. If you’re integrating a straightforward shuttle + reject gate at a stable station and just need reliable stop/go, well‑tuned SMEMA may be perfectly adequate. That’s the practical core of SMEMA vs Hermes in this cell.

6) Commissioning and verification checklist (inline + downloadable CSV)

Use the following steps during bring‑up. Record actual filter values, timing captures, and I/O maps in the turnover package.

Wiring, polarity, and isolation

Verify 24 VDC supply, GND continuity, and isolation. Confirm any “optional” grounds (e.g., Pin‑14) before tie‑in.

Use shielded twisted‑pair for BA/RTR/INH/FAIL; separate from motor/solenoid power.

Confirm connector orientation and gender per each machine’s manual; label harnesses both ends.

Handshake and I/O map tests

Use a test jig to toggle BA/RTR and confirm transfers at target conveyor speeds.

Validate INH behavior on bin‑full, interlocks open, or position‑not‑confirmed.

If NG flag comes from AOI or upstream PLC, map and test both OK and NG paths.

Timing, debounce, and acceptance

Set hardware input filters (per module) and software debounce (start 20–30 ms).

Capture traces: BA rising to transfer complete; confirm RTR hold 200–500 ms with no chatter beyond debounce. Document scan times and timer tolerances.

Direction and lane settings

For dual‑lane/bidirectional cells, document each lane’s SMEMA chain and reverse‑flow procedure; verify role assignment matches active flow.

Safety and interlocks

Validate e‑stop chains; confirm INH asserts on any safety breach and actuator power is cut on fault.

Downloadable CSV content (copy to .csv and attach to your turnover package):

Section,Check,Pass/Fail,Recorded Value/Notes

Wiring,24V and GND verified,,

Wiring,Optional GND (Pin14) confirmed per OEM,,

Wiring,Shield terminations and earth bonding,,

Wiring,Connector orientation/gender verified,,

I/O Map,BA input pin verified (upstream ↔ downstream),,

I/O Map,RTR/MR output pin verified (downstream),,

I/O Map,INH line behavior verified,,

I/O Map,FAIL/Alarm behavior verified,,

NG Logic,NG flag source mapped (AOI/PLC),,

NG Logic,OK path confirmed at speed,,

NG Logic,NG path diverts and confirms bin sensor,,

Timing,Hardware input filter (module),ms,

Timing,Software debounce (PLC),ms,

Timing,RTR hold during transfer,ms,

Timing,Transfer watchdog timeout,s,

Direction,Active flow direction labeled (FWD/REV),,

Direction,Dual-lane roles documented (L/R),,

Safety,E-stop chain validated,,

Safety,INH asserts on any safety breach,,

Sign-off,Final I/O map attached,,

Sign-off,Scope traces attached (BA/RTR/transfer),,

Sign-off,Maintenance labels installed,,

For module‑level filter configuration examples and cautions on over‑filtering, see Siemens device manuals and Rockwell I/O module guides linked earlier.

7) Troubleshooting and common pitfalls (reflow/NG focus)

Pin reversal and floating grounds: Many issues trace to upstream/downstream pin swaps or assuming a common ground where an isolated input expects a floating contact. The SICK Hermes‑SMEMA Connect notes on optional Pin‑14 ground are a frequent source of confusion—always verify the actual connector assignment in the machine manual (SICK Hermes‑SMEMA Connect manual).

EMI and heat‑induced false triggers: Place flyback diodes or RC snubbers per actuator vendor guidance; route signal cables away from solenoid power; apply modest hardware filtering plus 20–30 ms software debounce. Rockwell and Siemens references outline practical input filter options (Rockwell 5069‑UM004; Siemens ET 200SP input filter manual).

Mechanical timing vs conveyor speed: If the diverter arm moves too slowly for line speed, pre‑actuate on NG flag edge and confirm position before asserting RTR. If needed, locally throttle speed at the outfeed.

8) Practical micro‑example: reflow‑exit NG diverter using a SMEMA‑compatible shuttle

Disclosure: S&M Co.Ltd is our product.

In a reflow‑exit cell with a shuttle/diverter, the downstream module exposes a SMEMA 14‑pin interface and accepts an external NG flag. We wired BA from the oven outfeed sensor to the shuttle’s BA input, and the shuttle’s Machine Ready (RTR) back upstream. The shuttle PLC reads the NG discrete from the inspection step and pre‑actuates the diverter to the reject lane when NG = 1, waiting for a position‑confirmed input before dropping INH and accepting transfer. Hardware input filters were set to 3.2 ms on the module, with 25 ms software debounce; the RTR hold window was 350 ms around each transfer. Over a 2‑hour soak at reflow exit temperature, traces showed no chatter exceeding debounce. For a sense of shuttle behavior and dual‑station context, see the product overview for a dual‑station shuttle conveyor (Kahden aseman sukkulakuljetin).

9) References and further reading

Hermes specification and implementer overview: the official IPC‑HERMES‑9852 v1.6 details message states and Board IDs; Siemens’ documentation shows practical adoption and integration steps (IPC‑HERMES‑9852 v1.6; Siemens Hermes overview).

SMEMA electrical style and connector notes: examples from adapter/OEM documentation that echo IPC‑SMEMA‑9851 conventions (SICK Hermes‑SMEMA Connect manual; GPD Global IPC‑SMEMA‑9851 compliance).

Contextual internal reading on conveyors and outfeed handling: overview pages that frame shuttles and cooling in the reflow exit context (PCB conveyors and handling overview; PCB cooling conveyors guide).

For an external case study that documents commissioning steps and an NG (failed‑board) divert workflow with BA/RTR signaling, see Halvorsen’s 2021 “FM4017 Project Hapro — Final Report” (SMEMA AOI‑to‑soldering integration), which includes schematics, interface rationale, and practical debugging notes. (Consider rel=”nofollow” for this educational publication.)

IPC’s Digital Manufacturing overview referencing IPC‑SMEMA‑9851 (updated 2025) — official IPC page noting SMEMA‑9851’s legacy status and replacement by IPC‑HERMES‑9852.

What’s next

If your NG routing or traceability needs are ramping up, pilot a hybrid cell: keep SMEMA at low‑risk transfers while trialing Hermes where Board IDs and NG metadata will pay back immediately. Then standardize once your team is comfortable with the message map. And if you’re kicking off commissioning tomorrow, copy the CSV above into your turnover pack—then let’s get it moving.