You save real money when you use smt automation in your factory. Samsung cut its manufacturing costs by almost 20% after using smt machines. This shows smt machines are very good at saving money. S&M brings new ideas to smt solutions. Automation helps you lower costs. You save on labor, efficiency, materials, maintenance, yield, and scaling up. The main ways to save money are:

First Pass Yield gets better

Fewer defects happen

More products made faster

Machines work more often

Production gets more efficient

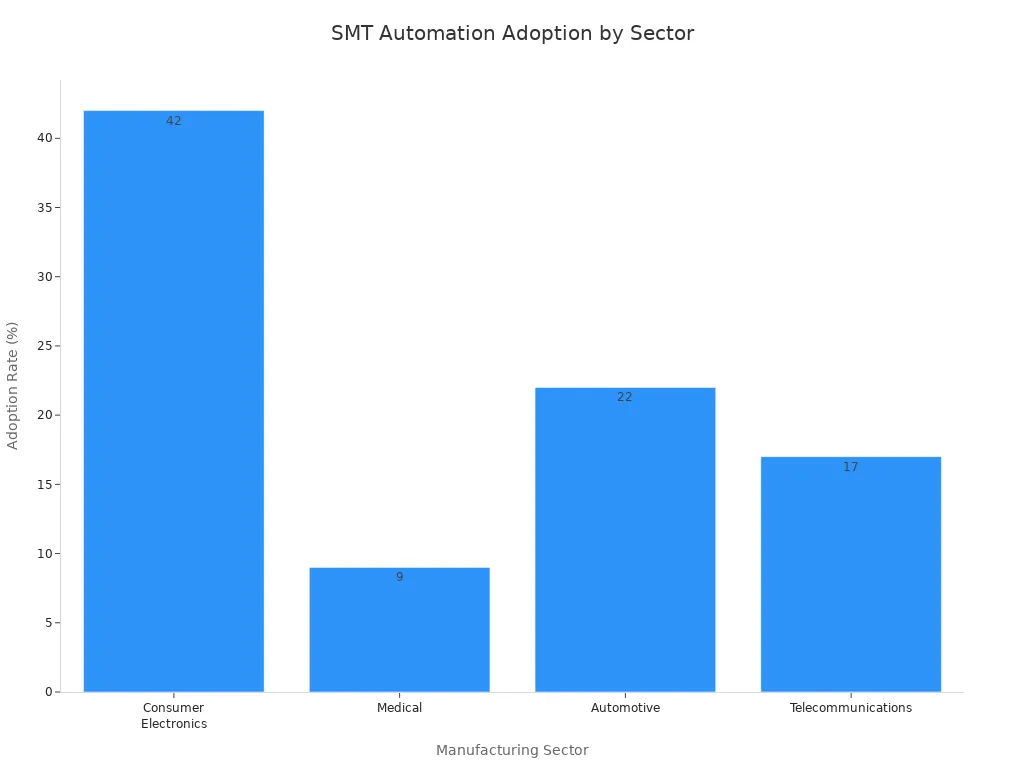

S&M’s smt automation helps you focus on saving money and making more profit. More companies use smt automation in electronics, cars, and other areas.

Key Takeaways

SMT automation can cut manufacturing costs by up to 20%. This helps factories save money on labor, materials, and efficiency.

Using Autonomous Mobile Robots (AMRs) means less manual labor. Workers can do more important jobs. This makes everyone more productive.

Automated inspection systems find defects early. This means fewer reworks and better quality products. It also saves time and money.

Predictive maintenance keeps machines working well. It lowers downtime and maintenance costs. This makes the whole factory work better.

S&M SMT solutions are flexible for growing production. Manufacturers can change quickly when demand changes. They do not have to spend a lot of money.

Labor Savings with SMT Automation

Minimizing Manual Labor

Automation brings big changes to your factory. It takes over many jobs that repeat a lot. Autonomous Mobile Robots (AMRs) move things around the factory. These robots carry and transfer items by themselves. People do not need to spend hours moving materials. This helps you use less labor and save money.

AMRs keep materials moving all the time.

Workers can do more important jobs instead of carrying parts.

Automated systems bring materials right where you need them.

Assembly automation makes building things easier and smoother.

When you use automation, your team has more free time. They can learn new things and do bigger jobs. Production does not get stuck as often, so you save time and money.

Reducing Human Error and Rework

Automation helps you avoid mistakes and use less labor. Machines follow instructions and do not get tired. This means fewer mistakes when building products. You spend less time fixing problems. You also have fewer broken items, so costs go down.

The Gartner report says automation changes jobs in factories. There are fewer middle managers. Leaders and workers talk to each other more. New jobs need digital skills. Your team learns new things at work to keep up.

