You face many problems when planning an SMT Factory to grow. Mistakes in scheduling, machine issues, and money problems can slow you down. Fixing these problems helps you grow faster and keep things working well. Here are some common problems you might see:

Challenge Type | Description |

|---|---|

Production Planning and Scheduling | Mistakes in planning and scheduling can cause big delays. |

Equipment Compatibility | Machines from different brands may not work well together. |

Cost Control | Prices for materials change and make budgets hard to manage. |

Market Changes | Demand changes quickly, so you must stay flexible and ready. |

S&M gives smart solutions to help you solve these problems and get your factory ready to grow.

Key Takeaways

Good planning and scheduling help stop delays in your SMT factory.

Using small parts needs exact machines to put them in the right place. This helps keep the product good.

Strong monitoring systems help find problems early. This makes the whole production better.

Smart inventory plans, like guessing what you will need, can keep your factory safe from supply chain problems.

Training and teaching technicians all the time is important. This helps keep production standards high.

Component Miniaturization

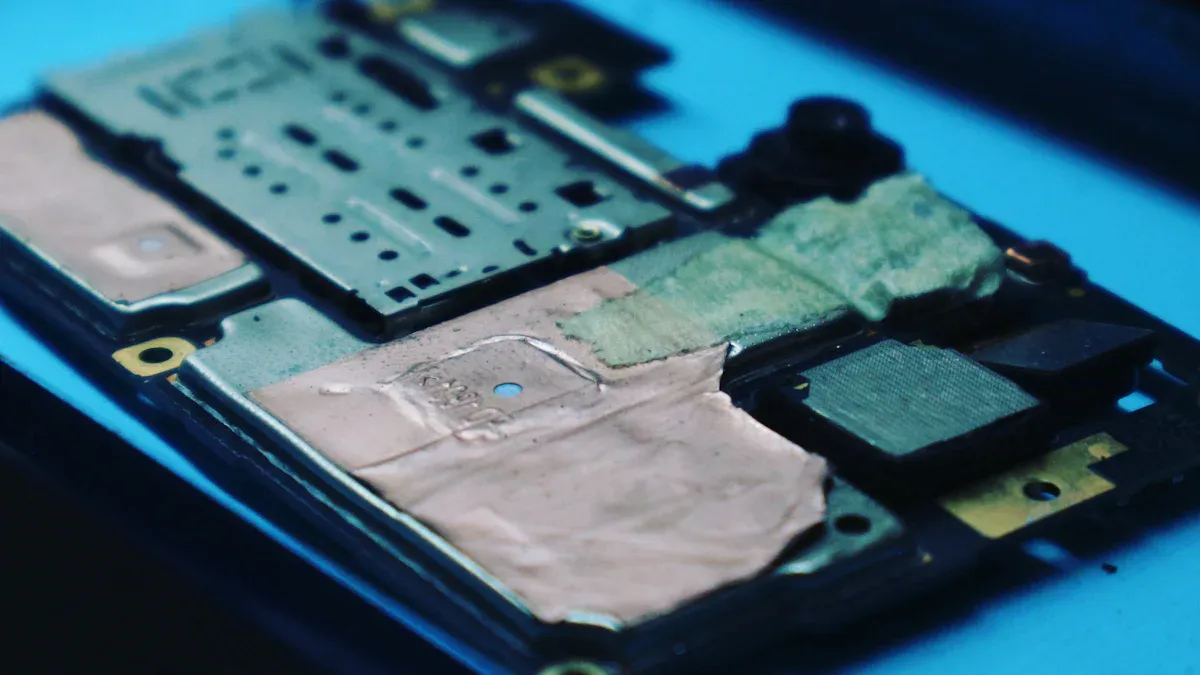

Miniaturized Components

Every year, electronic devices get smaller and smarter. This means you need to use miniaturized components in your SMT Factory. These tiny parts, like 01005 and 008004 chips, make products lighter and stronger. But, using these small parts brings new problems for your assembly process.

People want smaller devices, so you must use advanced SMT technologies.

You need machines that can place tiny parts very accurately.

More people want portable electronics, so you use more miniaturized resistors and ICs.

Modern devices need parts with lots of functions, and only SMT technology can do this.

When you use very small parts, you need equipment with ±0.003mm placement accuracy. This helps you avoid mistakes and keeps costs low. Standard sizes like 0402 or 0603 are easier to use, but now the market wants even smaller parts. S&M knows what you need and gives solutions for high-precision placement and checking in your SMT Factory.

