Esilämmitys- ja jäähdytysjärjestelmien merkitys SMT-kovetusuuneissa

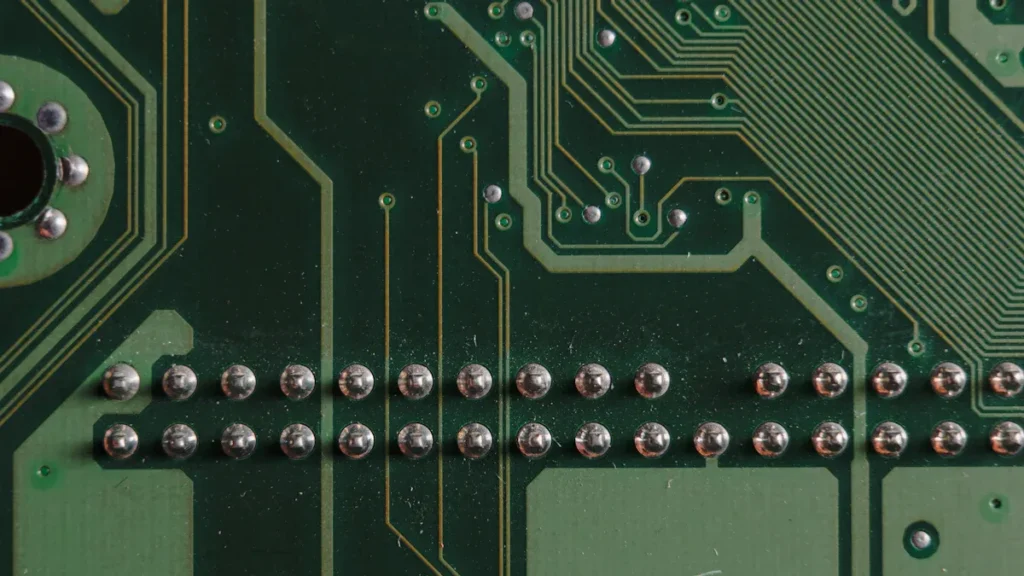

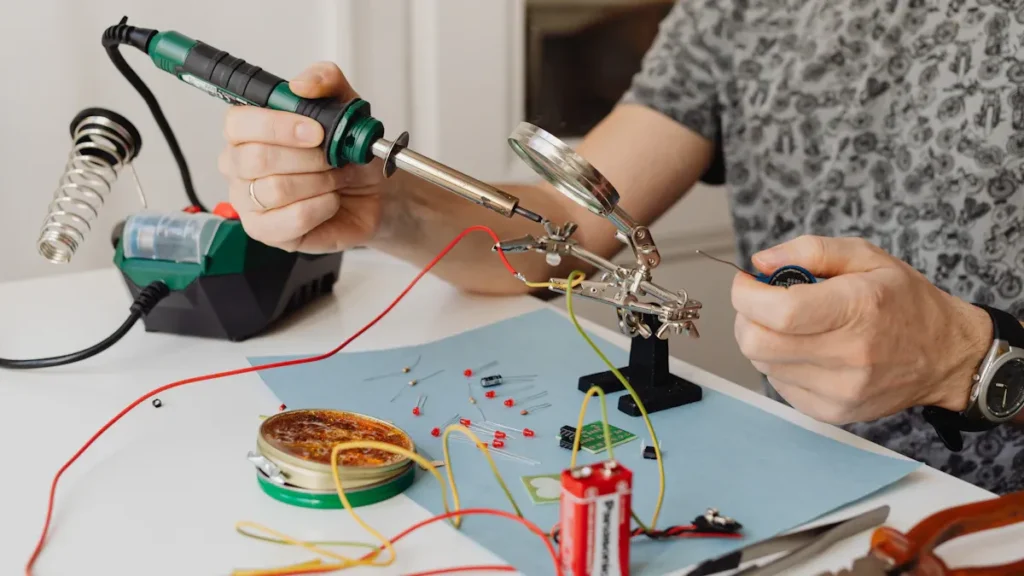

SMT-kuivausuunien esilämmitysjärjestelmät vähentävät lämpöshokkia, parantavat juotosliitosten laatua ja lisäävät piirilevyjen luotettavuutta hallitulla lämmityksellä ja jäähdytyksellä.