Training for SMT automation works best with hands-on practice. Skilled teachers help your team with real tasks. You can train at your factory to avoid stopping work. E-learning lets staff learn anytime. Small live classes help everyone pay attention and learn fast.

You get a team with better skills and smoother production. Automation helps you use less labor and makes assembly easier, so your factory works better.

Boosting Efficiency in SMT Production

Faster Assembly Speeds

You want your factory to work faster and smarter. SMT automation helps you make things quicker. Machines put parts in place fast and with care. You finish more products in less time. This helps you spend less money and work better.

Here is a table that shows how automation changes your factory:

Evidence Type | Description |

|---|---|

Cycle Time Reduction | Fully automated lines cut cycle times by 30-50%. |

Labor Cost Savings | Automation can lower labor costs by up to 72%. |

Production Efficiency | High-speed placement machines cut per-unit costs by 18-22%. |

You make more products every hour. Machines do not get tired or slow down. You can fill big orders and keep up with what people want. Speed and throughput optimization help you stay ahead in making things.

Tip: When you use SMT automation, you can make more or less products as needed. This helps you meet customer needs without spending extra money.

Consistent Output Quality

You want every product to be good. SMT automation helps you get the same quality every time. Machines do the same steps for each unit. This keeps your work smooth and stops mistakes.

Precision stencil printers put solder paste on each pad the same way.

High-speed placement systems put parts in the right spot every time.

Automated inspection tools like AOI and X-ray check every solder joint.

Speed and throughput optimization work with quality control. You see fewer mistakes and less waste. You save money because you do not need to fix as many problems. Your work stays strong, and customers get products they can trust.

Material Cost Reduction

Precise Component Placement

You can save a lot of money with SMT automation. Material costs are a big part of making things. You have to keep track of electronic parts and solder paste. These materials can get more expensive fast. Good relationships with suppliers help you control spending.

Modern SMT machines put each part in the right place. They are very accurate, down to ±0.01 mm. This stops waste and problems like tombstoning or parts not lining up. When you avoid these issues, you do not throw away costly parts. Your production line keeps moving without stopping.

Accurate placement means less waste because parts go in the right spot.

Smaller designs use less board space, so raw pcb costs go down.

Being precise means you do not need as many materials for fixing mistakes.

You will see these savings in your profits. You spend less on materials and your factory works better.

Lower Scrap and Waste

You want to make as little waste as possible. SMT automation helps you do this in many ways. Accurate machines use smaller parts and do not need drilled holes. This makes your work cleaner and more efficient.

Smaller designs fit more circuits on each board, so pcb costs drop.

Good planning and quality checks mean less scrap.

A well-run SMT line can keep defects under 100 parts per million, which saves money.

Being precise is also good for the environment. Modular designs let you swap out only broken parts. Machines that come apart easily can be recycled over 90% of the time. Using smaller parts means less scrap, which is better for the planet.

Note: Using good equipment and getting things right the first time keeps waste low and quality high.

You get a cleaner process, spend less, and help the environment when you build products this way.

Lower Maintenance and Downtime Costs

Predictive Maintenance

You want your machines to work well every day. S&M’s advanced SMT equipment uses predictive maintenance to stop problems early. Sensors and smart software watch your machines all the time. They tell you when a part needs fixing. You repair things before they break, so your line keeps running.

Predictive maintenance uses digital twins and real-time data. These tools help you plan repairs and keep machines healthy. You do not wait for a breakdown. You act early and save money. This gives you more control over your factory.

Here is a table that shows how predictive maintenance helps you save money:

Benefit | Value |

|---|---|

Reduction in machine downtime | 30-50% |

Increase in labor productivity | 5-20% |

Reduction in inventory carrying costs | 5-20% |

Positive ROI on maintenance projects | 95% |

Full payback within 12 months | 27% |

ROI in automotive case study | 250% within 18 months |

Reduction in emergency maintenance calls | 40% |

You see less downtime and fewer emergency repairs. You spend less on fixing machines and more on making products. Predictive maintenance also helps save energy and space because your machines run smoother and use less power.

Reduced Idle Time

Idle machines waste time and money. S&M’s SMT solutions help you keep your line moving. Automated systems plan work and balance tasks. You do not have machines sitting unused. Your team stays busy, and your production stays strong.

When you use predictive maintenance, you avoid sudden stops. You plan repairs during slow times. This keeps your machines working and helps you reach your goals. You also save energy and space because your equipment works better.

You lower inventory and material handling costs by keeping machines active. You do not need extra parts sitting around. Your process uses less space and less energy. S&M’s smart equipment helps you save money and improve your results.