Advancement Type | Description |

|---|---|

Lets you put together smaller parts with more pins for compact devices. | |

High-Speed Assembly Equipment | Makes your production faster and more efficient. |

Fine Pitch and BGA Components | Helps you place parts with tiny spaces and more connections. |

Advanced Soldering Techniques | Uses new ways to make your products more reliable. |

Component Inspection Technologies | Uses AOI, X-ray, and 3D SPI to check quality carefully. |

Integration of Robotics and Automation | Makes your assembly line faster and easier to change. |

Precision Placement

You need special systems to place miniaturized components. These systems use smart cameras and real-time programs to put parts in the right spot. For example, vision systems can see mistakes smaller than 15µm. This helps you reach 99.95% accuracy when checking. This is very important for small packages like 01005.

Precision placement helps you make more good products by lowering mistakes.

Real-time thermal compensation keeps machines steady, even during long work.

Sub-5µm placement accuracy means fewer solder problems and better products.

S&M gives you fast pick-and-place machines and smart checking tools. These help your SMT Factory get high first-pass yields and meet what modern electronics need.

Solder Paste and Printing Stability

Solder Paste Defects

You have to check for solder paste defects in your SMT line. These problems can make your products not work right. Some common problems are solder bridging, solder balls, and not enough solder. Each problem happens for different reasons and can cause things to break or need fixing. The table below lists the main solder paste defects, why they happen, and how they hurt your production:

Defect Type | Causes | Impact |

|---|---|---|

Solder Bridging | Oversized stencil apertures, poor alignment, high humidity | Electrical shorts, circuit failure, costly repairs |

Solder Balls | Excess moisture, inconsistent pressure, oxidation | Unintended connections, risk of shorts |

Insufficient Solder | Undersized apertures, worn stencils, paste degradation | Mechanical failure, weak joints |

Solder Paste Slump | Low viscosity, excessive volume, delayed reflow | Bridging, insufficient solder in key areas |

Misalignment | Inaccurate alignment, vibration, PCB flatness issues | Open circuits, weak joints |

Stencil Clogging | Poor cleaning, low-quality paste, small apertures | Missing paste deposits, insufficient solder |

You can see that these problems can slow down your line. They also make your product quality worse. If you want to stop these problems, you must control your printing process well.

Printing Process Control

Good printing process control keeps solder paste steady and your line working well. You can use special controls to keep temperature and humidity the same. This stops the solder paste from getting too thick or wet. Automatic paste supply systems make sure you always have enough paste. This means you do not have to stop your line.

Modern SMT lines use data collection and checking to watch the process. You can find problems early and change settings before things go wrong. Many factories use 3D optical scanning in SPI machines now. These machines measure solder paste very closely and give you feedback right away. You can change printer settings like squeegee pressure or speed fast.

Special stencil designs help you put the right amount of solder paste on each part.

Automated printing machines use cameras and robots to put paste in the right spot and lower mistakes.

By using these controls, you can have fewer problems, better first-pass yield, and a smoother SMT line. S&M gives you advanced printing solutions to help you get good, steady solder paste on every board.

Thermal Management in Reflow

Warpage Issues

Sometimes, PCBs bend or twist when they get hot in reflow. This is called warpage. Warpage can make solder joints bad. It can even break your components. Many things can cause warpage:

Temperature Stress: Fast temperature changes put stress on the board.

Uneven Copper Distribution: Some copper areas heat up faster than others.

Vias Limiting Expansion: Vias can stop the board from moving as it heats.

Weight of the PCB: Heavy parts can make the board bend down.

V-Cut Depth: Deep V-cuts make the board weak and easy to bend.

You can help stop warpage by lowering oven temperature. You can also change how fast you heat and cool the board. Using high Tg materials helps the board stay strong. Thicker and smaller PCBs do not bend as much. Special carriers made from strong materials keep the board flat.

Tip: Always check your PCB design for balance. Make sure copper is spread out evenly. This helps stop uneven heating and warpage.

Thermal Stress Solutions

Thermal stress can hurt sensitive parts and lower quality. You must control heat during reflow. Here are some ways to help:

Use thermal vias and heat sinks to spread heat out.

Add thermal relief patterns to protect sensitive parts.

Pick materials with close CTE values to stop stress between layers.

Keep your stack-up design even to lower stress from heat.

Strategy | Description |

|---|---|

Material Selection | Use materials with matching CTE values to stop warpage. |

Stack-up Design | Make your stack-up even to lower warpage from heat. |

Reflow Profile Optimization | Heat and cool slowly to avoid shock and protect parts. |

You can use thermal simulation tools to see how heat moves. This helps you fix your design before making boards. Put hot parts far apart to stop hot spots. Use special laminates or metal-core PCBs to move heat away fast. These steps help your SMT line work well and keep products strong.

SMT Factory Integration Challenges

Machine Connectivity

It can be hard to connect all machines in an SMT Factory. Many factories use machines from different brands. Each machine might use its own software and way to talk. This makes it hard for them to work together. You want your machines to share data right away. If they cannot, your line may slow down or have mistakes.

Some common integration challenges are:

It is tricky to join different data types and formats.

You must make sure your data is correct and good.

Some people do not like using new technology.

Money problems can stop you from buying new data tools.

You need strong ways to keep your data safe.

You need smart ways to connect your machines. S&M gives you equipment that uses open ways to talk. Their systems help you link machines from any brand. You can collect and share data across your whole line. This makes your SMT Factory ready to grow and change.

Tip: Pick machines that use standard ways to talk. This helps you add new machines later without trouble.

Data Format Consistency

You may also have trouble with data format consistency. Each machine might store and send data in its own way. This can cause mistakes when you mix information from many places. If your data is not the same, you might miss details or make wrong choices.

S&M helps you fix this with smart software tools. Their solutions make sure all your data uses the same format. You can trust your reports and watch your production with confidence. When your data is clear and correct, you can find problems early and make things better.

Good data helps you make better choices and keeps your SMT Factory working well.

Workforce Skills Gap

Technician Shortages

It is getting harder to find skilled SMT technicians. Many factories cannot hire enough people who know how to use new machines. This problem is growing because older workers are retiring. By 2025, about 2.7 million baby boomers will leave their jobs. When they go, factories lose a lot of important skills and knowledge. This makes it tough to keep production running smoothly and keep quality high.

A modern SMT line needs workers with many skills. You need people who can use digital tools for data and automation. They must run new machines to help work go faster. They also need to manage supply chains to keep things moving. If something goes wrong, they should fix problems quickly.

If you do not have enough skilled workers, your factory may make more mistakes. Production can slow down, and product quality can drop. You need to act early to fix this gap and keep your SMT line working well.

Training and Retention

You can build a strong team by training and keeping your best workers. Hands-on learning helps new technicians learn quickly. Pairing new workers with experienced staff gives them real skills. Training programs with practice make learning better. Learning all the time helps your team keep up with new technology.

Here are some good ways to train and keep skilled SMT technicians:

Pair new workers with experienced ones for on-the-job learning.

Make training programs that use hands-on practice.

Give more learning chances after the first training.

Strategy | Description | Impact |

|---|---|---|

Systemized Training | Focuses on key skills and makes starting easier. | Cuts time to be productive by 40% and helps workers stay. |

Advanced LMS | Uses a Learning Management System for personal learning. | Gets workers involved and makes training work better. |

Performance Metrics | Sets clear goals to check if training works. | Connects training to business results and helps decisions. |

Tip: Keep your training programs fresh and ask your team to learn new skills. This helps you stay ahead in a fast-changing industry.

Supply Chain Resilience

Component Shortages

Factories depend on global supply chains for SMT components. Many things can stop production and delay shipments. Natural disasters, health problems, and climate events can hurt your factory.

Earthquakes and tsunamis have closed semiconductor plants in Japan and Taiwan. The 2011 earthquake in Japan and recent ones in 2024 caused big trouble for electronics makers.

COVID-19 slowed shipping and shut down factories. Many Asian plants could not send parts on time.

More people wanted electronics during the pandemic. Remote work and online school made demand go up, especially for cars and medical devices.

Shortages of raw materials like semiconductors and rare earth metals made it hard to fill orders.

Climate change events, such as Hurricane Helene in 2024, stopped work at electronics and car factories. This showed supply chains are fragile.

You need to get ready for these risks. Plan ahead and watch for warning signs to make your supply chain stronger.

Inventory Strategies

Smart inventory strategies help protect your SMT factory from supply chain problems. These methods keep production going when parts are hard to find.

Use demand forecasting. Check past sales to guess what customers will want.

Calculate safety stock. Keep extra parts in storage for emergencies.

Try a Just in Case inventory plan. Hold more stock so you are ready for surprises.

Use warehouse automation. Machines help you store and find parts faster.

Try multi-warehousing. Keep inventory in different places to lower delay risks.