Tip: Regular checks and smart planning help you avoid surprises. You keep your machines running and your costs low.

You get a smoother process, fewer delays, and better results. S&M’s predictive maintenance features make your factory stronger and more reliable.

Improved Yield and Fewer Defects

Automated Inspection and Quality Control

You want your products to be good every time. Automated inspection and quality control help you do this in your factory. Machines like Automated Optical Inspection (AOI) systems check each board and solder joint. These machines find small problems, like bad soldering or parts not lined up. You catch mistakes early and stop them from going further.

AOI systems can find up to 99% of problems.

Machines do not get tired or lose focus, so checks stay the same.

You get fewer wrong alerts and always find real defects.

Experts say checking solder paste printing is very important. Half of soldering problems come from this step.

Automated inspection helps you have fewer defects and less rework. You spend less time fixing mistakes and more time making good products. You also make less waste and keep your costs down.

Fewer Defective Products

You want to send out products that work well and last long. Automated inspection systems help you lower defects and rework. These systems find problems early, so you do not send bad units to customers. One big electronics company saw 30% less rework after using AOI systems.

Early checks stop bad units from leaving the factory.

Quality tools like AOI help you meet tough standards.

You save money because you do not need to fix or replace as many products.

Using SMT automation in factories means fewer bad products and higher yield. You see 18% fewer wrong alerts while still catching all real defects. This means you send out good products and keep your costs low. Automated inspection and quality control help you trust every item you ship.

Tip: When you use automated inspection, your customers trust you more and your brand stays strong.

Scalability and Flexibility with S&M SMT Solutions

Cost-Effective Production Scaling

You want your factory to grow without wasting money. S&M SMT solutions help you scale up your manufacturing in a smart way. You can add new machines or lines when you need more output. The equipment works well with different setups, so you do not need to change everything when you expand. This saves you time and keeps your costs low.

S&M SMT solutions use advanced automation to boost precision and speed.

You get flexible systems that fit many industries, like LED, medical devices, and smart displays.

The machines help you keep quality high, even when you make more products.

You spend less on fixing mistakes because the process stays consistent.

Highlywin Electric Co., Limited supports you with turnkey projects and long-term technical help. This means you get full support when you grow your factory. You lower your risk and see a faster return on your investment. S&M’s approach makes cost-effective production possible for both small and large companies.

Tip: When you plan to scale, choose equipment that grows with your needs. S&M’s solutions let you add new features or lines without big changes.

Quick Product Changeovers

You need to switch between products fast to stay ahead. S&M SMT solutions make changeovers easy. The machines adjust quickly to new boards or components. You do not waste time setting up for each new run. This helps you fill orders for different products without slowing down.

You can change settings with simple controls.

The system remembers your favorite setups for each product.

You reduce downtime and keep your team working.

A table shows how quick changeovers help your factory:

Benefit | Result |

|---|---|

Fast setup | More products made |

Less downtime | Lower cost |

Easy adjustments | Flexible production |

You stay flexible and meet customer needs. S&M’s SMT solutions help you keep your manufacturing strong and your costs under control.

You save money when you use SMT automation in your factory. S&M’s solutions help you spend less on workers, materials, and time. The table below shows how you save more money over time, even if the machines cost a lot at first:

Aspect | SMT Costs | Savings/Benefits |

|---|---|---|

$1.50 per board | $7,500 saved on 5,000 units | |

Failure Rates | Higher | $2,000-$3,000 saved on repairs |

Production Volume | 10,000 units | 10-15% lower per-unit cost |

Manufacturers check their return on investment by doing these things:

Look at how things work now.

Add new machines to the factory.

Check what changes after using the new machines.

Make the process better.

In the future, you will see smaller parts, smarter machines, and factories that are better for the planet. S&M’s SMT equipment helps you keep costs low and make great products.

FAQ

What is SMT automation?

SMT automation means machines put and solder parts on boards. This makes production faster and quality better. Many factories use SMT automation to save time and improve how things are made.

How does SMT automation help lower costs?

SMT automation helps you use less labor and waste fewer materials. Machines work fast and do jobs with care. You fix fewer mistakes, so you spend less money. This helps you keep costs low and make more profit.

Can SMT automation improve manufacturing quality?

Yes. Automated systems check every product for mistakes. You get fewer defects and products work better. Customers trust your factory more.

Is it easy to upgrade to SMT automation?

You can upgrade slowly, one step at a time. Many companies start with one machine first. You learn how it works, then add more as you need.

What industries use SMT automation?

SMT automation is used in electronics, medical devices, LED, and smart displays. Many industries use it to work faster and save money.