Track inventory in real time. Watch your stock levels closely so you do not run out.

Focus on active forecasting. Update your guesses often to stay ahead.

Tip: Spread out your inventory and use smart tools to lower risks. S&M gives solutions to help you manage stock and keep your SMT line working well.

Workflow and Process Optimization

Planning well helps you get more from your SMT Factory. You need to do more than buy new machines. You should check every step in your process. Good workflow and process optimization help you make more products. They also help you stop wasting time.

Bottleneck Management

Bottlenecks slow down your work. You can find these problems by watching your line often. The table below lists common bottlenecks and ways to spot them:

Bottleneck Type | Description | Identification Method |

|---|---|---|

Equipment Problems | Old machines cause delays and downtime. | Real-Time Monitoring, Visual Inspection |

Staff and Skills Gaps | Unfilled jobs leave equipment idle. | Cycle Time Analysis, Visual Inspection |

Poor Factory Layout | Bad layout wastes time moving between stations. | Value Stream Mapping, Visual Inspection |

Supply Chain Issues | Outside problems stop your line. | Root Cause Analysis, Real-Time Monitoring |

Quality Problems | High defects mean more rework and delays. | Cycle Time Analysis, Visual Inspection |

Team Communication | Poor info flow makes small issues bigger. | Visual Inspection, Real-Time Monitoring |

Temporal Bottlenecks | Short disruptions that resolve quickly. | Visual Inspection, Cycle Time Analysis |

Long-term Bottlenecks | Ongoing issues limit output. | Root Cause Analysis, Real-Time Monitoring |

Static Bottlenecks | Same points always slow production. | Cycle Time Analysis, Visual Inspection |

Dynamic Bottlenecks | Bottlenecks shift with product mix. | AI-Powered Prediction, Real-Time Monitoring |

You can use real-time monitoring to find and fix these problems fast. Smart analysis helps you see where things slow down. S&M has tools to help you spot bottlenecks and keep your line moving.

Real-Time Monitoring

Real-time monitoring lets you see what is happening right now. You can watch machine status, material use, and worker actions. This helps you catch problems early and fix them fast.

AI-powered systems can cut downtime by up to 75%. You save money and keep your line running.

Watching materials all the time helps you find waste and make more products.

You can get Overall Equipment Effectiveness rates above 85% with smart monitoring.

Good changes can lower labor costs by 40%.

First-pass yields can go from 82% to 96%, showing better quality and efficiency.

S&M uses advanced monitoring tools to help your SMT Factory workflow. You get clear data and quick feedback. This helps you make smart choices and grow your business.

Tip: Always check your workflow and use real-time data to help you decide. This keeps your factory working well and ready for new problems.

Equipment Compatibility and Upgrades

Multi-Vendor Integration

You might want to buy machines from different brands for your SMT Factory. This helps your factory grow and do new jobs. But using machines from many brands can be tricky. Each machine may have its own software and way to store data. It can be hard to make all the machines work together.

Here is a table that lists common problems and smart ways to fix them for multi-vendor integration:

Challenge | Solution |

|---|---|

Data Synchronization | Use special programs so machines can share and match data. |

Security Concerns | Set up safe gateways with strong passwords and protect your data. |

Performance Optimization | Watch how machines work together and fix slow spots fast. |

Vendor Support and Maintenance | Pick vendors who give quick help and clear support rules. |

Customization and Scalability | Choose systems that let you add or change machines easily. |

Cost Considerations | Plan your spending to keep costs under control. |

Regulatory Compliance | Check your systems often to follow industry rules. |

Change Management and User Training | Train your team well and help them learn new changes. |

Continuous Improvement and Innovation | Use real-time data to find ways to work better and faster. |

You can fix these problems if you use the right tools and plan ahead. S&M has SMT solutions that work with many brands. Their systems use open standards, so you can add new machines easily. This keeps your factory ready for anything in the future.

Maintenance and Upgrade Costs

You need to think about how much it costs to keep your machines working well. New SMT machines may cost more at first, but they save money later. They break down less and do not need many repairs. Old machines can cost more because parts are hard to find. You may need to keep extra parts, which adds to your costs.

New machines are easier to upgrade. You can keep up with new industry standards.

Old machines may need more repairs and special parts.

New SMT equipment comes with better support and easy-to-find spare parts.

S&M gives you solutions that grow with your needs. Their equipment is easy to take care of and upgrade. You can trust S&M to help you manage costs and keep your SMT Factory running well.

Quality Assurance and Traceability

Monitoring Systems

You need strong monitoring systems to keep your SMT line running well. These systems help you find problems early and keep your products at a high standard. You can use tools like Statistical Process Control (SPC) to watch your production data. SPC tools show you when something changes in your process. You can fix small problems before they become big ones.

You should set clear quality goals for your factory. These goals help you know what to check and how to measure success. When you have clear goals, your team knows what to do. You can use checklists for inspections. These checklists cover steps like Solder Paste Inspection and Automated Optical Inspection. They make sure you do not miss any important checks.

You also need to keep good records. When you write down what happens at each step, you can find the cause of any problem. Good records help you follow rules and show customers that you care about quality.

Tip: Use real-time monitoring to catch mistakes early. This saves time and money.

Consistent Standards

You must use the same standards every time you build a product. Consistent standards help you make products that work well and last long. When you use the same inspection and testing steps, you lower the chance of mistakes.

Traceability is very important in SMT factories. It lets you track each part and board from start to finish. If you find a problem, you can see where it started. This helps you fix the issue fast and stop it from happening again.

Traceability also helps you manage recalls. If you need to recall a product, you can find only the affected units. This saves money and protects your brand. Customers trust you more when you can show where each part came from.

Traceability gives you clear information about your components.

You can act quickly during recalls and limit the impact.

Good tracking tools help you keep your reputation strong.

You can use S&M’s advanced monitoring and traceability solutions to keep your SMT line safe and reliable. These tools help you meet industry standards and give your customers confidence in your products.

Space and Layout Planning

Floor Space Utilization

You must use your factory space in a smart way. A good layout helps you do more work in less space. Think about how materials move from one step to the next. Shorter paths mean you save time and energy. Keep machines close, but leave space for safety and easy access.

Pick single-lane or dual-lane lines. Dual-lane lines are good for lots of work. Single-lane lines let you change things more easily.

Look at conveyor length and buffer zones. These change how fast your line works.

Put SPI and AOI machines where they fit best in your process.

Plan early for power, air, and ESD grounding. This keeps your line safe and ready.

Add DIP lines to your layout before new machines come.

You can also use space above the floor. Mezzanine floors or tall shelves help you store more. This means you do not need a bigger factory. Split your space into value-adding, value-supporting, and waste areas. Try to use every square meter to add value. Always follow safety rules and keep walkways open.

Tip: A smart layout helps you work faster and waste less movement.

Expansion Readiness

Your factory should be ready to grow bigger. Flexible layouts help you add new lines or change your setup. Modular designs let you move or add machines without big changes. This saves you time and money as your business grows.

Design Principle | Benefit for Scalability and Flexibility |

|---|---|

Modular designs | Easy to grow and change |

Optimized facility layout | Works well now and in the future |

Designed for product diversity | Can make different products |

Accommodates volume variation | Handles more or less work |

Facilitates automation upgrades | Ready for new machines |

New line additions | Easy to add more lines |

Plan your layout so you can handle new products or more work. Leave space for extra machines and easy upgrades. This way, your SMT Factory works well now and is ready for the future.

You must plan your SMT Factory carefully if you want to grow. The table below explains why planning ahead is important for long-term success:

Description | Importance for Scalability |

|---|---|

Stops you from using old equipment and helps you grow | |

Focusing on flexibility and scalability | Lets you change for new products and more demand |

Picking machines for future increases | Helps you reach your long-term production goals |

Understanding market changes | Makes your factory stay competitive |

Always try to get better so you can keep up in a fast-changing market:

You work faster and save money.

You make better products with fewer mistakes.

You can handle new problems quickly.

Look at your current plans often. S&M can help you make your SMT Factory stronger and ready for the future.

FAQ

What is the most common mistake in SMT line planning?

You often forget to plan for future growth. You should always think about how your factory might change. This helps you avoid problems when you need to add new machines or make new products.

How can you improve SMT line efficiency?

You can use real-time monitoring tools. These tools help you find slow spots and fix them fast. You should also train your team and keep your machines in good shape.

Why does component miniaturization matter?

Smaller parts make devices lighter and smarter. You need special machines to place these tiny parts. If you use the right equipment, you get better quality and fewer mistakes.

What helps you avoid supply chain delays?

You should keep extra stock and use smart forecasting. You can store parts in different places. This helps you keep production moving when there are shortages.

How do you keep quality high in SMT production?

Use automated inspection systems like AOI and SPI. These systems catch mistakes early. You should also keep good records and follow the same standards every time.